A kind of epoxy colored non-slip floor coating and its preparation and construction method

A floor coating and color technology, applied in epoxy resin coatings, coatings, roads, etc., can solve the problems of separation from the beauty of nature, lack of artistry, monotonous patterns, etc., and achieve enhanced mechanical properties, good ductility, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

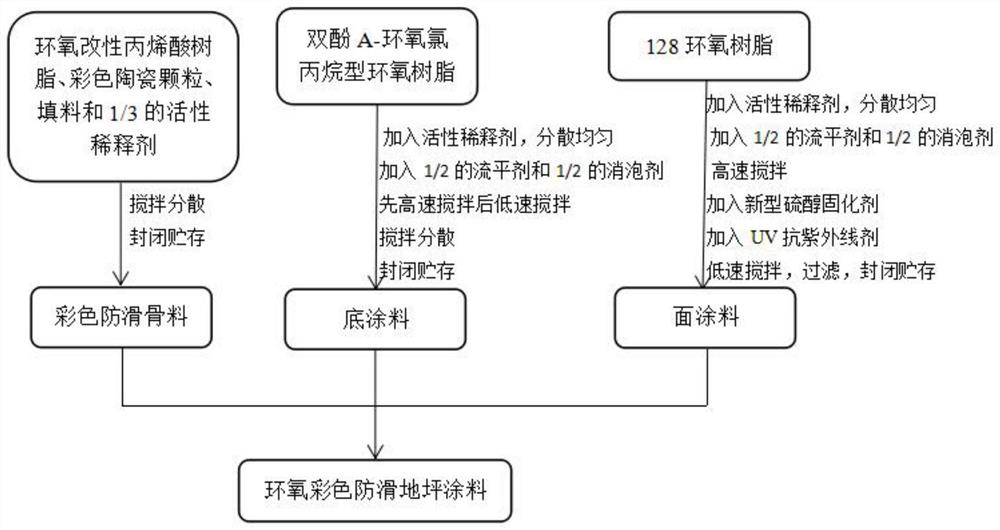

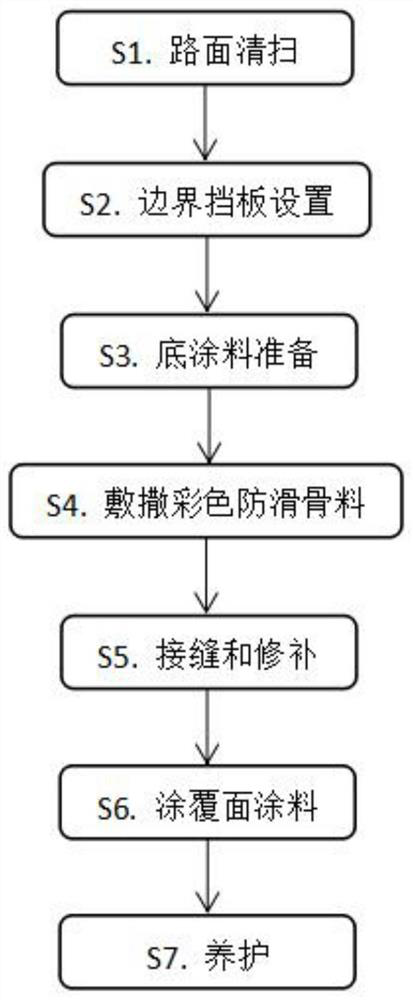

Method used

Image

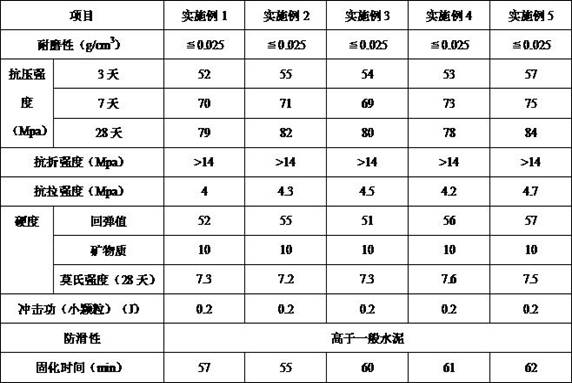

Examples

Embodiment 1

[0039] Embodiment 1 Preparation of epoxy colored anti-skid floor paint

[0040] Raw material composition (parts by weight): 100 parts of bisphenol A-epichlorohydrin type epoxy resin, 80 parts of 128 epoxy resin, 70 parts of epoxy modified acrylic resin, 50 parts of glass colored sand particles, new mercaptan curing agent 20 parts, 10 parts of neopentyl glycol diglycidyl ether, 5 parts of clay, 5 parts of polydimethylsiloxane, 1 part of polyacrylic acid and 1 part of graphene oxide modified benzophenone UV anti-ultraviolet agent;

[0041] Graphene oxide modified benzophenone UV anti-ultraviolet agent is prepared by the following method:

[0042] (1) Graphene oxide was prepared by the improved Hummers method;

[0043] Step 1. Weigh 10 g of natural graphite powder, 4 g of potassium persulfate, and 10 g of phosphorus pentoxide, and add them to a three-necked flask containing 24 mL of sulfuric acid while stirring, and react in a constant temperature water bath at 60°C for 3 h, an...

Embodiment 2

[0051] Embodiment 2 Preparation of epoxy color anti-skid floor coating

[0052] Composition of raw materials (parts by weight): 140 parts of bisphenol A-epichlorohydrin type epoxy resin, 120 parts of 128 epoxy resin, 90 parts of epoxy modified acrylic resin, 30 parts of bauxite particles, 40 parts of brown corundum particles , 40 parts of new thiol curing agent, 20 parts of phenyl glycidyl ether, 15 parts of kaolin, 15 parts of polyoxypropylene polyoxyethylene glyceryl ether, 5 parts of carboxymethyl cellulose and graphene oxide modified benzophenone UV 5 parts of anti-ultraviolet agent;

[0053] Graphene oxide modified benzophenone UV anti-ultraviolet agent is prepared by the following method:

[0054] (1) Graphene oxide was prepared by the improved Hummers method;

[0055] (2) Weigh 1g graphene oxide and add ethanol, ultrasonically disperse evenly, add 70g 2mol / L NaOH solution, stir mechanically for 2 hours, wash the reaction product with distilled water until the pH is 7,...

Embodiment 3

[0061] Embodiment 3 Preparation of epoxy colored anti-skid floor paint

[0062] Composition of raw materials (parts by weight): 110 parts of bisphenol A-epichlorohydrin type epoxy resin, 90 parts of 128 epoxy resin, 75 parts of epoxy modified acrylic resin, 55 parts of brown corundum particles, 27 parts of new mercaptan curing agent 12 parts, 12 parts of polypropylene glycol diglycidyl ether, 8 parts of talcum powder, 8 parts of polyoxypropylene glyceryl ether, 2 parts of polydimethylsiloxane and 2 parts of graphene oxide modified benzophenone UV anti-ultraviolet agent;

[0063] Graphene oxide modified benzophenone UV anti-ultraviolet agent is prepared by the following method:

[0064] (1) Graphene oxide was prepared by the improved Hummers method;

[0065] (2) Weigh 1g of graphene oxide and add ethanol, ultrasonically disperse evenly, add 65g of 2mol / L NaOH solution, stir mechanically for 2 hours, rinse the reaction product with distilled water until the pH is 7, then pickle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com