Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Not aging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

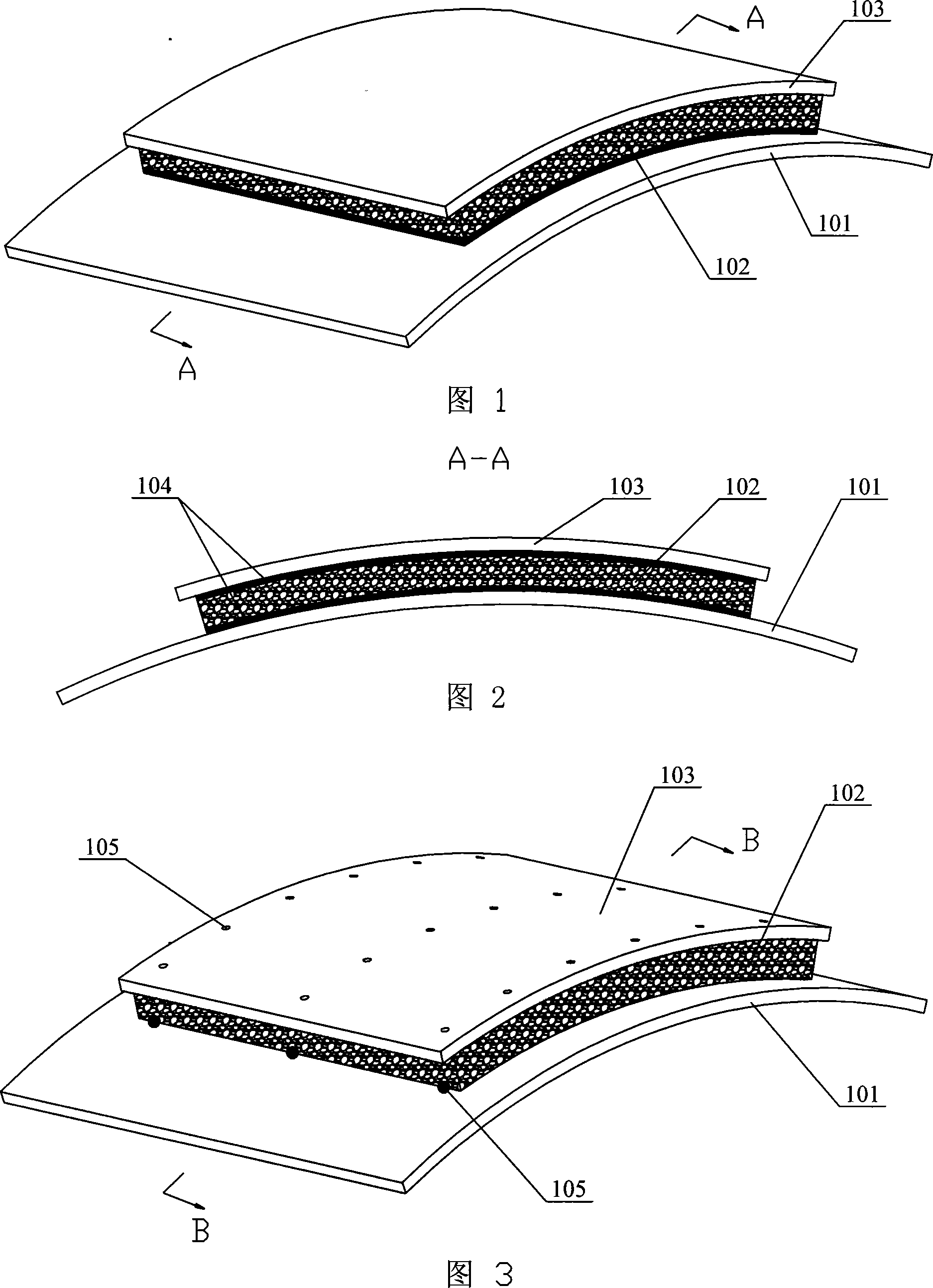

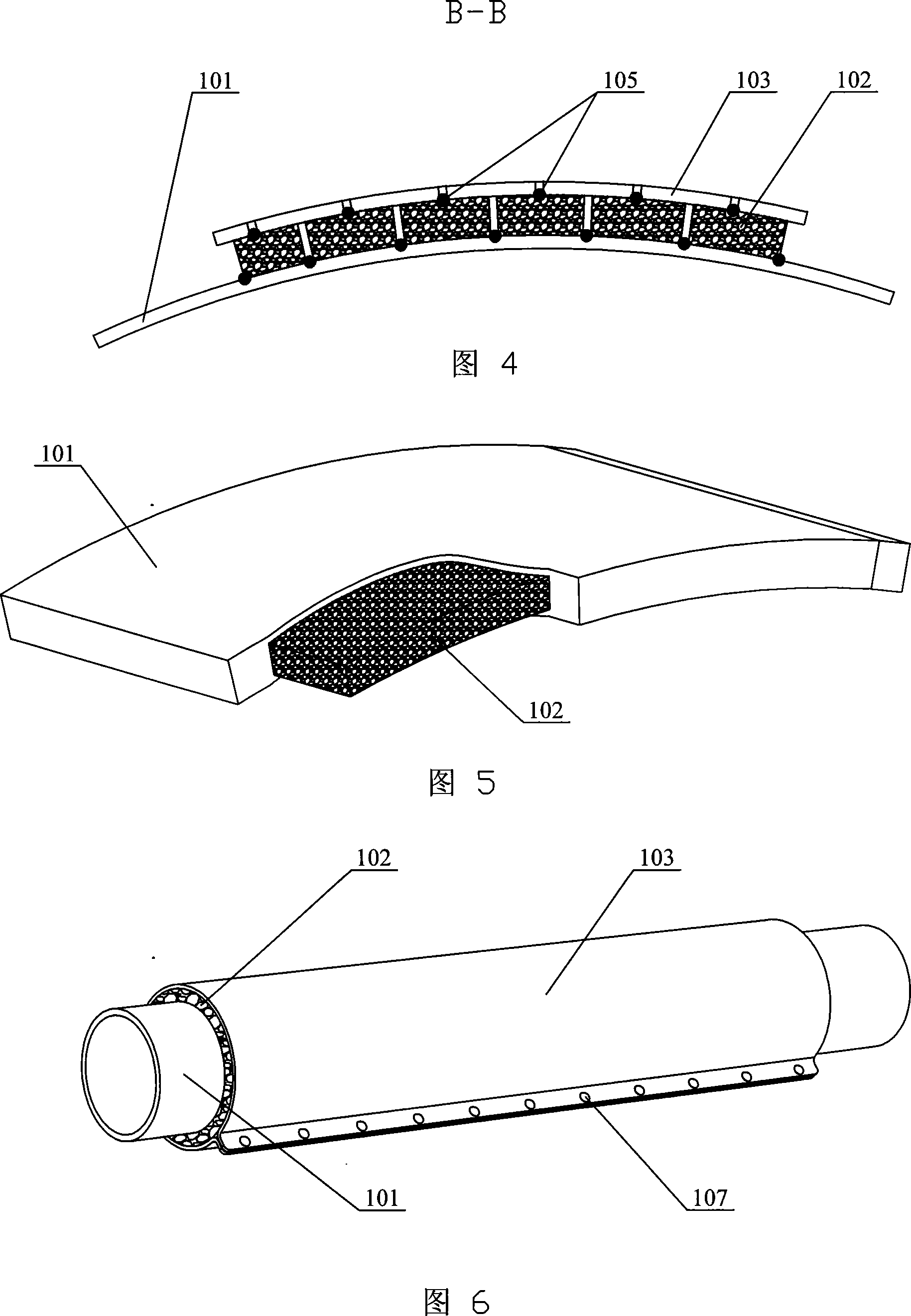

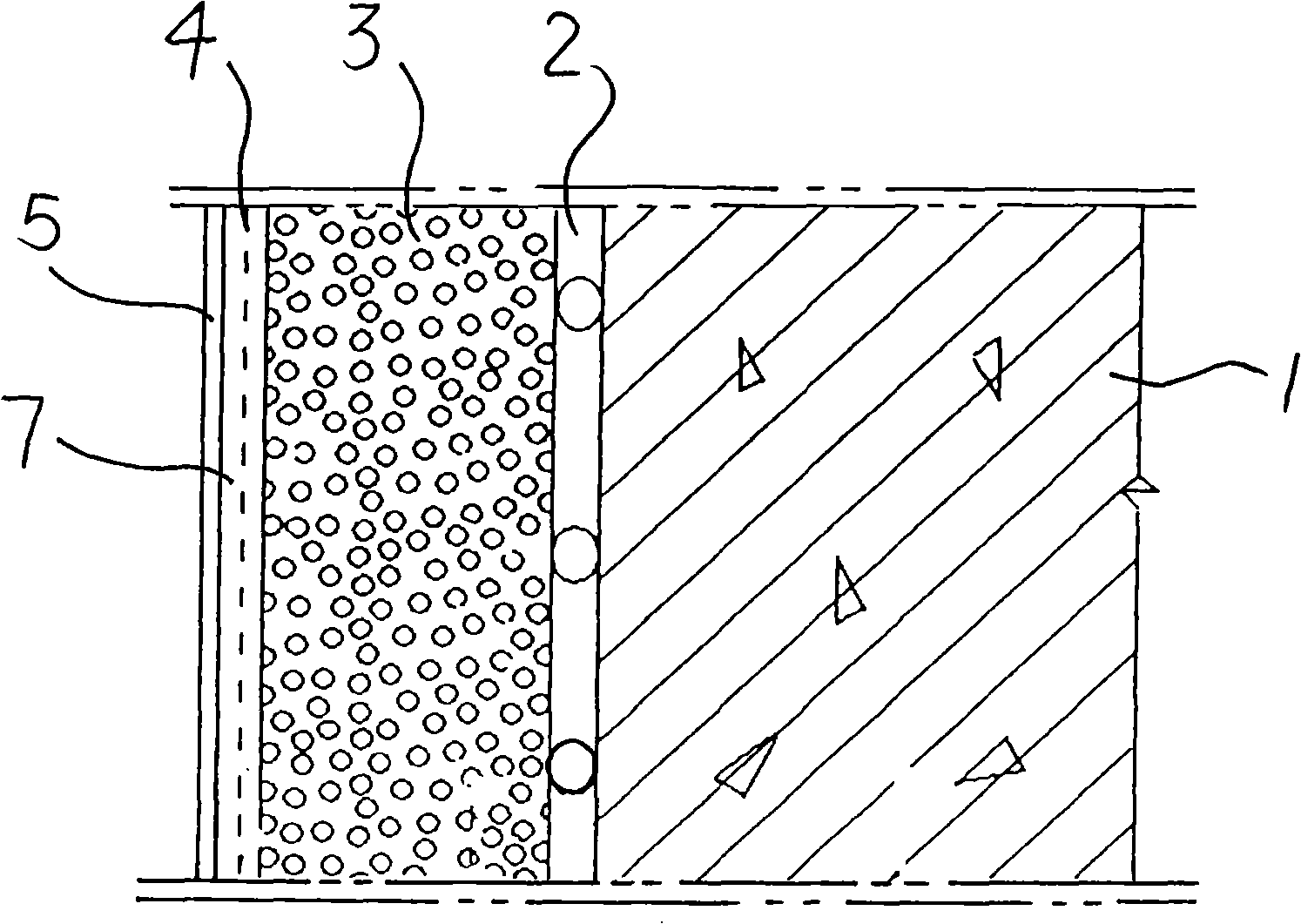

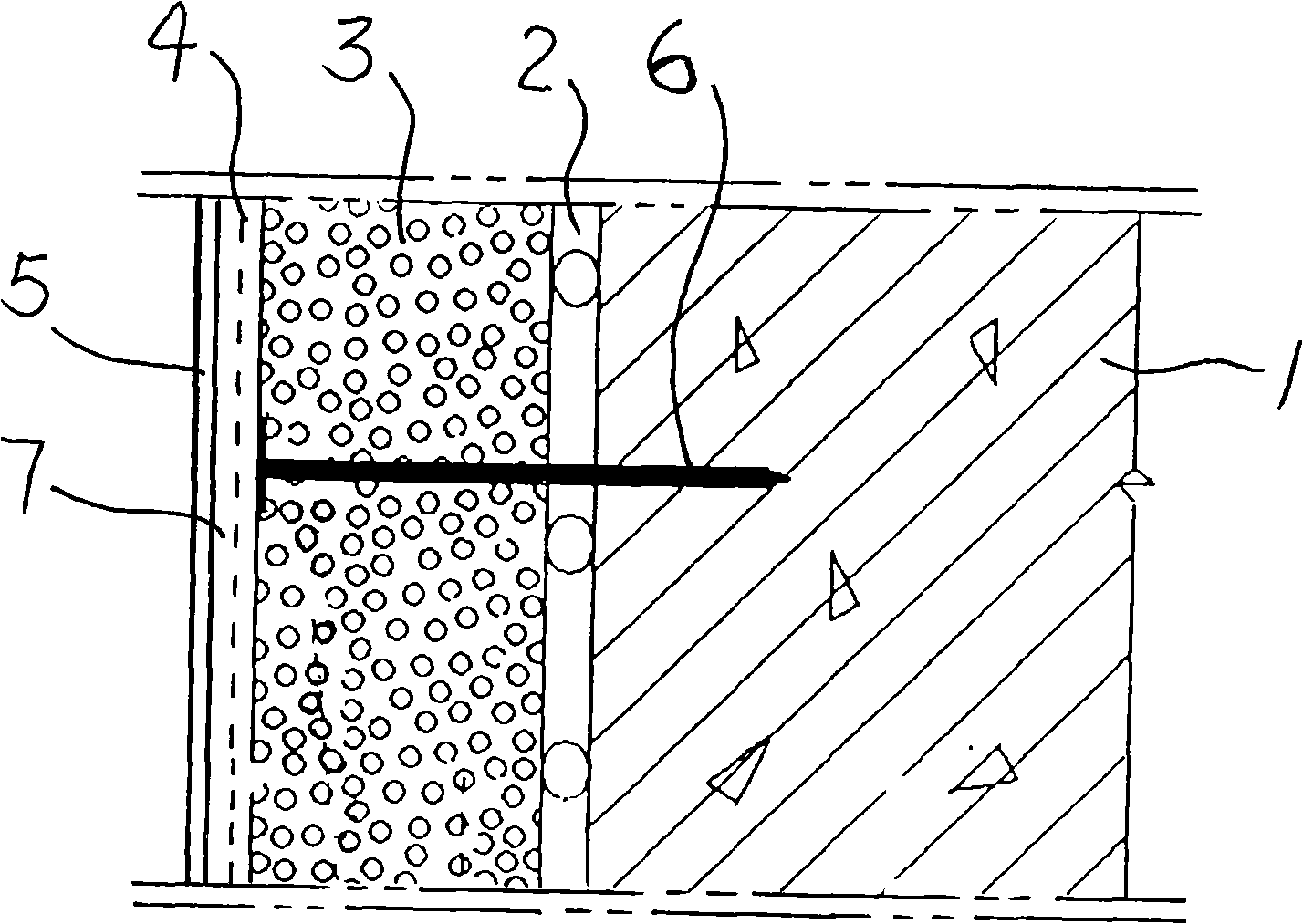

Composite damping material with interlayer being as metal rubber

InactiveCN101093008ACorrosion resistantVarious application methodsHigh internal friction springsRubber materialMetal rubber

This invention relates to a composite damp material with a metal rubber interlayer, in which a metal rubber layer is clamped between a base layer and a restriction layer, the lower surface of the metal rubber layer and the top surface of the base layer, the top surface of the rubber layer and the lower surface of the restriction layer are glued together by adhesives to prepare a composite damp material with a metal rubber interlayer, which replaces traditional rubber materials with metal rubber material having the advantages of anti-corrosion, anti-aging, high and low temperature resistant and not volatile in vacuum.

Owner:郑钢铁 +5

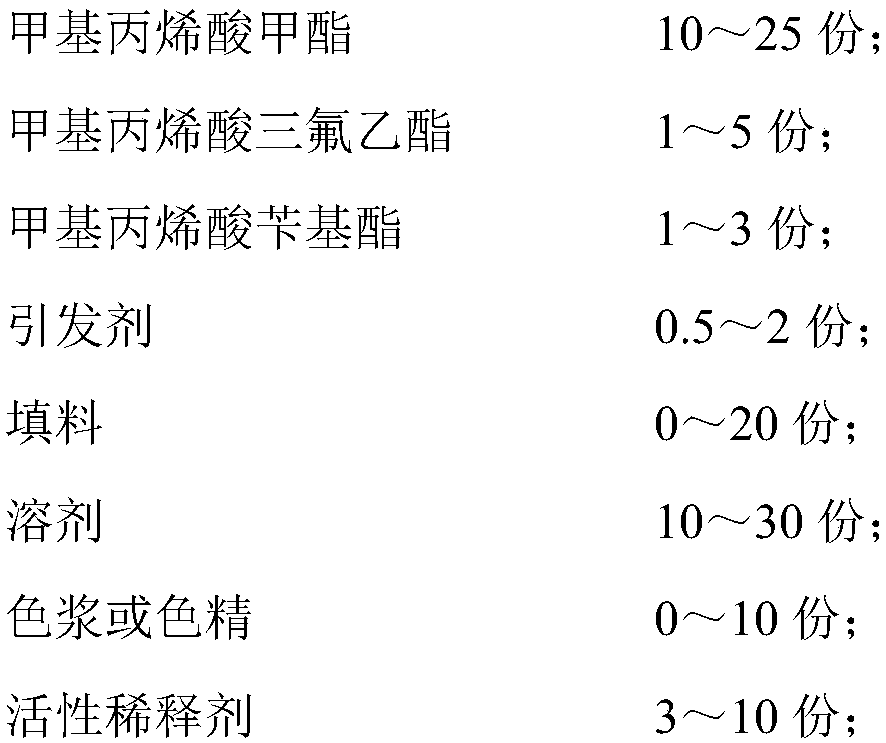

Reinforced textile type glass fiber treating compound and preparation thereof

The invention provides an impregnating compound for reinforced textile glass fibers, which takes novel organic polymer materials as a main body. The impregnating compound comprises the following compositions by weight percentage: 5 to 10 percent of polyvinyl acetate emulsion, 1 to 4 percent of polyester emulsion, 2 to 8 percent of epoxy resin, 0.2 to 2 percent of polyurethane emulsion, 0.01 to 0.2 percent of lubricant, 0.1 to 0.5 percent of coupling agent, 0.05 to 0.3 percent of antistatic agent, 0.2 to 3 percent of surfactant, 0.05 to 1 percent of acetic acid, and the balance being deionized water. The impregnating compound has good convergence, lubricity, film-forming property and antistatic property; the glass fibers which are treated by the impregnating compound have the characteristics of bending resistance, flexibility, tensile resistance, good solubility with resin and so on; and the impregnating compound is suitable for treating the surfaces of various reinforced textile glass fibers.

Owner:上海世鹏聚氨酯科技发展有限公司

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

Foamed ceramic thermal insulation plate and manufacture method thereof

The invention discloses a foamed ceramic thermal insulation plate and a manufacture method of the foamed ceramic thermal insulation plate. The foamed ceramic thermal insulation plate is prepared from the following components (by weight part): mud 35 to 65 parts, dickite 4 to 10 parts, kaolin 10 to 20 parts, feldspar 5 to 15 parts, calcite 2 to 5 parts, dolomite 5 to 10 parts, modifying agent 0.1 to 0.5 parts, stabilizing agent 0.5 to 1.2 parts, and SiC 0.4 to 1.5 parts. The invention also discloses the manufacture method of the foamed ceramic thermal insulation plate. The foamed ceramic thermal insulation plate provided by the invention has the advantages of low thermal conductivity, fire protection, high temperature resistance, high aging resistance, good consistency with concrete products, low water absorption, and high weatherability, etc., and can be used in the fields of construction, electricity, environmental protection and the like.

Owner:一方科技发展有限公司

Biologic waterproof glue and usage

InactiveCN1727424AImprove adhesionImprove impermeabilityNatural rubber adhesivesStarch adhesivesEmulsionAdhesive

A biologic water-proof adhesive for building, wood, metal, ceramic, glass, etc is prepared from glutinous rice, water, ethene-vinyl acetate emulsion, dioctyl phthalate, PVC, tung oil, acrylic emulsion and natural rubber. Its advantages are high weatherability, adhesion, tension strength, elongation percentage for breaking and resistance to water, acid and alkali.

Owner:赵春发 +1

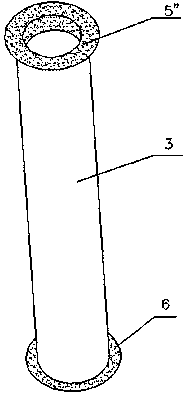

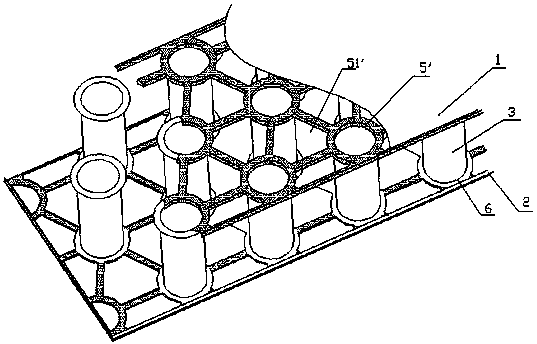

Sandwich metal plate

ActiveCN108397679APermanent service lifeLow intensitySheets/panelsMetal layered productsThermal insulationEngineering

The invention relates to a sandwich metal plate. The sandwich metal plate comprises an upper panel, a lower panel and a plurality of core tubes, wherein the multiple core tubes are arranged between the upper panel and the lower panel, penetrating air passages are arranged among the multiple core tubes, and the core tubes as well as the upper panel and the lower panel are brazed through fore-and-aft and / or left-and-right circulating heating by utilizing high-temperature gas through the air passages. On one hand, the sandwich metal plate has the advantages of light weight, high strength, heat insulation and the like, and on the other hand, the sandwich metal plate cannot be deformed by heat difference, so that the permanent service life of the sandwich metal plate is guaranteed.

Owner:张跃

Hot bending furnace for colored glazing glass, method for preparing colored glazing toughened hot-bent glass and colored glazing toughened hot-bent glass

The invention discloses a hot bending furnace for colored glazing glass, a method for preparing hot-bent glass by using the hot bending furnace and the prepared colored glazing toughened hot-bent glass. The hot bending furnace comprises a furnace body (1), a push-pull base (2), an electric heating device (3) consisting of a fixed heating furnace wire (7) and a movable heating furnace wire (8), and an electrical appliance control device (4). In the process of performing hot bending treatment by using the hot bending furnace, the movable heating furnace wire (8) performs local auxiliary heating on the bending position of glass so as to ensure that the glass is completely attached to a mould at the bending position; the radius of a bending arc of the prepared colored glazing toughened hot-bent glass is less than or equal to 90mm, and the bending radian fully meets design requirements; multiple hot bending treatment such as single bending, continuous bending and the like can be realized; and the defects that the conventional hot-bent glass cannot be completely attached to the appropriate position of the mould, the prepared hot-bent glass has only one bending arc and the radius of the bending arc is more than 90mm are overcome.

Owner:新福兴玻璃工业集团有限公司

Artificial stone integral bathtub and method for making same

InactiveCN101181823AGood insulation performanceStrong ability to withstand pressureBathsDouchesFilling materialsBathtub

The invention discloses a manufacturing method of an artificial stone integrated bathtub, the method comprising the following steps: making a bathtub inner mold, a bathtub outer mold and a bathtub bottom mold according to the shape of the bathtub, and the bathtub inner mold and the bathtub bottom mold are located at the bottom of the bathtub mold Form a casting port; apply a release agent on the inner surface of the bathtub mold; spray the high-quality product gel coat evenly on the inner surface of the inner mold of the bathtub and the outer mold of the bathtub to form the surface layer of the bathtub; Spread the filling layer material on the upper surface of the mold at the bottom of the bathtub, and then spread the fiber felt on the filling layer material at the bottom of the bathtub in turn; inject the filling layer material into the bathtub mold from the casting port; when the filling layer material fills the entire mold, put The casting mouth is sealed, and the demoulding process is performed after the filling layer is completely solidified and cooled to the demoulding temperature. The invention also discloses an artificial stone integral bathtub, which has a simple manufacturing method and good thermal insulation performance of the bathtub.

Owner:罗桂华

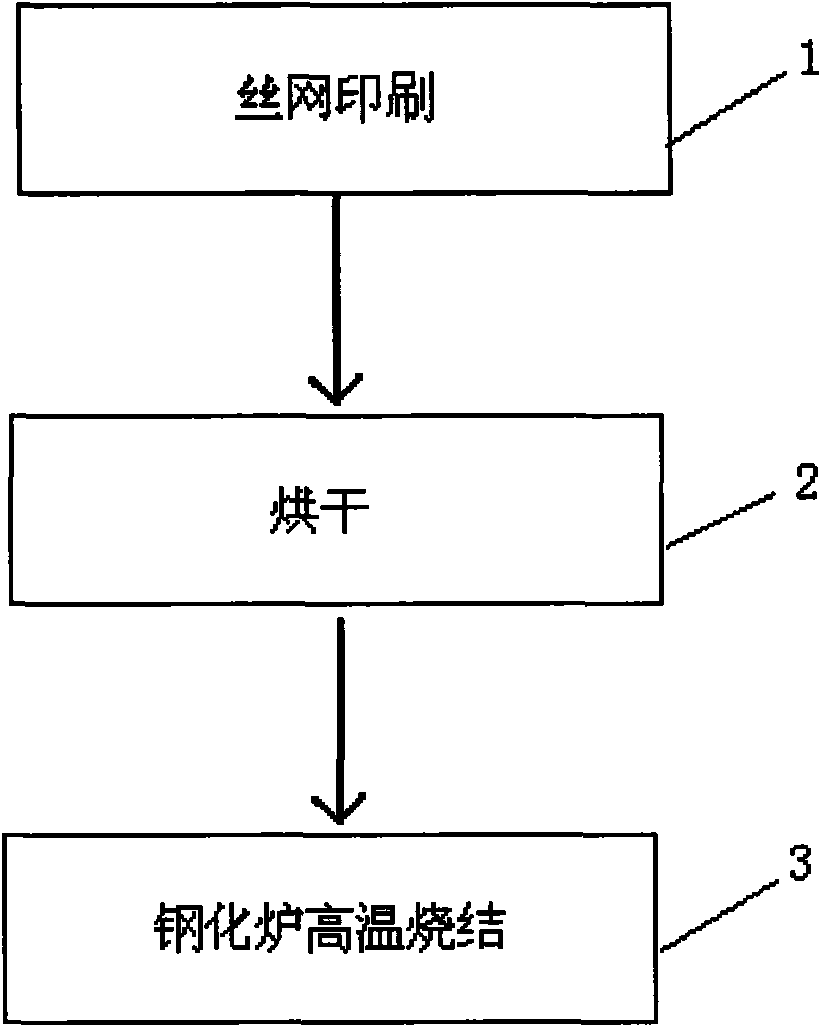

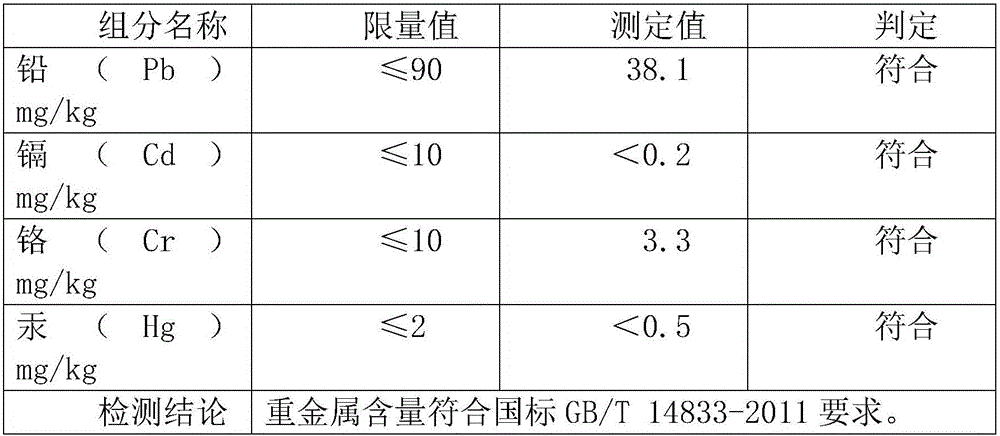

Manufacturing method of ceramic glaze art toughened glass for furniture and product thereof

InactiveCN101618951AHigh hardnessHigh strengthOther printing apparatusGlass tempering apparatusHigh intensityHardness

The invention discloses a manufacturing method of ceramic glaze art toughened glass for furniture and a product thereof, comprising the steps of screen painting, drying and high-temperature sintering in a toughening furnace. The invention also discloses the ceramic glaze art toughened glass manufactured by the manufacturing method. The invention has the advantages that the method utilizes inorganic high-temperature lead-free ceramic glaze inks; the ceramic glaze art toughened glass can be sintered in the toughening furnace at the high temperature of 700 DEG C; glaze and oxide film molecules are interconnected and deeply combined; a layer of color glaze with high hardness is formed on the surface of the glass, does not fall off, can not aging and never fades and has higher intensity; the impact resistance is 20 times of that of common glass, and the ceramic glaze art toughened glass is radiation-free, environment-protective and economic.

Owner:常熟市亿德五金有限公司

TPE (thermal plastic elastomer) and application thereof

The invention relates to a TPE (thermal plastic elastomer) and application thereof, and belongs to the technical field of the macromolecular TPE. The TPE is characterized by being prepared by adding the following raw materials in parts by weight into an internal mixer to be subjected to 105-DEG C internal mixing: 90 to 110 parts of chlorinated polyethylene, 10 to 20 parts of calcium carbonate, 0.5 to 1.5 parts of cross-linking agents, 0.3 to 1.5 parts of accessory ingredients, 0.3 to 1.5 parts of zinc oxide and 1.5 to 2.1 parts of azodicarbonamide. The TPE has the characteristics of aging resistance, color change avoidance, flame-retardant performance, high tensile strength and the like, and can be applied to runway color particles, lawn color particles, lawn buffer ground pads and prefabricated runway coiled materials.

Owner:山东世纪联合新材料科技有限公司

Method for preparing foam glass ceramics by utilizing red mud and waste glass

The invention relates to foam glass ceramic manufacturing method, in particular to a method for preparing foam glass ceramics by utilizing red mud and waste glass. The invention aims at providing a preparation method for preparing environment-friendly and energy-saving foam glass ceramics. According to the technical scheme, the method for preparing foam glass ceramics by utilizing red mud and waste glass comprises the steps: firstly mixing red mud and waste glass, carrying out ball milling to obtain powder batch mixture, and then conducting foaming and annealing treatment to obtain foam glass ceramics, wherein the red mud is polluting waste slag exhausted when the aluminum oxide is extracted in aluminum industry. The method has the beneficial effects of being simple in preparation technique and low in sintering temperature, lowering the production cost of foam glass ceramics, and obtaining higher economic benefits while solving the environment-friendly problem.

Owner:SHANDONG JIANZHU UNIV

Green environment-protecting co-squeezing core layer foaming special-shaped material and its production process

InactiveCN1908338AHigh hardnessStrong corrosion resistanceConstruction materialLayered productsCalcium carbonatePolymer chemistry

The invention relates to an environment-friend extrusion corn foaming section bar and relative production, wherein the inner layer is foaming layer, the outer layer is extrusion rigid layer; said foaming layer contains: polyvinyl chloride resin at 63-67%; calcium carbonate at 11-15%; chlorinated polyvinyl chloride at 3-7%; and chemical agent at 12-19%; the extrusion rigid layer contains: polyvinyl chloride resin at 42-46%; calcium carbonate at 42-46%; chlorinated polyvinyl chloride at 3.5-5%; and chemical agent at 7-9%. The invention can avoid deformation and color fade, with high rigidity and lower cost, while its smoothness can reach 95%.

Owner:金木根

Construction method of building wall

The invention relates to the building construction technical field, in particular to a construction method which is suitable for various industrial and civil building walling having the requirement of energy conservation in a large part of China under different climate conditions. The construction method comprises the following steps that: a bonding agent is used for bonding an insulation board on the walling; mortar is coated on the insulation board and a piece of medium-alkali mesh cloth is wrapped in the mortar; and coating is plastered on the mortar, and the insulation board is a foam glass insulation board. The construction method effectively utilizes waste resources, reduces the environmental pollution, improves the utilization rate of energy, not only solves the problems of cracking and hollowing of the building walling but also improves the heat-insulating property, guarantees the elegant appearance of a veneer of the building walling, prevents the occurrence of a fire disaster, and protects the life and property safety of people.

Owner:上海永丽节能墙体材料有限公司

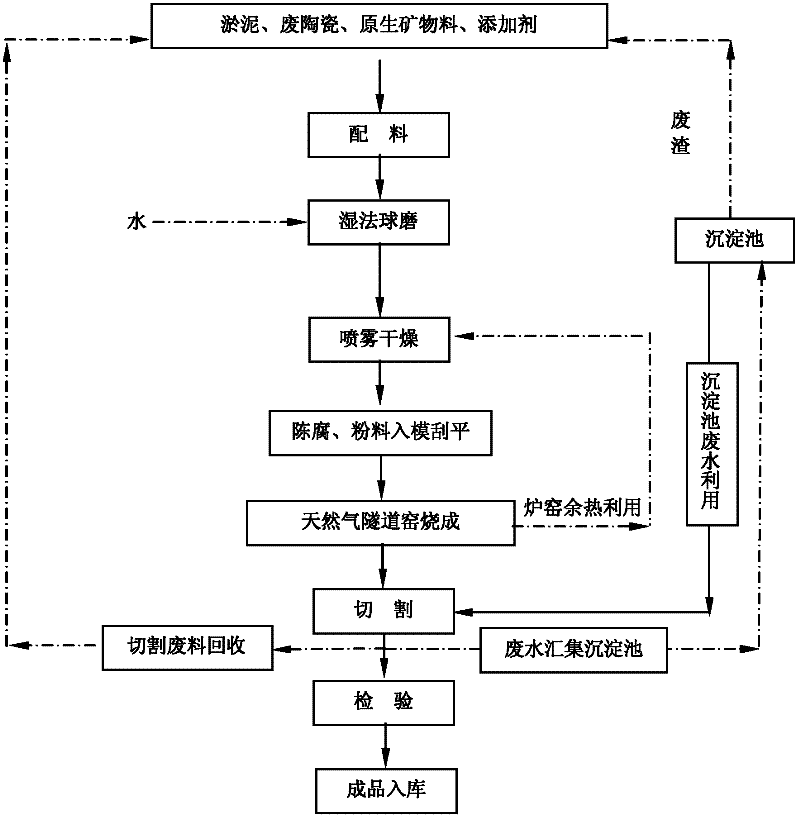

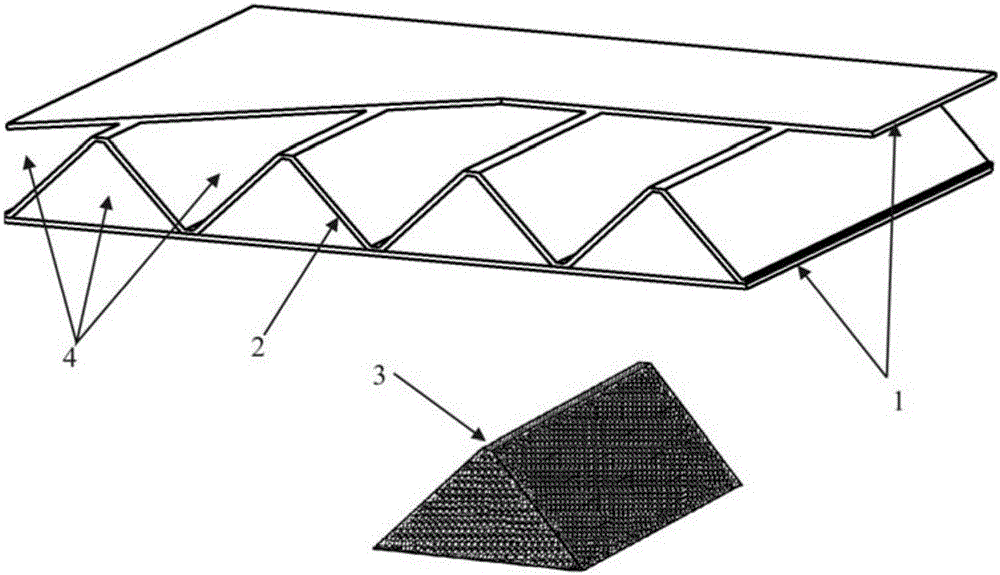

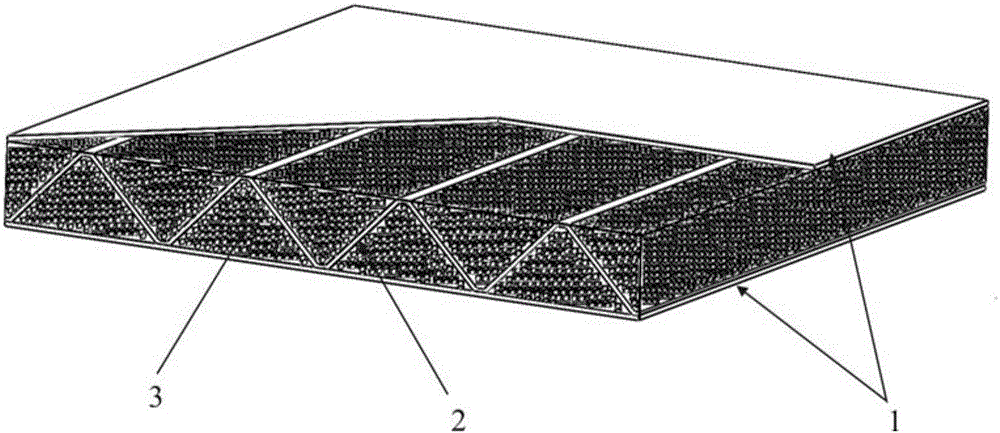

Metal corrugated-metal rubber composite material and preparation method thereof

InactiveCN106808759AImprove performanceEasy to combine structureLamination ancillary operationsLaminationMetal rubberAdhesive

The invention discloses a metal corrugated-metal rubber composite material and a preparation method thereof. A matrix metal corrugated material and stamped type metal rubber are adhered together through adhesives to obtain a multifunctional composite porous material, and preparation of the metal corrugated-metal rubber composite material is realized; the metal corrugated-metal rubber composite material has wide application prospect in fields of transportation, mechanical manufacture and military, structural damping can be effectively increased, nonlinear and variable damping properties are achieved, earthquake, vibration and sound absorption of the structure can be improved, and high strength, high rigidity and excellent damping performance in machine-building industry can be exerted; in addition, the composite porous composite material has the advantages of total environmental adaptability, corrosion resistance, high-and low-temperature resistance, no ageing, vacuum non-volatilization and the like and is light, simple in manufacture, low in cost and long in service life.

Owner:XI AN JIAOTONG UNIV

High strength acid resistant refractory brick and preparation method thereof

InactiveCN101555148AStrong corrosion resistanceImprove corrosion resistanceStrong acidsHigh intensity

The invention discloses a high strength acid resistant refractory brick which comprises the components with weight percentages as follows: 50-70% of Guizhou kaolin, 15-20% of Jiepai mud, 15-35% of fused quartz, 3-6% of talcum powder and 3-5% of powdered alumina. The invention aims at overcoming the shortcomings in the prior art and providing a high strength acid resistant refractory brick which is high temperature resistant, chilling resistant, good in strong acid erosiveness resistance and environment-friendly. The invention has another aim of providing a method for preparing the high strength acid resistant refractory brick.

Owner:湖南省醴陵市鑫荷化工填料有限公司

Floor board with environment-friendly, waterproof and flame-retardant functions and preparation method thereof

ActiveCN105885302AImprove flame retardant performanceImprove waterproof performanceCovering/liningsFlooring insulationsAgricultural engineeringLubricant

The invention relates to a floor board with environment-friendly, waterproof and flame-retardant functions and a preparation method thereof, and the floor board solves the technical problems that the current floor board is poor in flame resistance, poor in water resistance, easy to deform and crack, and not environmentally-friendly. The floor board comprises the following components in parts by weight: 30-35 parts of CPE, 10-20 parts of EVA, 40-50 parts of PVC, 12-20 parts of activated calcium carbonate powder, 0-2 parts of a lubricant and 0-1 part of OA6. The floor board with environment-friendly, waterproof and flame-retardant functions and the preparation method thereof are widely used for floor boards and preparation methods thereof.

Owner:WEIHAI HEGUANG FLOOR CO LTD

Method for preparing foam glass with plant ash and waste glass

The invention discloses a method for preparing foam glass with plant ash and waste glass. The method is characterized in that the plant ash and the waste glass are used as raw materials and mixed uniformly by a ball mill or a mixer so as to obtain a mixture; the mixture is poured into a die on a vibration table, enabled to be distributed densely and uniformly through vibration and then placed into a furnace to be fired, so that the foam glass is obtained. According to the method, a lot of solid waste of the plant ash and the waste glass is used, and no chemical additive is required, so that the production cost can be reduced substantially, the energy can be saved effectively, the environment can be protected, the waste can be changed into wealth, and the method has remarkable social benefit and economic benefit; the plant ash foam glass produced with the method is excellent in performance, has the advantages of light weight, high strength, good heat-insulation performance and the like, can meet requirements of buildings for heat insulation, is an excellent Level-A incombustible outer wall heat-insulation material and can be used as a substitute for roof and outer wall heat-insulation materials.

Owner:UNIV OF SCI & TECH OF CHINA

Surface wettability sensor

ActiveCN101893544AParameter stabilityGood measurement reproducibilityWeather/light/corrosion resistanceMaterial consumptionVoltage

The invention discloses a surface wettability sensor. The sensor comprises a signal source (1), a surface wettability sensing unit (2) and a detection output unit (3), wherein the signal source (1) generates an electric signal and provides the electric signal for the surface wettability sensing unit (2); the surface wettability sensing unit (2) detects surface wettability information and converts the information to a corresponding electric current signal; the detection output unit (3) converts the electric current signal of the surface wettability sensing unit (2) to a voltage signal to output; and the surface wettability sensing unit (2) comprises an insulator (6) and two metal wires (4, 5) which is wound on the insulator (6) in parallel, and the two metal wires separately form one detection electrode. The beneficial effects of the invention are as follows: sensor parameters are stable, the repeatability of the measuring result is good; the sensor is smaller and is more suitable to be used in narrow space; and electrode polarization and material consumption in liquid film can be avoided, thus the measuring result is more real.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Construction process of high-durability epoxy floor

InactiveCN108385933AImprove wear resistanceImprove skid resistanceAnti-corrosive paintsFlooring insulationsEpoxyGlass fiber

The invention specifically relates to the field of floors and particularly relates to a construction process of a high-durability epoxy floor. The construction process of the high-durability epoxy floor at least comprises the following steps: (1) treating a base layer; (2) laying a primer layer; (3) laying a first glass fiber layer; (4) laying a first epoxy mortar layer; (5) laying a second glassfiber layer; (6) laying a second epoxy mortar layer; (7) laying a third glass fiber layer; (8) laying a finishing coating layer; (9) cleaning and drying the finishing coating layer, so as to obtain the high-durability epoxy floor.

Owner:青岛舜捷通生物科技有限公司

Method for preparing non-sintered brick from industrial waste residues

The invention discloses a method for preparing a non-sintered brick from industrial waste residues and belongs to the technical field of building materials. The method comprises taking 85-95 parts by weight of industrial waste residues with particle sizes of 120-150 microns and 5-15 parts by weight of a metal oxide, grinding and uniformly mixing the raw materials to obtain powder with particle sizes of 120-150 microns, mixing the powder and a proper amount of water, carrying out wet pressing molding to obtain a brick-shaped blank, maintaining the brick-shaped blank in a carbon dioxide maintenance furnace for 2 days, and taking out the non-sintered brick, wherein the metal oxide comprises one or more of alkaline earth oxides. The method is free of a cement binder and autoclaved curing, utilizes greenhouse gas carbon dioxide and industrial waste residues to prepare a building material brick, is a novel preparation method for production and development of building materials and interior and outdoor finishing materials, can eliminate greenhouse gas carbon dioxide and produces positive effects on environment protection.

Owner:HUBEI UNIV OF TECH

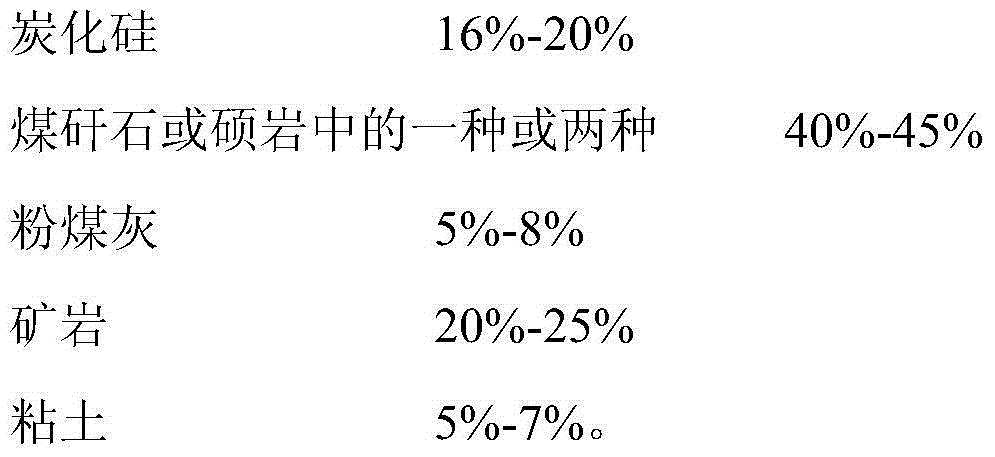

Foamed ceramic wall insulation material and preparation method thereof

ActiveCN103951457AFlame retardant and high temperature resistantLight weightCeramicwareChemical reactionRadioactive agent

The invention particularly relates to a foamed ceramic wall insulation material. The foamed ceramic wall insulation material is prepared from the following raw materials in weight fraction: 16%-20% of silicon carbide, 40%-45% of one or two of coal gangue or shale, 5%-8% of pulverized coal ash, 20%-25% of ore rock and 5%-7% of clay. According to the foamed ceramic wall insulation material, the thermal conduction efficiency is reduced and foamed ceramic has the characteristics of low heat transfer efficiency, excellent thermal shock resistance, reduced weight and the like, and is an ideal heat preservation and heat insulation material. The invention also provides a method for preparing the foamed ceramic wall insulation material by virtue of a physical reaction. Compared with the traditional chemical reaction process, the preparation method has the advantages that the process is more reasonable, the cost is reduced, no any radioactive material is generated in the production process, and thus the energy conservation and environment friendliness are achieved.

Owner:ZIBO LUYOU REFRACTORY MATERIAL

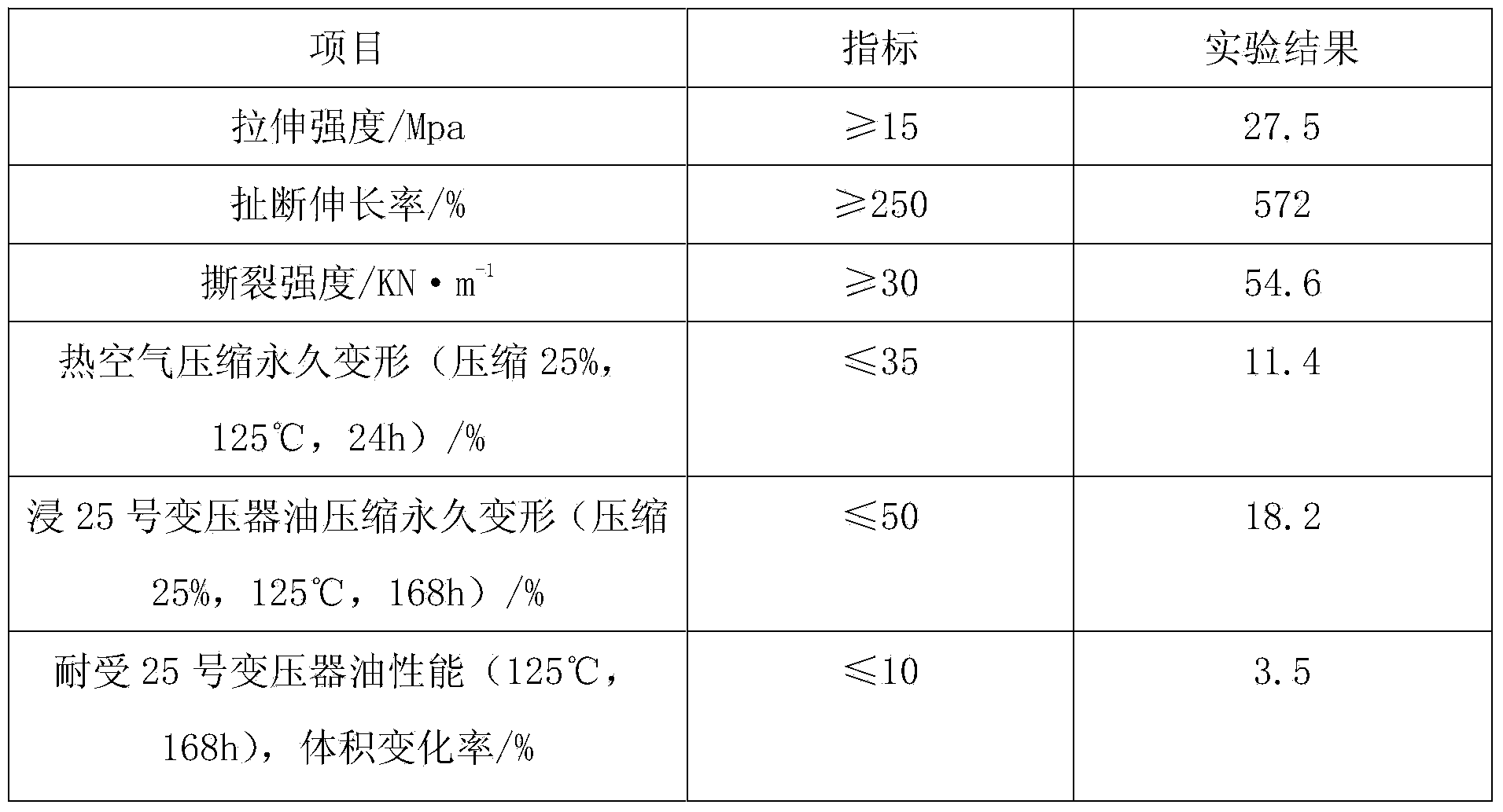

High-resilience transformer sealing gasket and preparation method thereof

InactiveCN103509217AImprove high temperature resistanceImprove low temperature resistanceTransformerPotassium

The invention discloses a high-resilience transformer sealing gasket and a preparation method thereof. The high-resilience transformer sealing gasket is prepared from 70-80 weight parts of methyl vinyl silicone rubber, 20-30 weight parts of polyurethane rubber, 15-20 weight parts of hexamethyldisilazane, 30-40 weight parts of fumed silica, 4-6 weight parts of diphenylsilanediol, 1-2 weight parts of zinc oxide, 2-3 weight parts of stearic acid, 1-2 weight parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.5-1 weight part of dicumyl peroxide, 2-3 weight parts of bis-(gamma-triethoxysilylpropyl)tetrasulfide, 1-2 weight parts of an antiager RD, 2-3 weight parts of an antiager TNP, 1-2 weight parts of an antioxidant 1010, 10-15 weight parts of coumarone resin, 5-10 weight parts of nanometer potassium feldspar, 4-8 weight parts of organobentonite, 6-12 weight parts of mica powder and 3-5 weight parts of a composite filling material. The high-resilience transformer sealing gasket is soft and smooth, has no toxicity and smell, has excellent high temperature and low temperature resistance, excellent compression resilience and high mechanical strength, can be used at a temperature of -70-250 DEG C for a long time, and does not age, deform and crack.

Owner:ANHUI KELIN ELECTRONICS

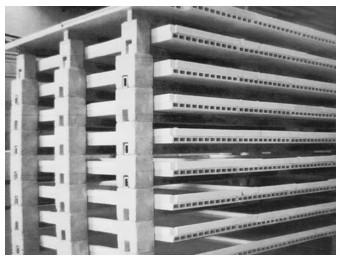

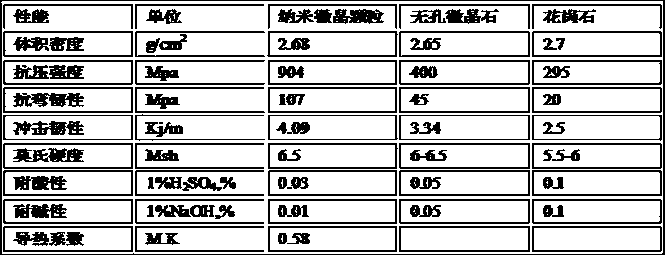

Nanocrystalline composite foamed ceramic assembly type wall masonry material and manufacturing method thereof

InactiveCN109180143AImprove stress resistanceImprove sound insulationCeramic materials productionCeramicwareAnti freezingFrit

The invention relates to a method for manufacturing a nanocrystalline composite foamed ceramic assembly type wall masonry material and a nanocrystalline composite foamed ceramic assembly type wall masonry material manufactured by adopting the method. The wall masonry material is prepared by the following steps: firing nanocrystalline frits by taking inorganic nonmetallic materials as raw materials, mixing the nanocrystalline frits with a mixed material prepared from foamed ceramic inorganic materials at an appropriate heat treatment firing temperature by using a controlled crystallization technology, and crystallizing the particles at a high-temperature heat treatment firing temperature, thereby obtaining the fired nanocrystalline composite foamed ceramic assembly type wall masonry material. The wall masonry material manufactured by the method is excellent in physical mechanical properties, compressive property, soundproof effect and stability, and has the advantages of being resistantto pollution, free in radioactive element, green, environmental-friendly, excellent in fireproof and flame retardant safety performance, anti-freezing, corrosion-resistant, aging-resistant and the like.

Owner:岑金涛

Nanocrystalline compound foaming ceramic assembling type wall masonry material and manufacturing method thereof

InactiveCN108947256AImprove stress resistanceImprove sound insulationCeramic materials productionCeramicwareAnti freezingAging resistance

The invention relates to a manufacturing method for a nanocrystalline compound foaming ceramic assembling type wall masonry material and the nanocrystalline compound foaming ceramic assembling type wall masonry material manufactured according to the manufacturing method. The nanocrystalline compound foaming ceramic assembling type wall masonry material is prepared according to the following steps:by taking an inorganic nonmetallic material as a raw material, baking into a nanocrystalline frit, and then adopting a controlled crystallizing technique for crystallizing grains under high heat treatment firing temperature together for a mixed material prepared from the nanocrystalline frit and a foaming ceramic inorganic material under an appropriate heat treatment firing temperature. The wallmasonry material manufactured according to the manufacturing method not only has physical mechanical performance, compression resistance, sound insulation effect and high stability but also has the advantages of fouling resistance, no radioactive element, environmental protection, high fireproof anti-flaming safety, anti-freezing property, corrosion resistance, ageing resistance, and the like.

Owner:岑金涛

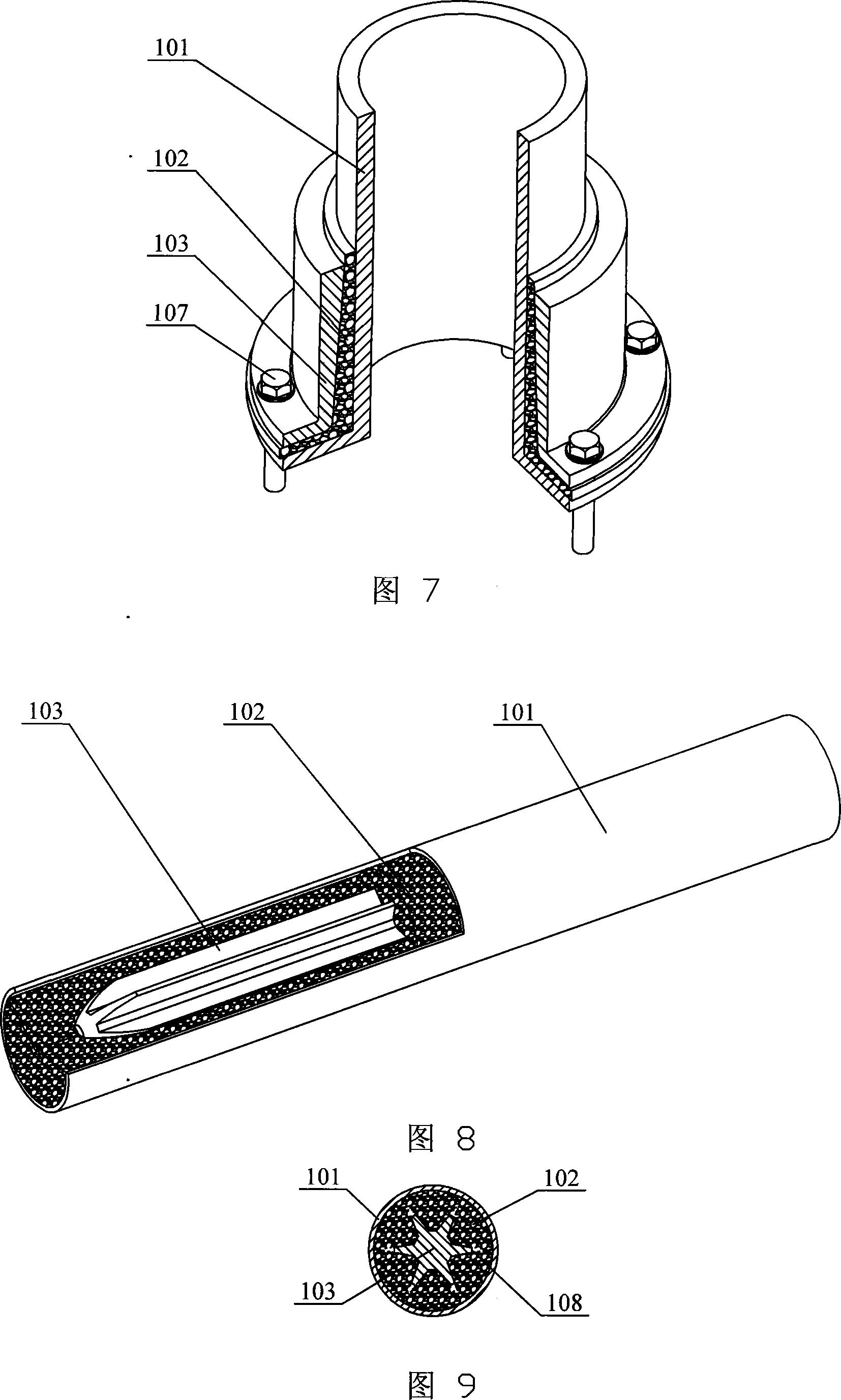

Method for preparing foam ceramic by using industrial and mining, building and sludge residue as raw materials

PendingCN107892583AReduce energy consumptionEfficient recyclingCeramic materials productionCeramicwareTunnel kilnSludge

The invention particularly relates to a method for preparing a foam ceramic by using industrial and mining, building and sludge residue as raw materials, and belongs to the technical field of environmental-protection foam ceramics, wherein protein foaming agent preparing, foam slurry preparing, molding and curing, high-temperature sintering, and detecting and packaging are performed to prepare thefoam ceramic. According to the present invention, the molded and cured foam slurry is conveyed to the tunnel kiln using liquefied petroleum gas as the fuel, and then enters the high temperature section through the sintering device, such that the two composite heating modes are innovatively connected in series so as to save the energy consumption or the fuel cost by 15-30%, and the technical problem that heavy metals, dioxins, and other organic pollutants cannot be completely removed during the combustion of industrial and mining, building and sludge residue is fundamentally solved; and the foam ceramic prepared through the method is the novel building material, and can have excellent performances of hydrophobicity, fire resistance, sound resistance, heat insulation, high compressive strength, acid resistance, alkali resistance, no aging, less deformation and the like according to the opened and closed gaps of the foam.

Owner:FUJIAN FUYONGDE ENVIRONMENTAL TECH CO LTD

Nanometer modified real stone paint base material

InactiveCN105255292AHigh boiling pointEnvironmental protection is goodAntifouling/underwater paintsPaints with biocidesStrong acidsHydroxyethyl cellulose

The invention provides a nanometer modified real stone paint base material, belonging to the technical field of constructional paint products. The nanometer modified real stone paint base material comprises the following raw materials by weight: 120 parts of water, 2 parts of hydroxyethyl cellulose ether, 2 parts of a high-efficiency thixotropic agent, 1 part of a multifunctional auxiliary agent, 3 parts of a film forming auxiliary agent, 1 part of a bactericide and 210 parts of a silicone-modified acrylate emulsion. A finished product prepared by uniformly mixing 680 parts of quartz sand with the base material composed of the above-mentioned raw materials has the following beneficial effects: excellent water resistance, no whitening, floating, falling and fading after immersion in water for 240 h, and no yellowing of a white real stone paint; high strength, good toughness, strong anti-impact force and small possibility of cracking; excellent adhesion and penetration performance, substantially prolonged service life, and co-existence of a nanometer modified real stone paint and a wall; and strong acid resistance and alkali resistance, antibacterial performance, mildew resistance, algae resistance and excellent resistance to high and low temperature.

Owner:李茂英

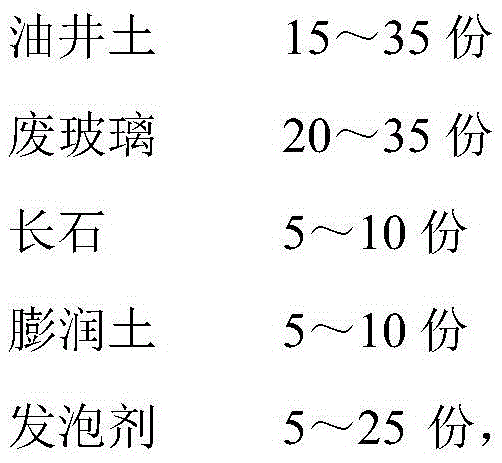

Foamed ceramic prepared by virtue of oil well earth and waste glass and method for foamed ceramic

InactiveCN105541371AImprove sound absorptionHigh strengthCeramic materials productionCeramicwareSodium BentoniteIndustrial equipment

The invention relates to foamed ceramic prepared by virtue of oil well earth and waste glass and a method for the foamed ceramic, and belongs to the technical field of ceramic materials. The foamed ceramic is prepared from the following raw materials in parts by weight: 15 to 35 parts of oil well earth, 20 to 35 parts of waste glass, 5 to 10 parts of feldspar, 5 to 10 parts of bentonite and 5 to 25 parts of a foaming agent. A preparation process for the foamed ceramic is simple, the firing temperature is low, and the prepared foamed ceramic is strong in strength and low in heat conductivity and specific gravity, and can be used as an excellent heat-preservation, sound-absorption and heat-insulation material. In addition, the foamed ceramic product is suitable to be used for heat preservation and heat insulation of industrial equipment and pipes, is more suitable to be used for heat preservation of building external walls and roofs, indoor heat insulation and the like, and has the characteristics of fire retardancy, waterproofness, no aging, corrosion resistance, zero radioactivity, high dimensional stability and the like, so that problems about environmental protection are solved, and meanwhile, better economic benefits are achieved.

Owner:HUBEI UNIV OF TECH

Commercial infrared gas stove

InactiveCN102022757BSo as not to damageNot agingDomestic stoves or rangesLighting and heating apparatusInfraredThermal energy

The invention relates to a commercial infrared gas stove comprising a stove casing. The stove casing comprises a mud infrared combustion chamber and an automatic water supply tank, the mud infrared combustion hearth is arranged in a groove with an upward opening in a suspended way, space between the external part of the mud combustion hearth and the inner side of the groove is filled with gypsum,and a water cavity is arranged in the middle of the gypsum. Water in the water cavity is supplied by the automatic water tank at one side. The water is absorbed through the gypsum so that the mud infrared combustion hearth is kept wet and no tempering, ageing or damage happens after long-time vigorous fire combustion. The invention has the characteristics of keeping the moisture of the combustionchamber and realizing long-time vigorous fire combustion without tempering, ageing or damage. Meanwhile, converted steam can also produce heat, and infrared strong-heat radiation which original commercial stove cannot adopt can be realized, so that a large quantity of energy resources is saved.

Owner:张达积

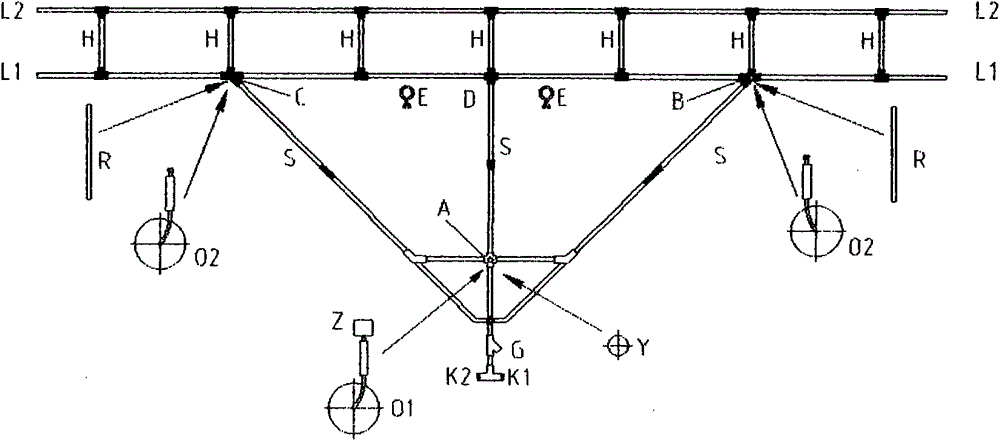

Agricultural irrigation device

InactiveCN104126488AReduce weightNot agingWatering devicesCultivating equipmentsTraction systemAgricultural irrigation

The invention relates to an agricultural irrigation device comprising a planar sprinkling structure, a dynamic traction system, and a stainless steel telescopic pipe. The device is characterized in that the water inlet of the planar sprinkling structure is connected with one end of the stainless steel telescopic pipe; the other end of the stainless steel telescopic pipe is connected with a water source; a traction power is fixedly arranged on the foremost end of the planar sprinkling structure or is fixed at a place several meters right in front of the planar sprinkling structure; a plurality rows of small holes are drilled on the back-lower parts of the sprinkling horizontal tubes of the planar sprinkling structure; the planar sprinkling structure can travel forward under the traction of the power; a controllable water pressure gauge can generate induction signals according to water pressures, and the speed of the planar sprinkling structure traveling forward can be controlled; manual control and remote control can also be realized; the planar sprinkling structure can be folded, such that the device can be easily moved and stored when not in use.

Owner:刘碰

Phenolic foam thermal-insulating fire-proof material and production method thereof

InactiveCN104327448ASound insulation rating is lowNo deformationPhenolformaldehyde foamFoaming agent

The invention discloses a phenolic foam thermal-insulating fire-proof material and a production method thereof. In the invention, the phenolic hard foam thermal-insulating fire-proof material is prepared with a foamable phenolic resin being employed as a main material and with malt paste, perlite, urea resin, an emulsifier, a foaming agent and a curing agent being employed as auxiliary materials. Compared with a thermal-insulating material in the same type, not only are the advantages of light self-weight, high strength, less thermal-conductive coefficient, low smoke density and less calorific value of a conventional phenolic hard foam thermal-insulating fire-proof retained, but also defects of being crisp, poor flexibility and being liable to crumb are overcome. When being fired with fire, only a carbonized layer is formed on the surface of the material and combustion and deformation phenomenon are free. Compared with a common external wall thermal-insulating material EPS / XP / PU in the prior art, the phenolic foam thermal-insulating fire-proof material is low in the smoke density, is fire-retardant and is low in thermal-conductive coefficient. A flame-retardant performance is greatly improved and can achieve an A grade according to GB8624-1997.

Owner:彭定忠 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com