Agricultural irrigation device

A technology of pipe fittings and planes, applied in the field of watering machinery and equipment, can solve problems such as unevenness, lowering ground temperature, and unscientific problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Under the condition that the power traction system and the stainless steel telescopic pipe are the same for the agricultural watering machine of the present invention, the planar sprinkling structure has multiple implementation modes.

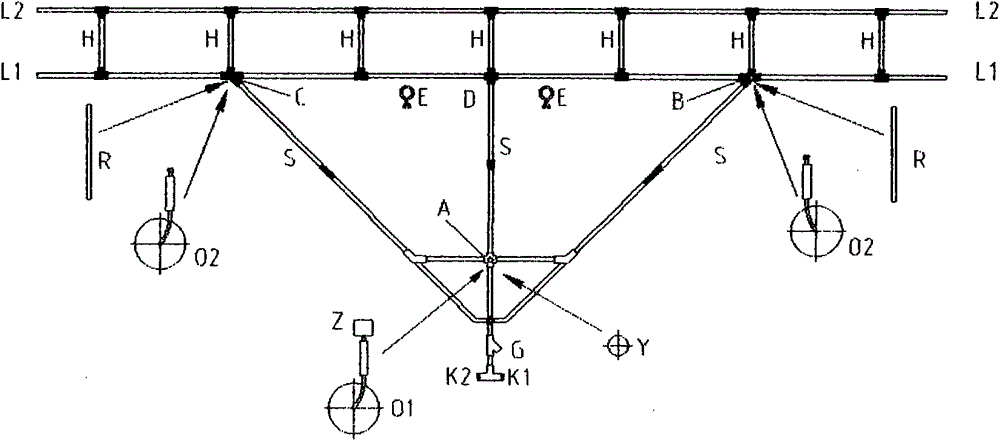

[0035] The first embodiment is as attached figure 1 , figure 2 As shown, the water source enters the planar overall structure from K1 or K2, enters the spraying horizontal pipe L1 through the diversion water delivery pipe S, and sprays backwards and downwards, and then enters another spraying horizontal pipe L2 through multiple short water delivery pipes H to Spray below and behind. The water pipeline S is in the shape of a herringbone or a circular arc. Its purpose is not only to stabilize the structure, but the main purpose is to make the water flow smoothly, reduce the water pressure attenuation, and evenly enter the middle of the two sides of the spraying horizontal pipe L1. For downward spraying, there are multiple short water de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com