Foamed ceramic prepared by virtue of oil well earth and waste glass and method for foamed ceramic

A technology of foam ceramics and waste glass, which is applied in the field of foam ceramics, can solve the problems of affecting the performance of final product foam ceramics, increasing the production cost of foam ceramics, unfavorable industrial application, etc., and achieves the advantages of small specific gravity, good dimensional stability and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

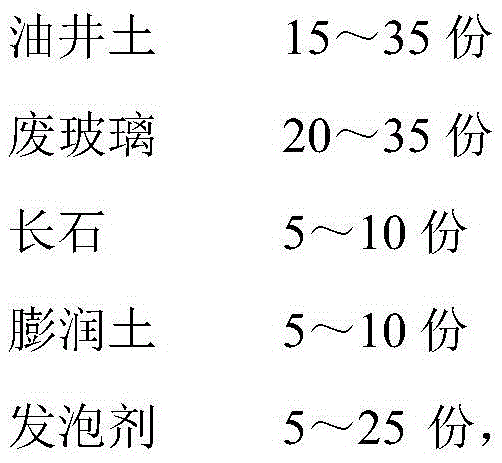

Method used

Image

Examples

Embodiment 1

[0024] The ceramic foam of this embodiment is prepared from the following components by weight: 35 parts of oil well soil, 35 parts of waste glass, 5 parts of feldspar, 10 parts of bentonite, and 15 parts of carbon powder.

[0025] The ceramic foam of the present embodiment is prepared by following method, and described method comprises the steps:

[0026] (1) Ball mill the oil well soil and waste glass to obtain powders, and then pass through 100-mesh sieves respectively, so that the particle size of the oil well soil and glass powder reaches the range of 120 μm to 150 μm;

[0027] (2) Take each raw material by weight as follows: 35 parts of oil well soil powder after ball milling described in step (1), 35 parts of waste glass powder after ball milling described in step (1), 5 parts of feldspar, bentonite 10 parts, 15 parts of carbon powder, and then put each raw material into a ball mill and mix them evenly until the particle size of the powder reaches the range of 120 μm to...

Embodiment 2

[0031] The ceramic foam of this embodiment is prepared from the following components by weight: 35 parts of oil well soil, 30 parts of waste glass, 5 parts of feldspar, 10 parts of bentonite, and 20 parts of carbon powder.

[0032] The ceramic foam of the present embodiment is prepared by following method, and described method comprises the steps:

[0033] (1) Ball mill oil well soil and waste glass to obtain powder, and then pass through 100-mesh sieve to make the oil

[0034] The particle size of well soil and glass powder reaches the range of 120 μm to 150 μm;

[0035] (2) Take each raw material by weight as follows: 35 parts of oil well soil powder after ball milling described in step (1), 30 parts of waste glass powder after ball milling described in step (1), 5 parts of feldspar, bentonite 10 parts, 20 parts of carbon powder, and then put each raw material into a ball mill and mix them evenly until the particle size of the powder reaches the range of 120 μm to 150 μm to...

Embodiment 3

[0039] The ceramic foam of this embodiment is prepared from the following components by weight: 35 parts of oil well soil, 25 parts of waste glass, 5 parts of feldspar, 10 parts of bentonite, CaCO 3 25 parts of powder.

[0040] The ceramic foam of the present embodiment is prepared by following method, and described method comprises the steps:

[0041] (1) Ball mill oil well soil and waste glass to obtain powder, and then pass through 100-mesh sieve to make the oil

[0042] The particle size of well soil and glass powder reaches the range of 120 μm to 150 μm;

[0043](2) Take each raw material by weight as follows: 35 parts of oil well soil powder after ball milling described in step (1), 25 parts of waste glass powder after ball milling described in step (1), 5 parts of feldspar, bentonite 10 parts, CaCO 3 25 parts of powder, and then put each raw material into a ball mill and mix them uniformly until the particle size of the powder reaches the range of 120 μm to 150 μm to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com