Manufacturing method of ceramic glaze art toughened glass for furniture and product thereof

A technology of tempered glass and manufacturing method, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of poor aging resistance, acid and alkali resistance, surface peeling, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with specific embodiments.

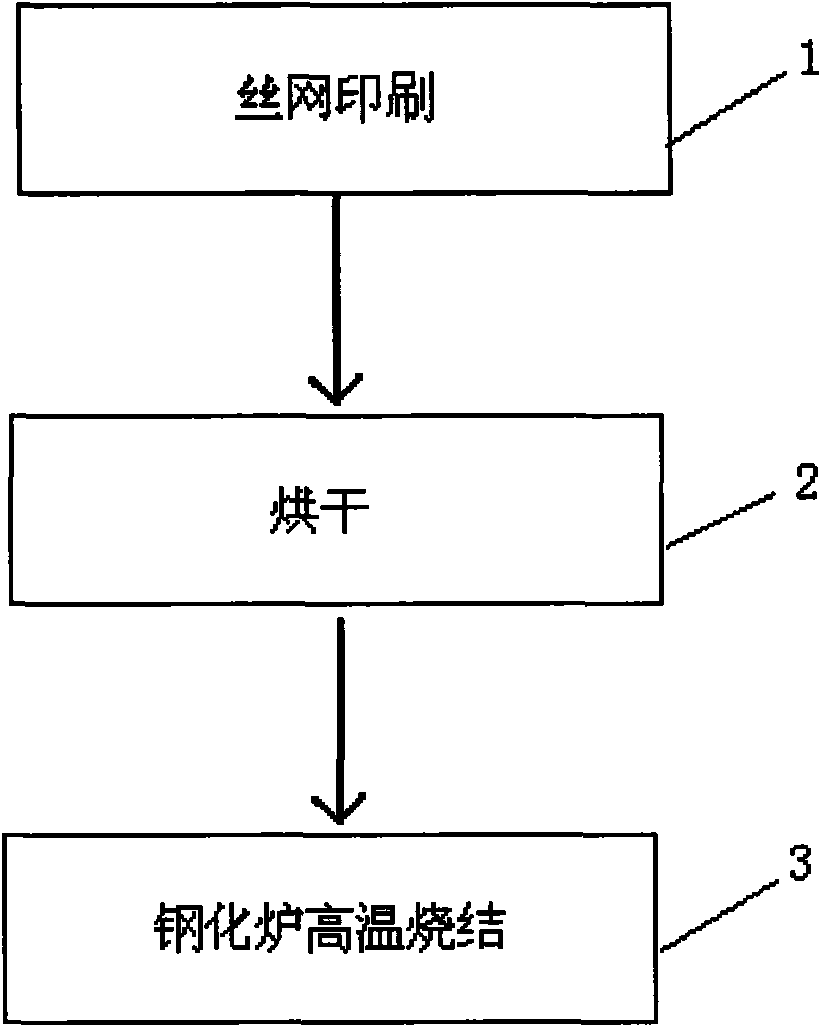

[0014] As shown in the accompanying drawings, the present invention consists of 3 steps of screen printing 1, drying 2 and high temperature sintering in a tempering furnace.

[0015] Wherein, screen printing 1 comprises the following steps:

[0016] (1) Make the film substrate, design the original manuscript according to the composition, image and color of the decorative painting, and the produced film substrate will make the product form a more complex pattern after printing.

[0017] (2) Put the film substrate on the photosensitive table, paste the film substrate on the printing surface (convex surface) of the screen, and then expose it in a vacuum exposure machine. The exposure time depends on the thickness of the photoresist, the energy of the exposure lamp, and the requirements of the screen to be made. Generally, the exposure time should be measured with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com