High-resilience transformer sealing gasket and preparation method thereof

A resilience and transformer technology, which is applied in the field of high resilience transformer gasket and its preparation, can solve the problems that the compression resilience cannot meet the sealing requirements, and achieve the best compression resilience, high mechanical strength, and good low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

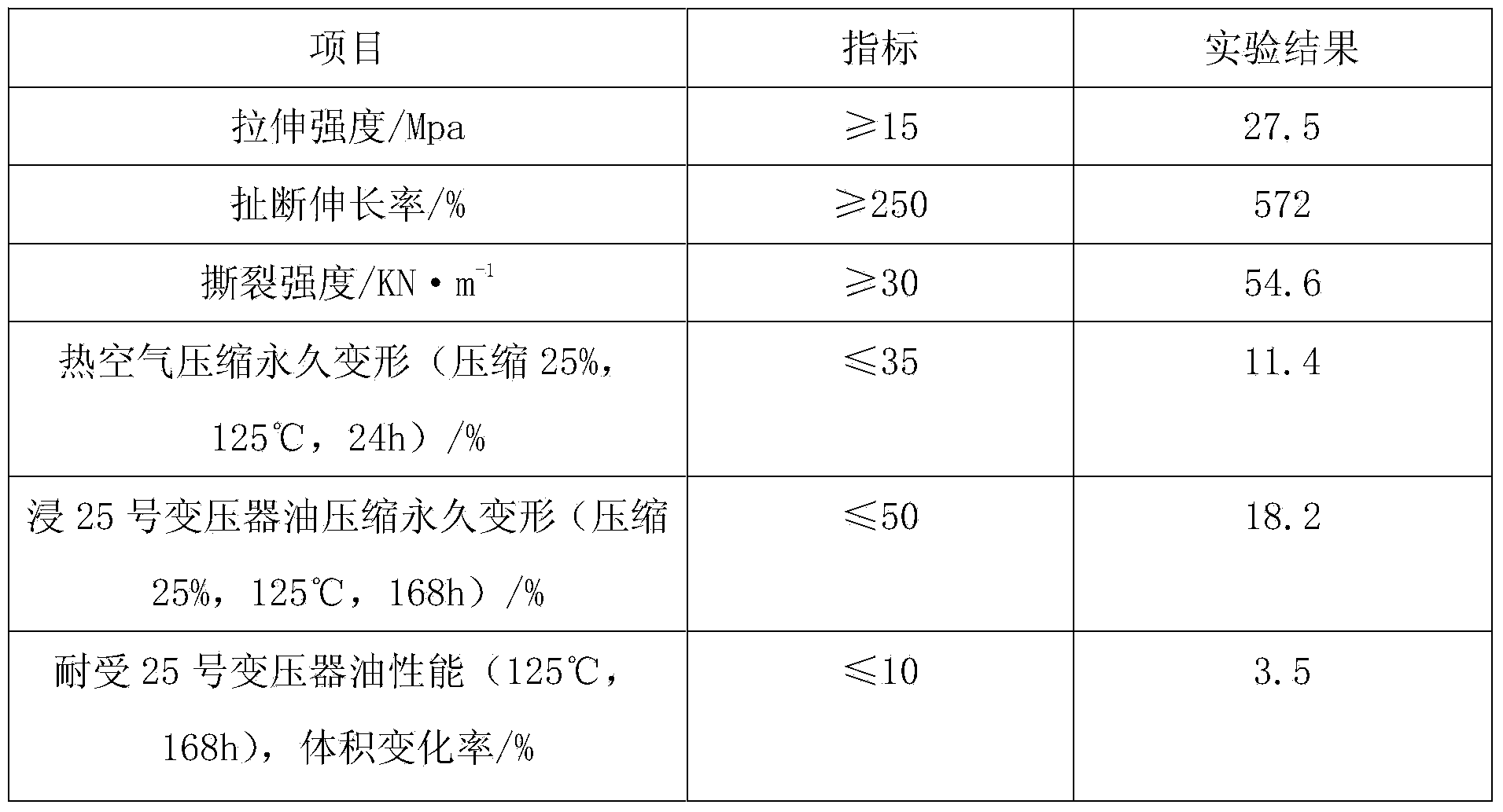

[0012] A high resilience transformer gasket made of the following raw materials by weight (kg): methyl vinyl rubber (N41) 80, polyurethane rubber (AR-200) 20, hexamethyldisilazane 15, gas phase white Carbon black 35, diphenylsilanediol 5, zinc oxide 1.5, stearic acid 2.5, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane 1, diisoperoxide Propylbenzene 0.5, bis-(γ-triethoxysilylpropyl) tetrasulfide 2, antioxidant RD1, antioxidant TNP2, antioxidant 10101.5, coumarone resin 10, nanopotassium feldspar 8, organic bentonite 6. Mica powder 8. Composite filler 4;

[0013] The preparation method of the composite filler is as follows: a. Weigh wollastonite, pyrophyllite and attapulgite in a weight ratio of 3:3:1 and mix them evenly, calcinate at 505°C for 4 hours, and put in hydrochloric acid with a concentration of 15% after cooling to normal temperature Soak in the solution for 2 hours, filter, wash the above-mentioned ore mixture with distilled water until neutral, dry, pulverize, and pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com