Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Good compression resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aramid nanofiber/MXene composite conductive aerogel and preparation method thereof

ActiveCN111040238ALarge aspect ratioImprove temperature resistanceForce measurementElectrically conductiveFibrous composites

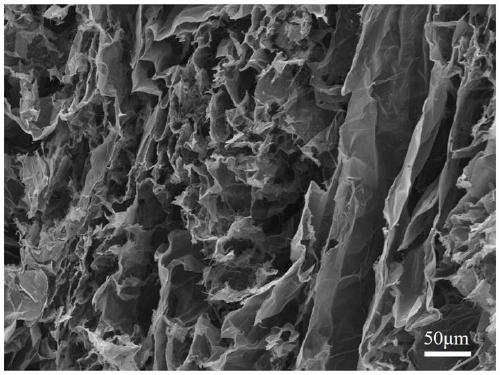

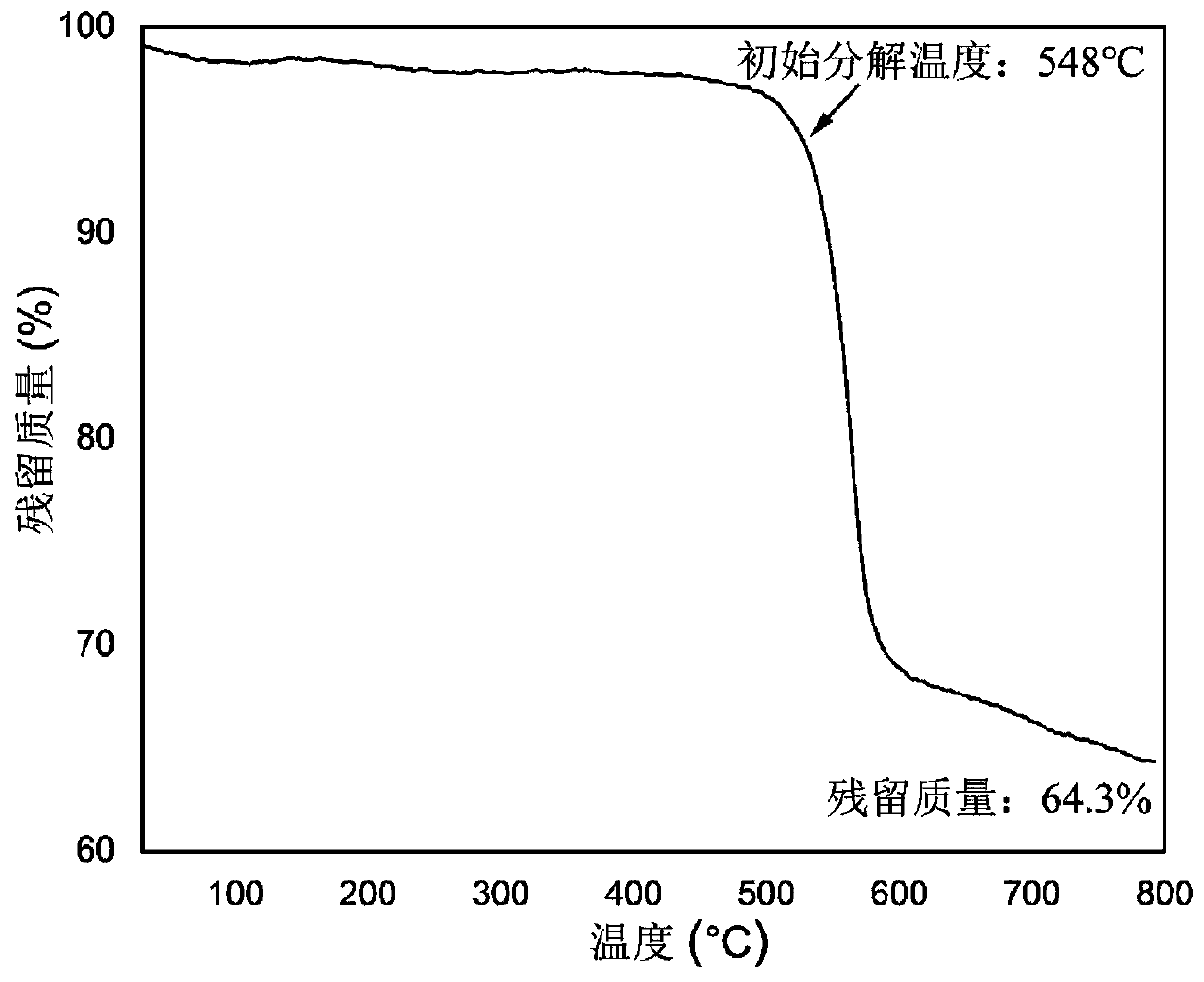

The invention discloses aramid nanofiber / MXene composite conductive aerogel and a preparation method thereof. By using aramid nanofibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using MXene with excellent conductivity, good chemical stability and a unique two-dimensional nano-film structure as a conductive and fillingcoating material, the aramid nanofiber / MXene composite conductive aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing an MXene dispersion liquid, preparing an aramid nanofiber / MXene composite dispersion liquid, preparing a gelatinous aramidnanofiber / MXene composite material and the like, thereby obtaining the aramid nanofiber / MXene composite conductive aerogel. The preparation process is simple and easy to implement, and the obtained aramid nanofiber / MXene composite conductive aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

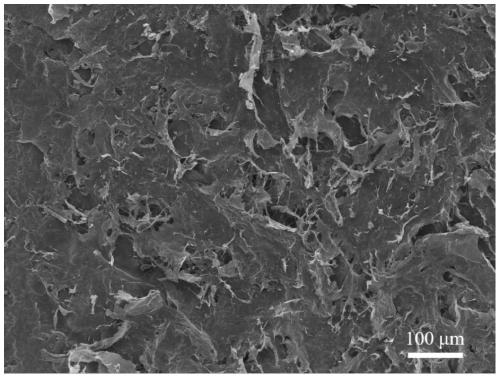

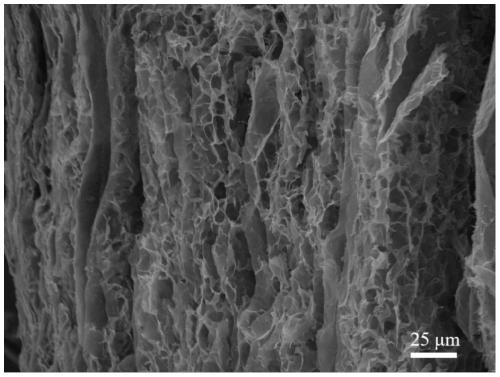

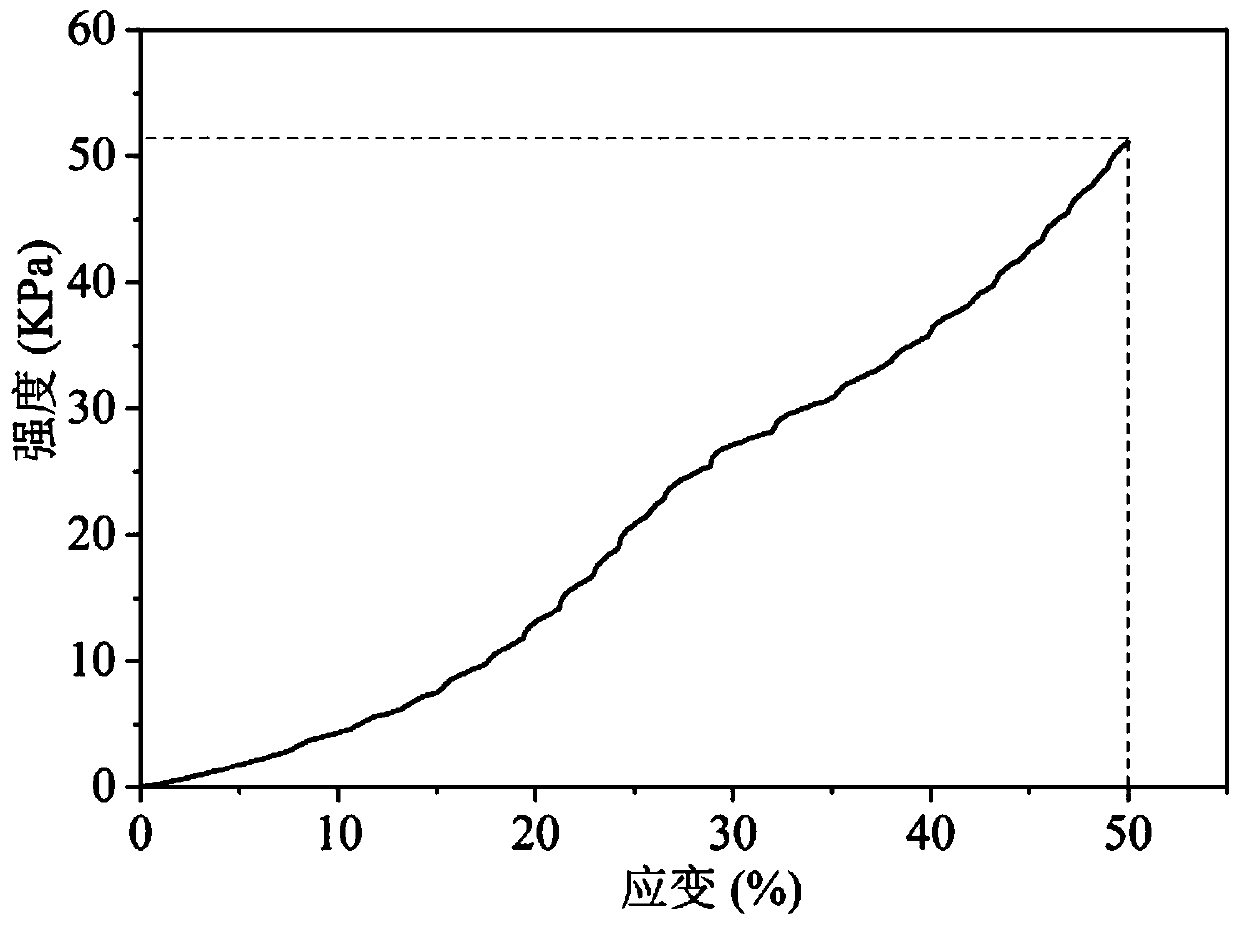

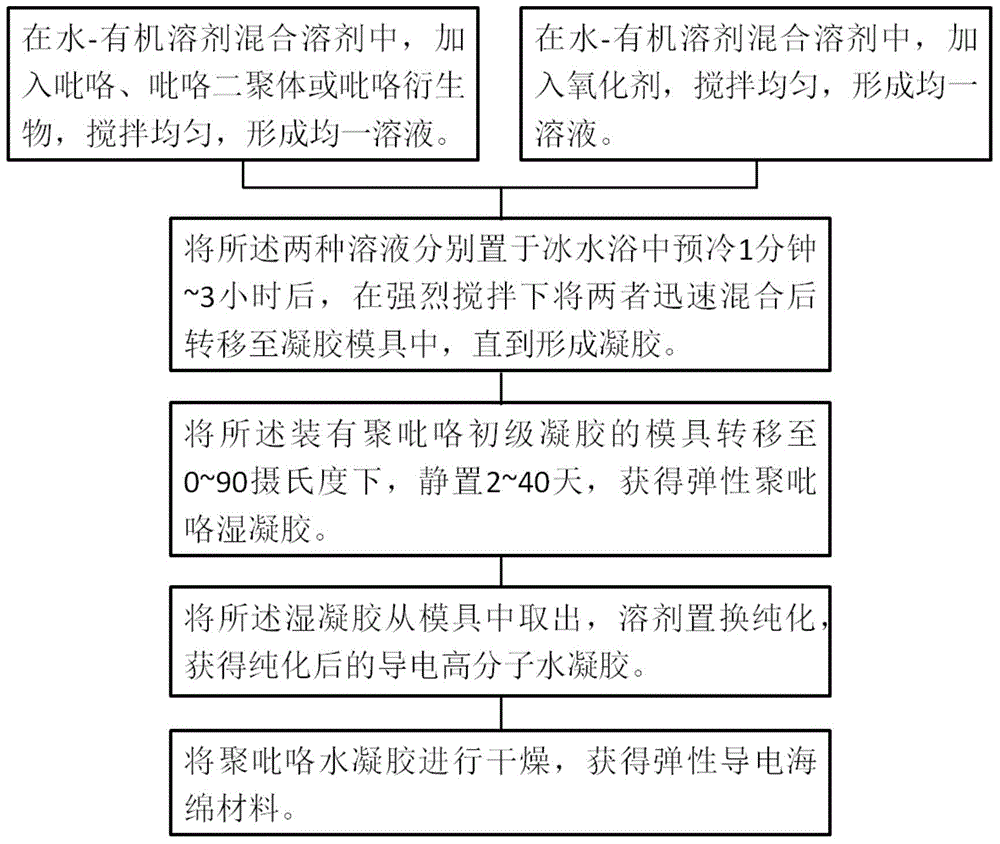

Elastic conducting polymeric hydrogel, sponge, preparation method and application thereof

ActiveCN105273187AHigh strengthIncrease elasticityOther chemical processesPolymer sciencePerylene derivatives

The invention discloses conducting polymeric hydrogel, sponge, a preparation method and an application thereof. Eigenstate conducting high-molecular polymer is used as a three-dimensional framework of the hydrogel, and the hydrogel is an organic conducting material having good mechanical strength and compression elasticity. The hydrogel can be obtained through step-by-step oxidative coupling polymerization on pyrroles and pyrrole derivatives by using an oxidizing agent and long-term secondary growth. Content of the conducting high-molecular polymer in the hydrogel is 1.5-21.5 wt%; maximum compression ratio can reach 90%; the hydrogel recovers to normal within 10 s to 5 min after compression; conductivity is 0.001-10 S / m; and the hydrogel has shape memory characteristics, and compression deformation recovery quantity is directly related to solvent volume. The sponge is obtained by drying the hydrogel. Mechanical strength, elasticity and conductivity of gel can be greatly maintained. With increasing of compression ratio, resistance value of the sponge is gradually reduced by 0-10%. The hydrogel and sponge of the invention can be widely applied in fields of dye adsorption, stress sensing, electrical switch and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Antibacterial deodorant ultra-fine denier polyester raschel blanket and production method thereof

InactiveCN101781830ALong-lasting antibacterial and deodorant functionNot easy to combWarp knittingHeating/cooling textile fabricsUltra fineMoisture

The invention provides an antibacterial deodorant ultra-fine denier polyester raschel blanket and a production method thereof. The blanket uses antibacterial deodorant polyester fiber with the fineness of below 1 denier as blanket fluff yarn raw material and uses 100 to 150-denier polyester filaments as base cloth. The production method of the raschel blanket is characterized by sequentially comprising the following steps: a) preparing the raw material according to the formula; b) weaving the raw material into grey cloth; c) slitting the grey cloth into specification size; d) performing printing or dyeing; e) performing post-treatment, f) performing heat setting; g) performing combing; and h) performing shearing to obtain a finished blanket. Compared with the prior art, the blanket has the advantages of changing the water-repellent non-breathable performance of polyester fiber, selecting and developing appropriate moisture-absorbing sweat-discharging softener and achieving firm moisture-absorbing sweat-discharging function through after-finishing after washing. In order to achieve the fluff style of raschel blankets, an ultra-fine fiber polyester blanket with the fineness of below 1 denier needs to have the moisture-absorbing sweat-discharging function with such fine fiber, as well as fine soft fluff, fluffy straight fluff, bright clean smooth fluff surface, good compression-resisting rebounding property, light weight and good warmth retention property, and similar products cannot achieve the effect.

Owner:宁波西田信染织有限公司

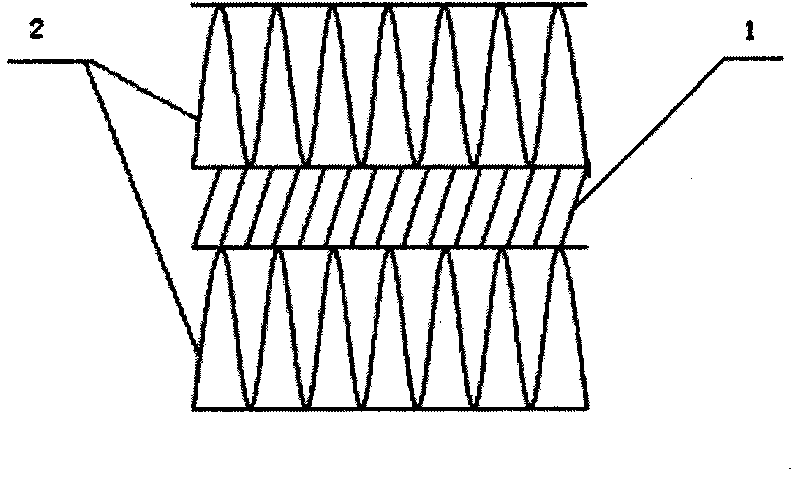

Composite sealing material and manufacturing method thereof

InactiveCN101747862AGood compression and rebound performanceGood long-term pressure resistance and sealing performanceOther chemical processesSurface finishingElastic membrane

The invention discloses a novel sealing material, which consists of a core plate and elastic membrane layers compounded on two sides of the core plate, wherein the core plate a metal or non-metal core plate after surface treatment; the elastic membrane layers are prepared from elastic foaming materials or non-foaming materials which are compounded on the surfaces of the core plate in a mechanical or chemical mode to form the membrane layers. The sealing material has the advantages of simple structure, excellent compression resilience, wonderful long-term pressurization sealability, very low creep relaxation performance, long service life and wonderful conformability with a sealing surface.

Owner:上海骏焱化工材料有限公司

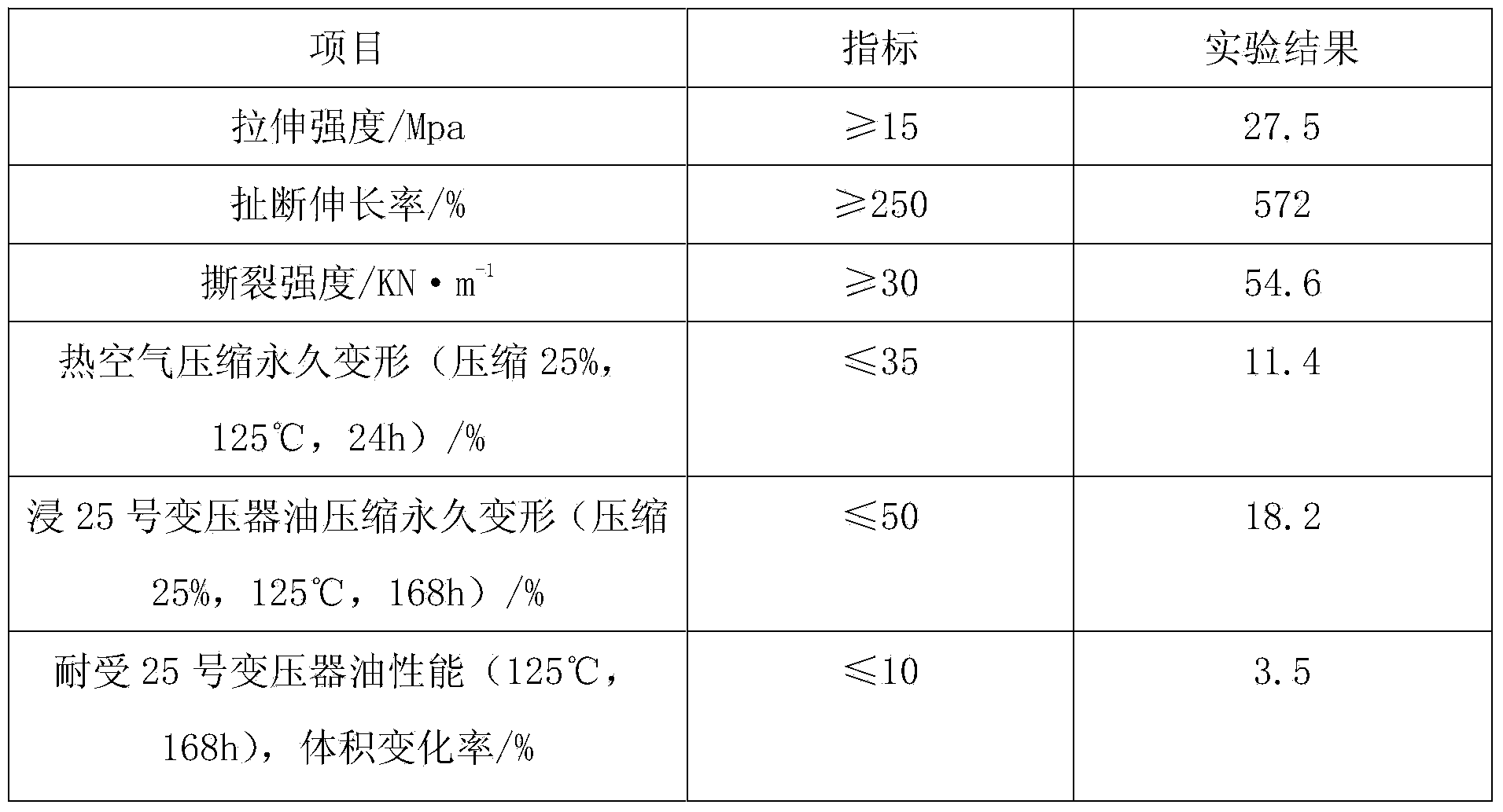

High-strength tear-resistant rubber sealing gasket and preparation method thereof

The invention discloses a high-strength tear-resistant rubber sealing gasket and a preparation method thereof. The high-strength tear-resistant rubber sealing gasket is prepared from raw materials, namely chlorosulfonated polyethylene rubber, silicon rubber, bisphenol A type polycarbonate, cashew nut shell oil modified phenolic resin, hexamethylenetetramine, dicumyl peroxide, spray carbon black, modified nano ceramics, silicon-magnesium-calcium crystal whiskers, nanometer wollastonite, zinc methacrylate, magnesium oxide, stearic acid, vinyl silicone oil, chlorinated paraffin 4-7, triethyl citrate and the like. According to the high-strength tear-resistant rubber sealing gasket and the preparation method thereof disclosed by the invention, the organic composite modification is carried out by adopting multiple nano ceramic powder, namely nanometer aluminum nitride, nanometer titanium carbide and nanometer zirconium boride, so that the compatibility of the nano ceramic powder and rubber can be enhanced; the modified nano ceramic powder, the silicon-magnesium-calcium crystal whiskers, the nanometer wollastonite and the like are filled in a modified rubber material together to prepare the sealing gasket, so that the mechanical strength, impact resistance and especially tear resistance of the sealing gasket can be remarkably improved; the heat resistance, abrasion resistance and the like of the rubber can also be improved.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Silicon rubber/polyurethane rubber composite hydraulic sealing gasket and preparation method thereof

The invention relates to a silicon rubber / polyurethane rubber composite hydraulic sealing gasket and a preparation method thereof. The silicon rubber / polyurethane rubber composite hydraulic sealing gasket is prepared from methylvinylsiloxane rubber, polyether based polyurethane rubber, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, diphenyl silanediol, hexamethyldisilazane, gas-phase white carbon black, modified wollastonite and the like. The methylvinylsiloxane rubber, which has the advantages of excellent heat resistance, excellent freezing resistance, excellent ozone resistance, excellent atmospheric aging resistance and small permanent compression set, and the polyurethane rubber with favorable mechanical properties are compounded and blended, so that the respective advantages are displayed, thereby enhancing the sealing property of the sealing material; and in the blending process, the organically / inorganically modified wollastonite is added to obviously improve the dispersity of the wollastonite in the rubber, thereby enhancing the mechanical strength, oil resistance, wear resistance, high temperature resistance and other properties of the sealing material.

Owner:WUHU YINHONG HYDRAULIC COMPONENTS

Fluorosilicone rubber/chloroprene rubber sealing gasket for high-temperature oil pump and preparation method thereof

The invention discloses a fluorosilicone rubber / chloroprene rubber sealing gasket for a high-temperature oil pump and a preparation method thereof. The sealing gasket is prepared from fluorosilicone rubber, chloroprene rubber, polyvinylidene chloride, diisobutyl phthalate, wollastonite powder, zinc oxide, magnesium oxide, nano aluminum oxide, dibutyltin dilaurate, nano titanium dioxide, dicumyl peroxide, modified nano-diamond, acetylene black, ammonium polyphosphate, magnesium hydroxide and other raw materials. The sealing gasket has excellent high-temperature resistance, can work at the temperature of 250-300 DEG C for a long time, has quite small mechanical strength and quite small volume changes, and has reliable sealing performance; and the sealing gasket has good corrosion resistance, is resistant to various media, has good air impermeability, is suitable for oil, water, gas, chemical media or other mixed media and the like, and realize effective sealing functions on oil, water, air, coal gas and various chemical media.

Owner:ANHUI TIANMA PUMP VALVE GROUP

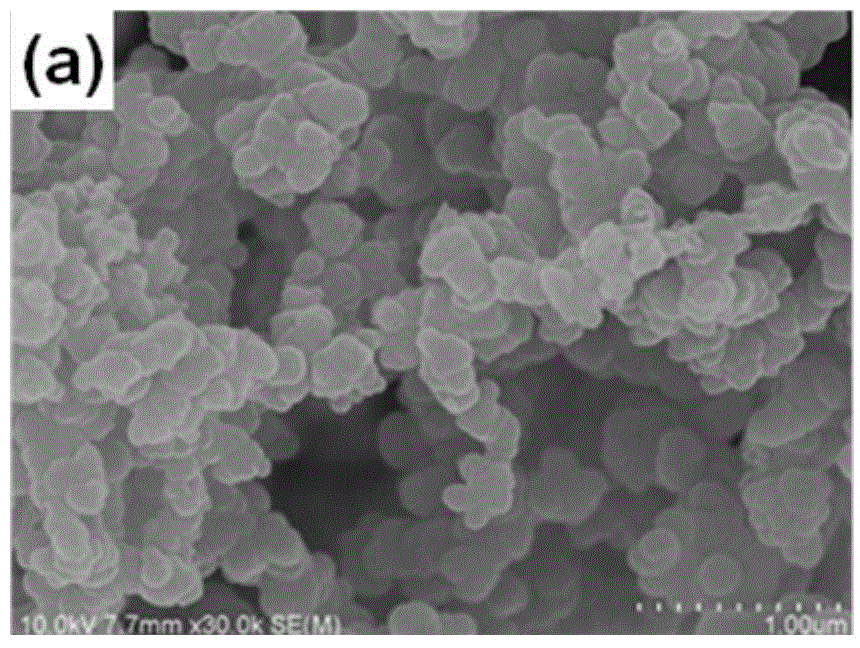

Elastic friction particle and preparation method thereof

ActiveCN103450522AGood compression resilienceHigh temperature resistantOther chemical processesPaper/cardboardLow noisePolymer science

The invention relates to an elastic friction particle and a preparation method thereof, and aims at providing an elastic friction particle which has the characteristics of good compression resilience, high temperature resistance, wear resistance, low noise, high and stable dynamic / static friction coefficient, close dynamic / static friction coefficient ratio and environmental friendliness. The provided method has the characteristics of simple and convenient preparation and relatively low cost. The technical scheme is as follows: an elastic friction particle for a wet paper-based friction sheet is a rubber elastic friction particle and comprises fluorine rubber, nitrile rubber, natural rubber, an accelerant DM, an anti-aging agent, stearic acid, polytetrafluoroethylene suspension resin, sulphur, nanometer SiO2 modified phenolic resin, boron carbide, antimony sulfide and a silicon carbide whisker. The preparation method comprises the following steps: (1) weighing all the raw materials according to the formula for later use; (2) feeding the raw materials into a rubber mixer for mixing, then feeding sulphur into the rubber mixer for mixing, and then taking a product out; (3) carrying out hot milling molding in an open mill; (4) crushing the particle; and (5) modifying the rubber elastic particle.

Owner:杭州汉乐科新材料科技有限公司

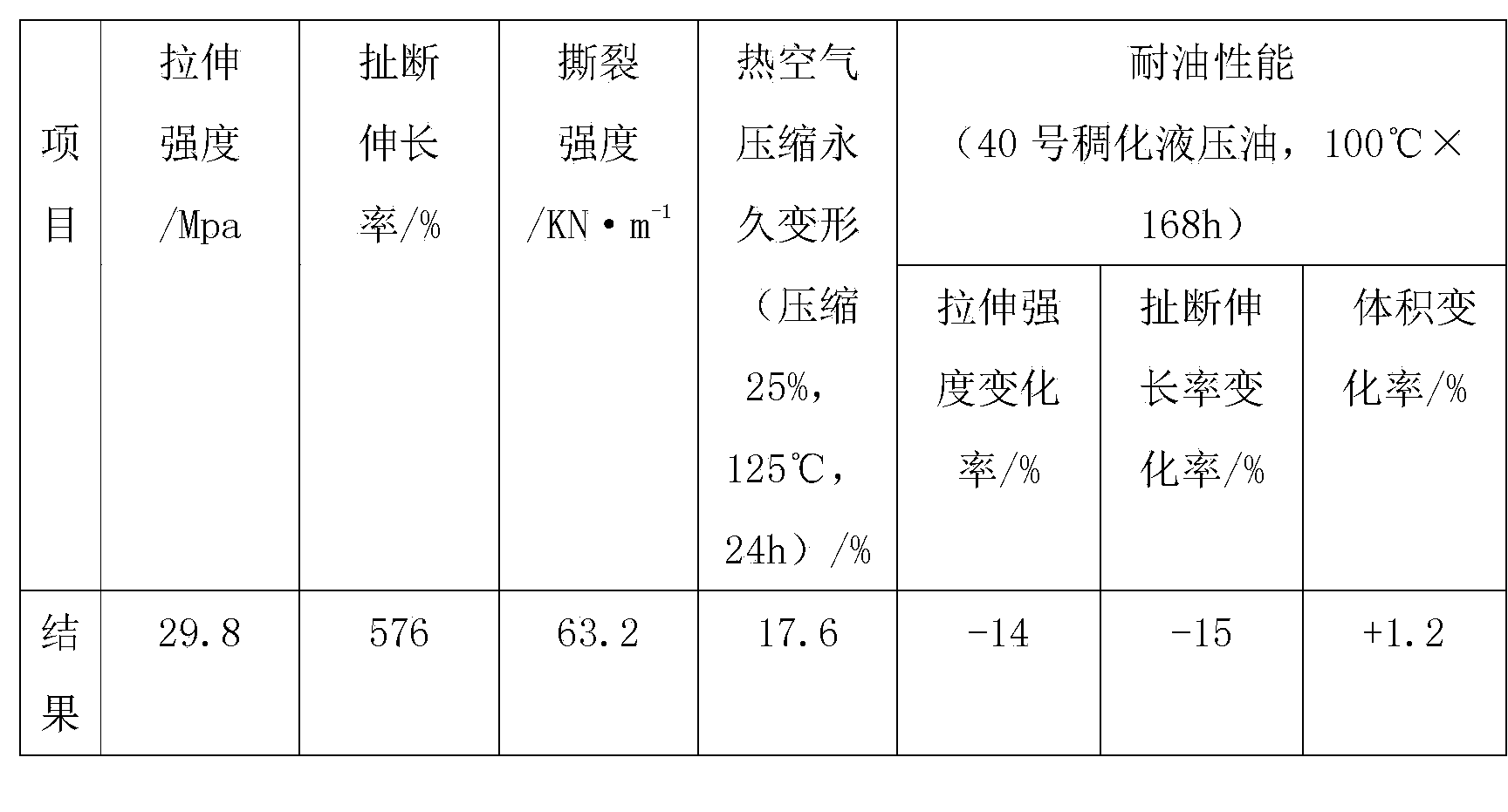

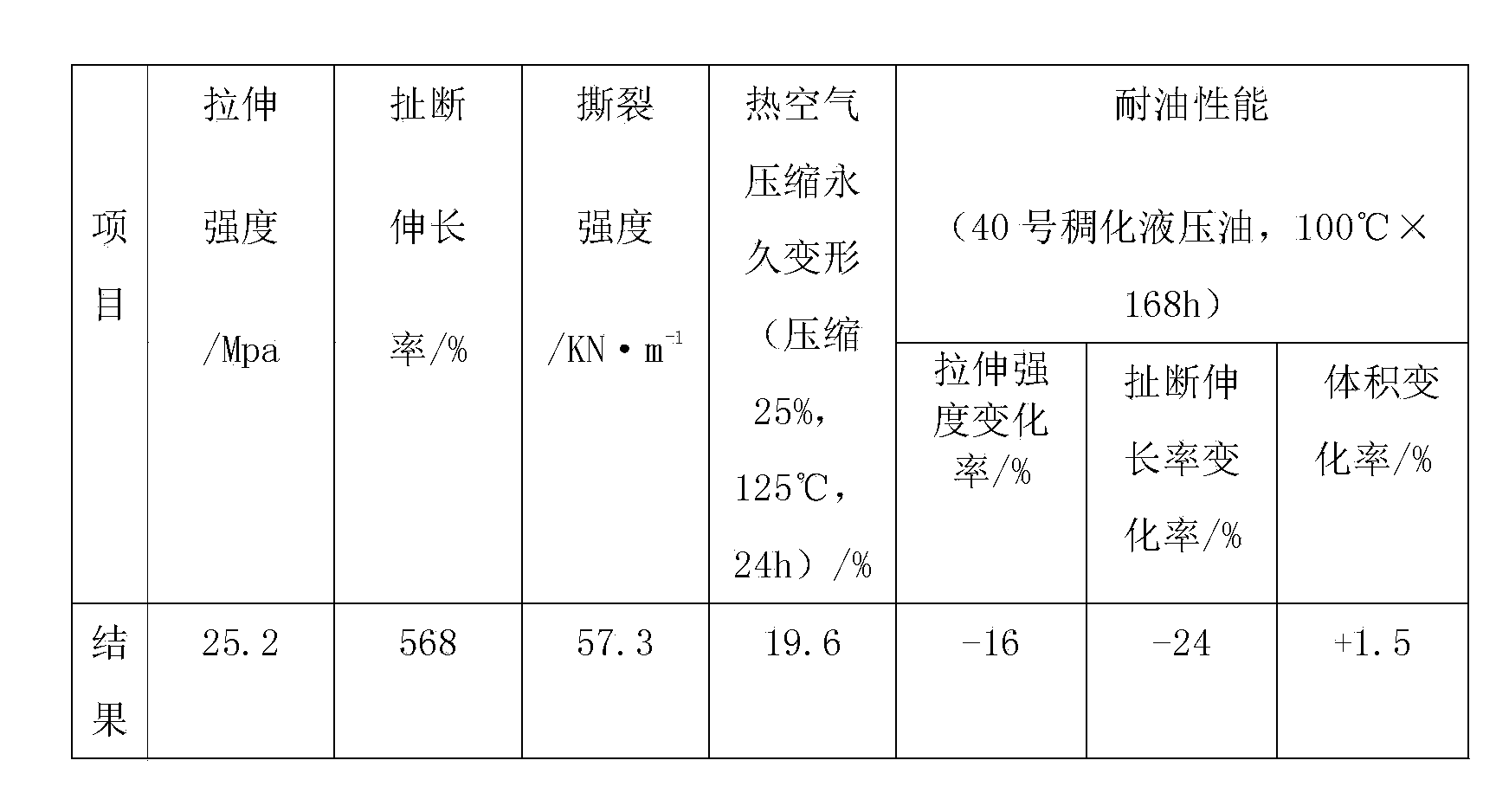

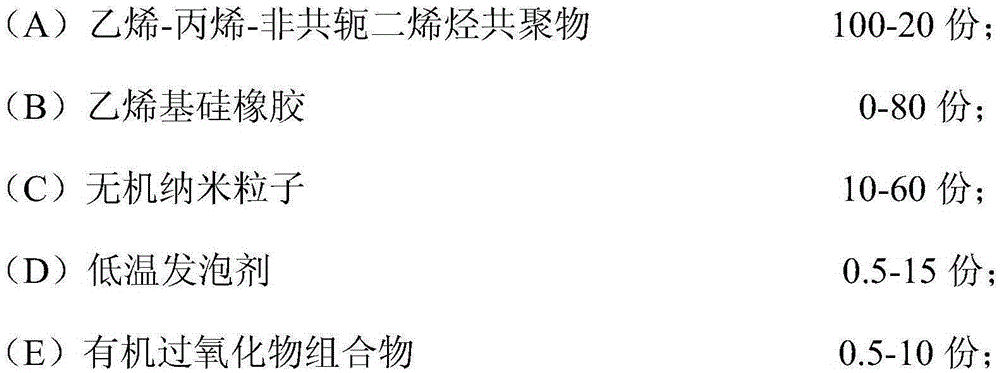

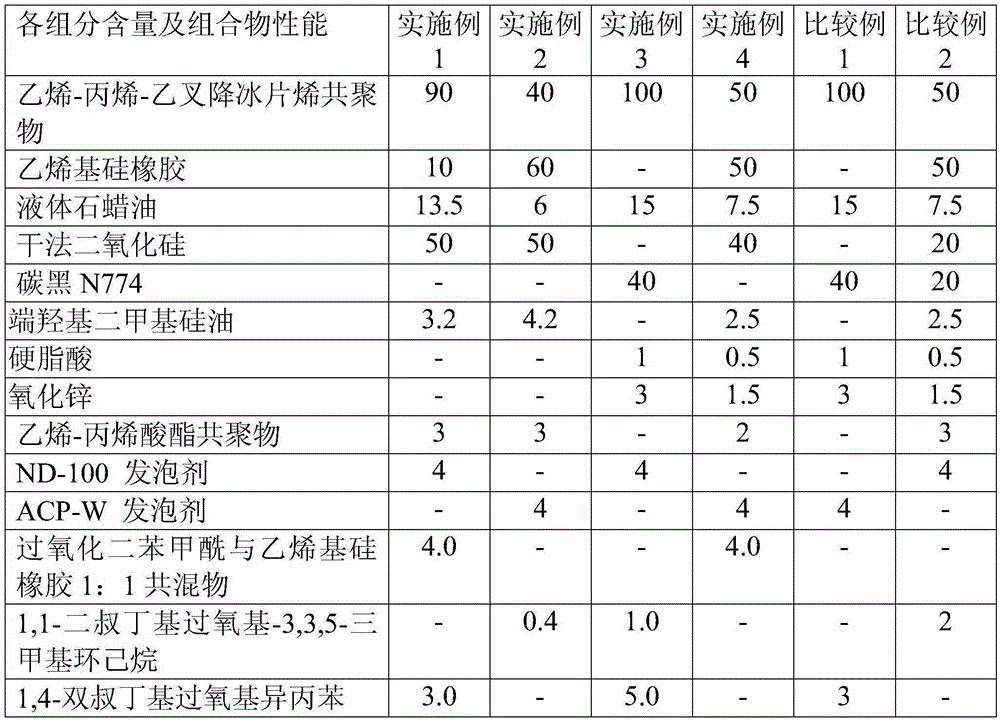

Micropore EPDM foamed material with excellent compression resilience performance and preparation method

The invention discloses a micropore EPDM foamed material with excellent compression resilience performance. The material is prepared from: by mass, 100-200 parts of ethylene-propylene-nonconjugated dialkene copolymer, 0-80 parts of vinylsiloxane rubber, 10-60 parts of inorganic nanoparticles, 0.5-15 parts of low temperature foaming agent and 0.5-10 parts of organic peroxide composition; wherein the nonconjugated dialkene is selected from ethylidene norbornene, hexadiene and isoprene, the mooney viscosity of the copolymer is not less than 20; the degree of polymerization of the vinylsiloxane rubber is not less than 1000 and the vinylsiloxane rubber contains at least two alkenyl groups connected with silicon atom; and organic peroxide composition includes two organic peroxides of which thermal degradation half-life for 1 min less than 155 DEG C and not less than 170 DEG C. The micropore EPDM foamed material with excellent compression resilience performance can be prepared according to the invention, the material has high mechanical strength, good appearance and uniform internal structure.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Polyvinyl alcohol-chitosan-graphene oxide sponge and preparation method thereof

The invention relates to polyvinyl alcohol-chitosan-graphene oxide sponge and a preparation method thereof. The preparation method comprises the following steps: dissolving polyvinyl alcohol in hot water to obtain an aqueous solution of polyvinyl alcohol; sequentially adding chitosan, graphene oxide, a foaming agent, inorganic acid and formaldehyde and stirring and mixing; pouring the mixed liquid into a mould; and curing and forming to obtain the polyvinyl alcohol-chitosan-graphene oxide sponge. Compared with the prior art, the polyvinyl alcohol-chitosan-graphene oxide sponge and a preparation method thereof have the following remarkable characteristics: 1) the prepared sponge has the advantages unavailable when the three materials are used independently; 2) the water absorption rate of the polyvinyl alcohol-chitosan-graphene oxide sponge is over 1410% and up to 1920%, the wet-state compression modulus is 40-60KPa, and the polyvinyl alcohol-chitosan-graphene oxide sponge has the advantages of moderate hardness, good compression elasticity and the like; and 3) the properties such as water absorbing capacity, organic liquid absorbing capacity and wet-state compression modulus of the sponge can be controlled by controlling the content of each component in the sponge formula.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Nanofiber flocculus with sandwich structure and preparation method of nanofiber flocculus

ActiveCN111485329ASmall diameterLarge diameterElectro-spinningNon-woven fabricsPolymer scienceSpinning

The invention relates to a nanofiber flocculus with a sandwich structure. The nanofiber flocculus is provided with a bottom layer, a middle layer and an upper layer with the longitudinal volume density being changed, the bottom layer and the upper layer are compact fiber layers, and the middle layer is a fluffy fiber layer; fibers, making contact with each other, in the nanofiber flocculus are crosslinked; the volume density of the compact fiber layers is 30-40 mg / cm3; the volume density of the fluffy fiber layer is 5-20 mg / cm3; and the compression resilience ratio of the nanofiber flocculus reaches 90% or above, and the CLO value is 2-4 clo. The nanofiber flocculus is prepared through an electrospinning technique, a polymer and a cross-linking agent are dissolved and dispersed in a solvent firstly, and sufficient stirring is conducted to obtain a spinning solution; and then continuous electrospinning is conducted under a specific humidity condition to obtain a composite nanofiber layer with the longitudinal volume density being changed, the composite nanofiber layer is subjected to crosslinking heat treatment, and the nanofiber flocculus is obtained.

Owner:DONGHUA UNIV

Heat preservation flocculus material, preparing method of heat preservation flocculus material and heat preservation product

InactiveCN105463697AFluffiness is goodGood compression resiliencePillowsSleeping rugSingle fiberMaterials science

The invention provides a heat preservation flocculus material, a preparing method of the heat preservation flocculus material and a heat preservation product, and belongs to the technical field of heat preservation flocculus materials. The heat preservation flocculus material comprises a plurality of stacked single fiber nets and spherical fiber assemblies at least distributed between part of the adjacent single fiber nets. The heat preservation flocculus material has the excellent comprehensive performance such as filling power, compression rebound resilience, heat preservation performance and washing resistance.

Owner:3M INNOVATIVE PROPERTIES CO

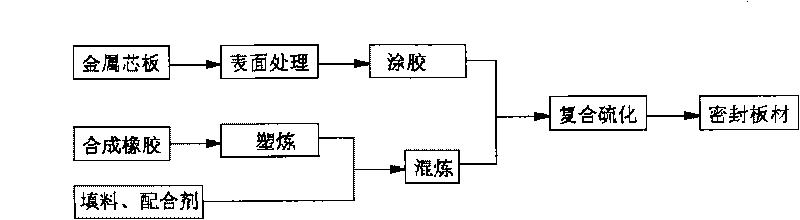

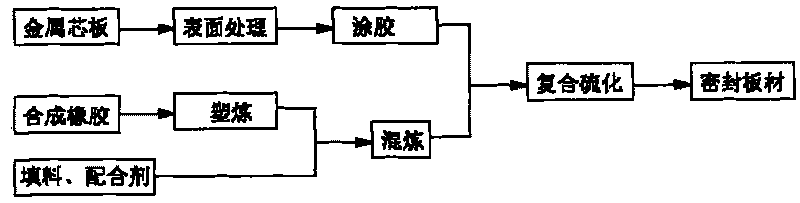

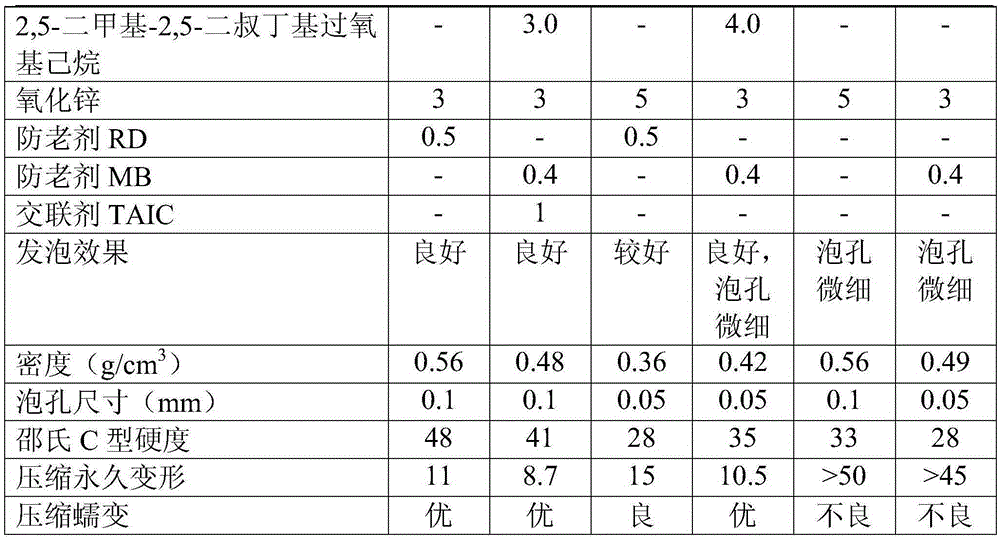

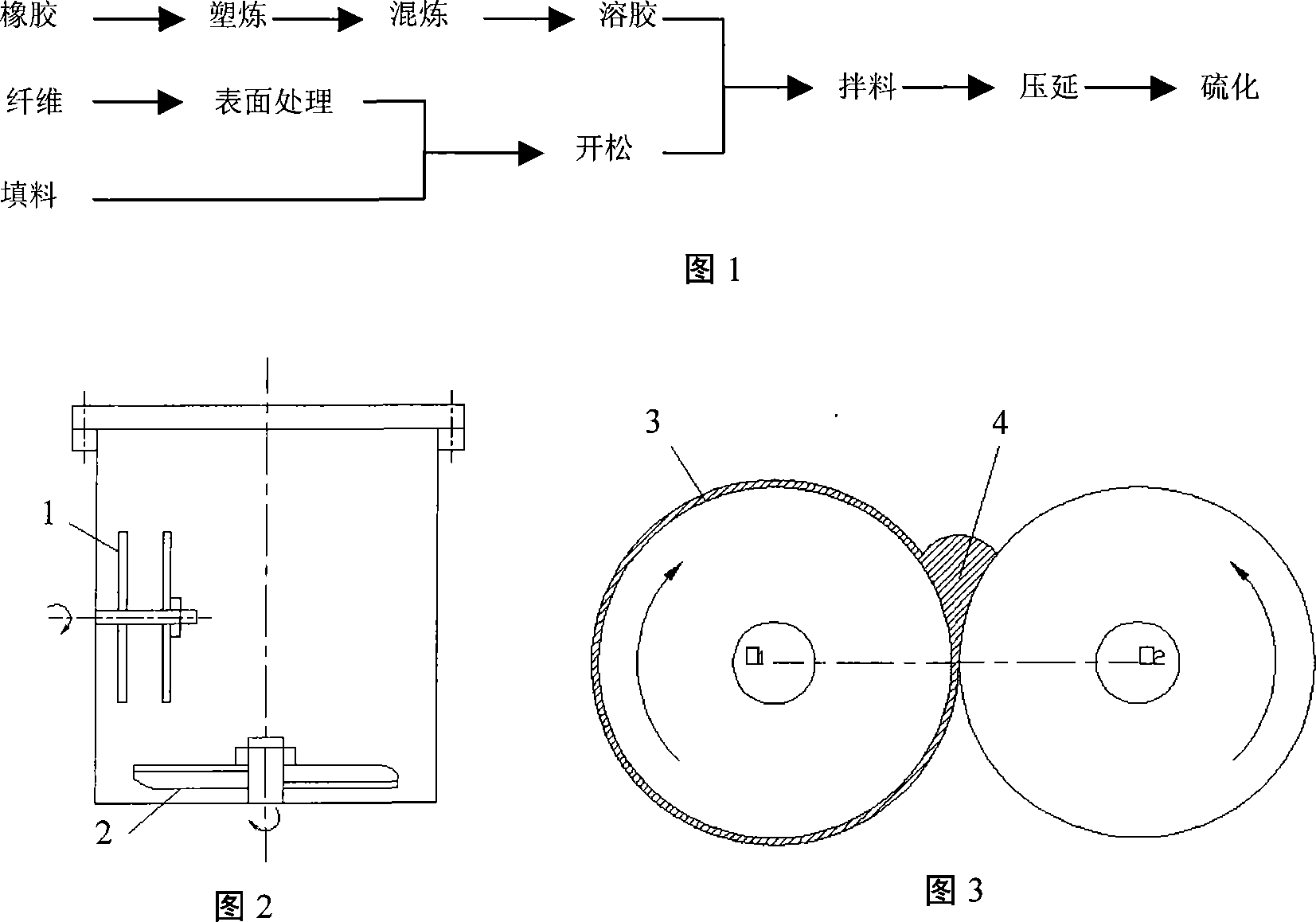

Short carbon fiber-staple glass fiber hybrid reinforced rubber-based sealing composite material and preparation technique thereof

The invention relates to a reinforced rubber based sealing composite materials and the preparation technology, in particular to a short carbon fiber-glass short fiber carbon fiber assorted reinforced rubber based sealing composite materials and the preparation technology. The invention adopts the assorted fiber of short carbon fiber-glass short fiber carbon fiber as the reinforcing fiber to optimize the formula of high temperature resistant NAFC materials on the basis of research of carbon fiber surface processing technology, and optimize the technological parameters of material rolling and sheet-shaping and forming to develop a new type NAFC material; the long term usage temperature can reach 350 DEG C within a year and the long term usage temperature reaches above 250 DEG C within three years which is expected to be used to replace asbestos rubber plate under severe working conditions.

Owner:NANJING UNIV OF TECH

Lead-acid storage battery separator and preparation method thereof

InactiveCN104852002AReasonable structureTightly bondedFinal product manufactureCell component detailsGlass fiberPolyester

The invention discloses a lead-acid storage battery separator which comprises 85-95 percent by weight of superfine glass fibers, 4-10 percent by weight of polyester fibers and 1-5 percent of cellulose acetate fibers. A preparation method comprises the following steps: pulping the superfine glass fibers for 5-10min and then adding the polyester fibers and the cellulose acetate fibers, pulping for 8-12min, forming and beating to enter a drying system at a constant speed, drying at a temperature of 160-2500 DEG C, winding and cutting to obtain the lead-acid storage battery separator. The lead-acid storage battery separator prepared by adopting the preparation method is reasonable in structure; the polyester fibers and the cellulose acetate fibers are added, so that the advantages of insulation, isolation and storage of an acid liquor of an existing AGM separator can be kept, the relatively high mechanical strength, excellent puncture resistance and excellent compression rebound property are obtained, the performance of a storage battery is improved, the service life of the storage battery is prolonged, and the application is relatively wide.

Owner:QIDONG HENGRUI POWER SUPPLY TECH CO LTD

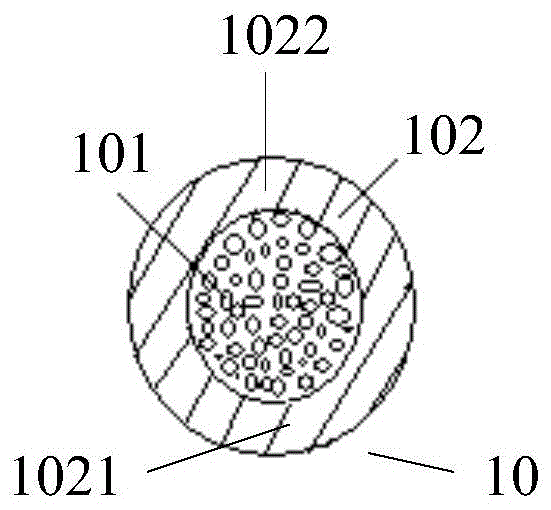

Sealing strip, electronic device and preparation method of sealing strip

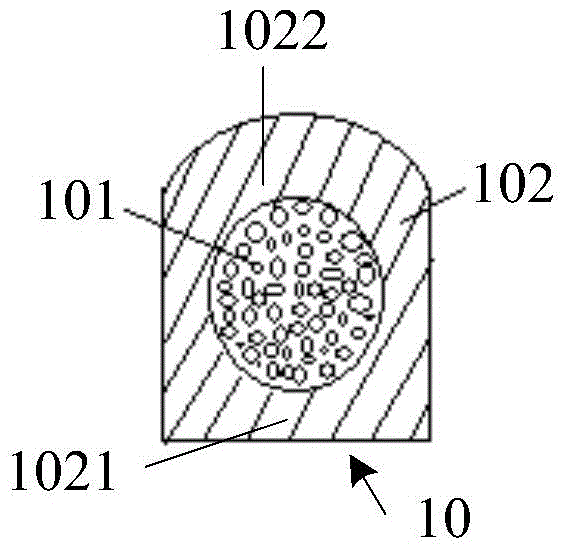

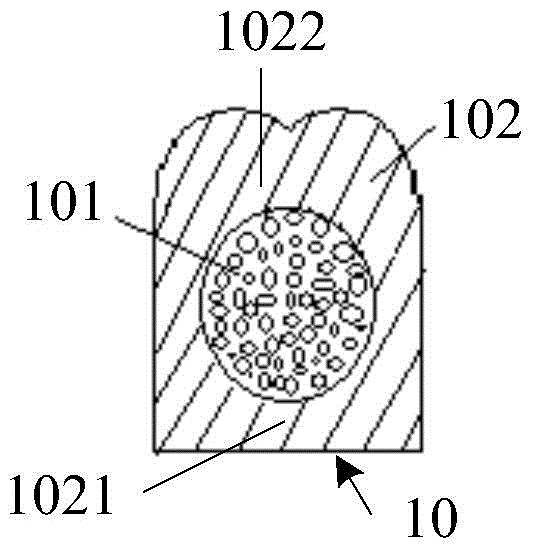

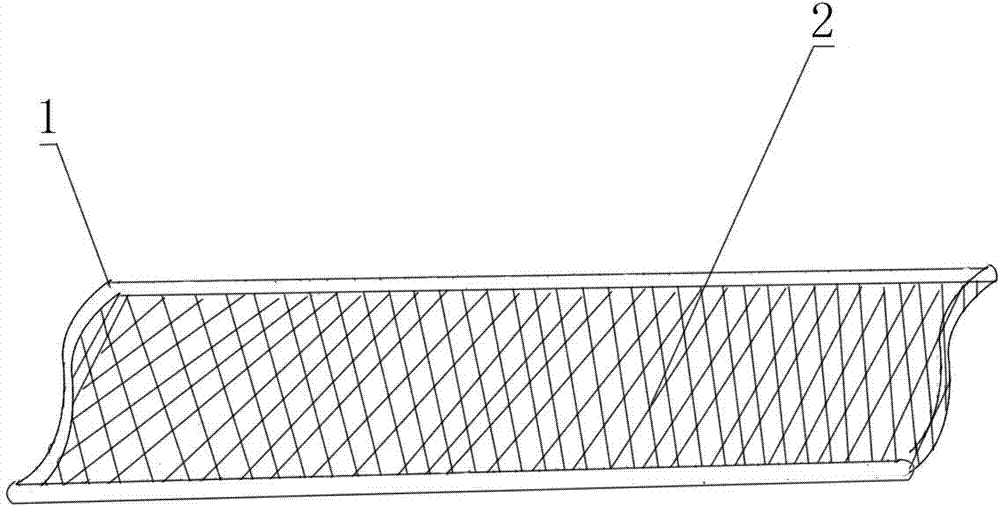

InactiveCN104653781ALarge compression rangeGood compression resilienceEngine sealsHermetically-sealed casingsFoam rubberEngineering

A sealing strip (10) comprises an electronic device of the sealing strip and a preparation method of the sealing strip. The sealing strip (10) comprises a foaming rubber inner core (101) and a physical rubber protection layer (102) that covers an outer surface of the inner core (101). The preparation method of the sealing strip comprises the following steps: providing an inner layer material cylinder of a dual-material extrusion device with a foaming rubber extrusion raw material, and an outer layer material cylinder with a physical rubber extrusion raw material; and extruding the sealing strip (10) through the dual-material extrusion device and forming at a time. The sealing strip (10) has advantages of a large compression range, low compression force, good compression resilience, not easy to be damaged and a simple preparation process.

Owner:ZTE CORP

High-damping silicone rubber modified ABS (acrylonitrile-butadiene-styrene) acoustic insulating material preparation method based on low-frequency noise protection

InactiveCN106700400AGood compression resilienceImprove heat resistanceMaterials preparationPolymer science

The invention discloses a high-damping silicone rubber modified ABS (acrylonitrile-butadiene-styrene) acoustic insulating material preparation method based on low-frequency noise protection. The preparation method comprises the following main steps of: mixing modified materials, preparing basis materials, mixing modified materials, blending basis materials, and then preparing a high-damping silicone rubber modified ABS acoustic insulating material. The preparation method has the beneficial effects that acrylonitrile-butadiene-styrene (ABS) is used as a host material, a home-made polyurethane foaming prepolymer is added to the ABS host material, the acoustic insulating material prepared after the polyurethane foaming prepolymer and the ABS are mixed has obvious sound insulation honeycombs, a very good effect on back and forth friction of sound and the characteristic of density of a cellular network structure, high-damping silicone rubber with a good dissipation effect on low-frequency noise at a room temperature and natural halloysite nanotubes are selected as modified materials for preparing the high-damping silicone rubber modified ABS acoustic insulating material.

Owner:邝耀燊

Conductive aramid nanofiber composite aerogel and preparation method thereof

ActiveCN111040237AHigh strengthReduce intensityElectrical/magnetic solid deformation measurementFiberCrystallinity

The invention discloses a conductive aramid nanofiber composite aerogel and a preparation method thereof. By using aramid nano-fibers with a nano-scale structure, high strength, a large length-diameter ratio and high temperature resistance as a matrix and using whisker carbon nanotubes with high crystallinity and high rigid structure are used as a conductive filler and a reinforced filling material, the conductive aramid nanofiber composite aerogel with low density, high strength and high compression resilience is prepared. The preparation method specifically comprises the following steps: preparing an aramid nanofiber dispersion liquid, preparing a whisker carbon nanotube dispersion liquid, preparing a whisker carbon nanotube / aramid nanofiber composite dispersion liquid, preparing a gelatinous whisker carbon nanotube / aramid nanofiber composite material, and the like, thereby obtaining the conductive aramid nanofiber composite aerogel. The preparation process is simple and easy to implement, and the obtained conductive aramid nanofiber composite aerogel has wide application prospects in the fields of pressure sensing, intelligent sensors, wearable equipment and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Lithium bromide absorptive shielding electric pump for air conditioner

ActiveCN101988514AReduce loadExtended service lifePump componentsPump installationsImpellerCavitation

The invention discloses a lithium bromide absorptive shielding electric pump for an air conditioner, comprising a pump body and a shielding motor connected with the pump body, wherein a circulation through hole is penetrated in a rotor shaft; one end of the circulation through hole is communicated with the inlet of the pump body while the other end is communicated with the inner cavity of a rear bearing pedestal; grooves are respectively arranged on an upper graphite bearing and a lower graphite bearing; the gap between a rotor shielding sleeve and a stator shielding sleeve is communicated with the cavity between a front bearing pedestal and an impeller back mouth ring through the groove on the lower graphite bearing, and communicated with the inner cavity of the rear bearing pedestal through the groove on the upper graphite bearing; and the cavity between the front bearing pedestal and the impeller back mouth ring is connected with an impeller chamber through an impeller balance hole. The lithium bromide absorptive shielding electric pump for the air conditioner greatly improves the cavitation overage, reduces the energy consumption, enhances the mass transfer coefficient and the change frequency of the lithium bromide, saves the cost and increases the efficiency of the air conditioning unit.

Owner:HEFEI XINHU CANNED MOTOR PUMP

Heat-conducting gasket and preparation method thereof

PendingCN113337253AImprove thermal conductivityEnsure ultra-high filler contentHeat-exchange elementsModifications by conduction heat transferPolymer sciencePolymer chemistry

The invention provides a heat-conducting gasket, which comprises a heat-conducting filler and a reinforcing material. The heat-conducting filler is a two-dimensional heat-conducting filler arranged along the thickness direction of the heat-conducting gasket, and the reinforcing material is filaments formed by high-molecular polymer wire drawing and / or carbon filaments formed by heat treatment of the filaments formed by high-molecular polymer wire drawing. The two-dimensional heat-conducting filler is tightly connected by the polymer filaments and / or the carbon filaments to form a filler / polymer and / or filler / carbon filament network structure.

Owner:CHANGZHOU FUXI TECH CO LTD

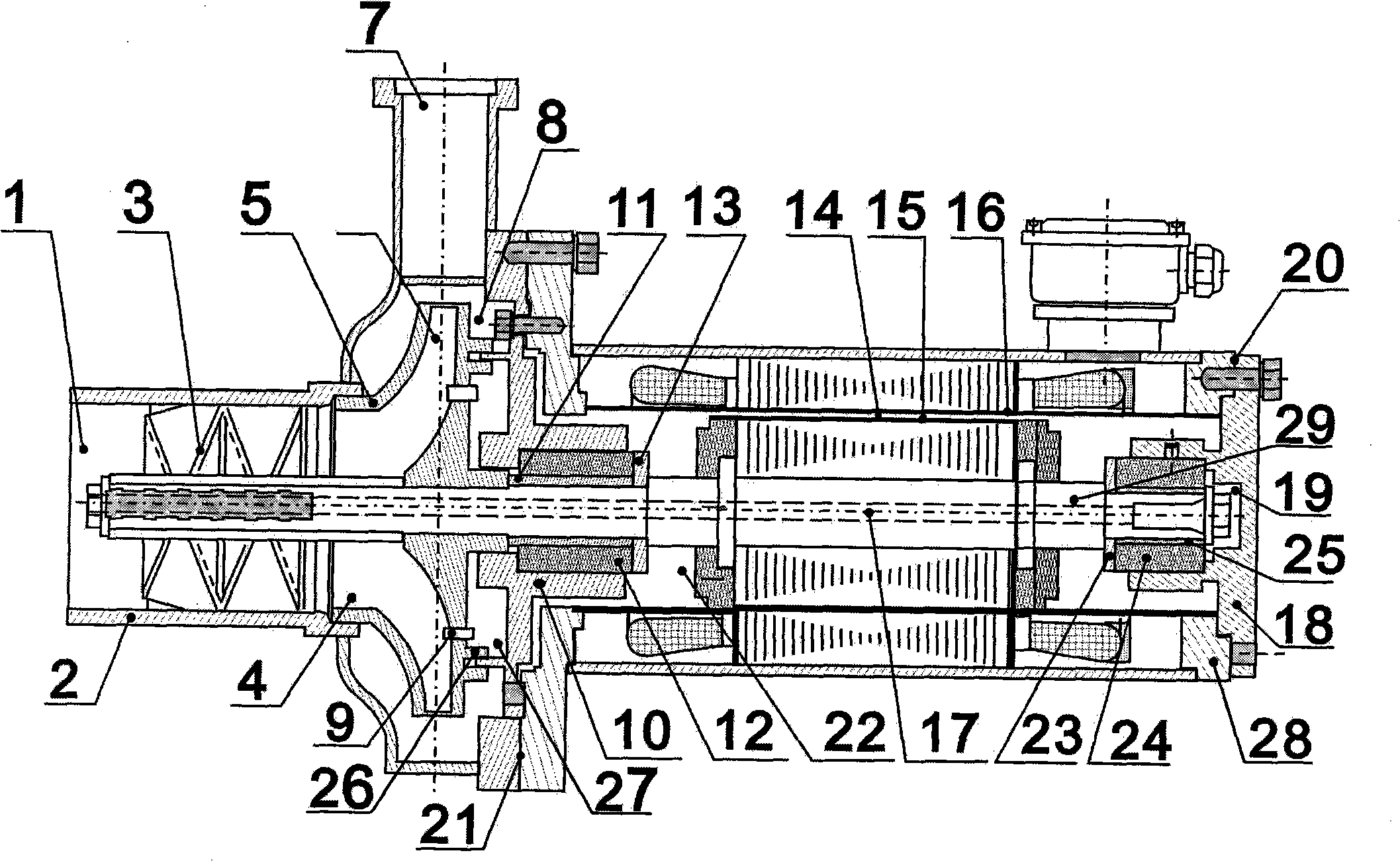

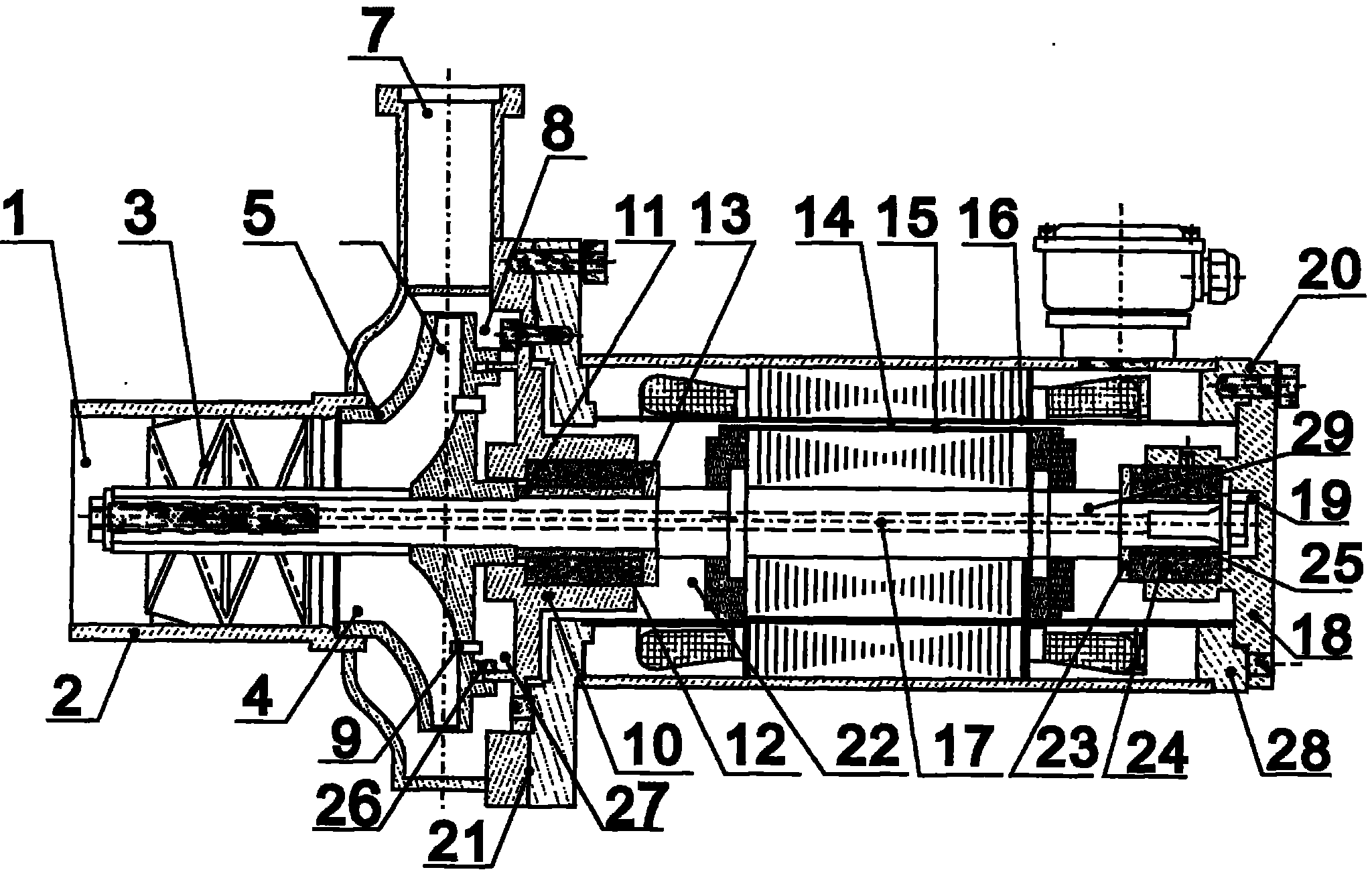

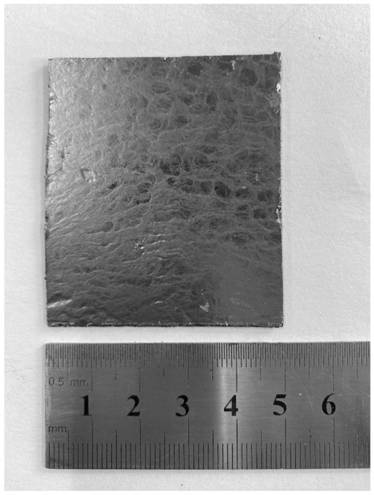

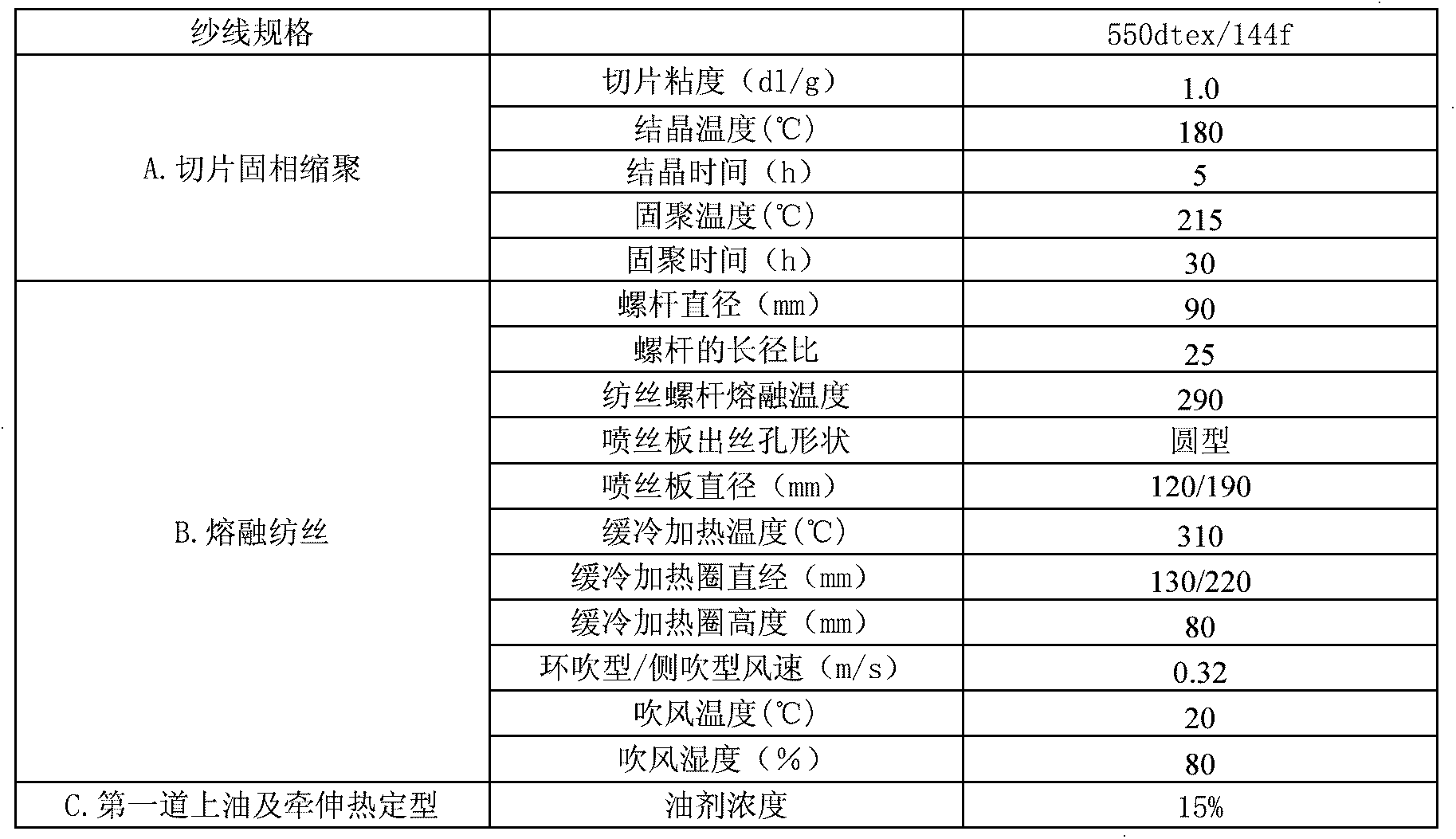

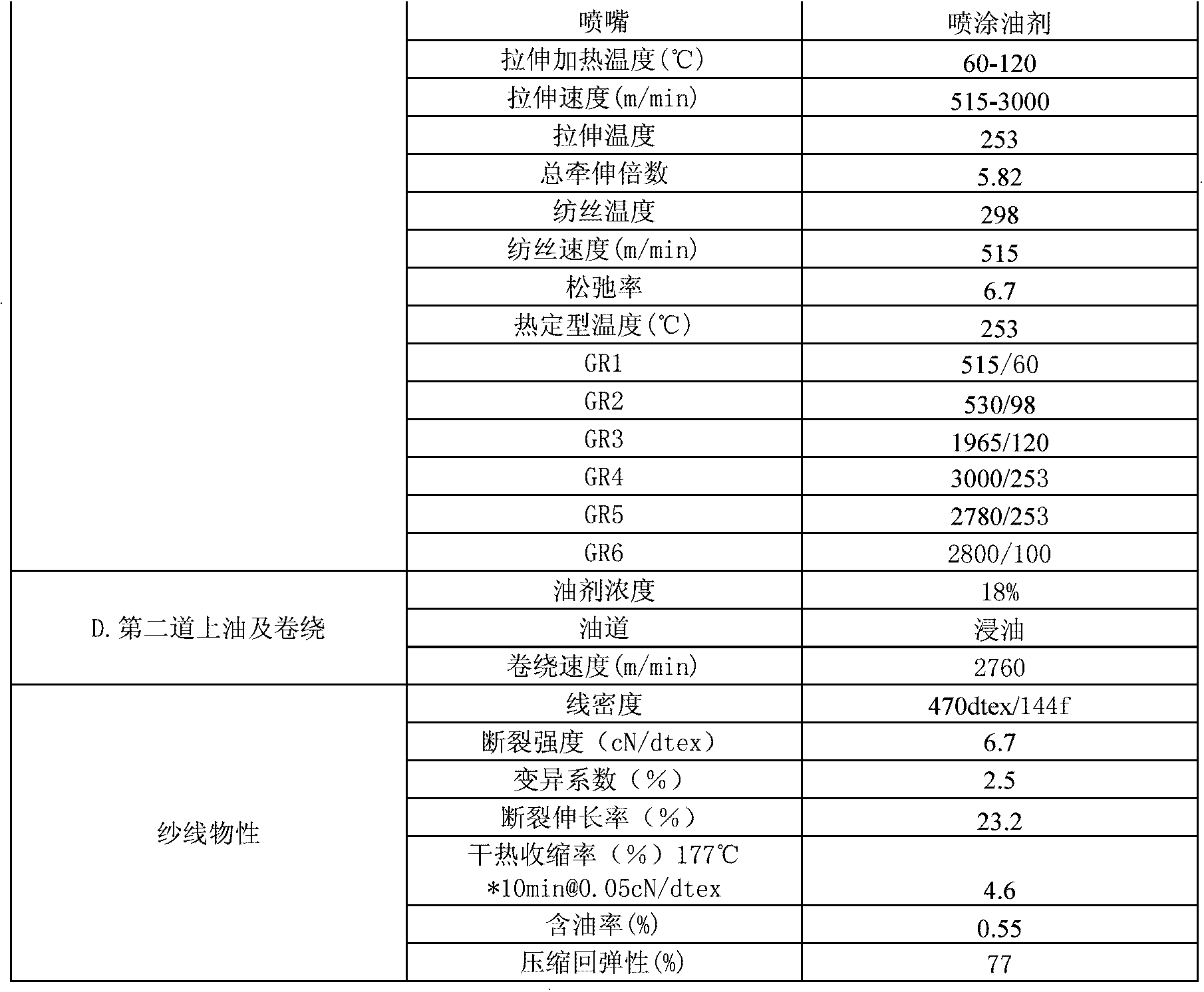

Preparation method of high-resilience polyester industrial filament yarns for supplementary restraint system

ActiveCN103397395AGood compression resilienceArtificial filament heat treatmentMelt spinning methodsSolid phasesAbnormal shaped

The invention discloses a preparation method of high-resilience polyester industrial filament yarns for a supplementary restraint system. The preparation method comprises the process steps of (1) adopting a continuous solid-phase polymerization method to prepare a high viscosity slicing sheet, (2) conveying the prepared high viscosity PET slicing sheet to a screw extruder, extruding out flux by the screw extruder at the high-temperature condition of 290-320 DEG C, enabling the flux to pass through a flux pipe and then be sprayed out from a circular or abnormal-shaped spinneret orifice, enabling the flux to sequentially pass through a slow cooling device and a cooling device, and then enabling the flux to enter a spinning shaft, (3) spraying the surfaces of nascent fibers with a first high-temperature resistance oiling agent and conducting multistage high-speed drafting and high-temperature slack heat shaping, and (4) conducing second oil applying on filament yarns after the slack heat shaping is carried out, enabling the concentration of the oiling agent to be 95%-100%, conducting three-dimensional and two-dimensional composite winding shaping on the oiled filament yarns at the winding speed of 2600-3800 per minute, and preparing the high-resilience polyester industrial filament yarns.

Owner:ORIENTAL IND SUZHOU

Heat insulation polyimide nanofiber aerogel and preparation method thereof

The invention relates to a heat insulation polyimide nanofiber aerogel and a preparation method thereof. The heat insulation polyimide nanofiber aerogel is prepared from the raw material components ofpolyamide acid nanofibers and water soluble polyamide acid, wherein the mass ratio of the polyamide acid nanofibers to the water soluble polyamide acid is (1-5) to 1. According to the heat insulationpolyimide nanofiber aerogel, the good compression returning performance is achieved, the heat conductivity coefficient is low, the good heat insulation capability is still achieved under the high temperature and compression, the combination property is excellent, the preparation process is simple and easy to operate, environmental protection is achieved, and the insulation polyimide nanofiber aerogel can be used in various heat insulation scenes.

Owner:DONGHUA UNIV

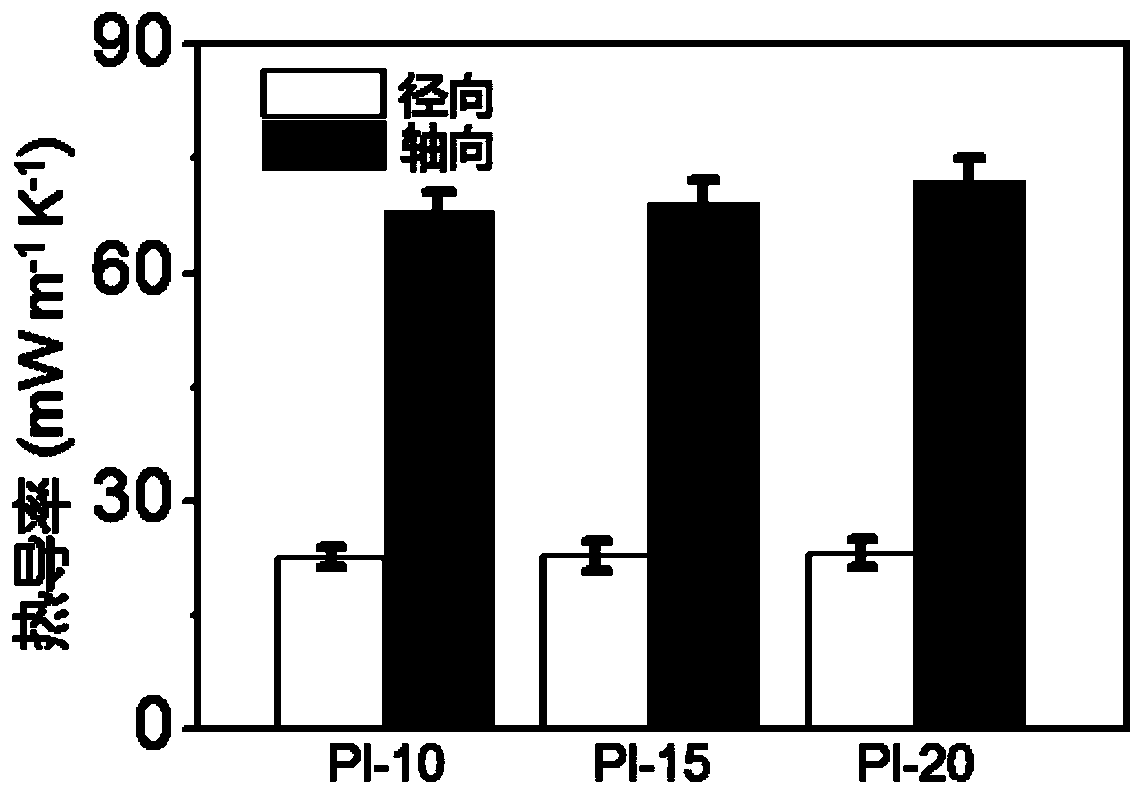

Thermal-insulation anisotropic polyimide nanofiber aerogel and preparation method thereof

The invention discloses a preparation method of a thermal-insulation anisotropic polyimide nanofiber aerogel. The preparation method comprises the following steps: 1) preparing a polyamide acid spinning solution, and electrospinning the polyamide acid spinning solution to prepare polyamide acid nanofibers; 2) uniformly mixing the polyamide acid nanofibers obtained in step 1), water-soluble polyamide acid and an organic amine in water, and performing dispersion to obtain a uniform dispersion of the polyamide acid nanofibers and water-soluble polyamide acid; 3) placing the dispersion obtained instep 2) in a mold, performing bidirectional refrigeration in a constant-temperature reaction bath, and drying the refrigerated dispersion in a freeze dryer; and 4) carrying out thermal imidization ona sample obtained in step 3) in a tubular furnace to obtain the thermal-insulation anisotropic polyimide nanofiber aerogel. The polyimide nanofiber aerogel of the invention has the advantages of goodcompression resilience, low radial thermal conduction coefficient and excellent comprehensive performances, and can be used in various thermal insulation scenes.

Owner:DONGHUA UNIV

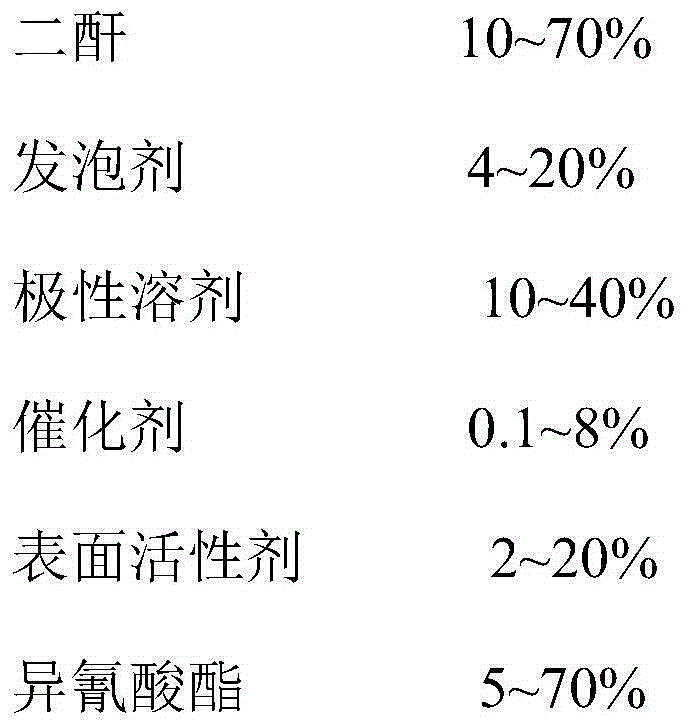

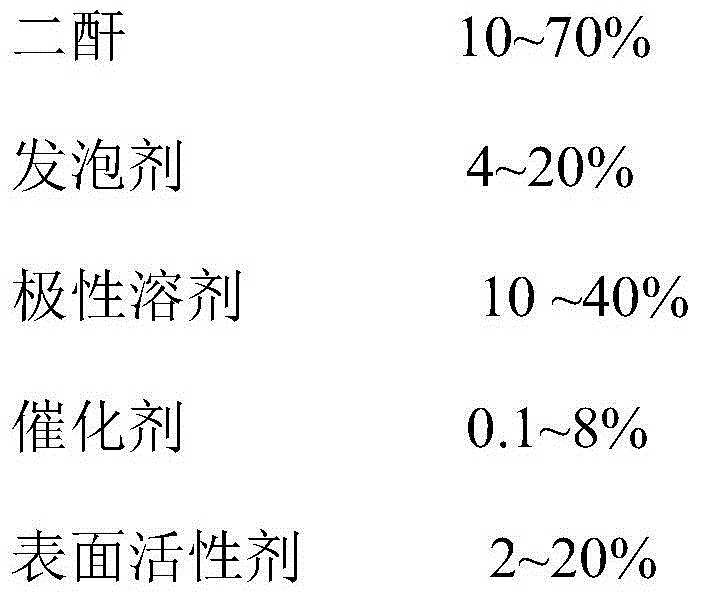

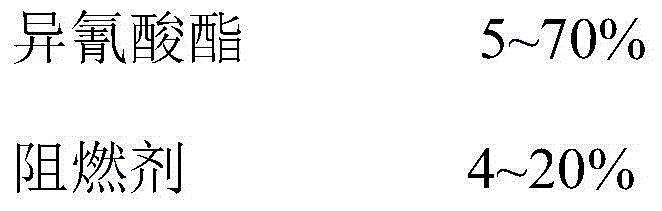

Polyimide foamed material and preparation method thereof

The invention belongs to the field of new materials, and in particular relates to a polyimide foam material and a preparation method thereof. The raw materials of the polyimide foam material include the following weight percentages: The preparation method is to firstly dissolve the dianhydride in a polar solvent, then add part of the foaming agent, then add a certain amount of surfactant, catalyst, remaining foaming agent and flame retardant, and finally add isocyanate for foaming. bubble treatment. The preparation process is simple, the process is easy to control, and the prepared foam material has good heat resistance and sound absorption performance.

Owner:CHANGZHOU TIANSHENG NEW MATERIALS

Preparation method of butyronitrile latex with high nitrile group content

The invention provides butyronitrile latex with high nitrile group content for manufacturing asbestos or a non-asbestus sheet. The butyronitrile latex is prepared by taking butadiene and acrylonitrileas monomers and adopting a compound emulsifying system formed by an anionic emulsifier and a non-ionic emulsifier and a redox initiation system formed by persulfate and mercaptan. An intermediate-temperate emulsion polymerization technology of a three-stage stepped temperature control process that the monomers, an emulsifying agent, an initiating agent, a reducing agent, an auxiliary reducing agent, and the like are added in batches is adopted so as to ensure that the polymerization stability of the latex is greatly improved, prevent the generation of gel and improve the mechanical stabilityof the latex. The content of the acrylonitrile combined by the latex is 28-33 percent, and the strength in each aspect of the nitrile latex exceeds the strength of the prior nitrile latex product. Particularly, the butyronitrile latex has good oil resistivity and low loss ratio in a solvent, thus the nitrile latex has excellent performance when used for manufacturing the asbestos or the non-asbestes sheet.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Preparation method of anti-buffering silicon dioxide aerogel heat insulation sheet

InactiveCN113651592ASolve the problem of falling powderInhibit sheddingSynthetic resin layered productsLaminationFiberSilicon oxide

The invention belongs to the field of heat insulation materials, and discloses a preparation method of an anti-buffering silicon dioxide aerogel heat insulation sheet. The preparation method comprises the following steps: cutting a felt body according to actual application requirements in a fiber felt stage, and combining the felt body with an anti-buffering part silicon rubber frame; and then, finishing the preparation process of the anti-buffering aerogel heat insulation sheet according to the processes of sol-gel, drying and packaging, so that the phenomenon that a large amount of aerogel powder falls off in the processes of cutting aerogel roll felt and packaging functional components in the traditional preparation process is avoided, and the conditions that the heat insulation performance of the aerogel heat insulation component is reduced and the distribution is not uniform are influenced to a certain extent. The anti-buffering aerogel heat insulation sheet obtained through drying is directly packaged, so that the powder falling problem existing in the existing aerogel sheet preparation process is effectively solved, and high packaging efficiency is achieved.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Ultra-strong MPP (modified polypropylene) power communication pipe and preparation method for same

The invention relates to an ultra-strong MPP (modified polypropylene) power communication pipe and a preparation method for the same. The ultra-strong MPP power communication pipe comprises PP (polypropylene), PE (polyethylene), an EPDM (ethylene propylene diene monomer), an inorganic filler, a silane coupling agent, an antioxidant and an auxiliary antioxidant. The preparation method comprises the following steps: feeding the inorganic filler into a high-speed mixer for stirring; feeding EPDM powder into the high-speed mixer for stirring; spraying the silane coupling into the high-speed mixer by virtue of a metering pump; feeding the PP and the PE into the high-speed mixer for stirring; feeding the antioxidant and the auxiliary antioxidant into the high-speed mixer for stirring; preparing a toughened raw material; extruding the mixed toughened raw material by virtue of an extruder. The ultra-strong MPP power communication pipe and the preparation method for the same have the beneficial effects that the components in the formula cooperate to strengthen the tensile strength of the pipe by 60 percent, improve the ring stiffness by 10 percent, improve the surface hardness by 50 and achieve high compression resilience, small deformation, high heat and aging resistance and high electric insulativity.

Owner:杭州联通管业有限公司

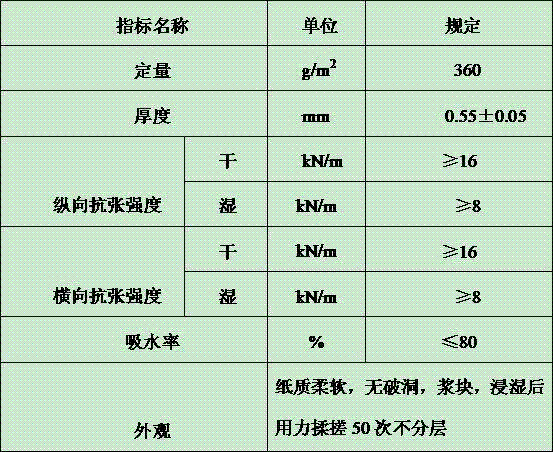

High-wet-intensity leather paper and preparation method and application thereof

ActiveCN104846689AImprove wet strengthImproved wet strength propertiesPaper coatingReinforcing agents additionFiberCellulose

The invention relates to high-wet-intensity leather paper and a preparation method thereof. The leather paper is made of main raw materials of one of cotton pulp or hemp pulp and needlebush pump, and sodium carboxymethylcellulose, wet strength agents and emulsion are added. Ceramic fibers are included in the emulsion, coating is performed through an impregnation method to perform surface sizing after body paper is made and dried, the sized paper is dried at the temperature ranging from 120 DEG C to 135 DEG C at the ordinary pressure, and accordingly, the high-wet-intensity leather paper is obtained. The high-wet-intensity leather paper is high in wet intensity and can be wetted according to a standard washing-resistant test method and does not layer by rubbing for 50 times hard with hands, and the leather paper is widely applied to the fields of clothing labels, tags and the like and particularly applicable to labels in no need of integrating the labels with jeans.

Owner:杭州特种纸业有限公司

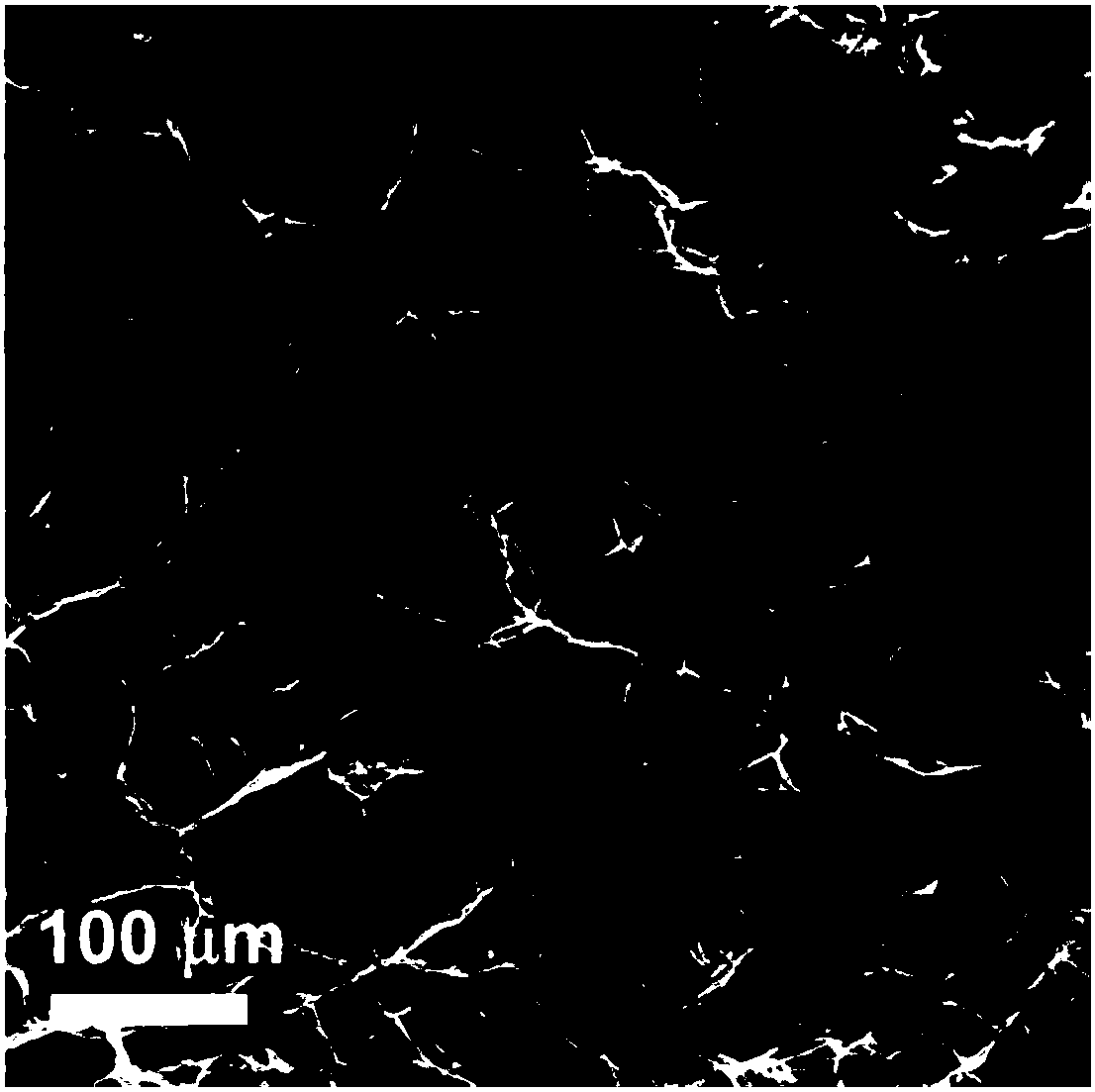

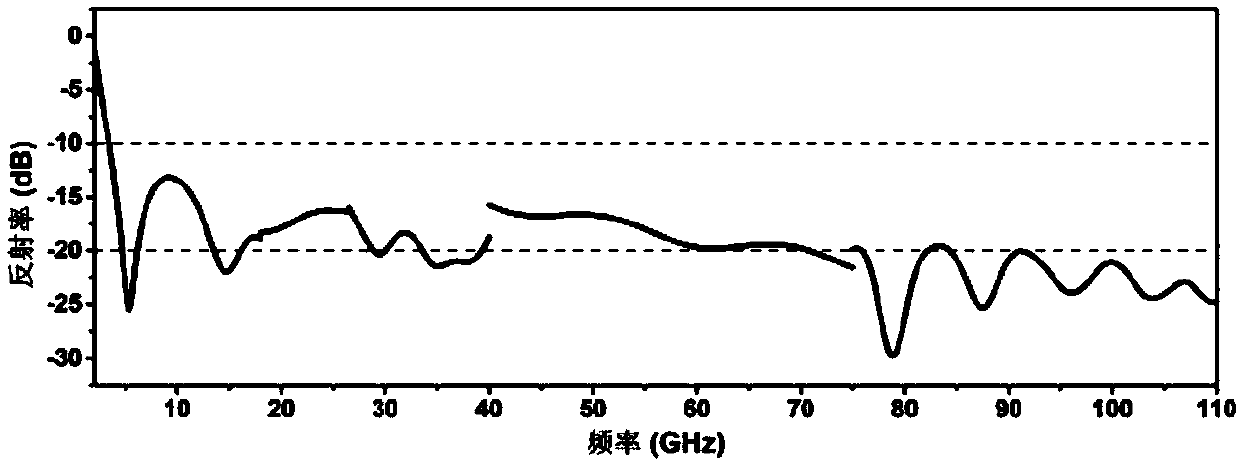

Graphene/ferroferric oxide composite material and preparation method and application thereof

InactiveCN110678055AEffective absorptionWith broadband absorbing characteristicsMaterial nanotechnologyOther chemical processesOxide compositeGraphite oxide

The invention provides a graphene / ferroferric oxide composite material which comprises reduced graphene oxide and ferroferric oxide nanoparticles and is of a three-dimensional porous structure. The invention further provides a preparation method of a graphene / ferroferric oxide composite material, the graphene / ferroferric oxide composite material prepared according to the preparation method and application of the graphene / ferroferric oxide composite material. In some embodiments, the graphene / ferroferric oxide composite material can be used as or used for preparing an electromagnetic wave shielding material or an electromagnetic wave absorbing material.

Owner:NANKAI UNIV

High performance impregnant for braided packing and impregnation process thereof

ActiveCN101984183APrevent leakageImprove creep resistanceFibre typesLiquid/gas/vapor removalState of artWater leakage

The invention relates to a high performance impregnant for braided packing and impregnation process thereof. The invention mainly solves the technical problems of poor thermal conductivity of existing packings prepared by the prior art, so that creep deformation is formed under the condition of higher linear velocity and granular media existed and performance degradation of products in size stability, pliability and extrusion resistance property is generated due to the large amount of abrasion loss, as well as water leakage. The impregnant provided by the invention comprises, by mass, 15%-25% of distilled water, 65%-75% of graphite emulsion and 10%-20% of polyacrylate adhesive.

Owner:浙江国泰萧星密封材料股份有限公司

High-resilience transformer sealing gasket and preparation method thereof

InactiveCN103509217AImprove high temperature resistanceImprove low temperature resistanceTransformerPotassium

The invention discloses a high-resilience transformer sealing gasket and a preparation method thereof. The high-resilience transformer sealing gasket is prepared from 70-80 weight parts of methyl vinyl silicone rubber, 20-30 weight parts of polyurethane rubber, 15-20 weight parts of hexamethyldisilazane, 30-40 weight parts of fumed silica, 4-6 weight parts of diphenylsilanediol, 1-2 weight parts of zinc oxide, 2-3 weight parts of stearic acid, 1-2 weight parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.5-1 weight part of dicumyl peroxide, 2-3 weight parts of bis-(gamma-triethoxysilylpropyl)tetrasulfide, 1-2 weight parts of an antiager RD, 2-3 weight parts of an antiager TNP, 1-2 weight parts of an antioxidant 1010, 10-15 weight parts of coumarone resin, 5-10 weight parts of nanometer potassium feldspar, 4-8 weight parts of organobentonite, 6-12 weight parts of mica powder and 3-5 weight parts of a composite filling material. The high-resilience transformer sealing gasket is soft and smooth, has no toxicity and smell, has excellent high temperature and low temperature resistance, excellent compression resilience and high mechanical strength, can be used at a temperature of -70-250 DEG C for a long time, and does not age, deform and crack.

Owner:ANHUI KELIN ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com