Polyimide foamed material and preparation method thereof

A technology of foam material and polyimide, which is applied in the field of polyimide foam material and its preparation, can solve the problems of poor product heat resistance, complex process, and insufficient product density, and achieve high yield and low raw material And the effect of simple process and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of polyimide foam material of the present invention may further comprise the steps:

[0045] (1) Add 10-70 parts by weight of dianhydride to a polar solution with a temperature of 90-130° C. and 10-40 parts by weight, stir at a constant temperature to dissolve the dianhydride, and then cool the solution to 70-85° C.;

[0046] (2) adding part of the foaming agent into the solution prepared in step (1), stirring evenly and dissolving, cooling the solution to 30-50° C. to obtain the first solution;

[0047] (3) Take 2-20 parts by weight of a surfactant, 0.1-8 parts by weight of a catalyst, 4-20 parts by weight of a flame retardant and the remaining foaming agent and mix them uniformly to obtain a second solution;

[0048] (4) Mix the first solution and the second solution evenly;

[0049] (5) Add 5 to 70 parts by weight of isocyanate into the mixed solution obtained in step (4), perform high-speed mixing treatment, the rotating speed is 800 to 4500 ...

Embodiment 1

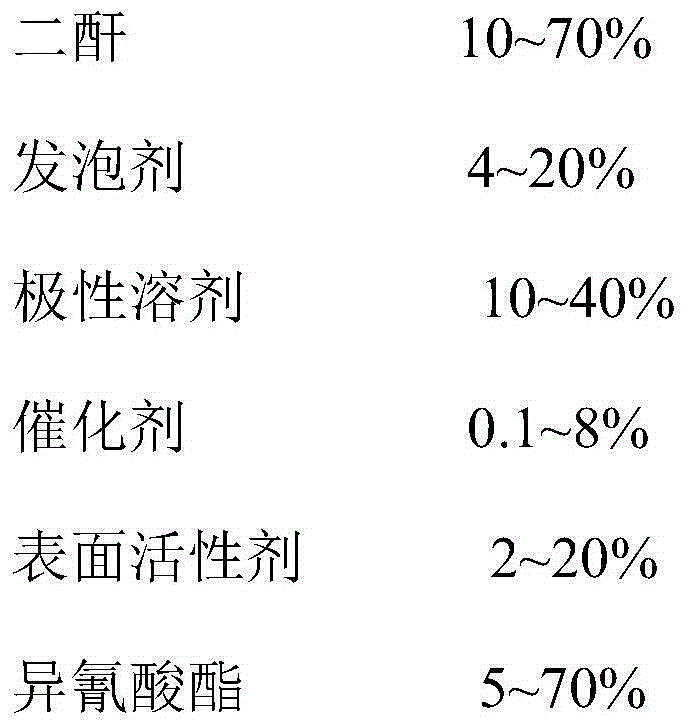

[0052] 1. Configure the polyimide foam material according to the following ratio

[0053]

[0054] 2. Preparation method

[0055] Dissolve 10 parts of pyromellitic dianhydride into 13 parts of N,N-dimethylformamide solution at a temperature of 99°C, and continue stirring at this temperature until the pyromellitic dianhydride is completely dissolved. The solution was then cooled to 79°C. After the solution is cooled, add 1 part of water and 1 part of methanol, and stir evenly. This is a slightly exothermic reaction, which makes the temperature of the solution rise by about 14°C. The solution was cooled to 49°C to obtain the first solution. Take 0.5 parts of DC193, 0.5 parts of DABCO DC198, 0.5 parts L-620, 0.5 parts 1 copy Mix with 2 parts of acetone, stir at room temperature to make the mixture uniform, and obtain the second solution. Pour the second solution into the first solution, mix well, and keep the temperature at 38°C. Add 70 parts of diphenylmethane diiso...

Embodiment 2

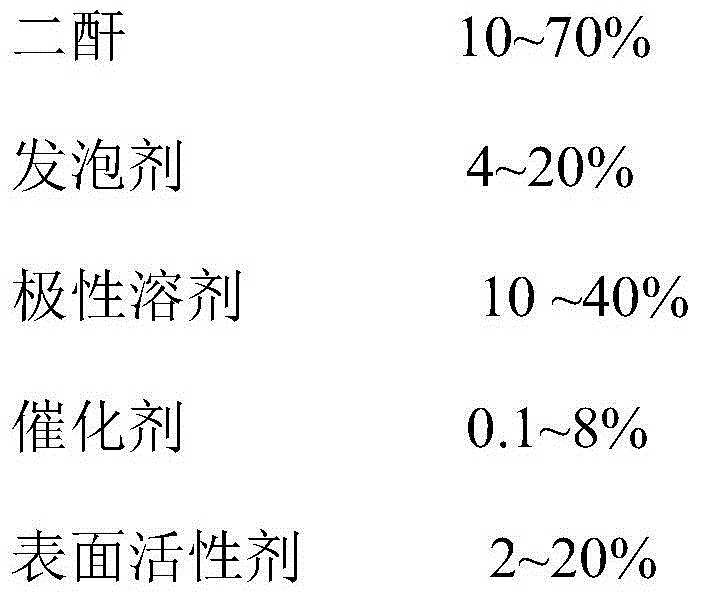

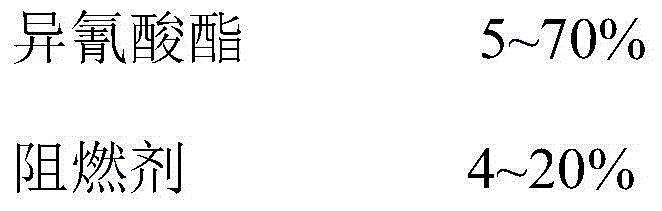

[0057] 1. Configure the polyimide foam material according to the following ratio

[0058]

[0059] 2. Preparation method

[0060] Take 10 parts of 4,4'-diphenyl ether dianhydride and dissolve 10 parts of N,N-dimethylformamide, 10 parts of N,N-dimethylacetamide and 9 parts of N-methyl In the mixed solution of pyrrolidone, continue stirring at this temperature until the solid is completely dissolved. The solution was then cooled to 75°C. After the solution is cooled, add 2 parts of hydrochlorofluorocarbons and stir evenly. This is a slightly exothermic reaction, which makes the temperature of the solution rise by about 10°C. The solution was cooled to 45°C to obtain the first solution. Take 1.5 parts of DC6154, 1.5 parts of B8513, 1.5 parts 1.5 parts of DABCODC198, 1 part of DC-197, 9.1 parts Mix K-15 with 2 parts of hydrochlorofluorocarbons and 1 part of hydrofluorocarbons, stir at room temperature to make the mixture uniform, and obtain a second solution. Pour the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com