High-wet-intensity leather paper and preparation method and application thereof

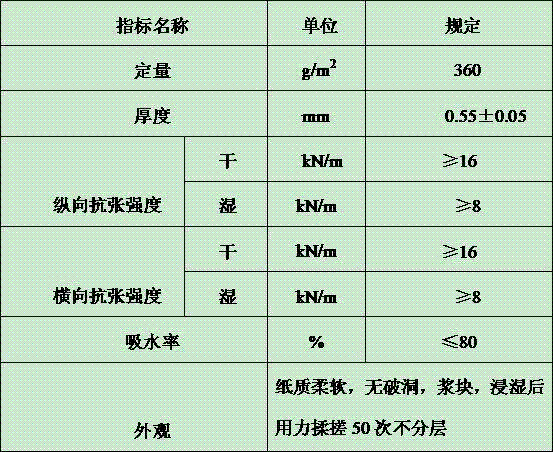

A leather-like, high-humidity technology, applied in the direction of paper, papermaking, paper coating, etc., to achieve the effect of high strength, low raw material composition, and good compression resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high wet strength imitation leather paper, calculated by mass percentage, is prepared from the following components:

[0036] Softwood pulp 30%

[0037] Cotton pulp 48%

[0038] Urea-formaldehyde resin 1%

[0039] Sodium carboxymethyl cellulose 0.5%

[0040] Waterborne Polyurethane Emulsion 18.5%

[0042] A kind of preparation method of high wet strength imitation leather paper:

[0043] Step 1. Select 30% of coniferous wood pulp and disintegrate it in a vertical hydraulic pulper for 4 minutes, then add 48% of cotton pulp in a mass ratio and disintegrate it for 6 minutes, and mix evenly to form pulp;

[0044] Step 2, adding 1% urea-formaldehyde resin to the pulp slurry prepared in step 1, stirring evenly, beating, beating in the Valley beater, the beating degree range is controlled at 30°SR, and the average fiber length of the pulp is 1.3mm;

[0045] Step 3: adding 0.5% sodium carboxymethyl cellulose to the mixed pulp slurry prepa...

Embodiment 2

[0051] A high wet strength imitation leather paper, calculated by mass percentage, is prepared from the following components:

[0052] Softwood pulp 35%

[0053] Hemp pulp 44%

[0054] Melamine formaldehyde 1.5%

[0055] Sodium carboxymethyl cellulose 0.5%

[0056] Styrene Acrylic Emulsion 16%

[0058] A kind of preparation method of high wet strength imitation leather paper:

[0059] Step 1. Select 35% of coniferous wood pulp and disintegrate it in a vertical hydraulic pulper for 4 minutes, then add short fiber hemp pulp in a mass ratio of 44% and disintegrate it for 6 minutes, and mix evenly to form pulp;

[0060] Step 2, adding 1.5% melamine formaldehyde to the pulp slurry prepared in step 1, stirring evenly, beating, beating in the Valley beater, the beating degree range is controlled at 38°SR, and the average fiber length of the pulp is 1.8mm;

[0061] Step 3, adding 0.5% sodium carboxymethyl cellulose to the mixed pulp slurry prepared...

Embodiment 3

[0067] A high wet strength imitation leather paper, calculated by mass percentage, is prepared from the following components:

[0068] Softwood pulp 32%

[0069] Cotton pulp 48%

[0070] Epichlorohydrin 1.5%

[0071] Sodium carboxymethyl cellulose 0.6%

[0072] Styrene Acrylic Emulsion 15.5%

[0073] Ceramic fiber 2.4%

[0074] A kind of preparation method of high wet strength imitation leather paper:

[0075] Step 1, selection and proportioning of pulp raw materials: 48% of cotton pulp and 32% of softwood pulp by weight percentage, uniformly mixed;

[0076] Step 2, adding 1.5% epichlorohydrin resin to the pulp slurry prepared in step 1, stirring evenly, beating, and beating degree;

[0077] Step 1. Select 32% of long-fiber wood pulp coniferous wood pulp and disintegrate it in a vertical hydraulic pulper for 4 minutes, then add 48% of cotton pulp in a mass ratio and disintegrate it for 6 minutes, and mix evenly to form pulp;

[0078] Step 2. Add the wet strength ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com