Adhesive and preparation method thereof

A technology of adhesives and adhesive resins, applied in the direction of adhesive types, mineral oil hydrocarbon copolymer adhesives, non-polymer adhesive additives, etc., can solve the problem of poor adhesion of adhesives, adhesion Excessive fluidity of the agent, falling off of the noise absorber, etc., to achieve the effects of prolonging the service life, good adhesion, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

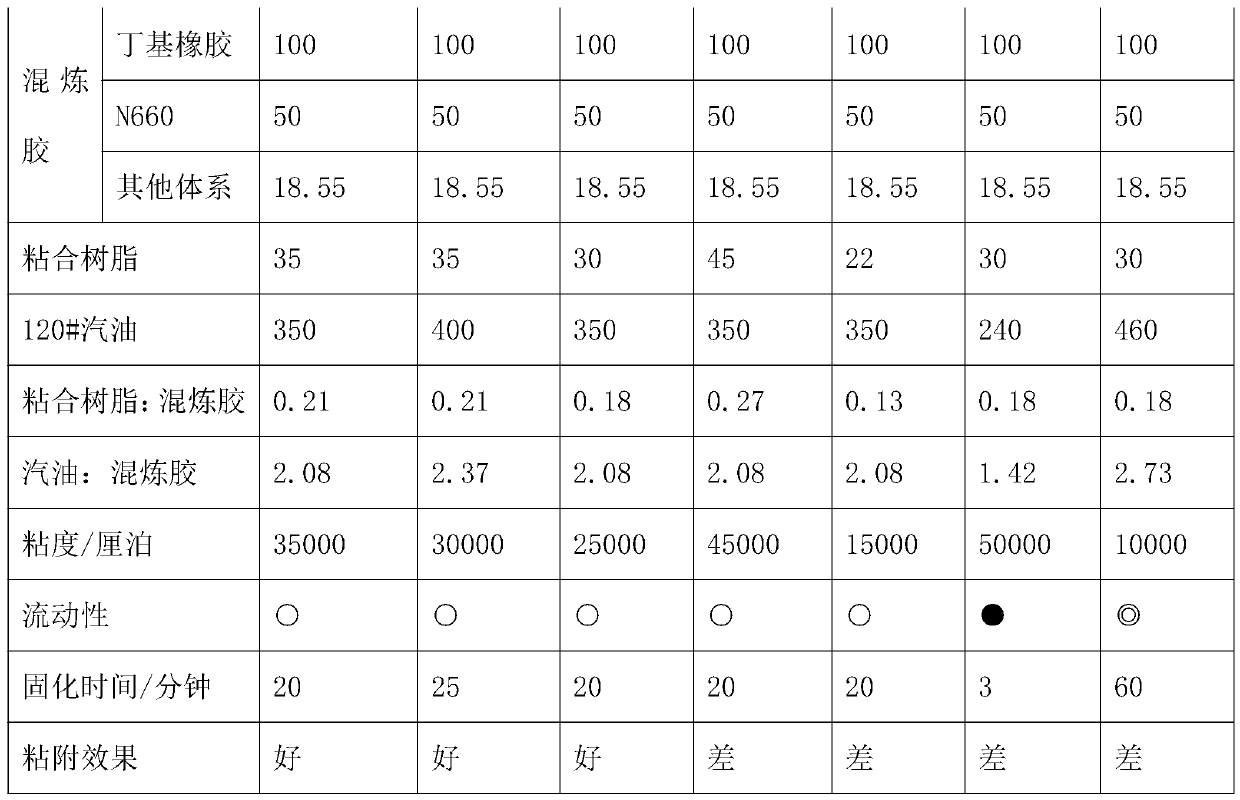

[0044] A kind of adhesive, described adhesive comprises the component of following mass parts:

[0045] Rubber compound 168.55phr

[0046] Adhesive resin 25-40phr

[0047] Gasoline 250-450phr

[0048] Wherein said rubber compound comprises the component of following mass parts:

[0049] Butyl rubber 100phr

[0050] N660 50phr

[0051] Other systems 18.55phr.

[0052] The butyl rubber is halogenated butyl rubber, and the halogenated butyl rubber is one or more of chlorinated butyl rubber or brominated butyl rubber.

[0053] Such other systems include activators, vulcanizing agents, accelerators, and scorch retarders.

[0054] The binder resin is at least one of hydrocarbon resin, terpene resin and indene resin.

[0055] The gasoline is one of No. 93 gasoline, No. 97 gasoline and No. 120 gasoline; No. 120 gasoline is preferred for gasoline.

[0056] The viscosity of the adhesive at room temperature is 20000-40000 centipoise.

[0057] For details, see Table 1 below:

[...

Embodiment 2

[0070] A method for preparing an adhesive, comprising the steps of:

[0071] S1. Preparation of mixed rubber in M1 section

[0072] (1) Start the internal mixer to preheat, then take 2 / 3 of 50phrN660 and 100phr butyl rubber into the preheated internal mixer, press the top bolt of the internal mixer for 60s, and then lift the top bolt 10s;

[0073] In (1) of the step S1, before adding the N660 and butyl rubber, it is necessary to adjust the rotational speed of the internal mixer to 40 r / min. (2) Add the remaining 1 / 3 of 50phrN660, press the top bolt of the internal mixer for 30s, and then lift the top bolt for 10s;

[0074] (3) Finally, when the top bolt is pressed for 90s or the temperature reaches 145°C, the rubber is discharged to obtain the mixed rubber of the M1 stage;

[0075] Before weighing N660 and butyl rubber, start the internal mixer for preheating. During the preheating process of the internal mixer, the weighing and proportioning of N660 and butyl rubber can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com