Concrete performance regulator and preparation method thereof

A conditioner and concrete technology, applied in the field of concrete admixtures, can solve the problems of not reflecting the compatibility of polycarboxylate superplasticizers, unsatisfactory aggregate gradation, low amount of glue materials, etc. The effect of reducing resistance and improving graft polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

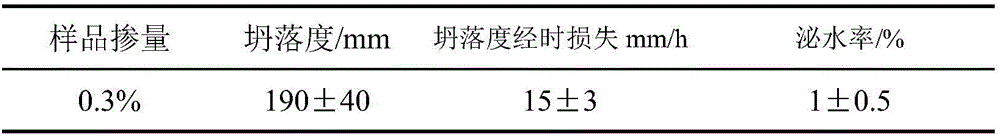

Examples

Embodiment 1

[0022] The invention provides a concrete performance regulator, comprising the following components in mass percentage:

[0023] Acrylamide 14wt%, AMPS 6wt%, crosslinking agent 6wt%, sorbitol 18wt%, sodium bisulfite 2wt%, ammonium persulfate 4wt%, water 50wt%.

[0024] The present invention also provides a preparation method of concrete performance regulator, comprising the steps of:

[0025] (1) Get each raw material of above-mentioned formula quantity;

[0026] (2) dilute acrylamide and AMPS with water;

[0027] (3) Add sorbitol and cross-linking agent, stir and heat up to 120-140°C, and react for 20-40 minutes;

[0028] (4) adding sodium bisulfite and ammonium persulfate;

[0029] (5) Keep the temperature at 90-120°C for 1-1.5 hours to form a colloidal liquid.

Embodiment 2

[0031] The invention provides a concrete performance regulator, comprising the following components in mass percentage:

[0032] Acrylamide 16wt%, AMPS 8wt%, crosslinking agent 8wt%, sorbitol 12wt%, sodium metabisulfite 3wt%, hydrogen peroxide 3wt%, water 50wt%.

[0033] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0035] The invention provides a concrete performance regulator, comprising the following components in mass percentage:

[0036] Acrylamide 25%, AMPS 3wt%, crosslinking agent 4wt%, sorbitol 8wt%, ferrous sulfate 2wt%, hydrogen peroxide 3wt%, water 55wt%.

[0037] The preparation method of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com