Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119results about How to "Increase polymerization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

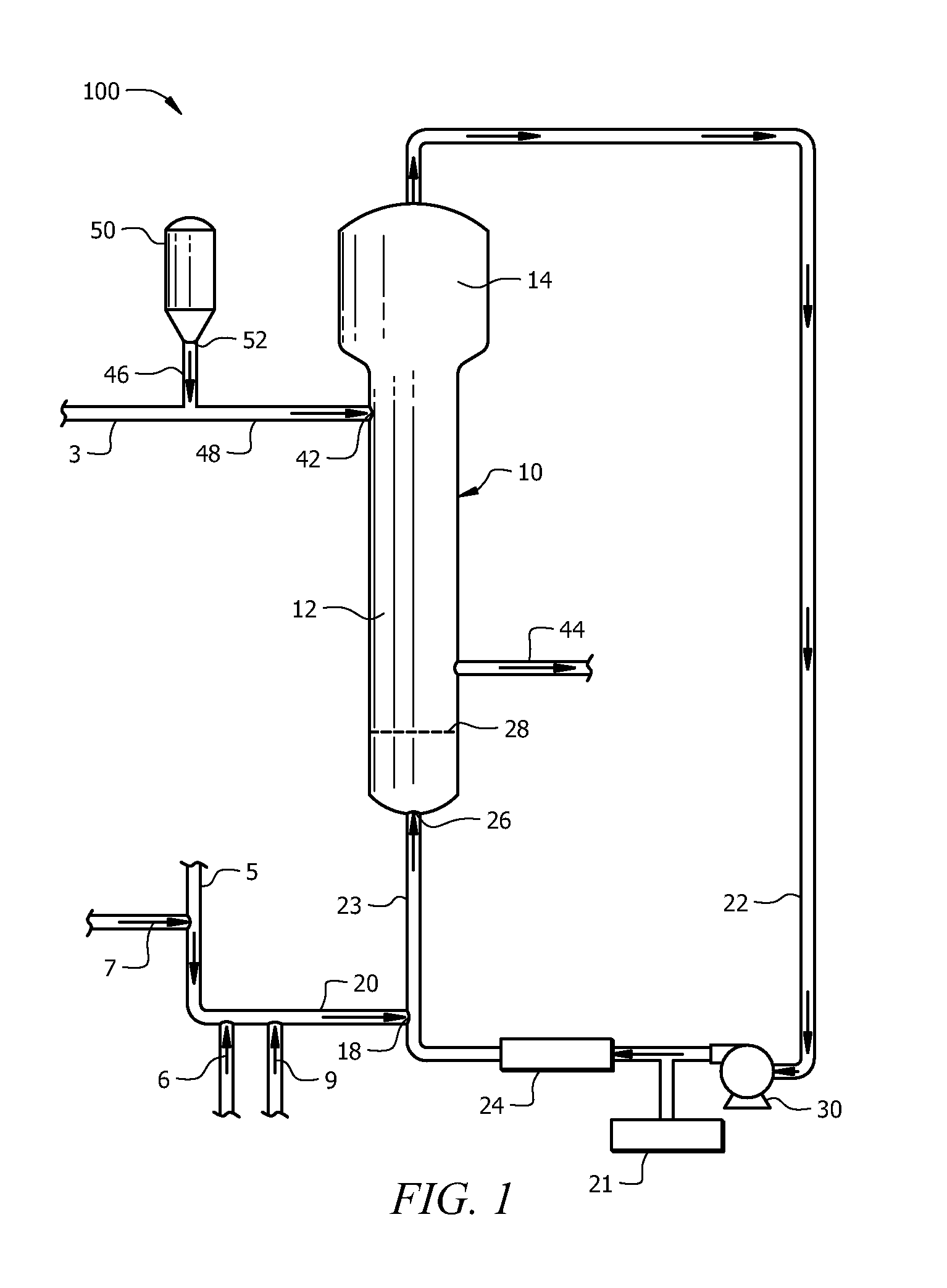

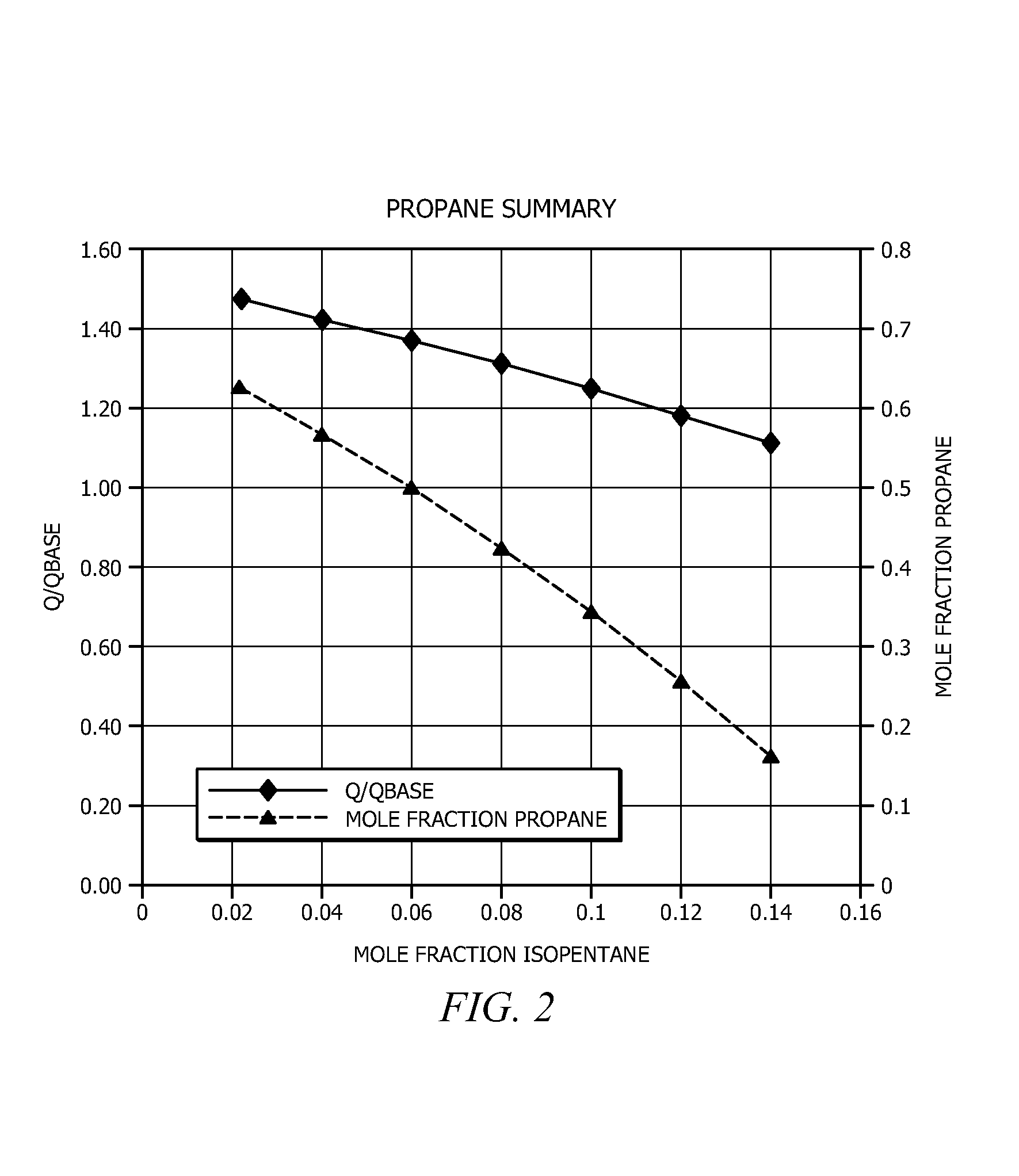

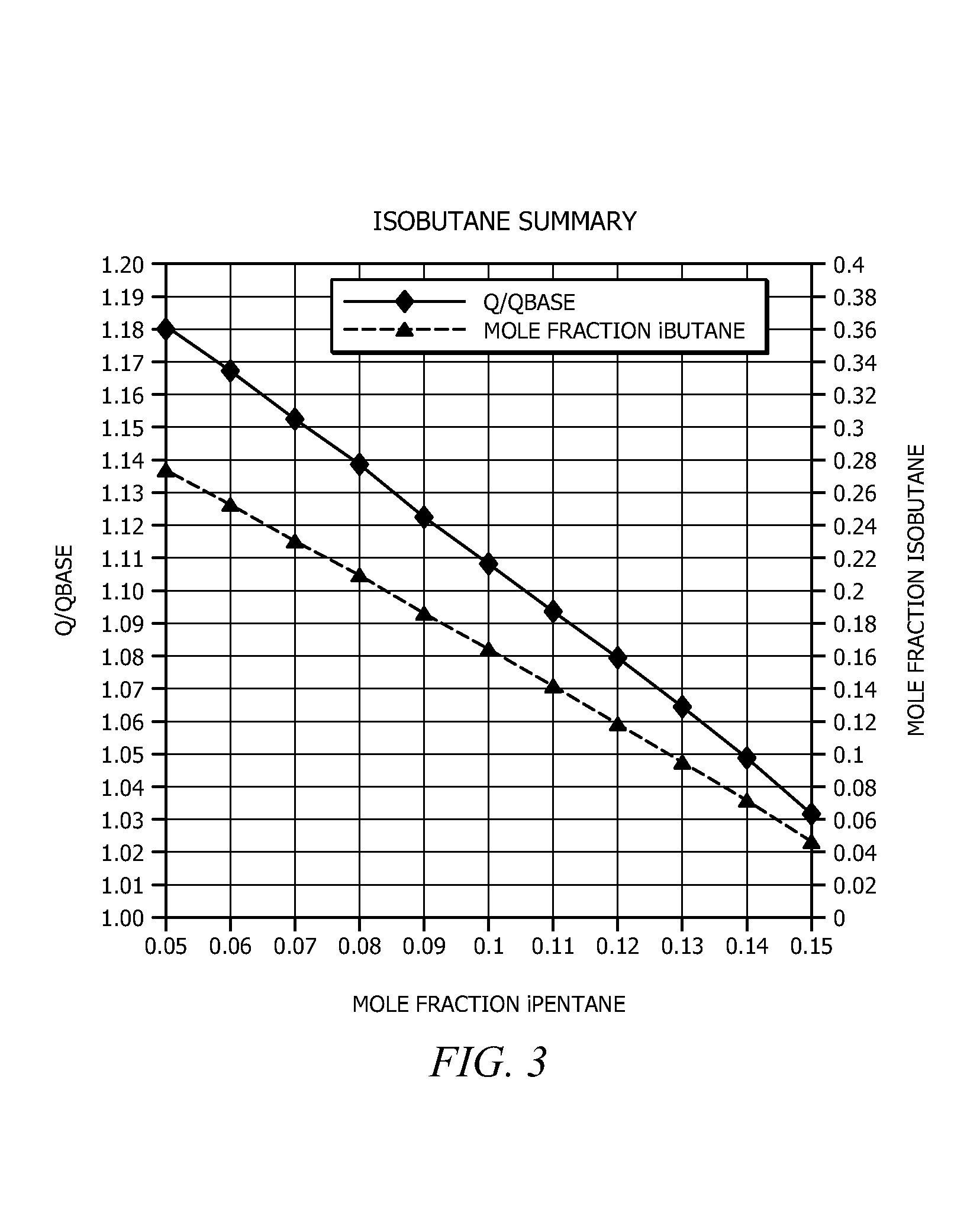

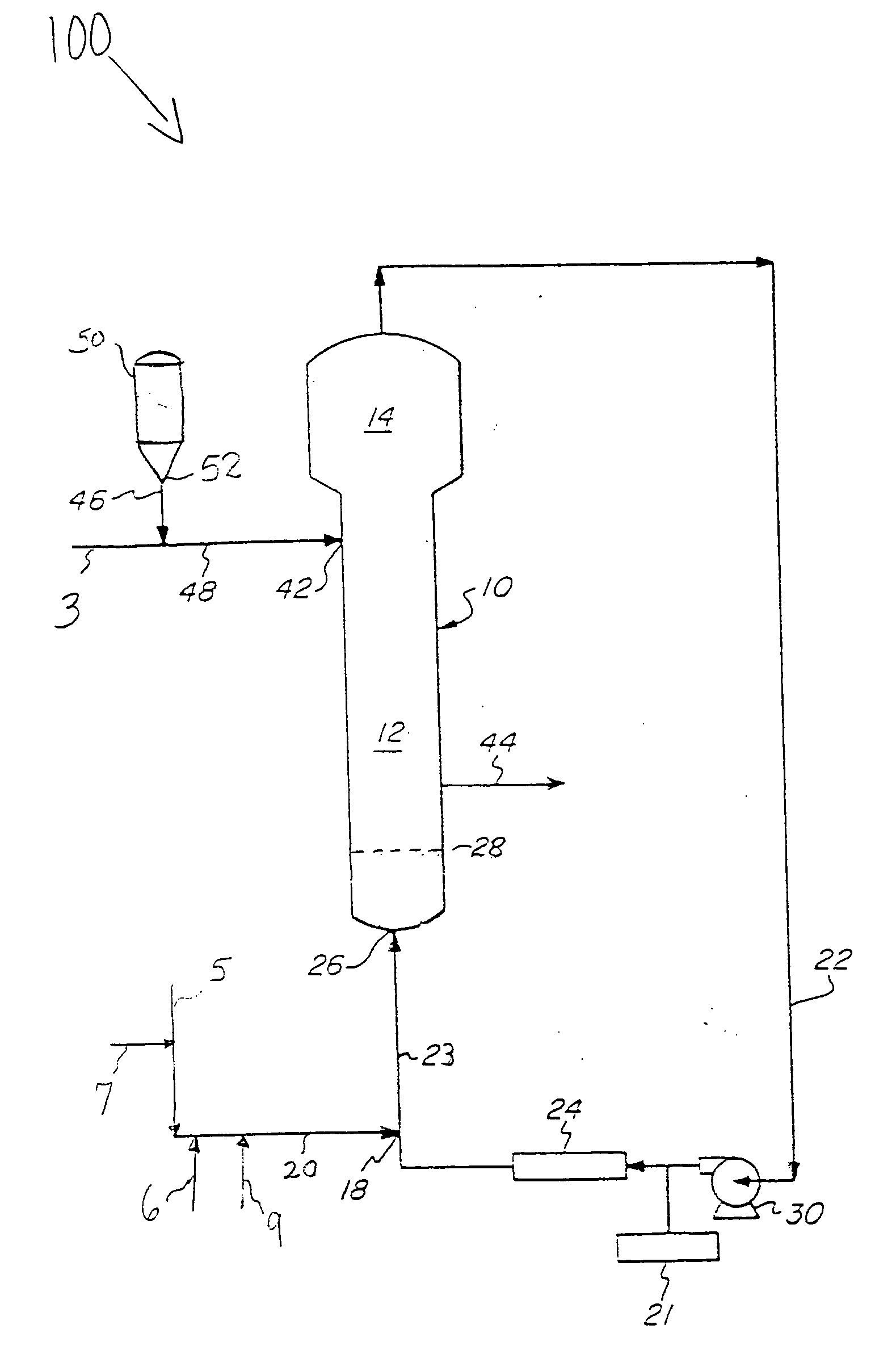

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

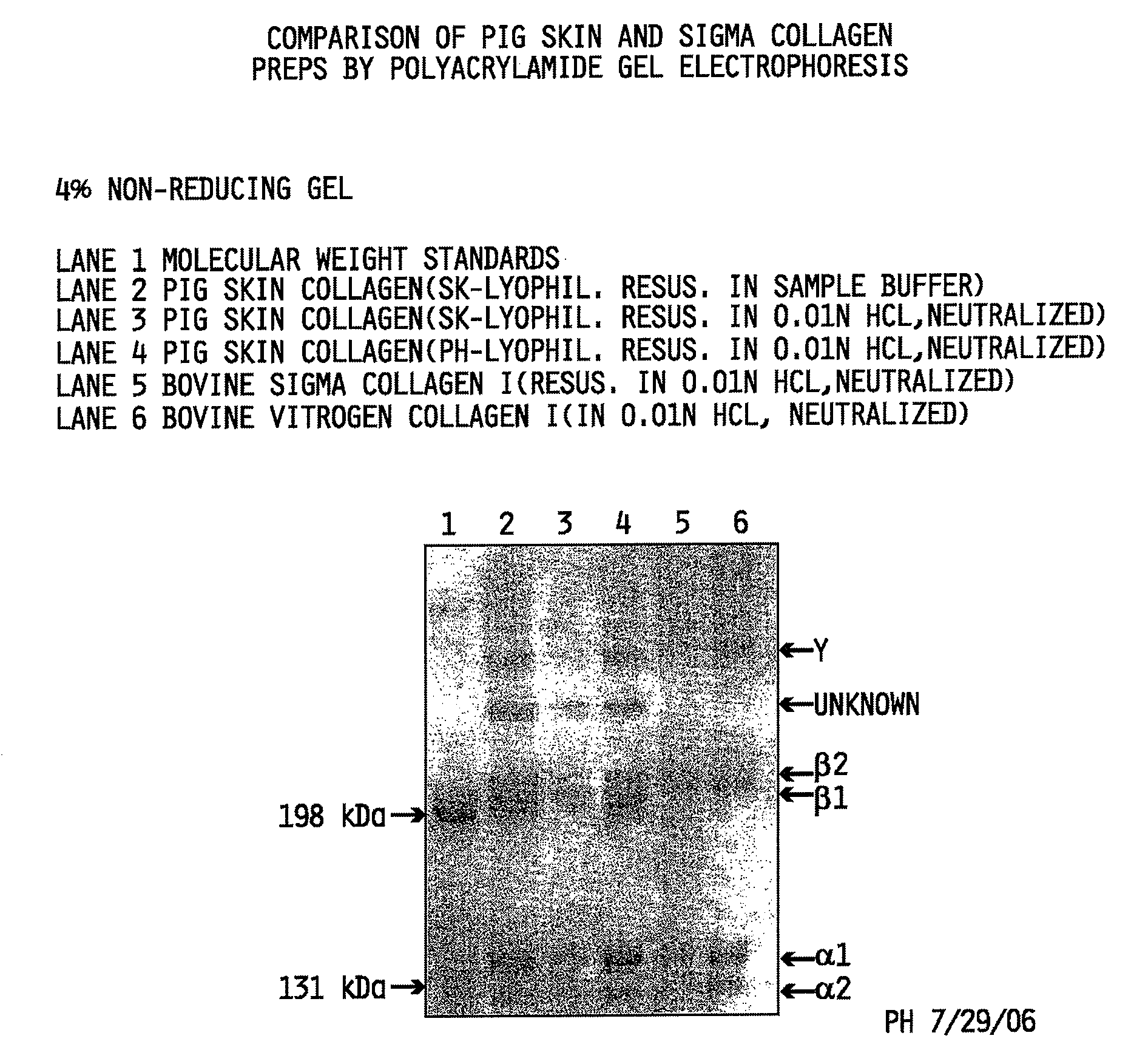

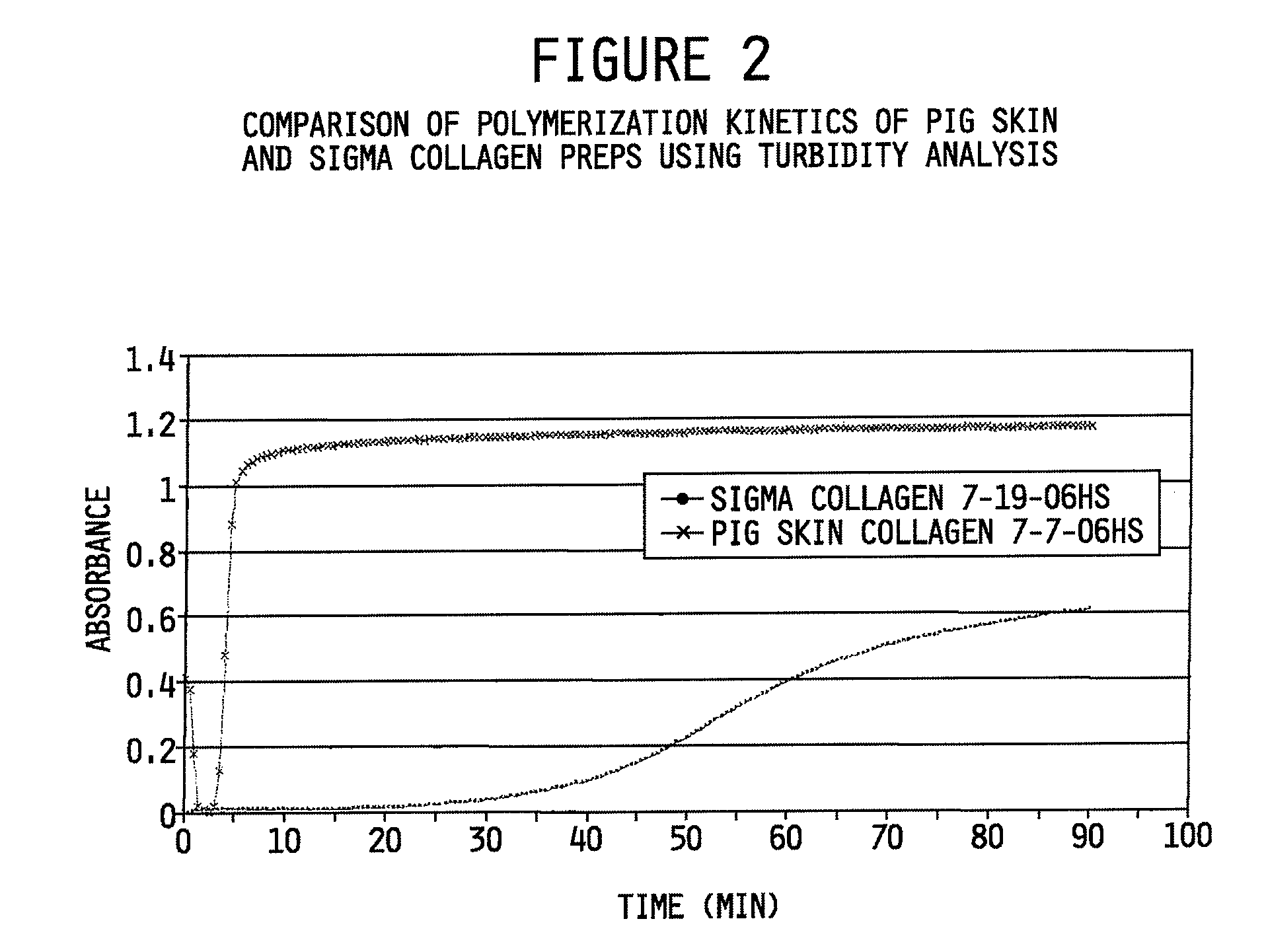

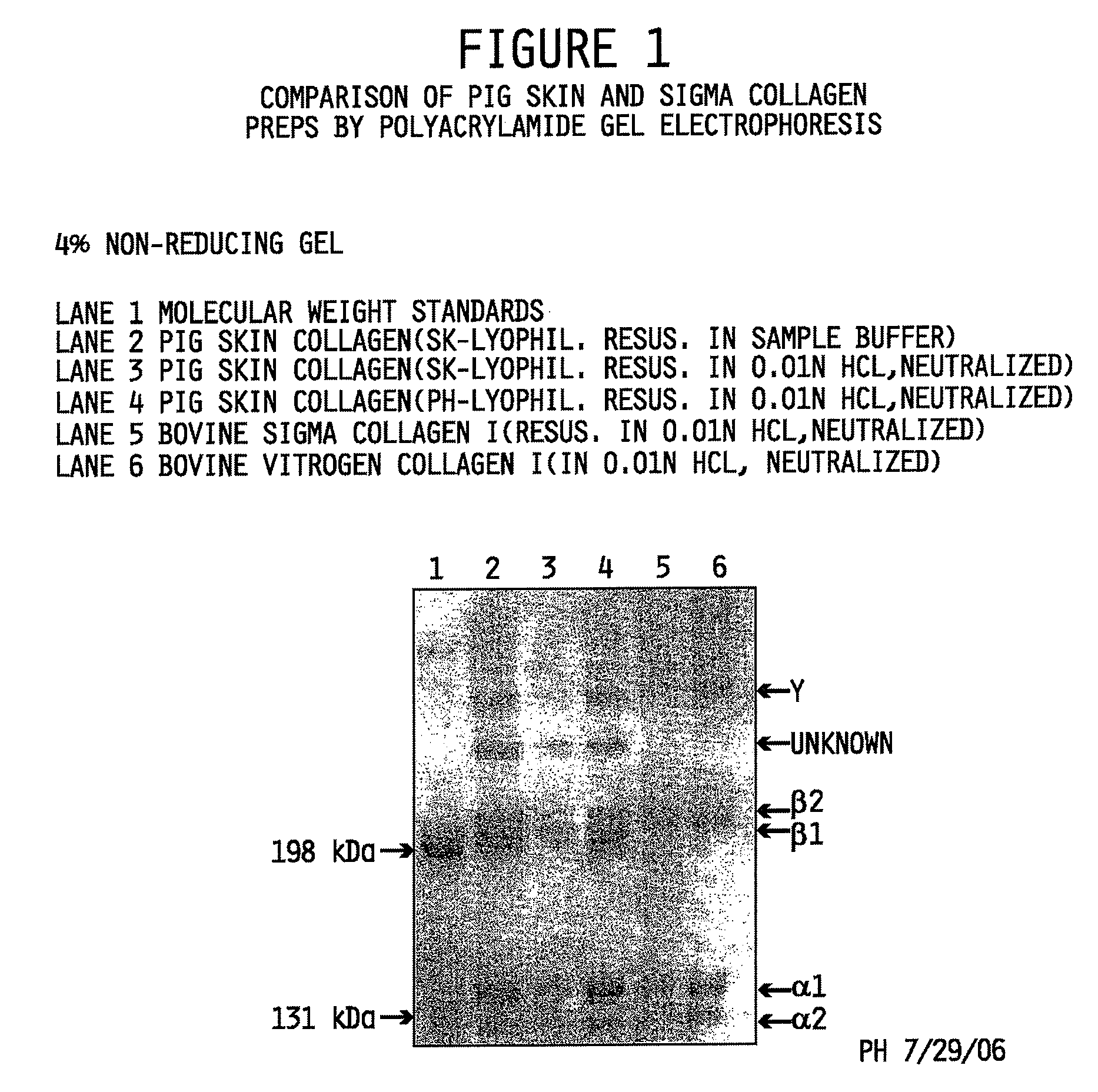

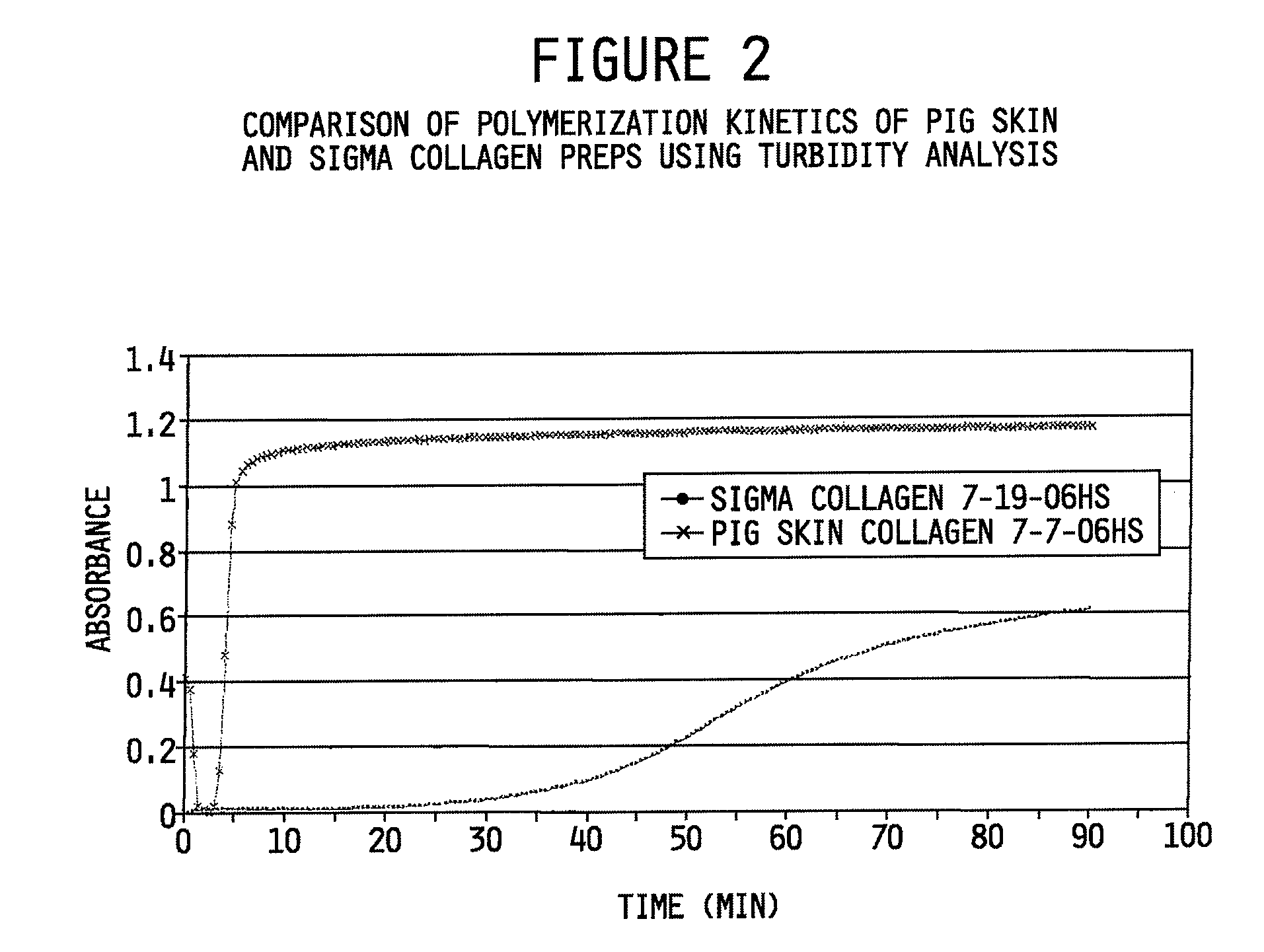

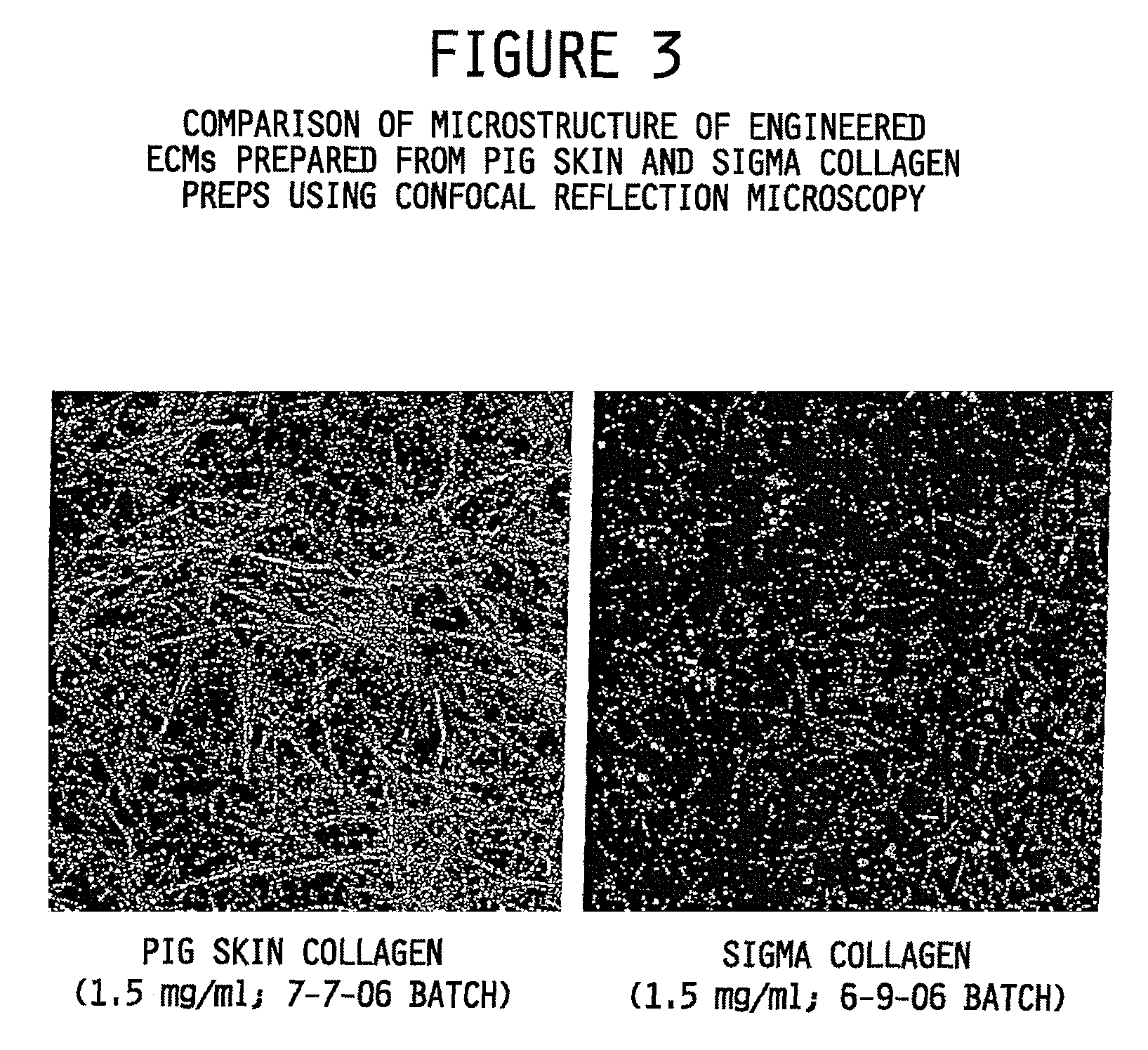

Collagen preparation and method of isolation

ActiveUS20080268052A1Facilitate hierarchical assemblyImprove mechanical propertiesPowder deliveryConnective tissue peptidesCollagen VIMechanical property

Collagen compositions, methods for preparing those collagen compositions, and graft compositions formed from those collagen compositions are provided. In particular, methods of isolating collagen that exhibits an enhanced rate of polymerization and enhanced microstructural and mechanical properties upon polymerization, such collagen compositions, and graft compositions formed from such collagen compositions are provided.

Owner:PURDUE RES FOUND INC

Supercritical polymerization process and polymers produced therefrom

ActiveUS20040122191A1High catalytic activityDrop in molecular weightBulk chemical productionPolymer sciencePtru catalyst

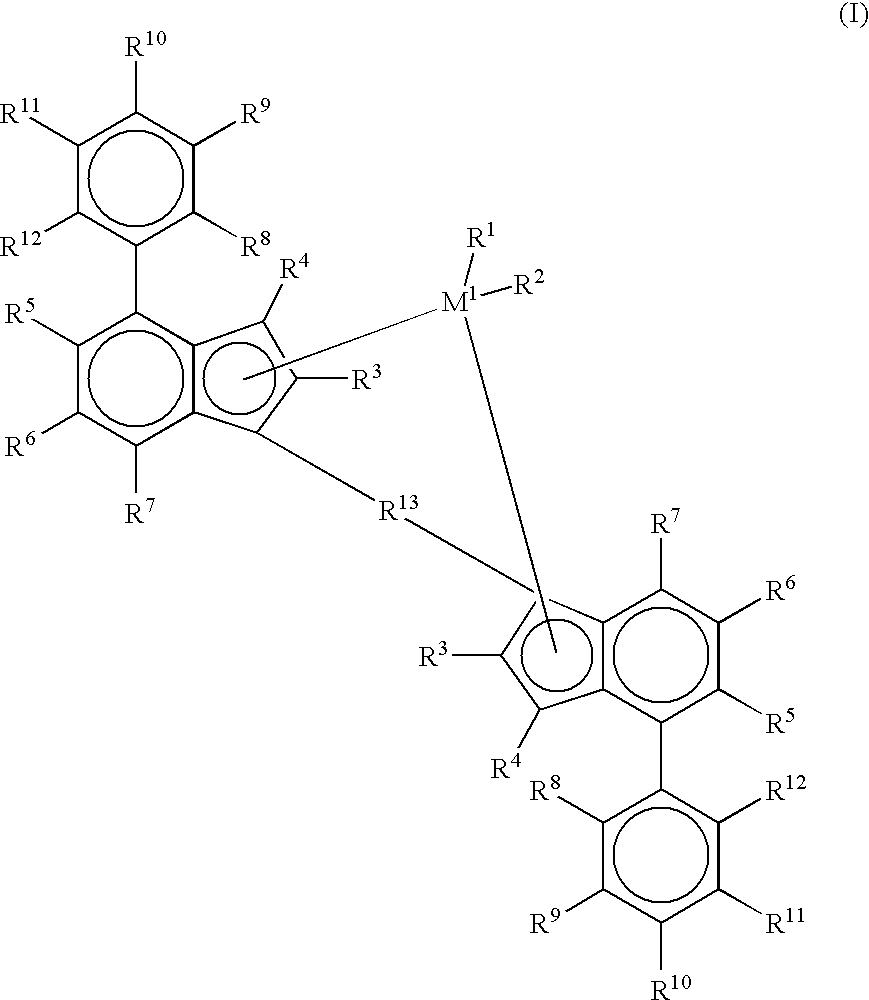

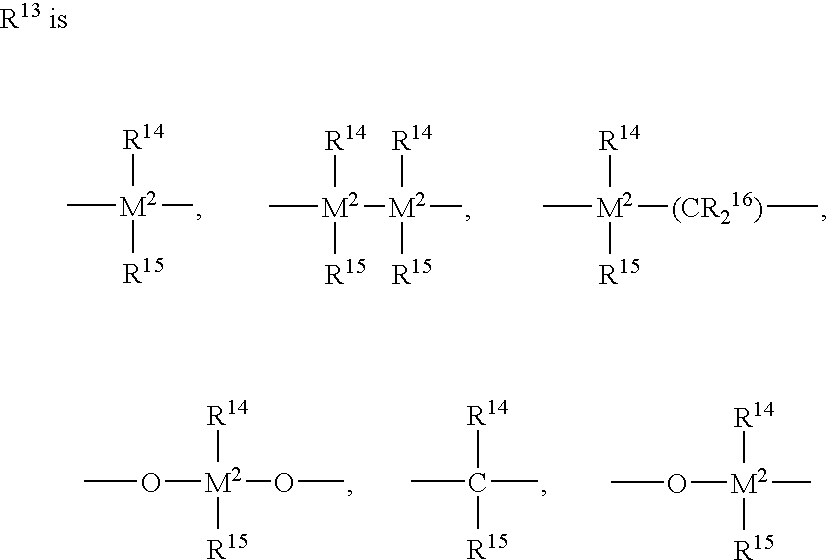

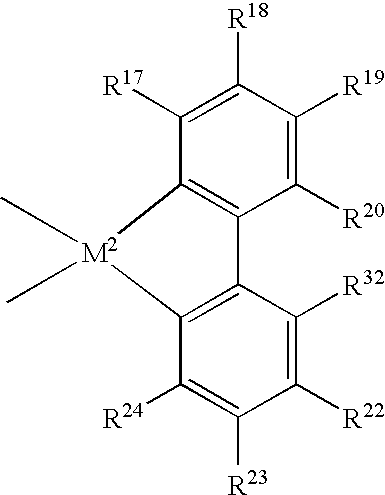

This invention relates to a process to produce propylene polymers comprising contacting a metallocene catalyst compound and an activator in a reaction medium comprising propylene, from 0 to 30 volume % of one or more solvents and from 0 to 30 mole % of one or more comonomers, under temperature and pressure conditions below the melting point of the propylene polymer and where: a) the temperature is at or above the critical temperature for the reaction medium, and the pressure is at least 500 kPa above the critical pressure of the reaction medium; or b) the temperature is 1° C. or more above the critical temperature for the reaction medium, and the pressure is at or above the critical pressure of the reaction medium; or c) the temperature is 1° C. or more above the critical temperature for the reaction medium, and the pressure is at least 500 kPa above the critical pressure of the reaction medium.

Owner:EXXONMOBIL CHEM PAT INC

Stable free radical polymerization processes

InactiveUS6156858AIncrease polymerization rateTime requiredDevelopersPhotochemistryRadical initiator

A process for the preparation of polymer comprising heating a mixture comprised of a free radical initiator, a stable free radical agent, a base selected from the group consisting of inorganic bases and organic bases, and at least one polymerizable monomer compound and optionally cooling, followed by optionally isolating the polymer product.

Owner:XEROX CORP

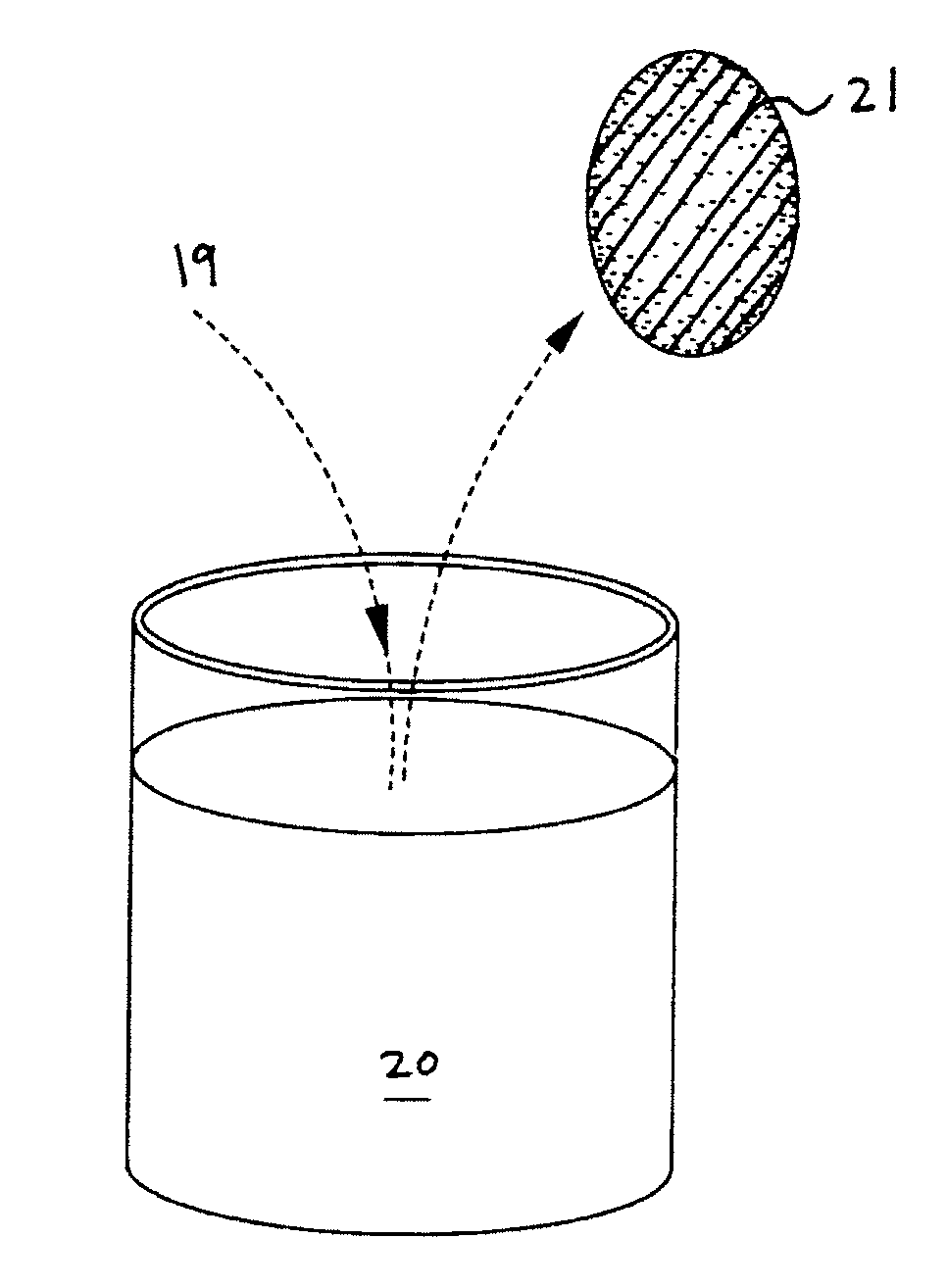

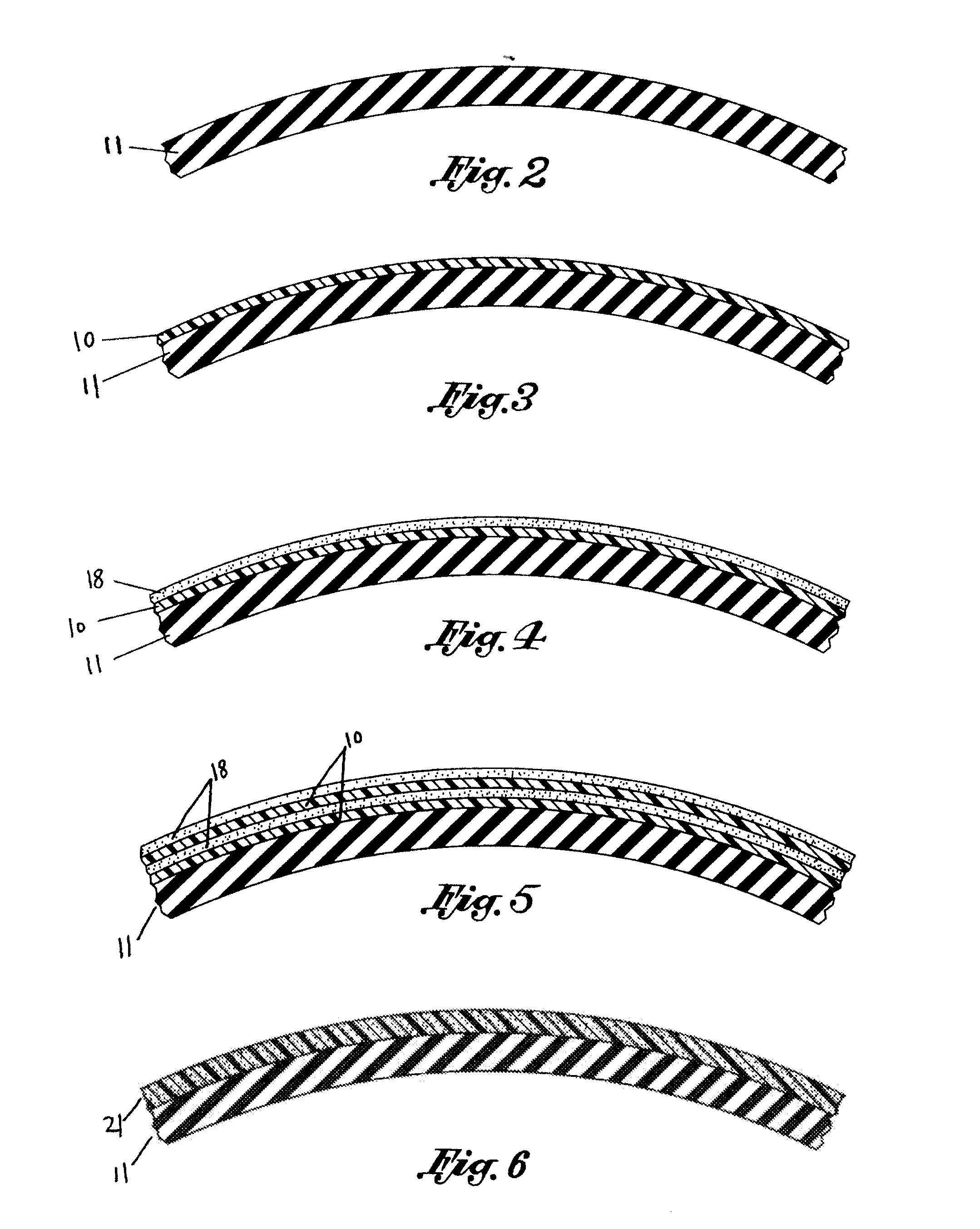

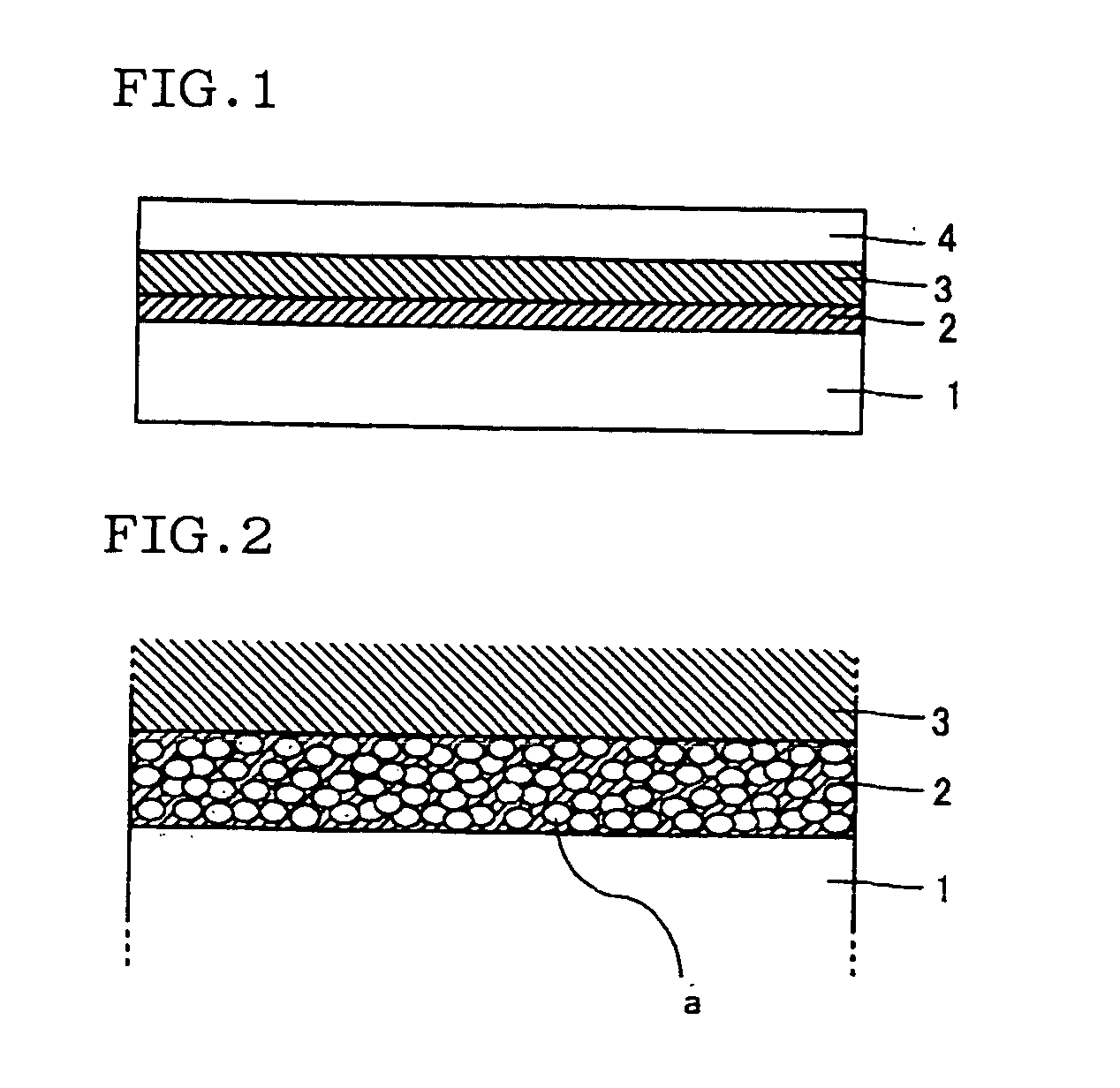

Implants and methdos for manufacturing same

InactiveUS20110093069A1Easy to fixDiscourages organizationMammary implantsPretreated surfacesParticulatesTexture design

Implantable prosthesis, components of prosthesis, and methods of making same are provided. The methods generally include the steps of providing an implant shell, applying a curable fluid composition to the shell to form a coating thereon and applying a particulate component to the composition. The composition is a mixture, for example, an emulsion, containing a silicone-based elastomer dispersion and droplets of a suspended leachable agent. After the elastomer is stabilized and cured, the particulate component and leachable agent are removed, resulting in an implantable member having a porous, open-cell surface texture designed to be effective in reducing incidence of capsular formation or contraction.

Owner:ALLERGAN INC

Aqueous emulsion polymerization of fluorinated monomers in the presence of a partially fluorinated oligomer as an emulsifier

InactiveUS20070004848A1Increase speedSmall particle sizeTransportation and packagingFibre treatmentPolymer scienceOligomer

The present invention relates to a method for making a fluoropolymer comprising an aqueous emulsion polymerization of one or more fluorinated monomers wherein said aqueous emulsion polymerization is carried out in the presence of an oligomer that comprises one or more ionic groups, has a partially fluorinated backbone, a number average molecular weight of not more than 2000 g / mol and that has a combination of repeating units different from that of the fluoropolymer that is being produced by the polymerization of said one or more fluorinated monomers. Since the polymerization of the one or more fluorinated monomers to produce the desired fluoropolymer is carried out in the presence of the oligomer, the resulting dispersion will contain the oligomer in addition to the fluoropolymer. Thus, in a further aspect, the invention relates to an aqueous dispersion of a fluoropolymer comprising the oligomer.

Owner:3M INNOVATIVE PROPERTIES CO

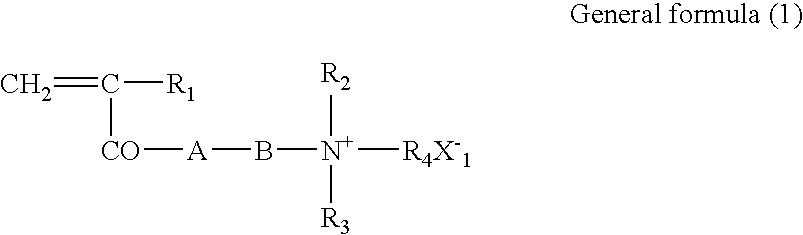

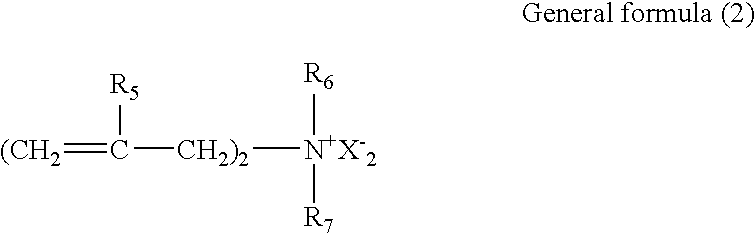

Water-soluble polymer dispersion, process for producing the same and method of use therefor

InactiveUS20060162882A1Marked effectImproved yieldNatural cellulose pulp/paperSpecial paperWater soluble polymersIon

A water-solible polymer dispersion, p process for producing the same and a method of use therefor. In particular, the water-soluble polymer dispersion is one comprising water-soluble polymer fine particles of 100 μm or less diameter having at least one ionic property selected from among cationic, amphoteric, nonionic and anionic properties together with a polyalkyleneimine and / or a product of polyalkyleneimine modification wherein according to necessity an appropriate amount of water-soluble inorganic salt is incorporated. The provided process enables easily performing the production in dispersed form by means of production facilities of low cost. The obtained water-soluble polymer dispersion is excellent in storage stability and exhibits satisfactory fluidity and solubility so as to enable use in papermaking raw material pretreatments added to papermaking raw materials prior to machine operation and also for enhancement of freeness, increase of sizing degree and enhancement yield. Further use can be found in incorporation in an organic sludge or paper mill sludge for flocculation and ensuing drainage.

Owner:HYMO CORPORATION

Method for operating a gas phase polymerization reactor

Disclosed herein is a method of operating a polymerization reactor for a polymerization reaction comprising modifying a recycle gas composition to increase the heat capacity of the recycle gas wherein the recycle gas composition is modified by reducing or eliminating the nitrogen concentration in the recycle gas. In an embodiment, the nitrogen concentration is reduced or eliminated by reducing or eliminating one or more nitrogen input sources to the polymerization reactor and replacing the nitrogen with an alternate inert fluid (a gas or liquid that is inert to the catalyst and reactants). The alternate inert fluid has a higher heat capacity and a higher molecular weight than nitrogen. In an embodiment, the nitrogen utilized to convey a catalyst into the polymerization reactor is replaced with an alternate inert fluid. In an embodiment, the alternate inert fluid is ethane, propane, isobutane, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Emulsifier free aqueous emulsion polumerization process for making fluoropolymers

Emulsifier free fluoropolymer manufacturing method in which (a) a chain transfer agent, or a mixture of chain transfer agents are used wherein the chain transfer agents do not yield more than 0.4 weight % relative to the monomer feed of water soluble fluorinated compounds, or (b) a chain transfer agent or a mixture of chain transfer agents selected from alkanes, dialkyl ethers, hydrofluoroethers and / or hydrofluorocarbons.

Owner:3M INNOVATIVE PROPERTIES CO

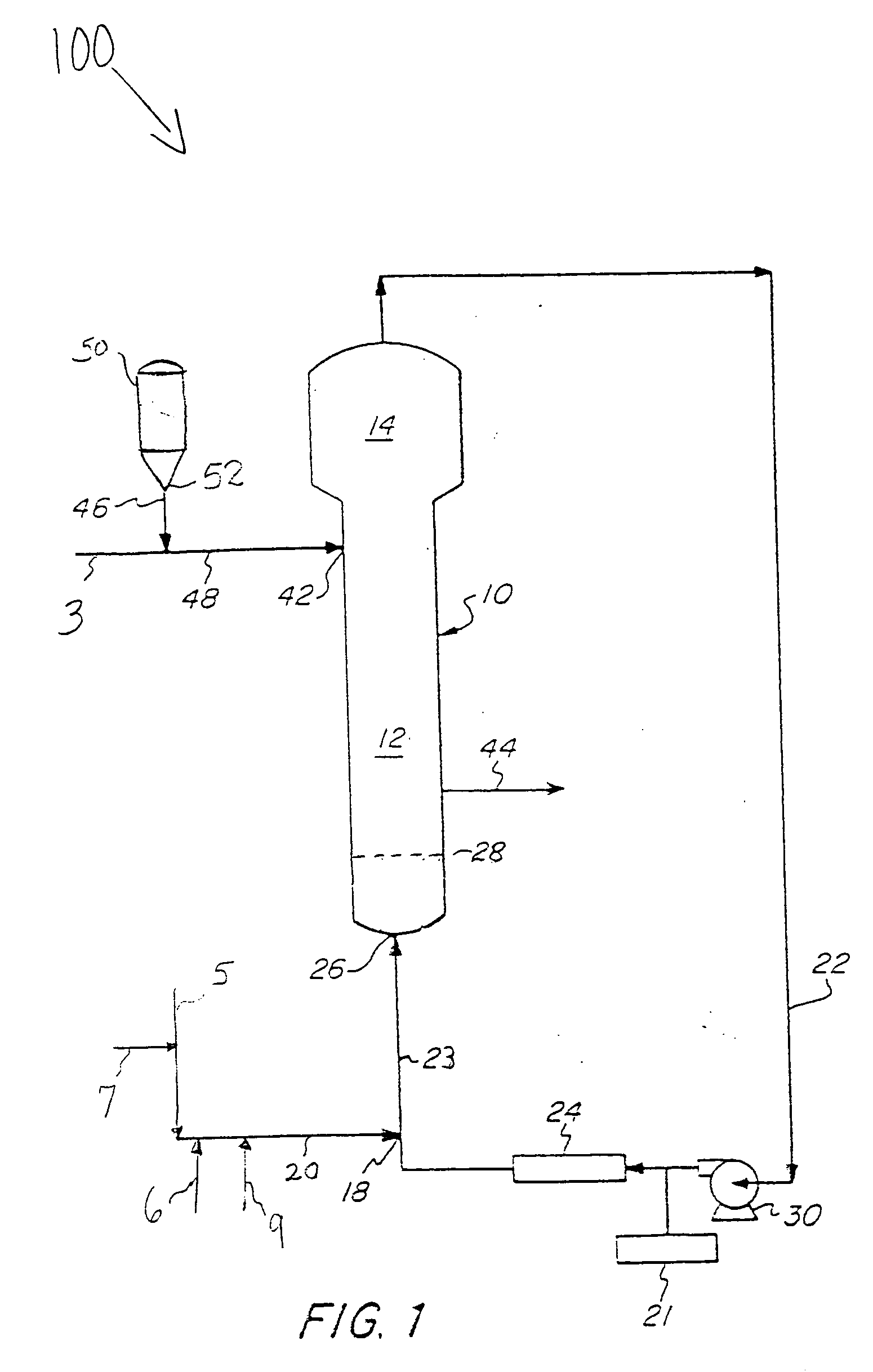

Multifunctional thermal insulation coating containing titanium dioxide/attapulgite nanocomposite material and preparation method thereof

ActiveCN104725971APromote complexationPrevent subsidenceReflecting/signal paintsThermal insulationUltraviolet

The invention belongs to the technical field of coating and particularly relates to a thermal insulation coating with excellent thermal insulation performance, water resistant performance, weather fastness and mechanical property and a preparation method thereof. The method comprises the following steps: loading rutile nano-titanium dioxide on the surface of the attapulgite to obtain the titanium dioxide / attapulgite nanocomposite material, organically modifying through a silane coupling agent and carboxylic acid, copdymerizing with styrene and acrylic monomer to prepare the modified styrene-acrylic emulsion, and adding micron titanium dioxide, glass bead, far infrared ceramic powder, a moist disperser, a defoamer, a coalescing agent and water to obtain the thermal insulation coating with excellent thermal insulation performance, water resistant performance, weather fastness and ultraviolet resistance ability.

Owner:CHANGZHOU UNIV

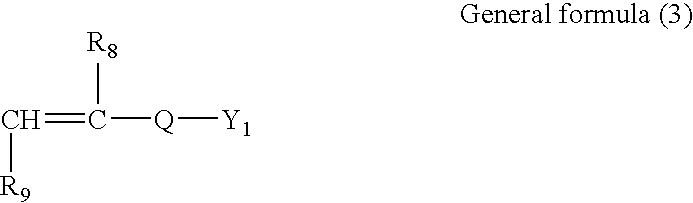

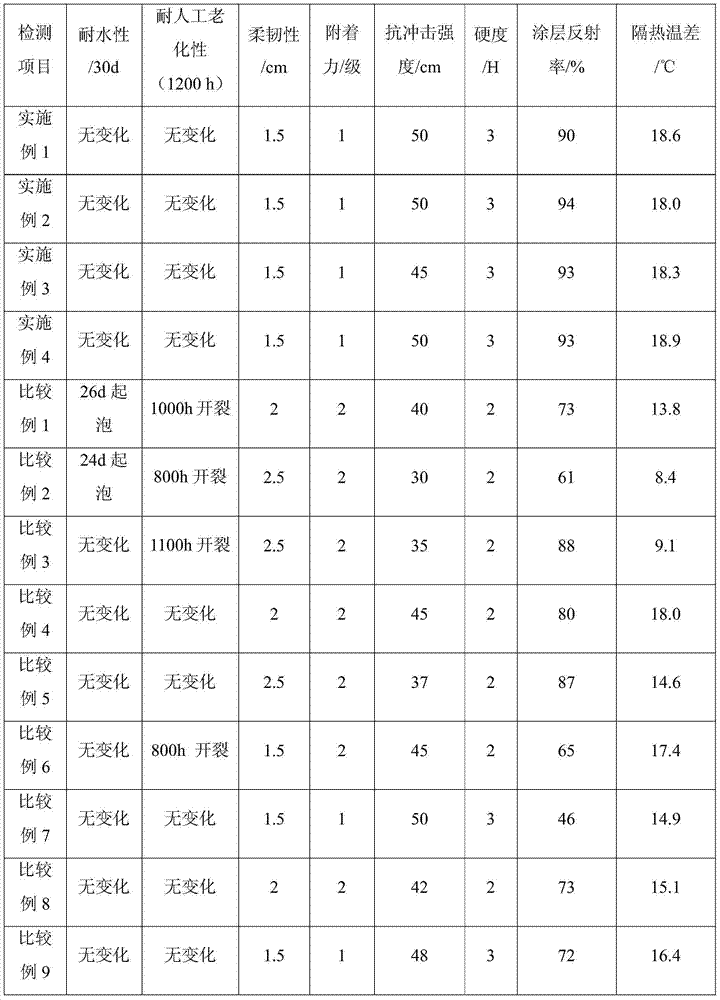

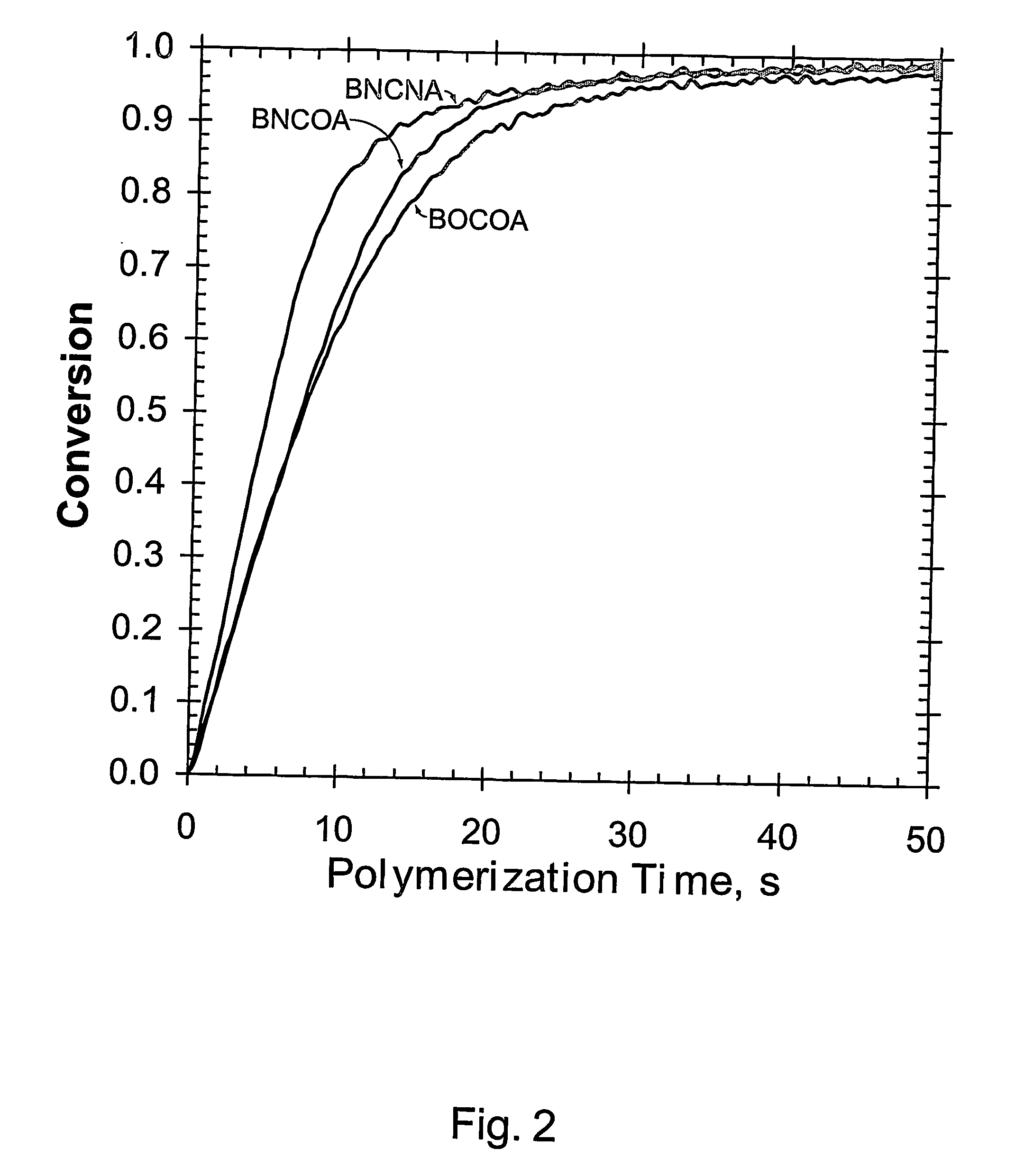

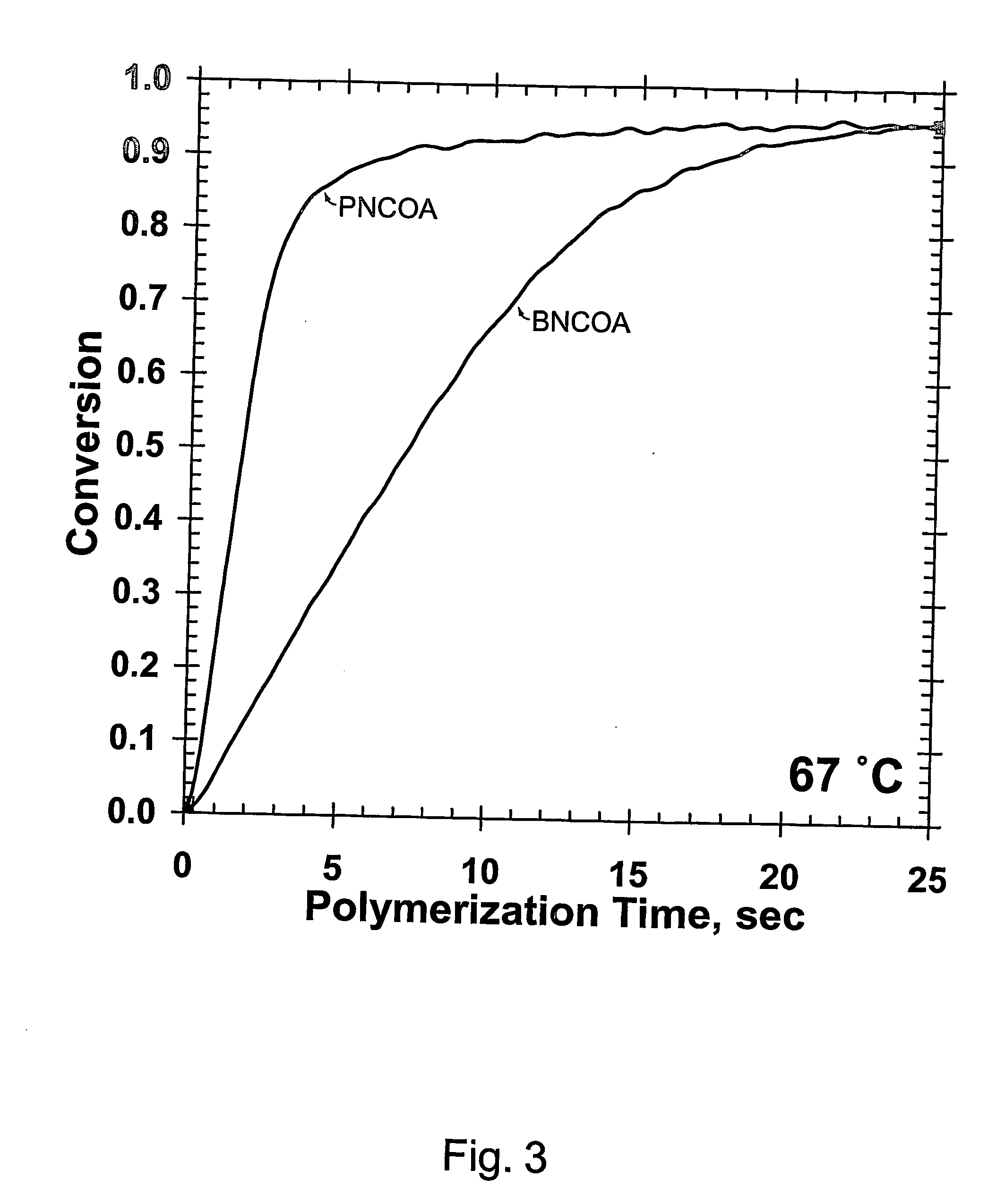

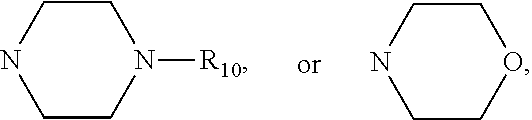

(Meth)arcrylic and (meth)acrylamide monomers, polymerizable compositions, and polymers obtained

InactiveUS20060252900A1Increase polymerization rateDecrease in maximum attainable double bond conversionCarbamic acid derivatives preparationOrganic compound preparationMeth-Methacrylic acid

The present invention provides novel (meth)acrylic and (meth)acrylamide monomers and polymers produced from those monomers. The monomers of the invention each include only a single vinyl functionality and at least one non-vinyl functionality that can be varied to achieve desired monomer / polymer properties. The invention additionally provides methods of producing polymers from these mono-vinyl monomers.

Owner:UNIV OF COLORADO THE REGENTS OF

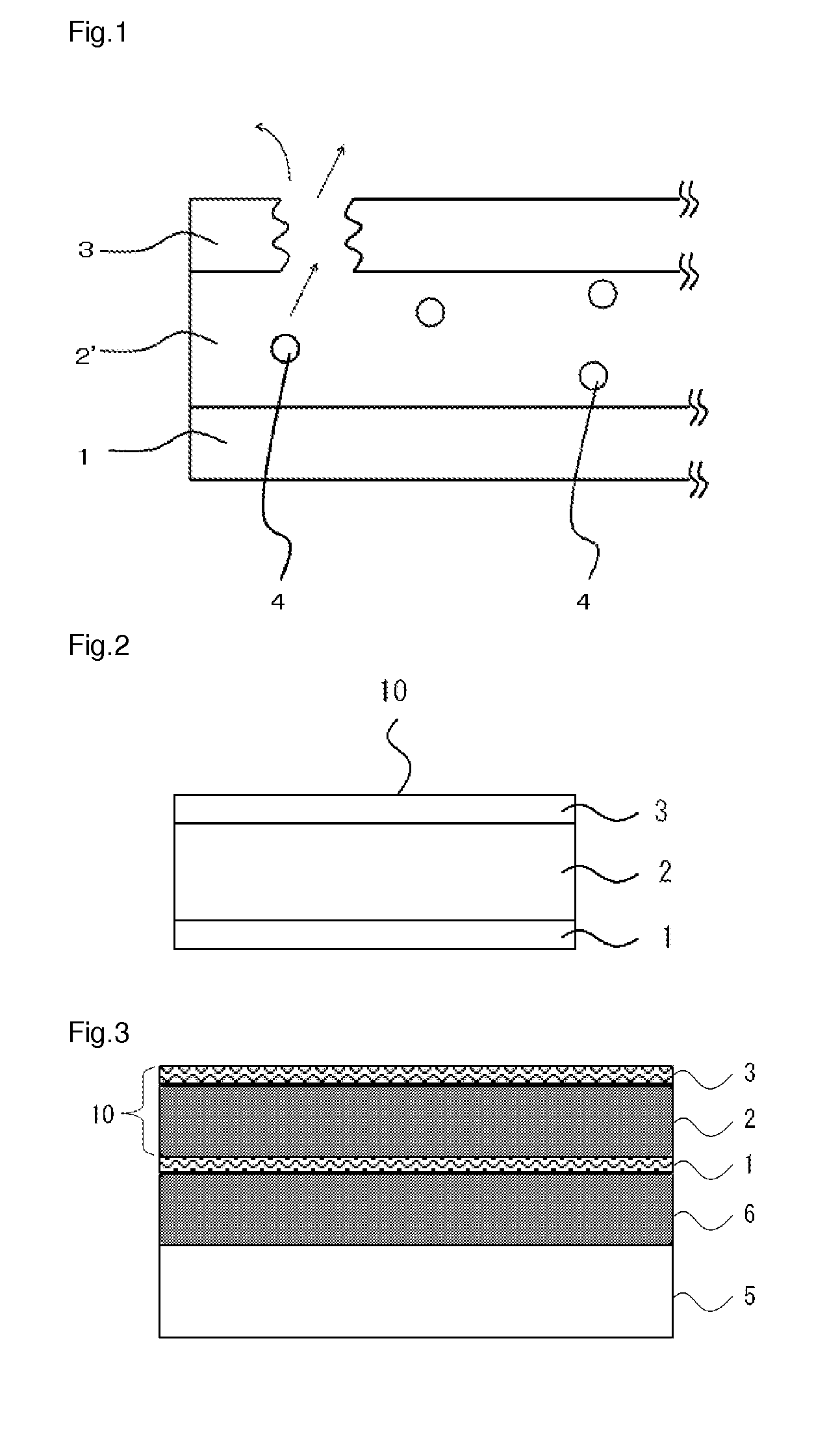

Lithographic printing plate precursor and lithographic printing method

InactiveUS20050037282A1Good storage stabilityImprove propertiesPhotosensitive materialsSemiconductor/solid-state device manufacturingChemical compoundImage recording

Owner:FUJIFILM CORP

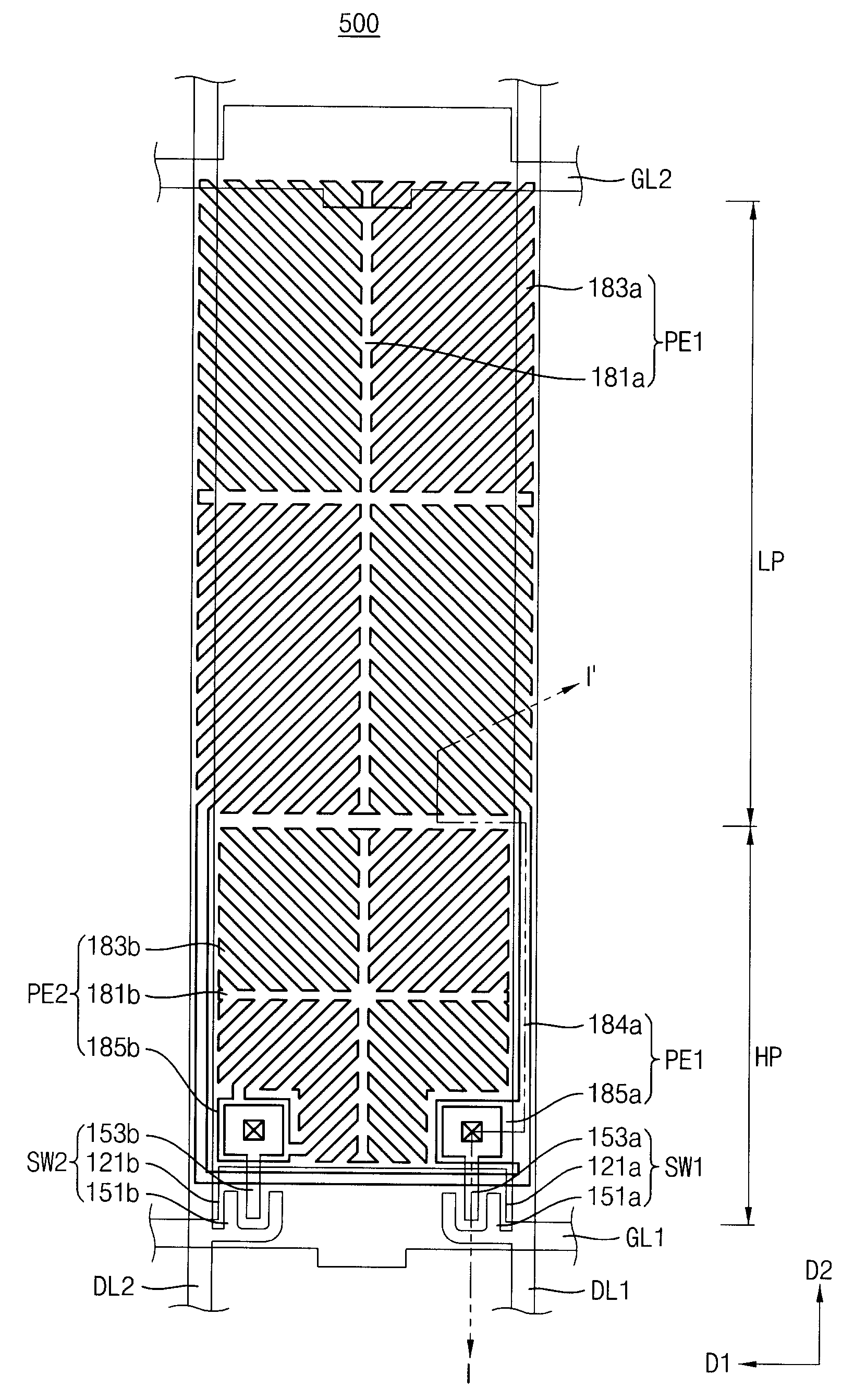

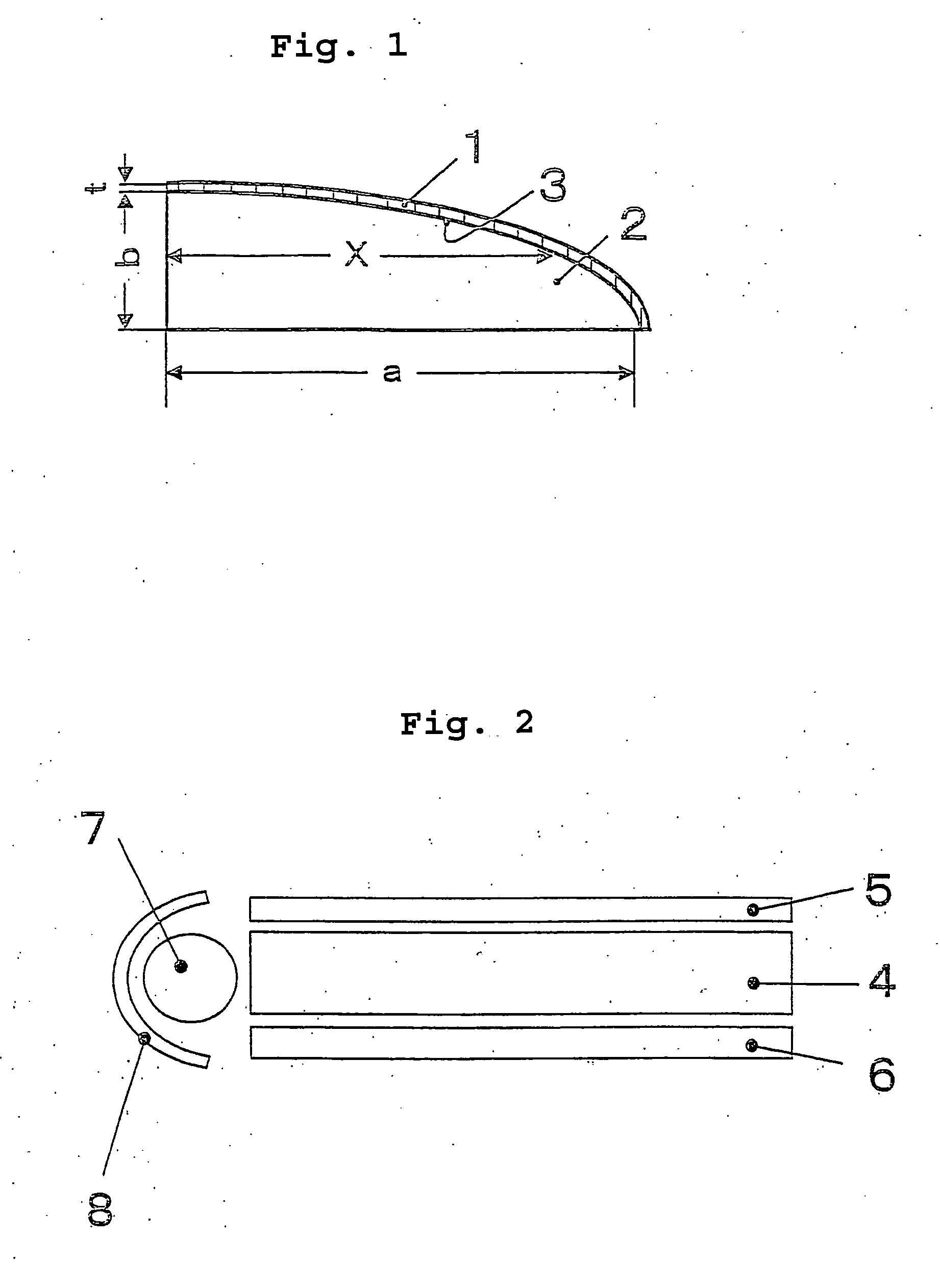

Liquid crystal display panel and method of manufacturing the liquid crystal display panel

InactiveUS20100231845A1Simple structureStabilize free radicalLiquid crystal compositionsThin material handlingLiquid-crystal displayEngineering

A liquid crystal display (“LCD”) panel includes a first substrate including a pixel electrode defining pixel areas, a first alignment layer disposed on the pixel electrode and a first reactive mesogen layer disposed on the first alignment layer, a second substrate including a common electrode layer disposed on an entire portion of the second substrate facing the first substrate, a second alignment layer disposed on the common electrode layer and a second reactive mesogen layer disposed on the second alignment layer, and a liquid crystal layer disposed between the first and second substrates and including a first liquid crystal compound represented by Chemical Formula 1, a second liquid crystal compound represented by Chemical Formula 2 and a third liquid crystal compound represented by Chemical Formula 3:

Owner:SAMSUNG DISPLAY CO LTD

Implants and methods for manufacturing same

ActiveUS20130302511A1Easy to fixDiscourages organizationMammary implantsPharmaceutical containersParticulatesElastomer

Implantable prosthesis, components of prosthesis, and methods of making same are provided. The methods generally include the steps of providing an implant shell, applying a curable fluid composition to the shell to form a coating thereon and applying a particulate component to the composition. The composition is a mixture, for example, an emulsion, containing a silicone-based elastomer dispersion and droplets of a suspended leachable agent. After the elastomer is stabilized and cured, the particulate component and leachable agent are removed, resulting in an implantable member having a porous, open-cell surface texture designed to be effective in reducing incidence of capsular formation or contraction.

Owner:ALLERGAN INC

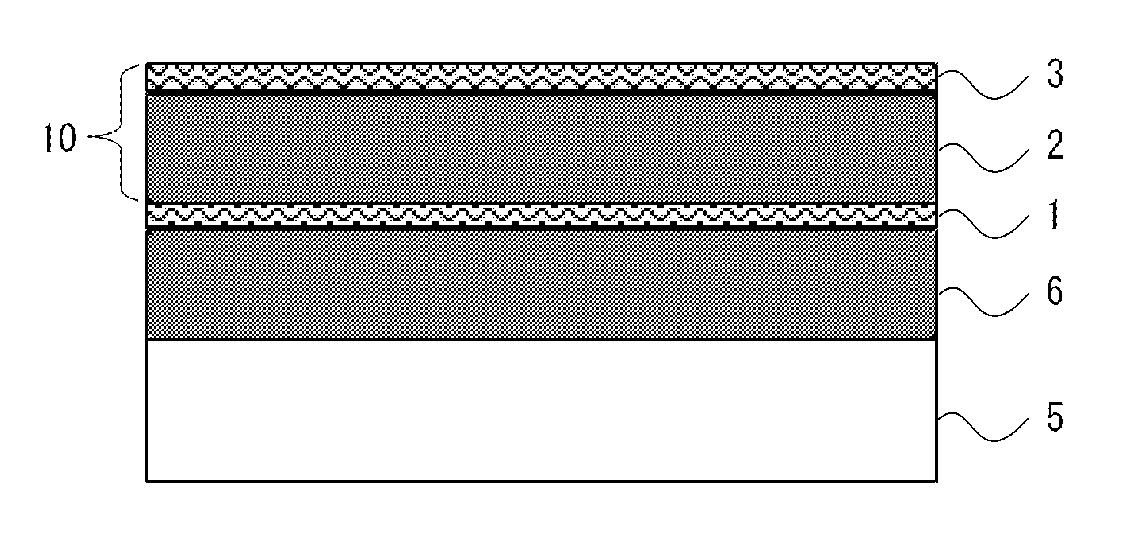

Pressure-sensitive adhesive type optical film and image display

InactiveUS20050084670A1Improve adhesionReduce partial omissionAdhesive processes with surface pretreatmentElectroluminescent light sourcesEmulsionDisplay device

A pressure-sensitive adhesive type optical film which comprises an optical film and a pressure-sensitive adhesive layer superposed on at least one side thereof through an anchor layer formed from a resin emulsion. It is easy to handle because the pressure-sensitive adhesive does not peel off even when an edge of the film comes into contract during handling in use.

Owner:NITTO DENKO CORP

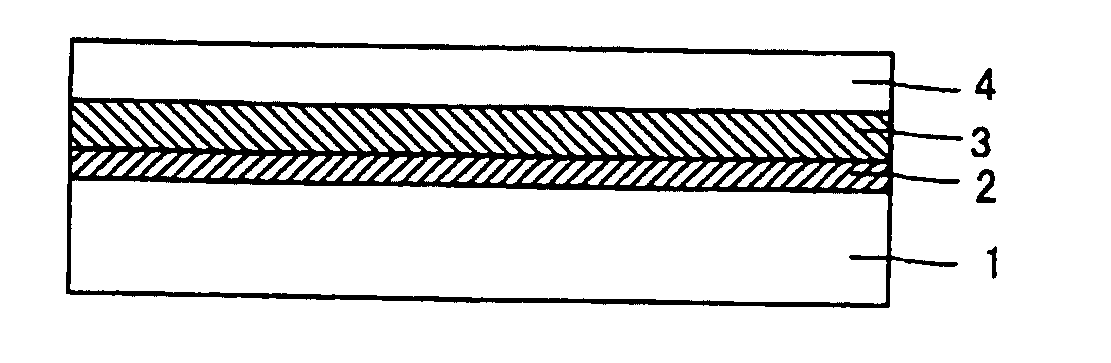

Barrier laminate and novel polymer compound

InactiveUS20140170345A1Improve adhesionLittle gas generationSynthetic resin layered productsPhotomechanical apparatusPolymer scienceOrganic layer

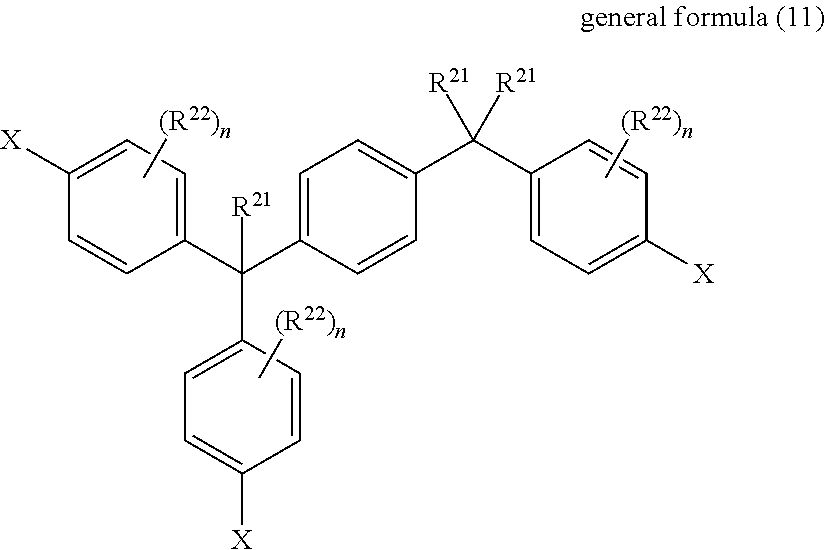

The present invention provides a barrier laminate with enhanced heat resistance performance, comprising at least one organic layer and at least one inorganic barrier layer, the organic layer being formed by curing a polymerizable composition comprising a polymerizable compound having two or more polymerizable groups, and the total quantity of uncured component in the organic layer being 1.5 weight % or less of the total weight of the organic layer, and a novel polymerizable compound that can preferably used as the polymerizable compound, which is denoted by general formula (11):in general formula (11), R21 denotes hydrogen atom or methyl group; R22 denotes methyl group or cyclohexyl group; n denotes an integer of 0 to 2; and each instance of X denotes a group comprising a polymerizable group.

Owner:FUJIFILM CORP

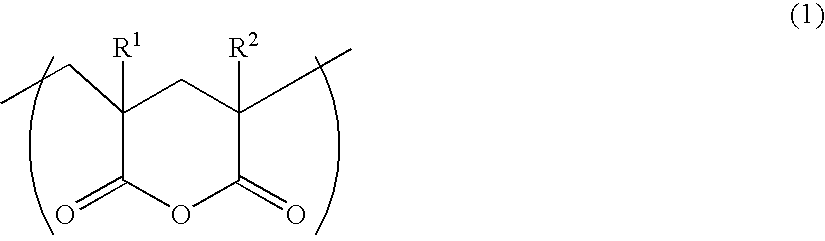

Thermoplastic polymer, process for producing the same, and molded article

InactiveUS20050119418A1Less impuritiesEffective preventionOptical elementsGlutaric anhydrideVitrification

A thermoplastic polymer containing glutaric anhydride units of the following general formula (1) and having an absorbance at a wavelength of 280 nm of at most 0.5 (the absorbance is a value of the polymer film having a thickness of 100 μm, measured with a UV-visible spectrophotometer) and a glass transition temperature of not lower than 130° C. has high-level colorless transparency and good heat resistance, moldability and dwell stability. wherein R1 and R2 are the same or different and each represents a hydrogen atom or an alkyl group having from 1 to 5 carbon atoms.

Owner:TORAY IND INC

Solid Phase Polymerization Catalyst System

ActiveUS20090198022A1Efficient preparationImproving solid state polymerization rateOrganic-compounds/hydrides/coordination-complexes catalystsCeramic shaping apparatusPolyesterPolyethylene terephthalate

The invention is a method for making condensation polymers, such as polyethylene terephthalate polyester. The method includes introducing a catalyst system, which includes a coordination catalyst component and an acid component, to a polycondensation reaction.

Owner:DAK AMERICAS MISSISSIPPI INC

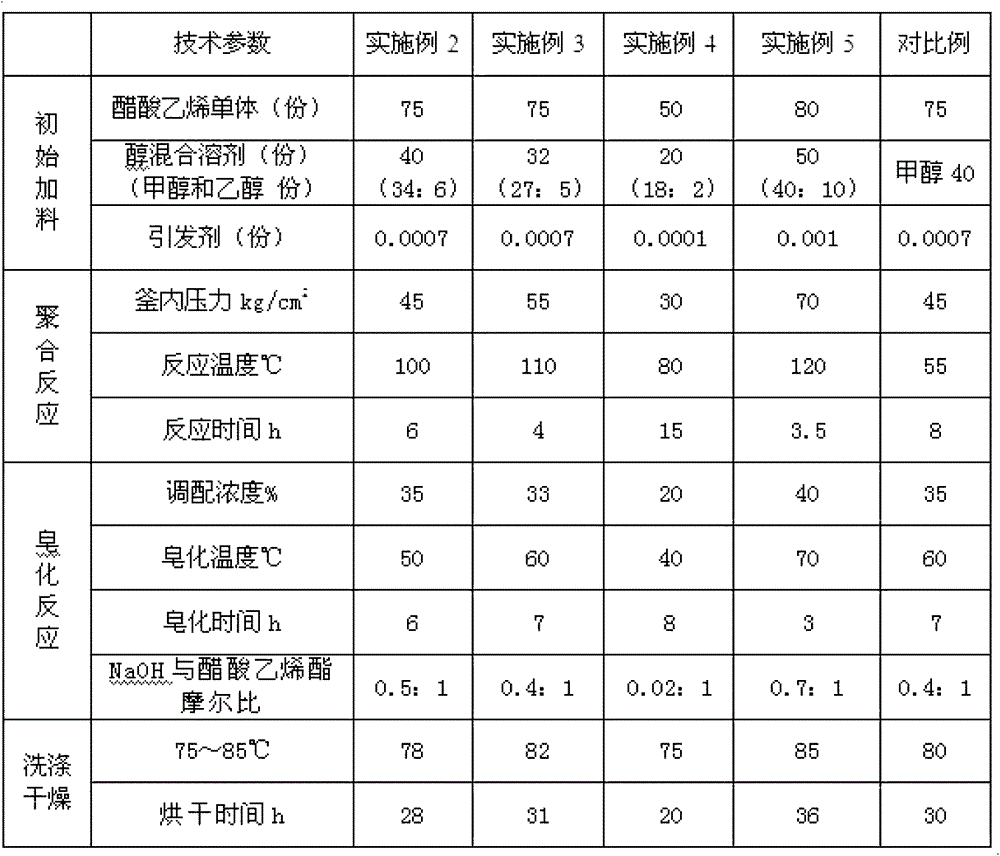

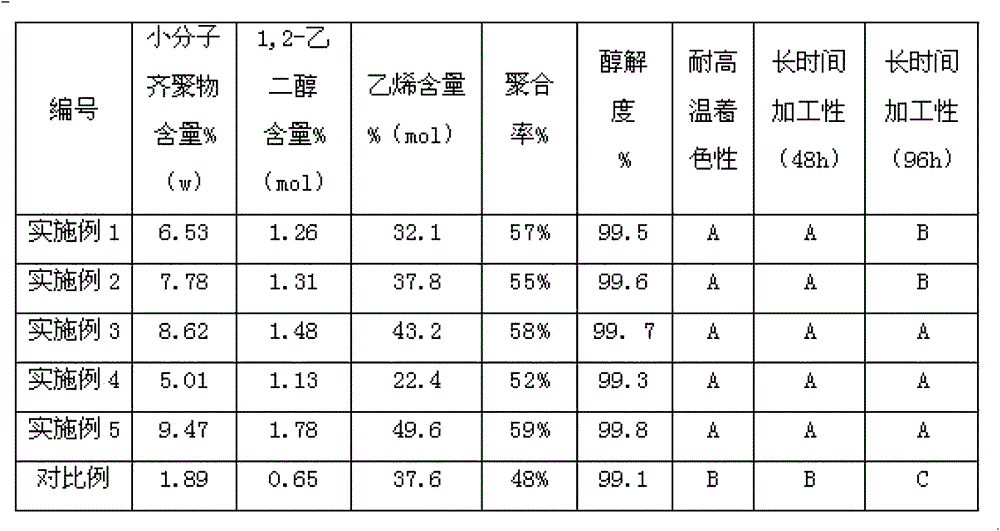

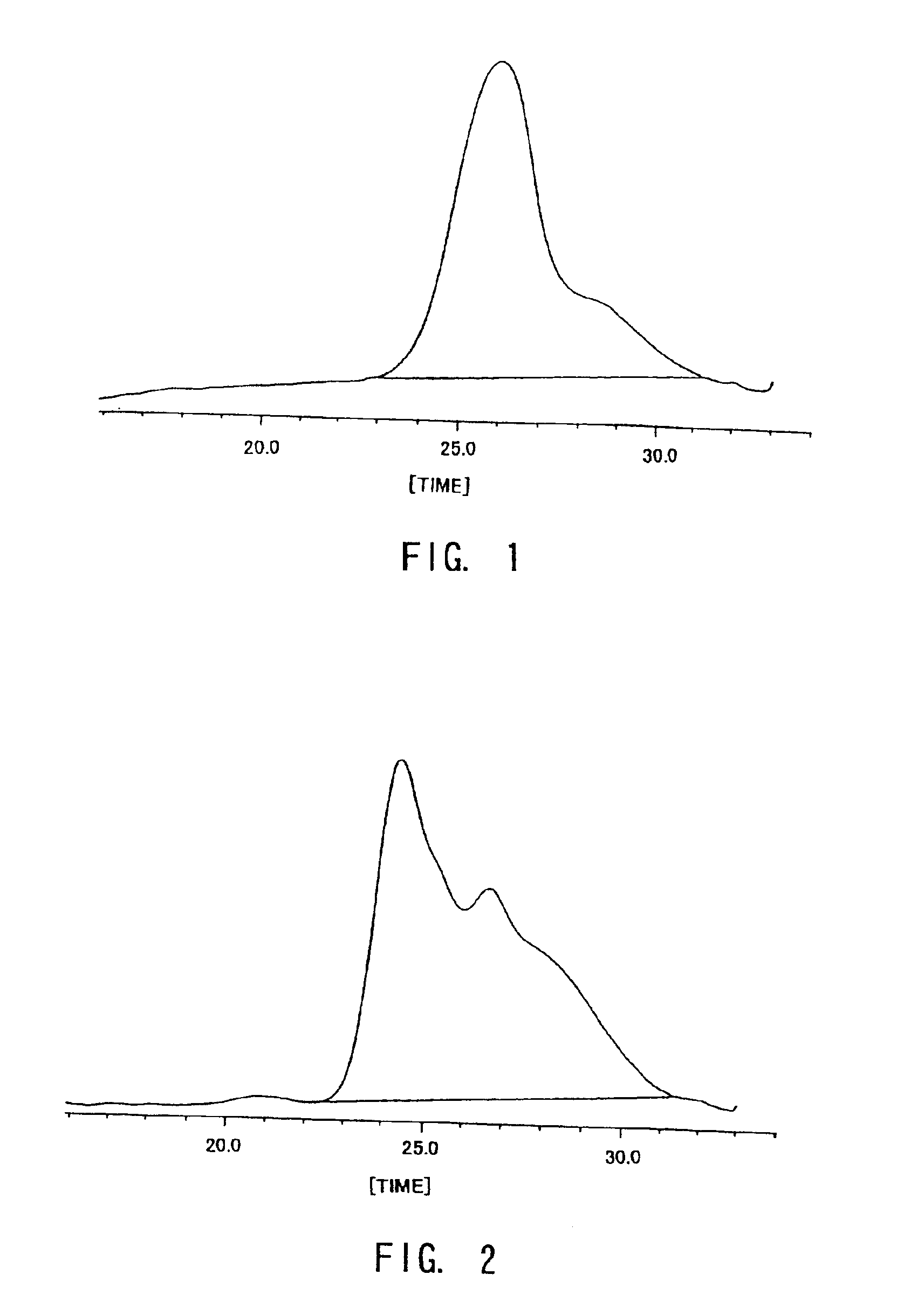

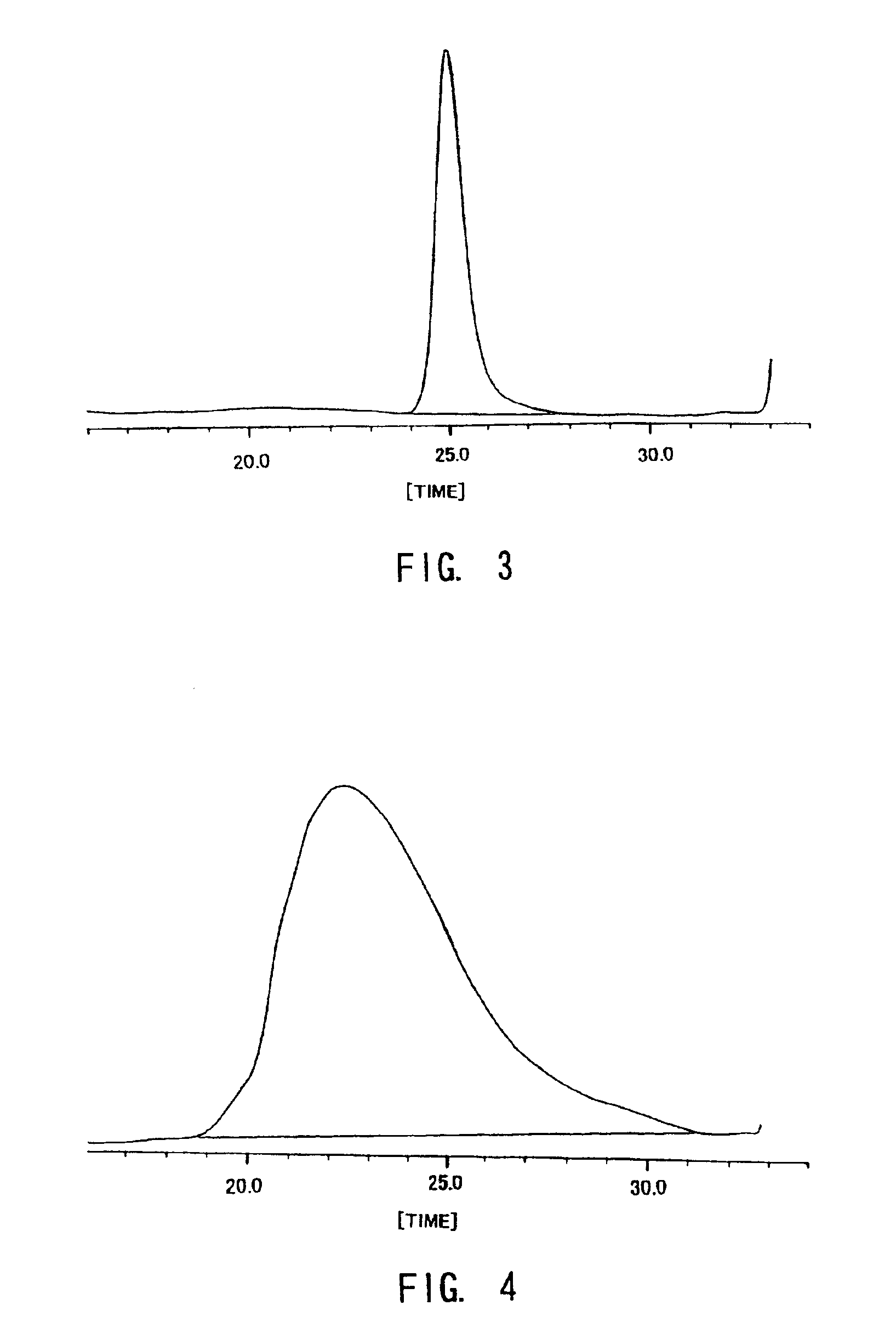

Composition containing ethylene-vinyl alcohol copolymer, and preparation method thereof

The invention relates to a composition containing an ethylene-vinyl alcohol copolymer, and a preparation method thereof. The composition comprises 90-95wt% of the ethylene-vinyl alcohol copolymer and 5-10wt% of an ethylene-vinyl alcohol micro-molecular oligopolymer, and the molecular structure of the ethylene-vinyl alcohol copolymer contains 1-2%mol of a 1,2-glycol structure. The preparation method of the composition comprises the following steps: polymerizing 50-80 parts of a vinyl acetate monomer, 20-50 parts of an alcoholic solvent and 0.0001-0.001 parts of an initiator at 80-140DEG C under 30-70kg / cm<2>, and carrying out a saponification reaction to obtain the composition. The molecular structure of the composition contains 1-2%mol of the 1,2-glycol structure having a viscosity reducing effect, and also contains 5-10mol% of the micro-molecular oligopolymer having a plasticising effect, so it is in favor of the melting processing property of the ethylene-vinyl alcohol copolymer, and the problems of the bad repeated utilization of the routine ethylene-vinyl alcohol copolymer, the easy migration of inorganic salt additives to the surface of the polymer, and environment pollution are overcome. The preparation method has the advantages of simple process, safety, environmental protection, high product quality, and suitableness for industrial production.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation of nano composite gel with organic/inorganic hybrid microspheres as crosslinking points

ActiveCN101524630AGood mechanical propertiesEvenly arrangedMicroballoon preparationMicrocapsule preparationMicrosphereAqueous electrolyte

The invention relates to a preparation of nano composite gel with organic / inorganic hybrid microspheres as cross linking points. The preparation comprises the following steps: (1) dissolving clay in 0-0.5mol / L aqueous electrolyte solution, ultrasonically treating after fully stirring, dropwise adding to the clay solution during the ultrasound process, heating to 70-80 DEG C after further ultrasonic treatment for a period, polymerizing in nitrogen atmosphere for 6-8 hours to obtain crosslinking point hybrid microsphere emulsion; and (2) mixing 20g of the crosslinking point hybrid microsphere emulsion with 5-10g of a water soluble monomer, 0.01-0.05g of a water soluble initiator and 8-24mul of a catalyst to obtain prepolymerized solution, polymerizing the prepolymerized solution at the room temperature of 20-30 DEG C for 30-50 hours to obtain the nano composite gel. The preparation has the advantages of simple process and high polymerization rate, the obtained macromolecular microsphere composite gel has excellent mechanical properties, and the method has large raw material range and great application value.

Owner:DONGHUA UNIV

Emulsifier free aqueous emulsion polymerization process for making fluoropolymers

InactiveUS20020198334A1Easy and convenient to practiceGood latex stabilityIonEmulsion polymerization

Emulsifier free fluoropolymer manufacturing method in which (a) a mixture of an oxidizing agent and reducing agent is used to start the polymerization and where one or the other but not both, are further added during polymerization, or (b) an oxidizing metal ion is added to start polymerization and where additional oxidizing metal ion is added during polymerization.

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous emulsion polymerization of fluorinated monomers using a fluorinated surfactant

InactiveUS7776946B2Low toxicityGood chemical and thermal stabilityLiquid surface applicatorsFibre treatmentEmulsion polymerizationEther

The present invention provides an aqueous emulsion polymerization of fluorinated monomers including gaseous fluorinated monomers using a perfluoro ether surfactant as an emulsifier. The perfluoro ether surfactants correspond to formula (I)Rf—O—CF2CF2—X (I)wherein Rf represents a linear or branched perfluoroalkyl group having 1, 2, 3 or 4 carbon atoms and X represents a carboxylic acid group or salt thereof. In a further aspect, the invention also provides an aqueous fluoropolymer dispersion comprising the perfluoro ether surfactant and the use of such dispersion in the coating or impregnation of substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation process of acrylic acid ester polymer

A process for the preparation of an acrylic acid ester polymer, includes carrying out polymerization of an acrylic acid ester or block copolymerization of an acrylic acid ester and another (meth)acrylic monomer in the presence of an organolithium compound and an organoaluminum compound represented by the following formula (I):AlR1R2R3 (I)wherein R1 represents an alkyl group having at least 3 carbon atoms, an alkoxy group having at least 3 carbon atoms or an aryloxy group, R2 and R3 each independently represent an aryloxy group or may be coupled together to form an arylenedioxy group. The process makes it possible to heighten the reaction rate and living properties upon polymerization and heighten the block formation efficiency upon block copolymerization.

Owner:KURARAY CO LTD

Organic/inorganic nano hybridized hydrogel for tooth root canal filling material

ActiveCN101647756AImprove mechanical propertiesBroaden your optionsImpression capsDentistry preparationsCross-linkSide effect

The invention relates to a nano hybridized hydrogel which can be used as a tooth root canal filling material. The organic / inorganic nano hybridized hydrogel for the tooth root canal filling material is formed by polymerizing a silane coupling agent modified inorganic nano particle, a monomer, an initiating agent and a cross-linking agent, wherein the inorganic nano particle is a mixed nano particle of ZnO and ZrO2; and the monomer is an amide or ester water-soluble organic compound. The organic / inorganic nano hybridized hydrogel has specific swelling performance, favorable biocompatibility, excellent stability and favorable service behaviour, no toxic and side effect and durable antibiosis and can thoroughly eliminate phenomena of microgaps and coronal leakage of the traditional root canalmaterial caused by polymerization shrinkage, be convenient to disinfect, use and remove and achieve X-ray radiation resistance so as to be convenient for examination. In addition, compared with the traditional gel material, the gel is greatly improved on mechanical performance and has high application value.

Owner:DONGHUA UNIV

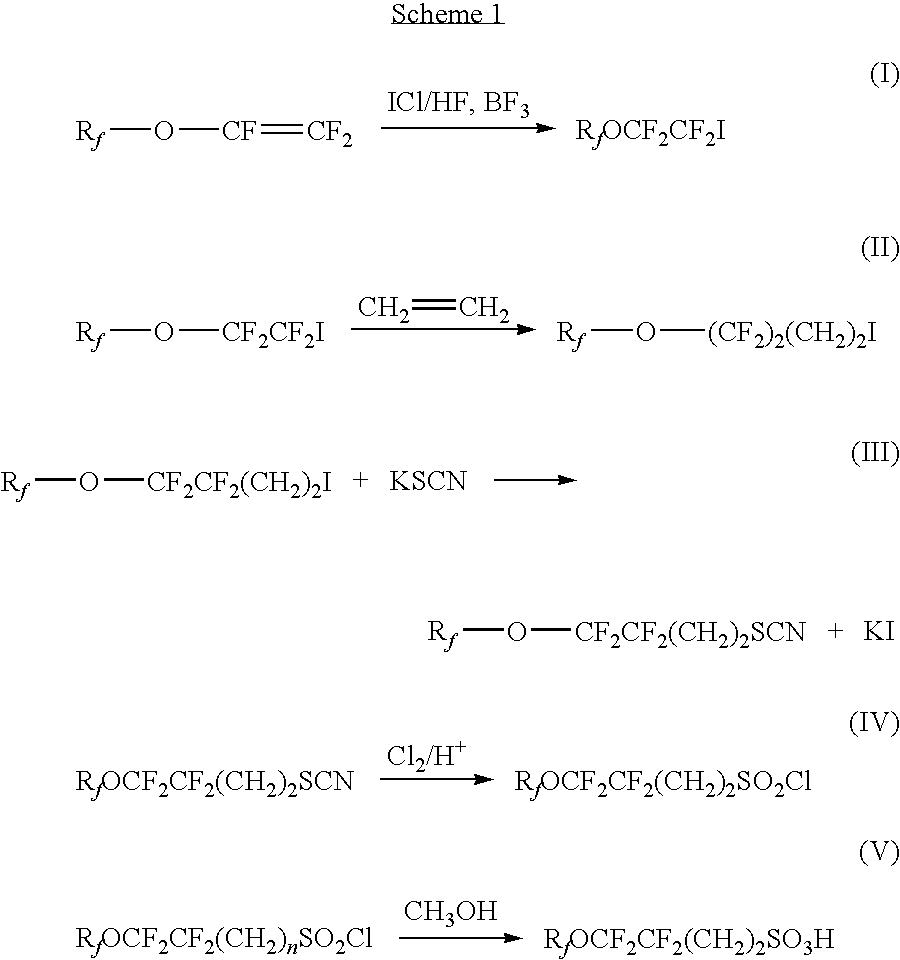

Fluoroalkyl ether sulfonate surfactants

InactiveUS20100120980A1Good dispersionIncrease polymerization rateCosmetic preparationsOrganic chemistryChemistryEther

Owner:EI DU PONT DE NEMOURS & CO

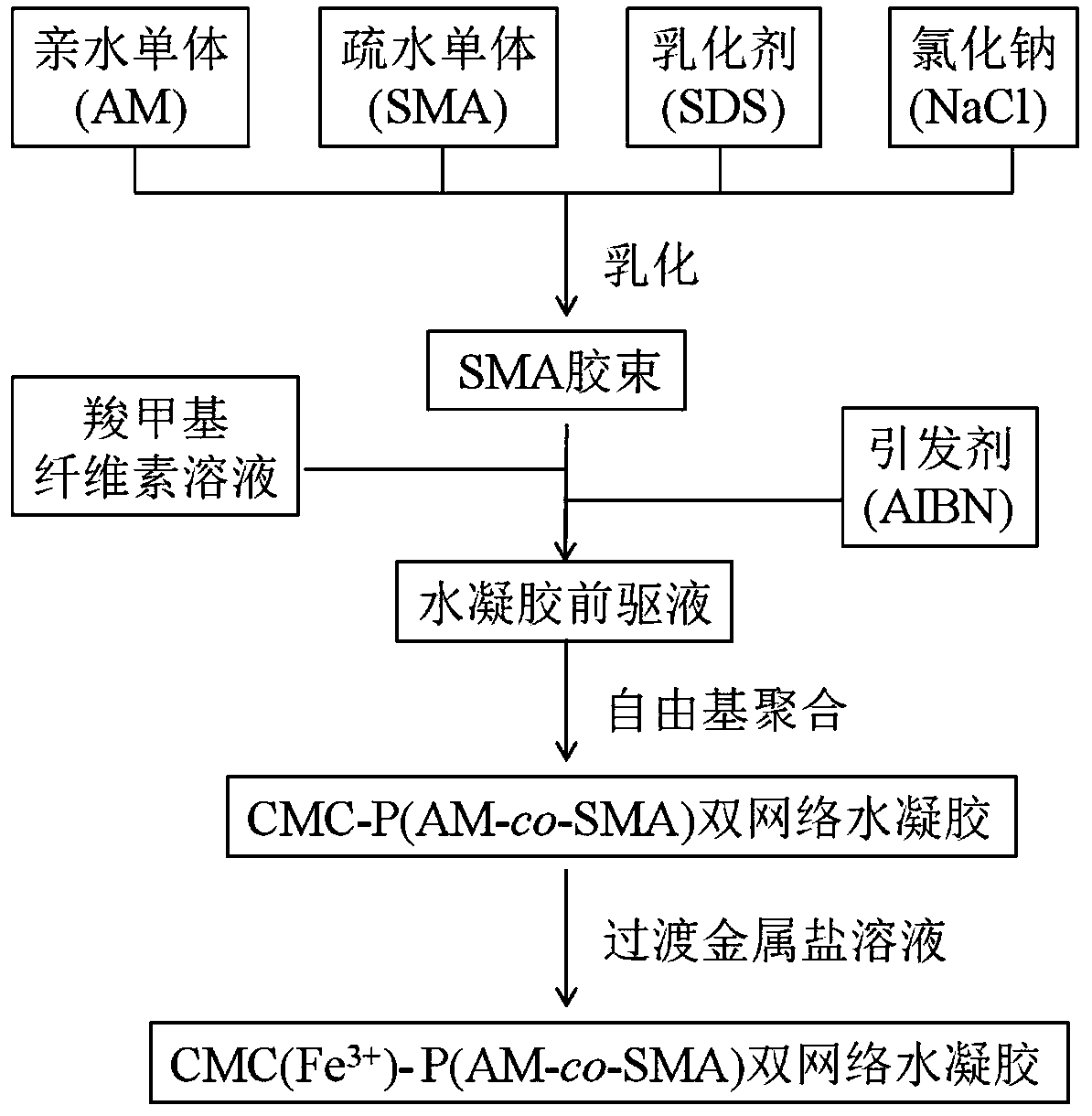

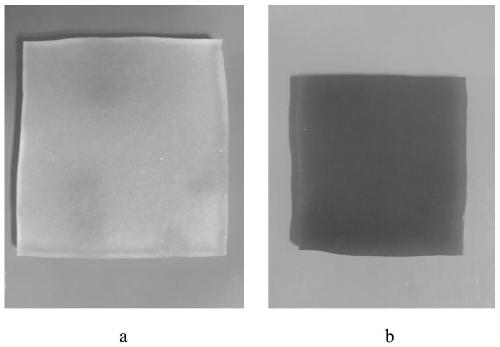

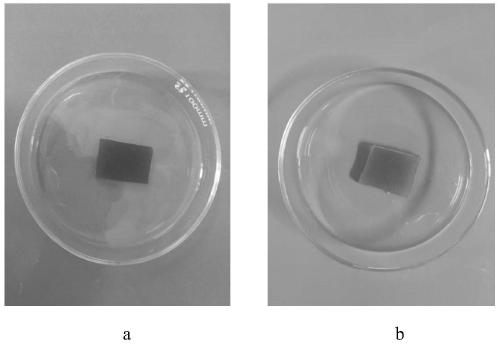

Preparation method of double-network hydrogel based on coordination crosslinking and hydrophobic association crosslinking

InactiveCN109929073AImprove mechanical propertiesImprove structural stabilitySolubilityDouble network

The invention relates to a preparation method of double-network hydrogel based on coordination crosslinking and hydrophobic association crosslinking. The polyacrylamide hydrogel is formed by adoptingan AIBN thermal initiation mode, and a coordination bond is formed by adopting a post-coordination crosslinking mode, so that the double-network polyacrylamide hydrogel containing coordination crosslinking and hydrophobic association crosslinking mechanisms is formed. The preparation method does not need light shielding operation, and the selected initiator has moderate solubility in water and anoil phase; polymerization inside and outside the micelle is initiated at the same time, and a coordination bond is formed in a metal salt soaking manner after molding. The method has the advantages ofeasily available monomers, simple process and high polymerization rate, and the obtained hydrogel has excellent mechanical properties and structural stability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Collagen preparation and method of isolation

ActiveUS8084055B2Increase ratingsImprove mechanical propertiesPowder deliveryConnective tissue peptidesMicro structureMechanical property

Owner:PURDUE RES FOUND INC

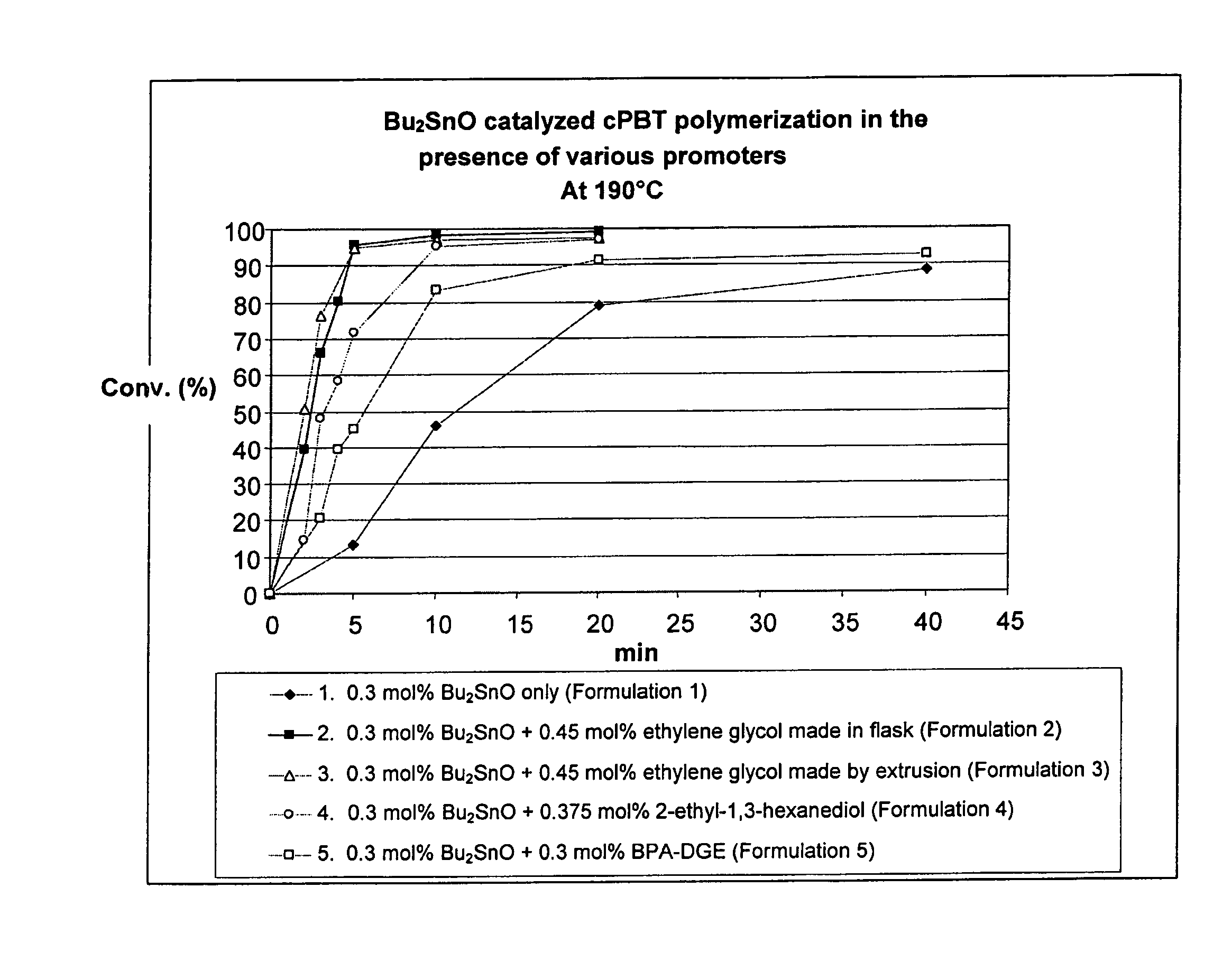

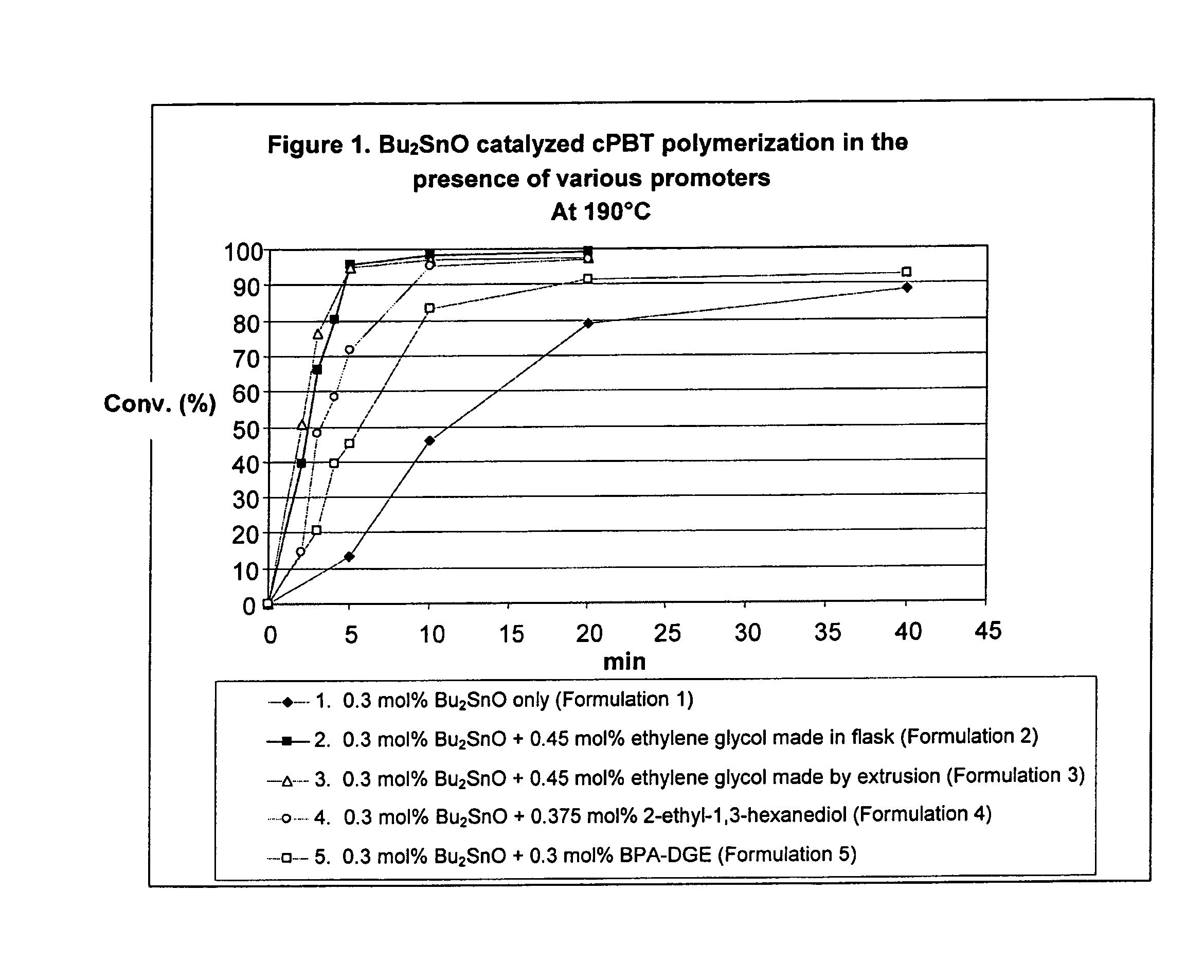

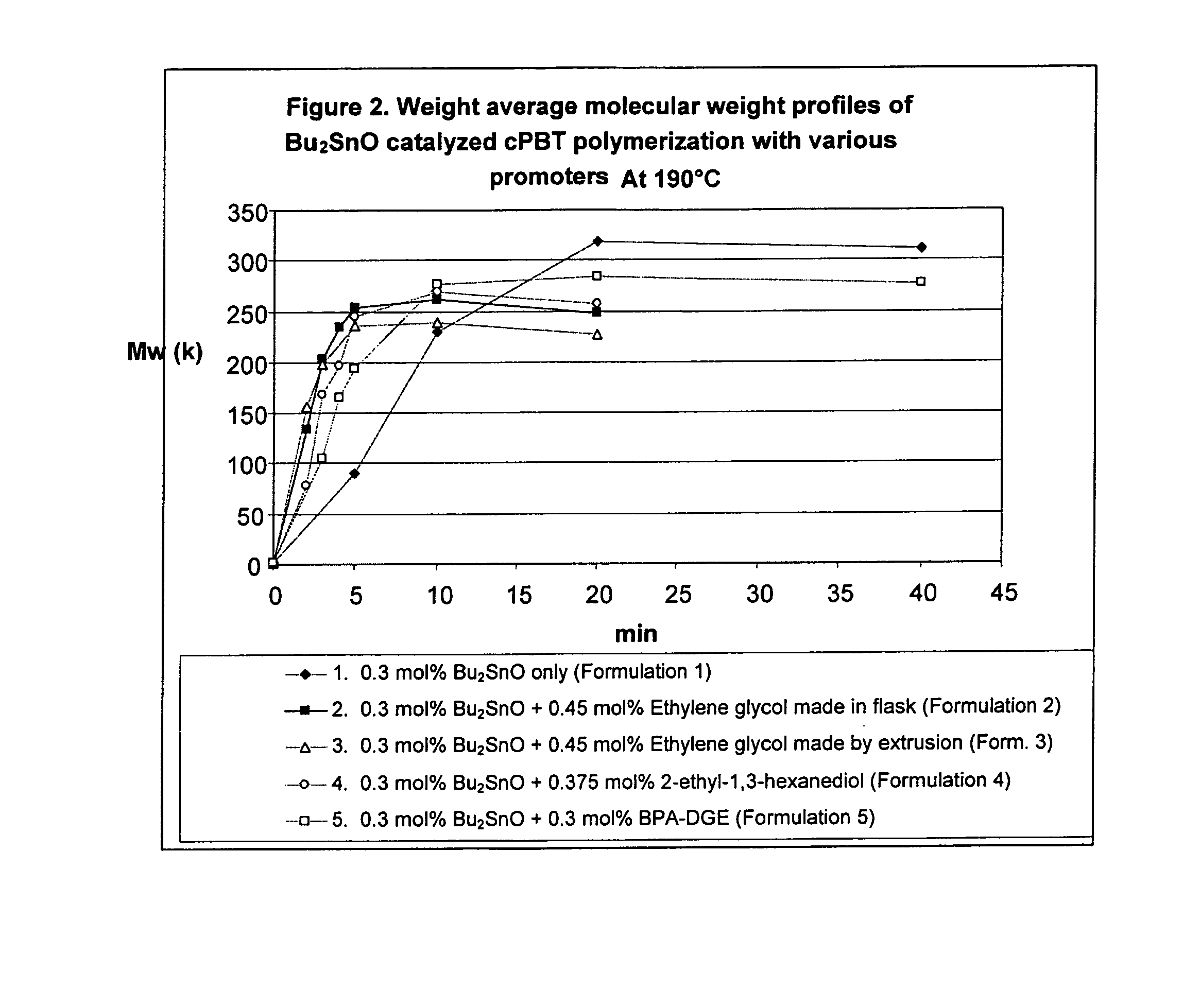

Methods for polymerizing macrocyclic polyester oligomers using catalyst promoters

InactiveUS7256241B2Extended shelf lifeGood processing characteristicsOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsPolyesterOligomer

The invention provides methods and formulations involving the use of promoters that accelerate the polymerization of macrocyclic polyester oligomers (MPOs). For example, in certain embodiments, the invention provides blends of macrocyclic polyester oligomer (MPO), catalyst, and promoter that are substantially stable at ambient temperature for a period of time. The blend material may be stored without premature polymerization of MPO or deactivation of catalyst. The invention also provides processes employing one-part, ready-to-polymerize blends that contain MPO, catalyst, and promoter, as well as processes in which the catalyst and promoter are used in separate streams and are contacted when it is desired to accelerate polymerization of MPO. Methods of the invention offer advantages in the manufacture of thermoplastic parts and composites, due at least in part to the unique properties of MPO.

Owner:LIQUID THERMO PLASTICS

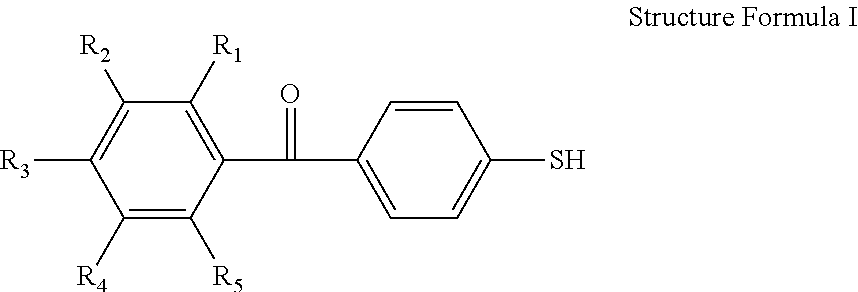

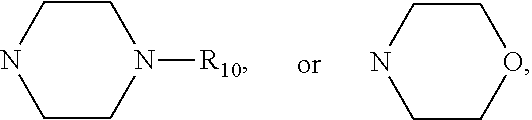

Mercapto Benzophenone Compounds, Compositions and Preparation Method Thereof

ActiveUS20130150479A1Easy to remainEasy to migrateThiol preparationOrganic compound preparationChemistryPhotoinitiator

The present invention provides a photocurable composition prepared using mercapto benzophenone compounds as key raw materials. The present invention aims to solve the problems existing in the prior photo-curing technology that low-molecular photoinitiators are easy to remain and migrate, while macromolecular photoinitiators has low initiation efficiency due to a low content of effective components and also has the problem of certain migration. The photocurable composition in the present invention can be easily prepared and has high addition efficiency with ethylenically unsaturated compounds, and the photocurable composition obtained by addition has no residual mercapto and has features of high initiation activity and zero migration rates when it is used in photocurable coatings, binder and ink formula.

Owner:INSIGHT HIGH TECH (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com