Composition containing ethylene-vinyl alcohol copolymer, and preparation method thereof

A vinyl alcohol copolymer and vinyl acetate copolymerization technology, applied in the field of compositions containing ethylene-vinyl alcohol copolymer, can solve the problems of reducing the gas barrier property of the polymer, decreasing the melt processing stability, and deteriorating the quality of the polymer, etc. Overcome the effects of poor reusability, high product quality, and improved high temperature colorability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

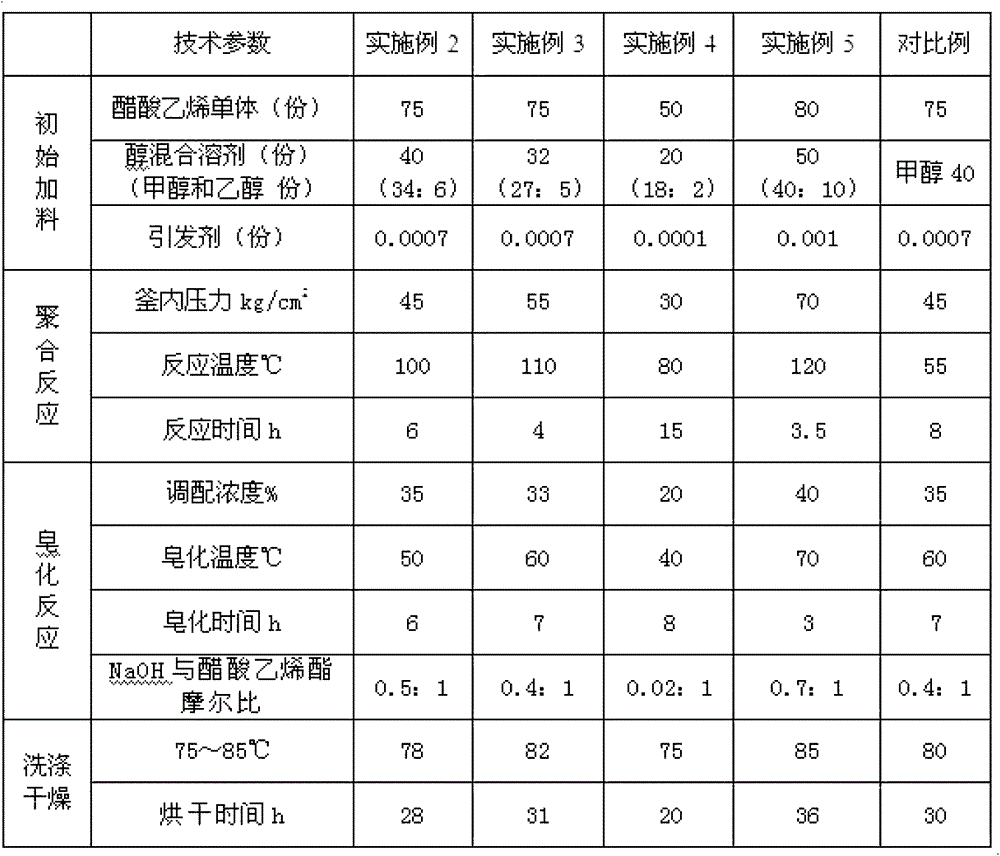

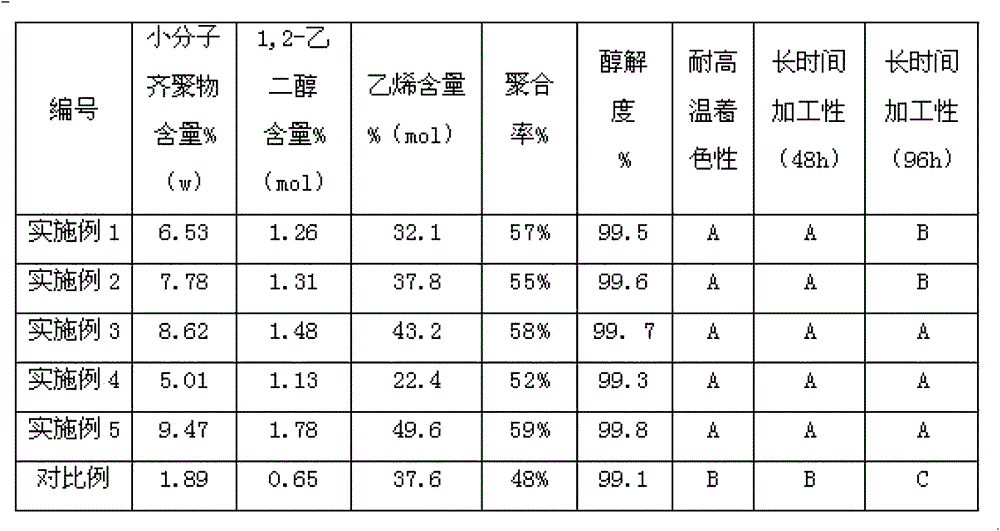

Examples

Embodiment 1

[0035] A preparation method of a composition containing ethylene-vinyl alcohol copolymer, as follows:

[0036] 1), initial feeding

[0037] Add 75 parts of vinyl acetate monomer, 45 parts of methanol and ethanol (90%:10%) mixed solvent, and 0.0007 part of azobisisobutyronitrile into the stainless steel reaction kettle.

[0038] 2), replacement in the kettle

[0039] Inject 8-12 bar of N2 at room temperature to replace and remove oxygen from the initial mixture twice, each time for 5 minutes; then introduce 8-12 bar of ethylene gas to replace and remove nitrogen from the initial mixture twice; 5min.

[0040] 3), polymerization reaction

[0041] Feed ethylene gas, control the pressure in the kettle to be 40kg / cm 2 , when the temperature reaches 95°C, start timing, stop the reaction after 8 hours, close the ethylene inlet valve, cool down to below 40°C, release the pressure and discharge to obtain the polymerized ethylene-vinyl acetate copolymer.

[0042] 4) Blowing off resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com