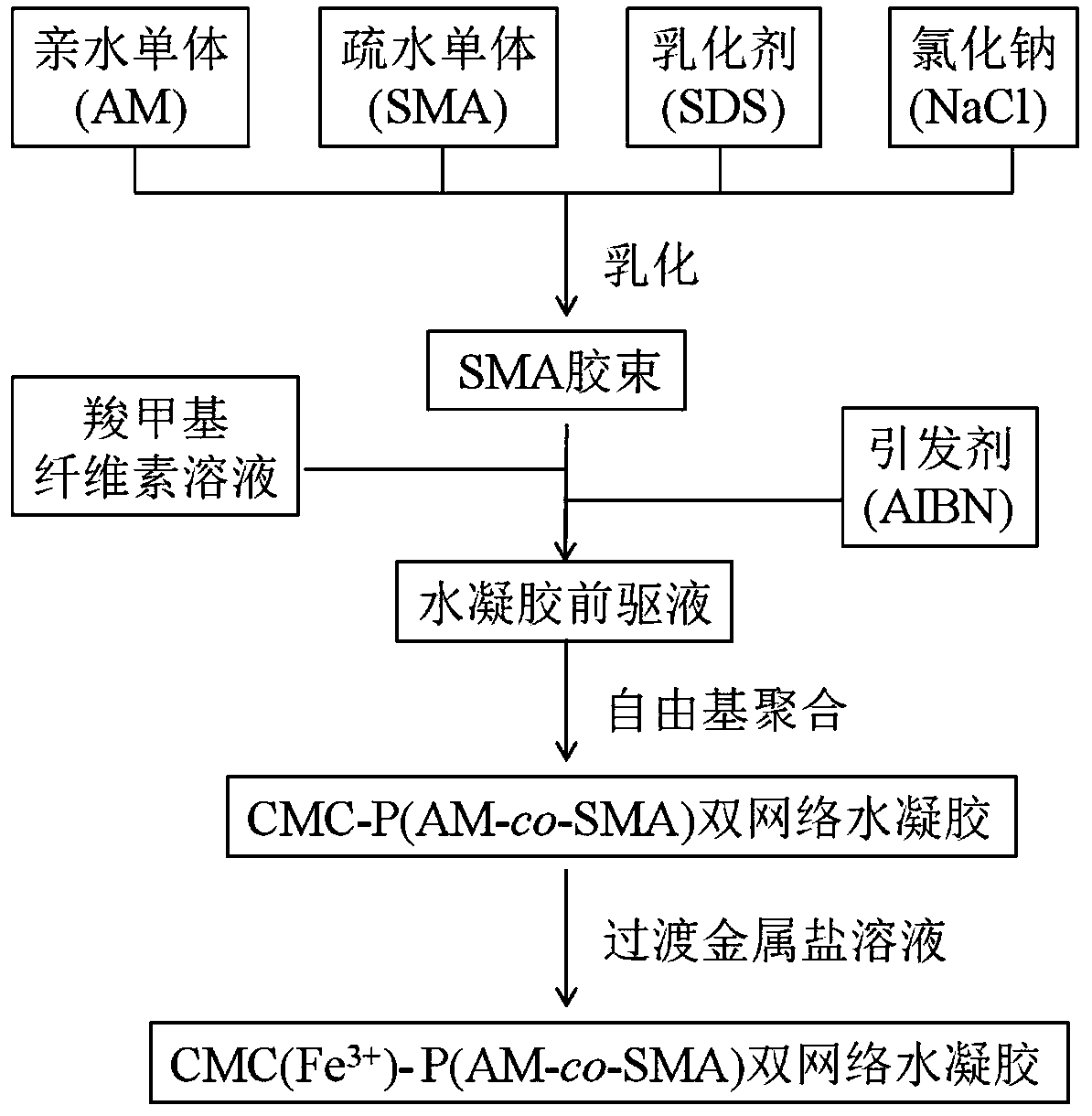

Preparation method of double-network hydrogel based on coordination crosslinking and hydrophobic association crosslinking

A technology of coordination cross-linking and hydrophobic association, which is applied in the field of preparation of double network hydrogels, can solve problems such as difficult removal, fragility of the first network hydrogel, and insufficient mechanical properties of hydrogels, and achieves improved mechanical properties. performance, excellent mechanical properties and structural stability, and the effect of high polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step (1): Weigh 2g of carboxymethylcellulose (CMC) and 30g of deionized water and mix them in a magnetic stirring water bath at a temperature of 70°C for 30 minutes, so that the carboxymethylcellulose is fully dissolved in water and drops to At room temperature, carboxymethylcellulose solution was obtained.

[0038] Step (2): Weigh 10g of acrylamide (AM), 0.7141g of hydrophobic monomer octadecyl methacrylate SMA, 2.5g of sodium dodecyl sulfate (SDS), 1.5g of NaCl and 20g of deionized water, mix, and stir to dissolve at room temperature.

[0039]Step (3): Mix the carboxymethyl cellulose solution prepared in step (1) with the solution obtained in step (2), and stir in a magnetic stirring water bath at a water temperature of 40°C for 30 minutes to mix the two solutions evenly Bring to room temperature. Weigh 46.9 mg of azobisisobutyronitrile (AIBN), dissolve it in 4 g of deionized water, pour it into the above mixed feed solution, and stir at room temperature for 10 minu...

Embodiment 2

[0043] Step (1): Weigh 2g of carboxymethylcellulose (CMC) and 30g of deionized water and mix them in a magnetic stirring water bath at a temperature of 70°C for 30 minutes, so that the carboxymethylcellulose is fully dissolved in water and drops to At room temperature, carboxymethylcellulose solution was obtained.

[0044] Step (2): Weigh 10g of acrylamide (AM), 0.7141g of hydrophobic monomer octadecyl methacrylate SMA, 2.5g of sodium dodecyl sulfate (SDS), 1.5g of NaCl and 20g of deionized water, mix, and stir to dissolve at room temperature.

[0045] Step (3): Mix the carboxymethyl cellulose solution prepared in step (1) with the solution obtained in step (2), and stir in a magnetic stirring water bath at a water temperature of 40°C for 30 minutes to mix the two solutions evenly Bring to room temperature. Weigh 46.9 mg of azobisisobutyronitrile (AIBN), dissolve it in 4 g of deionized water, pour it into the above mixed feed solution, and stir at room temperature for 10 min...

Embodiment 3

[0049] Step (1): Weigh 1g of carboxymethylcellulose (CMC) and mix it with 30g of deionized water, and stir in a magnetic stirring water bath at a temperature of 70°C for 30 minutes, so that the carboxymethylcellulose is fully dissolved in water and then drops to At room temperature, carboxymethylcellulose solution was obtained.

[0050] Step (2): Weigh 10g of acrylamide (AM), 0.7141g of hydrophobic monomer octadecyl methacrylate SMA, 2.5g of sodium dodecyl sulfate (SDS), 1.5g of NaCl and 20g of deionized water, mix, and stir to dissolve at room temperature.

[0051] Step (3): Mix the carboxymethyl cellulose solution prepared in step (1) with the solution obtained in step (2), and stir in a magnetic stirring water bath at a water temperature of 40°C for 30 minutes to mix the two solutions evenly Bring to room temperature. Weigh 46.9 mg of azobisisobutyronitrile (AIBN), dissolve it in 4 g of deionized water, pour it into the above mixed feed solution, and stir at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com