High-elasticity aging-resistant waterproof adhesive and preparation method thereof

An anti-aging, waterproof adhesive technology, applied in adhesives, epoxy resin adhesives, polymer adhesive additives, etc., can solve problems such as increased sensitivity, pollution of the surrounding environment, and increased incidence of cancer among workers, achieving reduction Degradation effect, high bond strength, effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

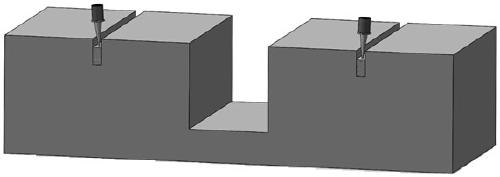

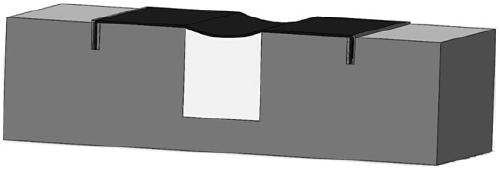

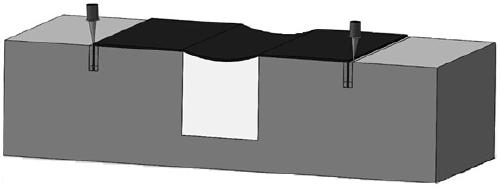

Image

Examples

Embodiment approach 1

[0027] This embodiment provides a high-elastic anti-aging waterproof glue: it is composed of component A and component B with a weight ratio of 1:1; wherein component A is composed of the following raw materials and their parts by weight: bisphenol Type A epoxy resin (E-44) 1400 parts, reactive diluent propylene oxide benzyl ether 150 parts, inactive diluent benzyl alcohol 120 parts, toughening agent polyether 50 parts, hydrophobic fumed silica (R -202) 120 copies. Component B is composed of the following raw materials in parts by weight: 1300 parts of modified phenalkamine, 55 parts of silane coupling agent (KH-550), 3 parts of defoamer Radium (W-10), anti-flow agent (NP- 607) 25 parts, hydrophilic fumed silica (N-20) 90 parts.

[0028] The preparation method of the above-mentioned highly elastic anti-aging waterproof glue is as follows:

[0029] Step 1: Prepare A component

[0030] Weigh 1400 parts of bisphenol A type epoxy resin (E-44), 150 parts of reactive diluent prop...

Embodiment approach 2

[0038] This embodiment provides a high-elastic anti-aging waterproof glue: it is composed of component A and component B with a weight ratio of 1:1; wherein component A is composed of the following raw materials and their parts by weight: bisphenol Type A epoxy resin (a mixture of E-44 and N-127 in a mass ratio of 1:3) 1400 parts, active diluent propylene oxide benzyl ether 140 parts, inactive diluent benzyl alcohol 120 parts, toughening agent poly 50 parts of ether, 130 parts of hydrophobic fumed silica (R-202). Component B is composed of the following raw materials in parts by weight: 1300 parts of modified phenalkamine, 55 parts of silane coupling agent (KH-550), 3 parts of defoamer (Raipu W-10), 3 parts of anti-flow agent (NP- 607) 25 parts, hydrophilic fumed silica (N-20) 90 parts. The preparation method of the above-mentioned highly elastic anti-aging waterproof glue is as follows:

[0039] Step 1: Prepare A component

[0040] Weigh 1400 parts of bisphenol A epoxy res...

Embodiment approach 3

[0045] This embodiment provides a high-elastic anti-aging waterproof glue: it is composed of component A and component B with a weight ratio of 1:1; wherein component A is composed of the following raw materials and their parts by weight: bisphenol Type A epoxy resin (N-127) 1400 parts, reactive diluent propylene oxide benzyl ether 120 parts, inactive diluent benzyl alcohol 120 parts, toughening agent polyether 50 parts, hydrophobic fumed silica (R -202) 130 copies. Component B is composed of the following raw materials in parts by weight: 1300 parts of modified phenalkamine, 55 parts of silane coupling agent (KH-550), 3 parts of defoamer Radium (W-10), anti-flow agent (NP- 607) 25 parts, hydrophilic fumed silica (N-20) 90 parts.

[0046] The preparation method of the above-mentioned highly elastic anti-aging waterproof glue is as follows:

[0047] Step 1: Prepare A component

[0048] Weigh 1400 parts of bisphenol A type epoxy resin (N-127), 120 parts of active diluent prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com