Dedicated press-clip type wiring box for cadmium telluride thin film assembly

A thin film module, cadmium telluride technology, applied in electrical components, photovoltaic power generation, photovoltaic modules and other directions, to achieve the effect of increasing the heat dissipation area, improving the strength, and improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

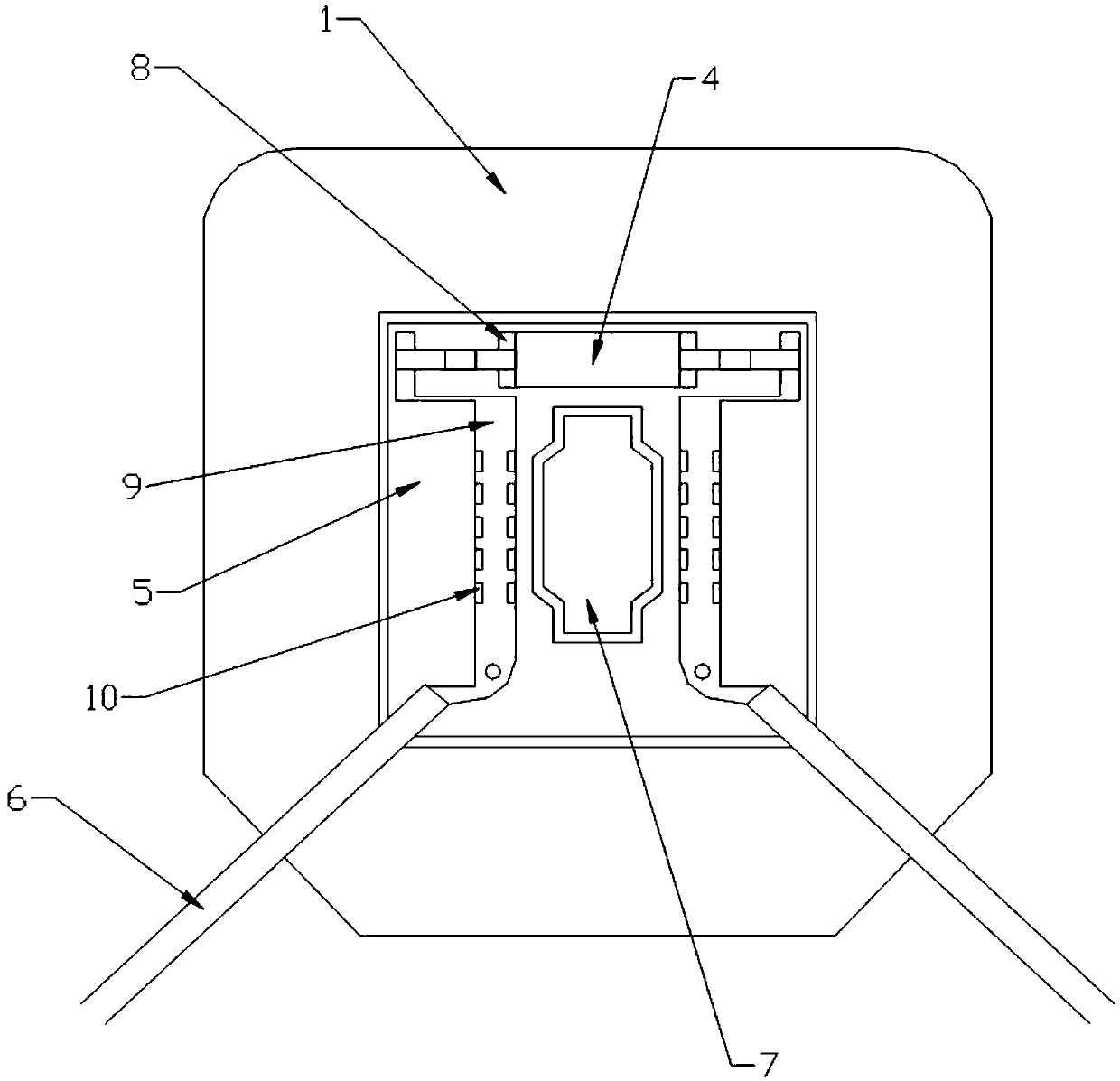

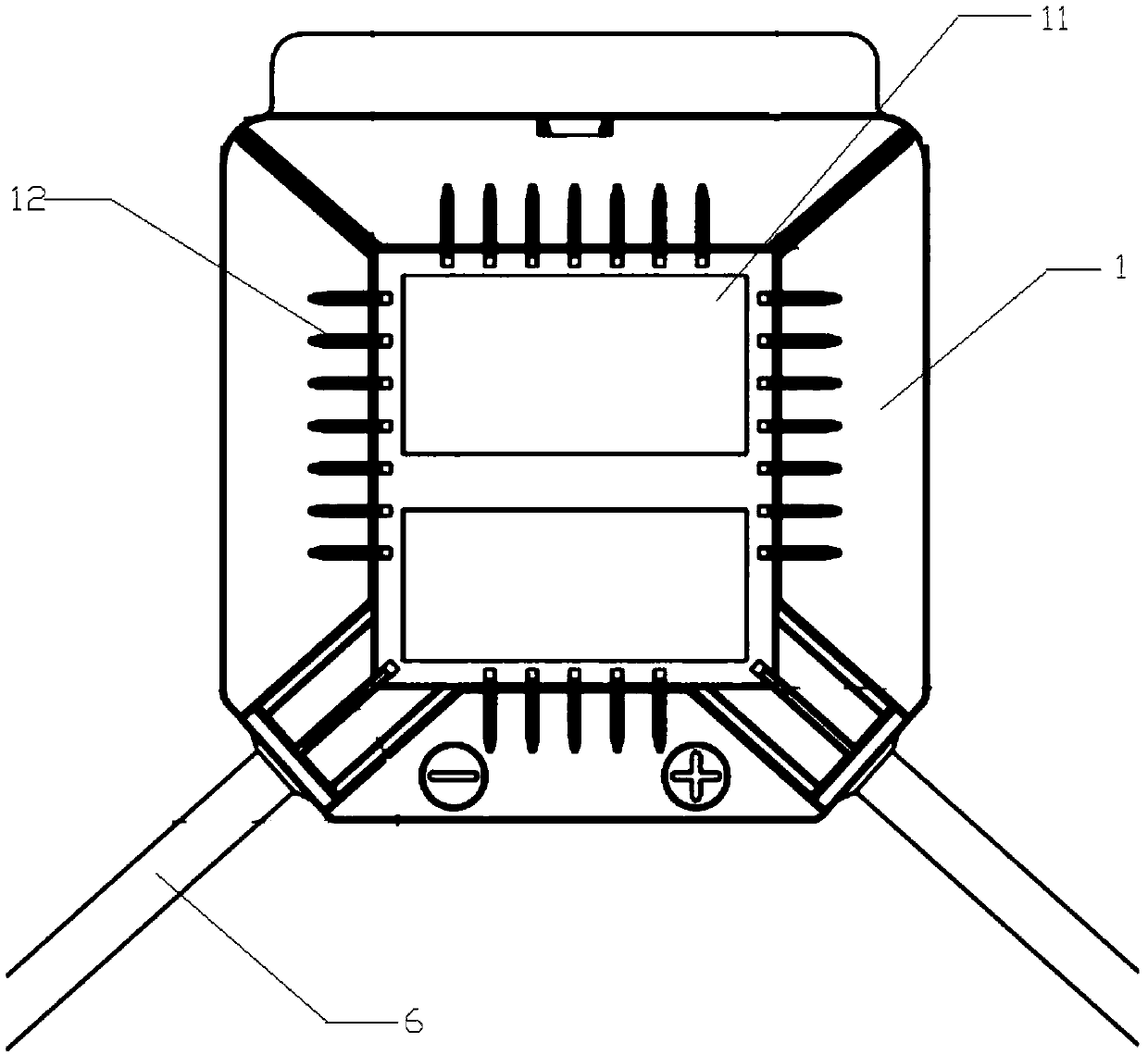

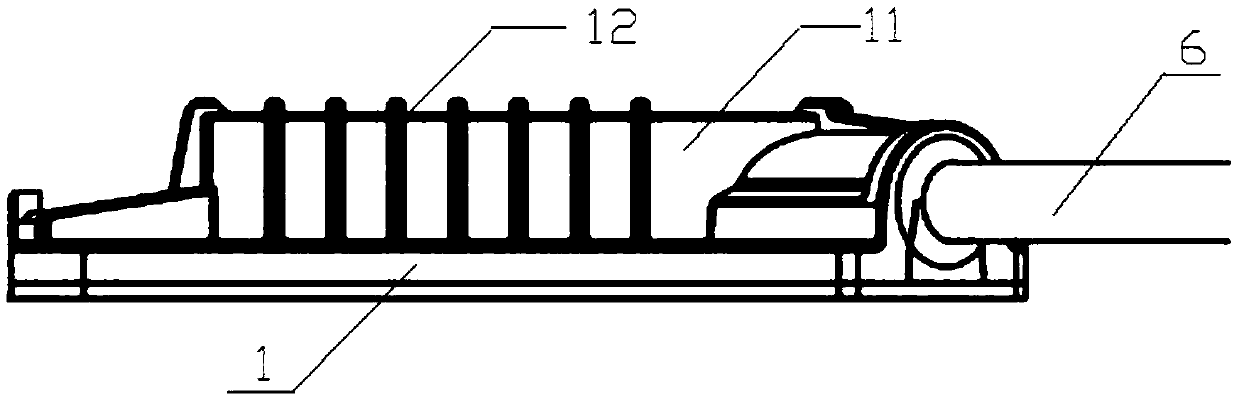

[0024] Such as Figure 1-Figure 7 As shown, the present invention is interlocked to form a box body 1, a bottom plate 2, and a base 3 of an installation cavity; a diode 4 is installed in the installation cavity; Mounting slot 5, the mounting slot 5 forms a boss 11 protruding from the box body 1 on the back of the box body 1; a number of cooling fins 12 are provided on the edge of the boss 11; The wire groove of the groove 5, the cable 6 is connected with the diode 4 through the wire groove; the bottom plate 2 is corresponding to the shape of the installation groove 5 and can be embedded in the installation groove 5 to form a plane with the bottom of the box body 1; the middle part of the bottom plate 2 has a sub-box 15. The bottom of the sub-box body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com