Long-acting anti-icing coating for high-pressure facilities and preparation method of long-acting anti-icing coating

A technology for anti-icing and facilities, applied in coatings, primers, etc., can solve the problems of good hydrophobic effect and poor durability of long-term anti-icing coatings, achieve excellent super-hydrophobic properties, improve roughness, and good electrical resistance Corrosion properties and the effect of volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

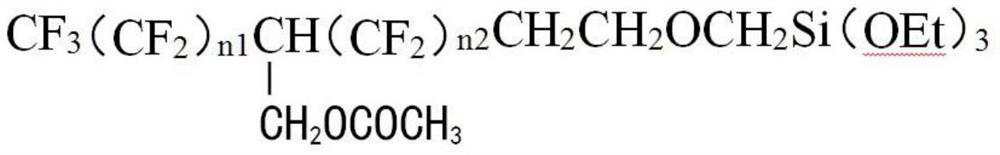

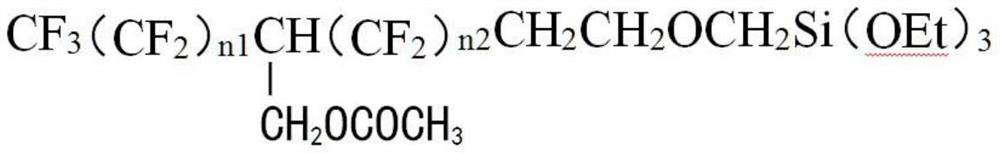

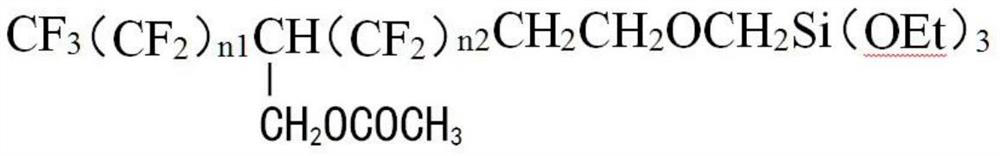

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned long-acting anti-icing coating for high-pressure facilities comprises the steps:

[0048] 1) Add the formulated amount of hydroxyl-terminated polydimethylsiloxane into the kneader, stir evenly at a speed of 40-60rpm, then add white carbon black, aluminum hydroxide and decabromodiphenylethane in sequence, and adjust the speed 80-120rpm; after heating to 80-120°C, turn on the vacuum to remove air bubbles and small molecular substances, and keep it at 80-120rpm for 1.5-2h to mix the materials in the kneader evenly;

[0049] 2) After the material obtained in step 2) is cooled to room temperature, transfer it to a three-roll machine for grinding until the grinding fineness of the material is below 20 μm, then transfer it to the first stirring tank, and then add No. 120 gasoline of the formula , after initial dispersion at a speed of 40-80rpm, transfer to an emulsifier for repeated emulsification for 3-5 times and mix evenly to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com