Composite modification method for phenolic resin adhesive

A technology of composite modification and phenolic resin, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of no better solution, etc., and achieve easy operation and no environmental pollution , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

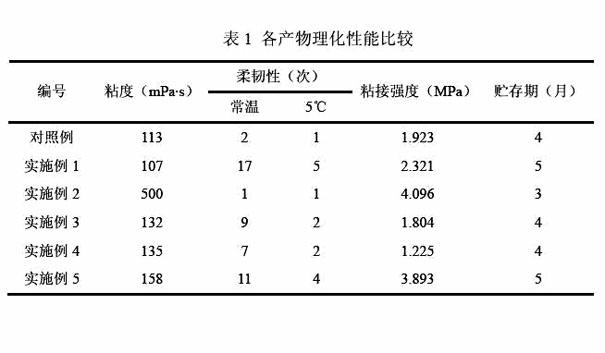

Examples

Embodiment 1

[0030] Add 0.75 g of modifier organosilicon and molten phenol into the reactor, and obtain a dark red transparent solution under the operating conditions of the comparative example.

Embodiment 2

[0032] Under the operating conditions of Example 1, the modifier organosilicon was replaced with 0.5 g of sucrose and the melted phenol was added into the reaction vessel for reaction to obtain a dark red and viscous transparent solution.

Embodiment 3

[0034] Complete the polymerization process according to the operation steps of the comparative example, that is, after reflux at 90°C for 2 hours, then add 2.5 g of modifier polyoxypropylene glycol (polyether 210) into the reactor, and continue to reflux for 2 hours to obtain wine red Clear solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com