Preparation method of phase change microcapsule

A technology of phase-change microcapsules and phase-change materials, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., and can solve the problems of increased breakage rate of phase-change microcapsules, incomplete prepolymer reaction, and free formaldehyde content. Higher problems, achieve the effect of reducing residual formaldehyde content, low damage rate, and low free formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

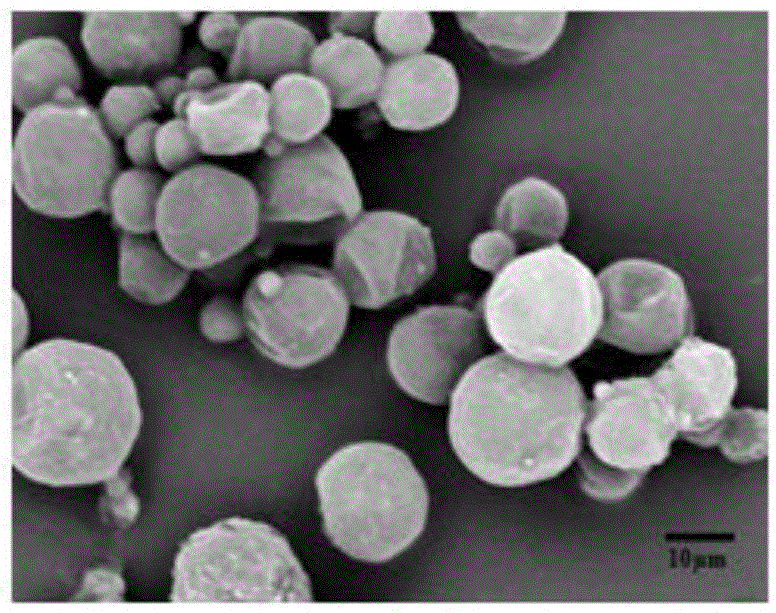

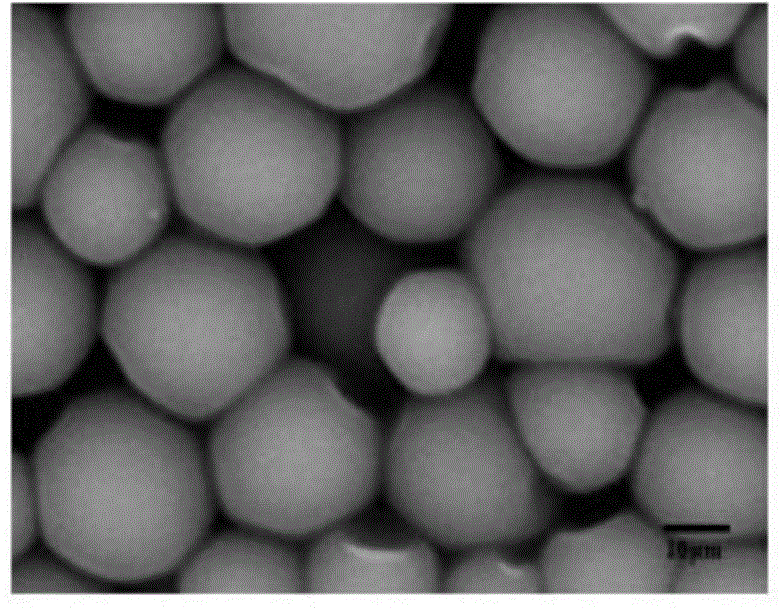

Image

Examples

Embodiment 1

[0024] (1) Synthesis of prepolymer

[0025] Add 10ml of distilled water, 4g of melamine and 9.5g of formaldehyde solution with a concentration of 37% in a 250ml three-necked flask, stir and heat to 70°C, adjust the pH value of the solution to 10 with triethanolamine, and react at a constant temperature for 30min to prepare a melamine-formaldehyde resin preparation Polymer. Divide the prepared prepolymer into two equal parts of 5:5.

[0026] (2) Emulsification of phase change materials

[0027] With 4.5g styrene-maleic anhydride copolymer (SMA) as emulsifier, join in 250ml water, heat to dissolve, then add 40g paraffin, emulsify in high-shear emulsifier, emulsification condition is: rotating speed 5000 rpm, The emulsification time is 10min, and the paraffin emulsion is prepared.

[0028] (3) The first drop of prepolymer

[0029] The pH value of the emulsion in (2) was adjusted to 4 with citric acid, stirred at a speed of 800 rpm, and the temperature of the emulsion was 70°C...

Embodiment 2

[0034] (1) Synthesis of prepolymer

[0035] Add 15ml of distilled water, 2g of melamine, 2g of urea and 9.5g of 37% formaldehyde solution into a 250ml three-necked flask, stir and heat to 70°C, adjust the pH value of the solution to 9 with triethanolamine, and react at a constant temperature for 30min to obtain urea- Melamine-formaldehyde resin prepolymer. The prepared prepolymer was divided into three parts of 6:2:2.

[0036] (2) Emulsification of phase change materials

[0037] With 4.5g styrene-maleic anhydride copolymer (SMA) as emulsifier, join in 250ml water, heat to dissolve, then add 45g paraffin, emulsify in high-shear emulsifier, emulsification condition is: rotating speed 10000 rev / min, The emulsification time is 5min, and the paraffin wax emulsion is obtained.

[0038] (3) The first drop of prepolymer

[0039] The pH value of the emulsion in (2) was adjusted to 3 with citric acid, stirred at a speed of 800 rpm, and the temperature of the emulsion was 70°C. Add...

Embodiment 3

[0046] (1) Synthesis of prepolymer

[0047] Add 15ml of distilled water, 4.5g of urea and 9.5g of 37% formaldehyde solution into a 250ml three-neck flask, stir and heat to 70°C, adjust the pH value of the solution to 8 with triethanolamine, and react at constant temperature for 40min to prepare urea-formaldehyde resin prepolymer. Divide the prepared prepolymer into two parts with a ratio of 7:3.

[0048] (2) Emulsification of phase change materials

[0049] With 4.5g styrene-maleic anhydride copolymer (SMA) as emulsifier, join in 250ml water, heat to dissolve, then add 40g paraffin, emulsify in high-shear emulsifier, emulsification condition is: rotating speed 12000 rpm, The emulsification time is 6min, and the paraffin wax emulsion is obtained.

[0050] (3) The first drop of prepolymer

[0051] The pH value of the emulsion in (2) was adjusted to 3 with citric acid, stirred at a speed of 800 rpm, and the temperature of the emulsion was 70°C. Add 70% prepolymer dropwise to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com