Technology for preparing composite package cushioning material from rice straw fibers

A straw fiber and composite packaging technology, which is applied in the field of preparing composite packaging cushioning materials using straw fiber, can solve the problems of air pollution, unfavorable room temperature effect, environmental pollution, etc., and achieve the effects of low density, simple process flow, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

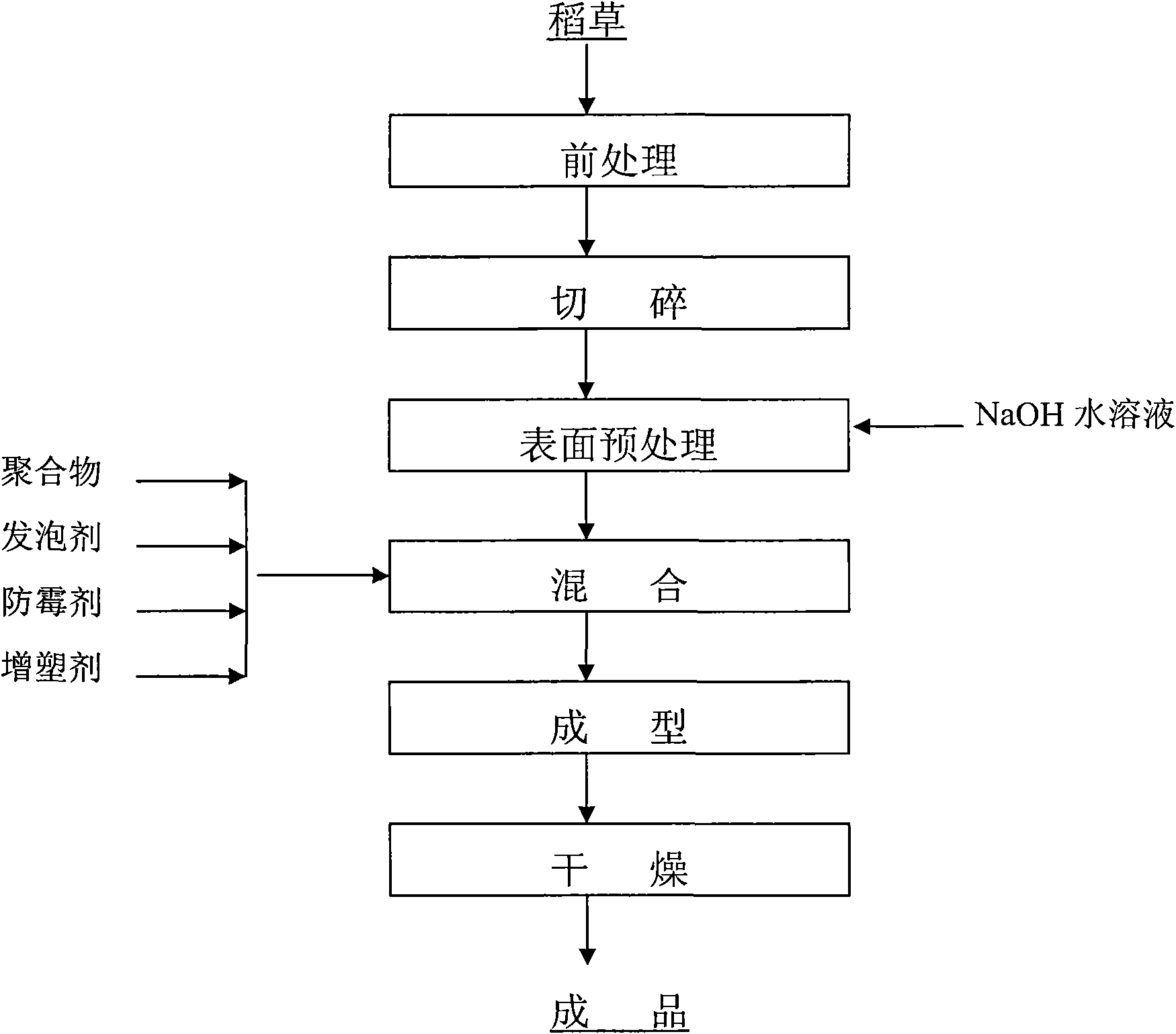

[0028] A process for preparing composite packaging cushioning materials with straw fibers,

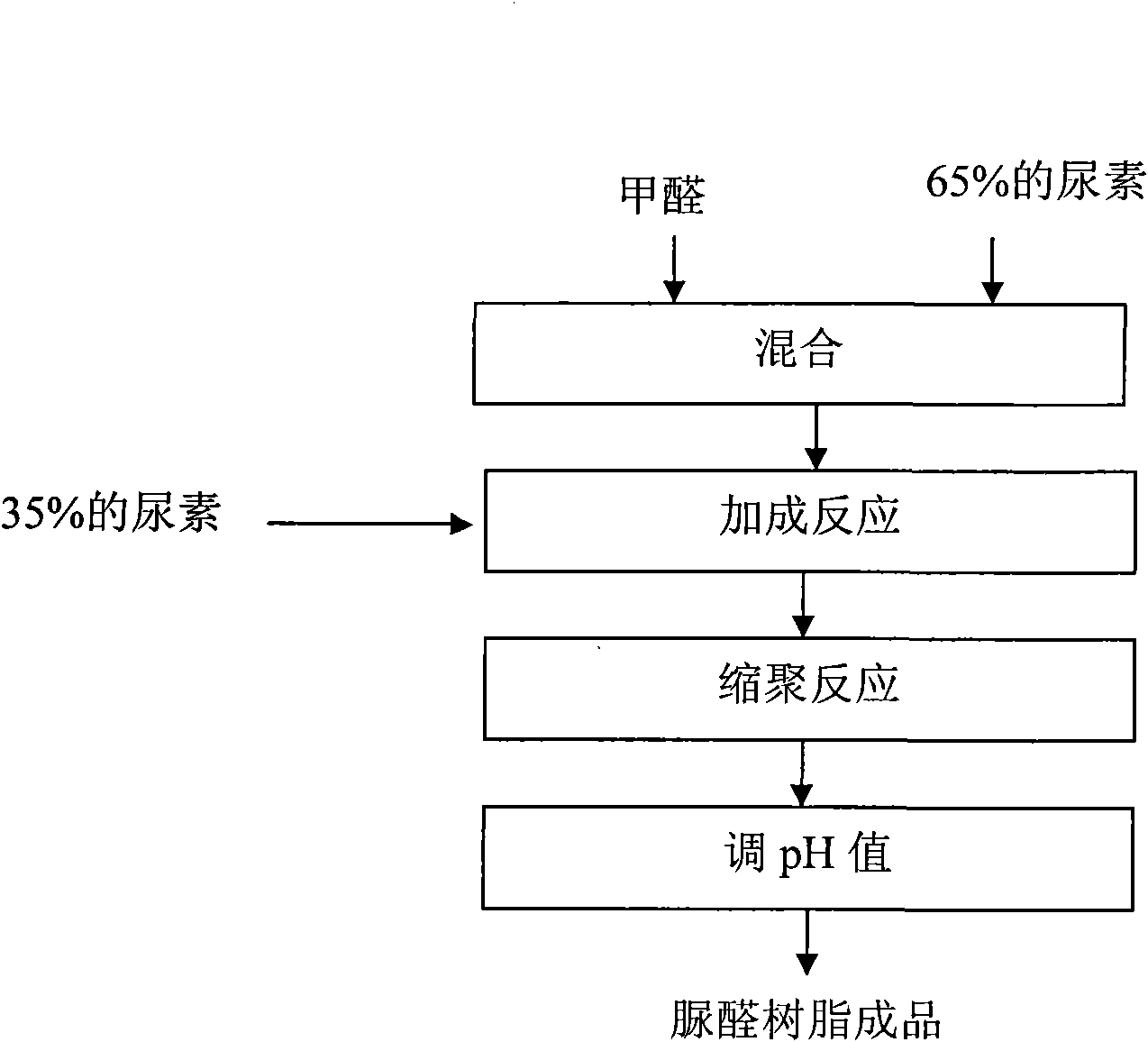

[0029] 1. First prepare a special 35% urea-formaldehyde resin:

[0030] (a), mixing: add 217g formaldehyde solution (37%), 65g urea and 4g hexamethylenetetraammonium into the there-necked flask and stir evenly, adjust the pH to 7.8 with 30% NaOH, heat up to 90°C within 40min, and Constant temperature reaction 20min;

[0031] (b) Addition reaction: keep the temperature of the reaction system at 90°C, add 35g of urea for the second time, and continue the constant temperature reaction for 20min;

[0032] (c), polycondensation reaction: keep the reaction temperature at 90°C, adjust the pH to 5.0 with 20% formic acid, and after 10 minutes of constant temperature reaction, add 20 g of ethylene glycol, and continue the constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com