Catalyst for preparing lactides from lactic acid and method for preparing lactides from lactic acid

A lactide and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of affecting product yield, reaction temperature, etc. The effect of increasing the chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Catalyst preparation:

[0045] a. Preparation of ZnO-TiO 2 Composite oxide: Weigh 17.0g of butyl titanate, add it into 40mL of absolute ethanol under strong stirring, then add 16mL of glacial acetic acid into it, after stirring evenly, slowly drop into it 7.2mL of water, 20mL ethanol, 14.85g Zn(NO 3 ) 2 •6H 2 A solution composed of O zinc nitrate, and keep stirring until a uniform and transparent sol is formed. After standing for 24 hours, after aging the gel, dry it at 100°C for 10 hours to obtain a dry gel, and then bake it at 500°C for 4 hours to obtain ZnO- TiO 2 composite oxides.

[0046] b. Graphene oxide supported ZnO-TiO 2 Composite oxide: ultrasonically disperse 0.1g of graphene oxide into 20mL ethanol solution, then add 9.9g of ZnO-TiO 2 After the composite oxide is evenly stirred, it is transferred to a closed reaction kettle, subjected to hydrothermal treatment at 150-250°C for 6-8 hours, cooled, filtered, washed, and vacuum-dried at 65°C for 12 hours...

Embodiment 2

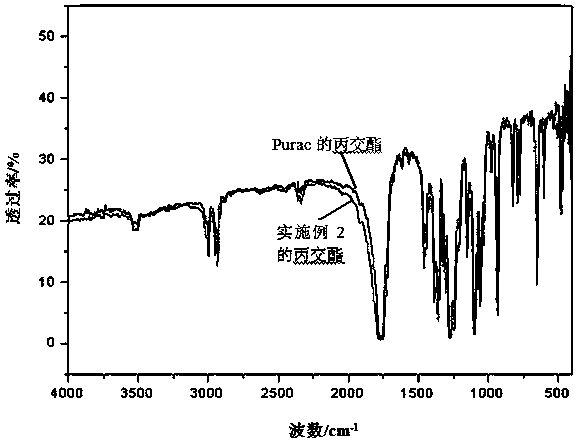

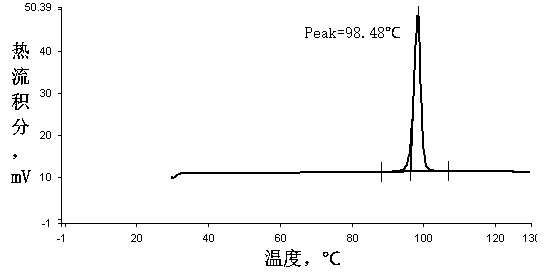

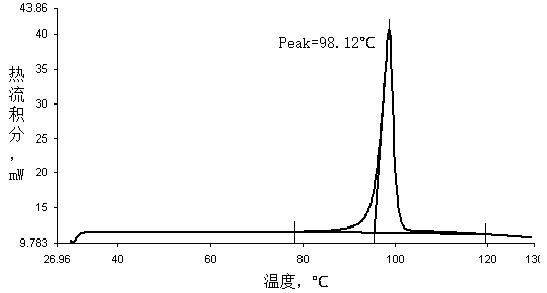

[0048] Preparation of lactide:

[0049] (1) Lactic acid free water: take 600g L-lactic acid (the lactic acid content is about 88.0%), put it into a four-necked flask with a stirring system, use a vacuum circulating pump to maintain the system pressure at 50kpa, and start the process under vacuum. Heating, gradually heating to 110°C~120°C, dehydration for 2 hours, at this time, the free water in the reaction system is slowly distilled out of the reaction system.

[0050] (2) Lactic acid polycondensation reaction to generate lactic acid oligomers: After the free water in the system is almost completely removed, add 3.0 g of the catalyst prepared in Example 1 to the system, and increase the vacuum degree of the system to reduce the pressure of the system to Slowly drop to about 10.0kPa, the temperature of the feed liquid gradually rises to 140~150℃, and react for 3 hours. At this time, the polycondensation reaction occurs between the lactic acid molecules, and the water generated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com