Preparation method for low-cost insulating phenolic resin laminated board resistant to moisture and heat

A phenolic resin, low-cost technology, used in pressure impregnation, manufacturing tools, wood processing appliances, etc., can solve the problems of high water absorption speed, high water absorption rate and high price, and achieve the effect of simple preparation process and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

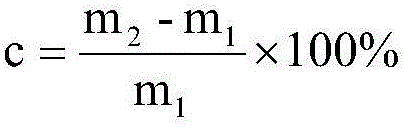

[0022] Specific implementation mode 1: The preparation method of heat and humidity resistant low-cost insulating phenolic resin laminate in this implementation mode is specifically carried out according to the following steps:

[0023] 1. Control the temperature at 45°C to melt phenol, add NaOH solution with a mass concentration of 40%, and react for 10 minutes; add the first batch of formaldehyde solution with a mass concentration of 37%, raise the temperature to 70°C to 75°C, add KH550, and then heat up to 80°C-85°C, react for 1 hour; then lower the temperature to 70°C-75°C, then add the second batch of formaldehyde solution with a mass concentration of 37%, raise the temperature to 80°C-85°C, react for 190-210min, then cool down to 40°C Below ℃, the material is discharged to obtain phenolic resin;

[0024] 2. Dry the poplar veneer, control the moisture content to 5% to 12%, and cool it down;

[0025] 3. Put the veneer obtained in step 2 into the dipping tank, put spacers b...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the molar ratio of phenol to NaOH in step 1 is 1:0.1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the molar ratio of phenol and the total addition amount of two batches of formaldehyde is 1: 2.1 in the step one, wherein the addition amount of the first batch of formaldehyde solution is the same as that of the second batch The mass ratio of formaldehyde solution addition is 4:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com