Method for preparing microorganism-dedicated soybean protein isolate

Soybean protein isolate, special-purpose technology, applied in chemical instruments and methods, plant peptides, peptide sources, etc., can solve the problems of unsuitable microbial culture, low sterilization temperature, and many bumps, and achieves a suitable degree of enzymatic hydrolysis and suitable viscosity. , the effect of increasing the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

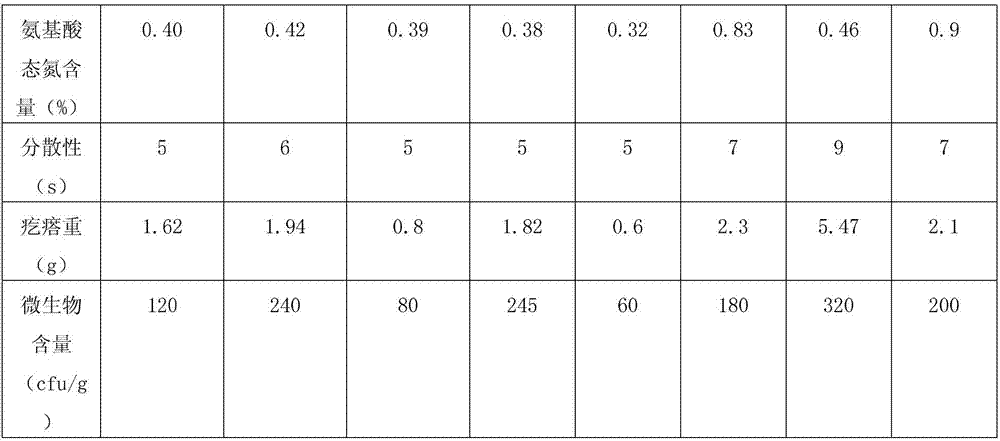

Examples

Embodiment 1

[0038] A method for preparing microorganism-specific soybean protein isolate, comprising the following steps:

[0039] (1) Alkali dissolution: at a temperature of 50-55°C, immerse the low-temperature defatted soybean meal in an NaOH aqueous solution with a pH value of 9.6, the mass ratio of the low-temperature defatted soybean meal to the NaOH aqueous solution is 1:9.5, and the mass concentration is 30 35% hydrochloric acid to adjust the pH value to 6.8, adjust the sugar content to 8.2 with the process water treated by reverse osmosis, and stir for 50 minutes; through solid-liquid separation, a crude protein extract is obtained;

[0040] (2) Acid precipitation: at room temperature, add 30% hydrochloric acid to the crude protein extract obtained in step (1) to adjust the pH of the solution to 4.54, stir for 20 minutes, and centrifuge to obtain the acid precipitation protein, wherein the acid precipitation protein curd is dehydrated 52%;

[0041] (3) Neutralizing enzymatic hydr...

Embodiment 2

[0044] A method for preparing microorganism-specific soybean protein isolate, comprising the following steps:

[0045] (1) Alkali dissolution: at a temperature of 50-55°C, immerse the low-temperature defatted soybean meal in a KOH aqueous solution with a pH value of 9.8, the mass ratio of the low-temperature defatted soybean meal to the KOH aqueous solution is 1:9.5, and the mass concentration is 30- 35% hydrochloric acid to adjust the pH value to 6.8, adjust the sugar content to 8.6 with the process water treated by reverse osmosis, and stir for 50 minutes; through solid-liquid separation, a crude protein extract is obtained;

[0046] (2) Acid precipitation: at room temperature, add 30% hydrochloric acid to the protein crude extract obtained in step (1) to adjust the pH of the solution to 4.52, stir for 20 minutes, and centrifuge to obtain the acid precipitation protein, wherein the acid precipitation protein curd is dehydrated 51.6%;

[0047] (3) Neutralization and enzymoly...

Embodiment 3

[0050] A method for preparing microorganism-specific soybean protein isolate, comprising the following steps:

[0051] (1) Alkali dissolution: at 50-55°C, soak the low-temperature defatted soybean meal in a KOH aqueous solution with a pH value of 9.6, the mass ratio of the low-temperature defatted soybean meal to the KOH aqueous solution is 1:9.5, and the mass concentration is 30-35 % hydrochloric acid to adjust the pH value to 7, adjust the sugar content to 8.2 with the process water treated by reverse osmosis, and stir for 50 minutes; through solid-liquid separation, the protein crude extract is obtained;

[0052] (2) Acid precipitation: at room temperature, add 30% hydrochloric acid to the protein crude extract obtained in step (1) to adjust the pH of the solution to 4.55, stir for 20 minutes, and centrifuge to obtain the acid precipitation protein, wherein the acid precipitation protein curd is dehydrated 51.7%;

[0053] (3) Neutralization and enzymolysis: at room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com