Flame-retardant bismaleimide resin and preparation method thereof

A technology of maleimide resin and bismaleimide, which is applied in the field of flame-retardant bismaleimide resin and its preparation, can solve the problem that the flame-retardant modification effect of polysiloxane is not fully reflected , reduced thermal stability and rigidity, large dielectric constant and loss, etc., to achieve the effect of environmentally friendly operation process, high flame retardancy and toughness, and outstanding dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

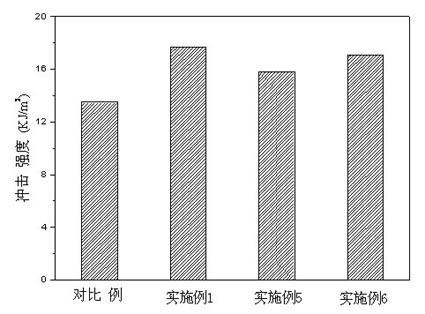

Examples

Embodiment 1

[0036] Embodiment 1: This embodiment provides a kind of flame-retardant bismaleimide resin, and its preparation steps are as follows:

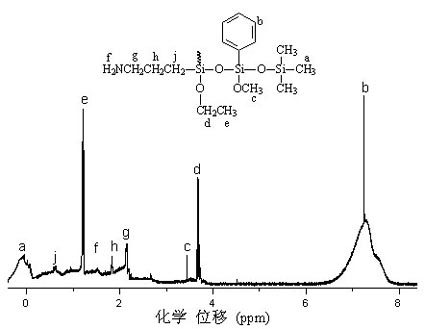

[0037] 1. Synthesis of polysiloxanes containing amino functional groups

[0038]1) Under stirring conditions, add 13.26g γ-aminopropyltriethoxysilane, 27.7g phenyltrimethoxysilane and 3.67g deionized water into a three-necked flask, and reflux at a constant temperature of 40°C for 2 hours to obtain solution A;

[0039] 2) Under stirring conditions, dissolve 32.98g of hexamethyldisilazane in a mixed solvent of 16.50mL of methanol and 33.00mL of pyridine to obtain solution B;

[0040] 3) Under stirring conditions, pour solution B into solution A at 60°C, and reflux for 6 hours at a constant temperature, and then distill under reduced pressure to obtain a crude product;

[0041] 4) After dissolving the crude product in dichloromethane, filter out the insoluble matter, and after vacuum distillation and vacuum drying, the polysiloxane containing ...

Embodiment 2

[0050] 1. Synthesis of amino-functional polysiloxanes

[0051] 1) Under stirring conditions, add 0.44g of γ-aminopropyltriethoxysilane, 39.20g of phenyltrimethoxysilane, and 5.50g of deionized water into the three-necked flask, and reflux at a constant temperature of 90°C for 8 hours to obtain a solution A;

[0052] 2) Under stirring conditions, dissolve 48.60 g of hexamethyldisiloxane in a mixed solvent of 21.60 mL of methanol and 10.80 mL of pyridine to obtain solution B;

[0053] 3) Under stirring conditions, pour solution B into solution A at 90°C, and reflux for 8 hours at a constant temperature, and obtain a crude product after vacuum distillation;

[0054] 4) After dissolving the crude product in dichloromethane, the insoluble matter was filtered off, and after vacuum distillation and vacuum drying, the polysiloxane containing amino functional groups was obtained.

[0055] 2. Preparation of flame retardant bismaleimide resin

[0056] By weight, 100 g of toluene-type ...

Embodiment 3

[0058] 1. Synthesis of amino-functional polysiloxanes

[0059] 1) Under stirring conditions, add 22.10g γ-aminopropyltriethoxysilane, 13.6g methyltrimethoxysilane, and 4.68g deionized water into a three-necked flask, and reflux at a constant temperature of 60°C for 5 hours to obtain solution A;

[0060] 2) Under stirring conditions, dissolve 48.16g of hexamethyldisilazane in a mixed solvent of 24.08mL of methanol and 24.08mL of pyridine to obtain solution B;

[0061] 3) Under stirring conditions, pour solution B into solution A at 70°C, and reflux for 7 hours at a constant temperature, and then distill under reduced pressure to obtain a crude product;

[0062] 4) After dissolving the crude product in dichloromethane, the insoluble matter was filtered off, and after vacuum distillation and vacuum drying, the polysiloxane containing amino functional groups was obtained.

[0063] 2. Preparation of flame retardant bismaleimide resin

[0064] By weight, 100 g of bismaleimide res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com