Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Active release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

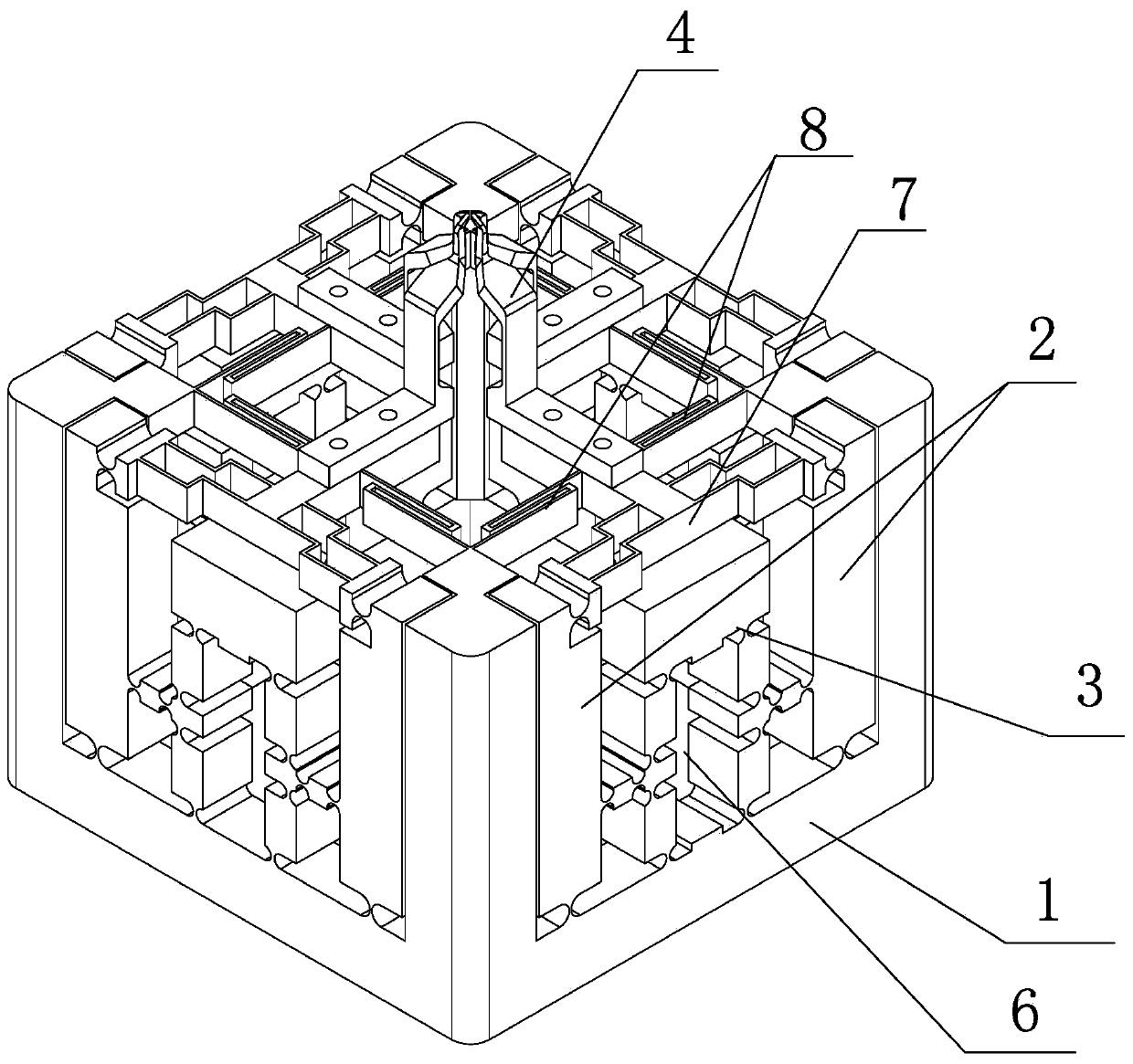

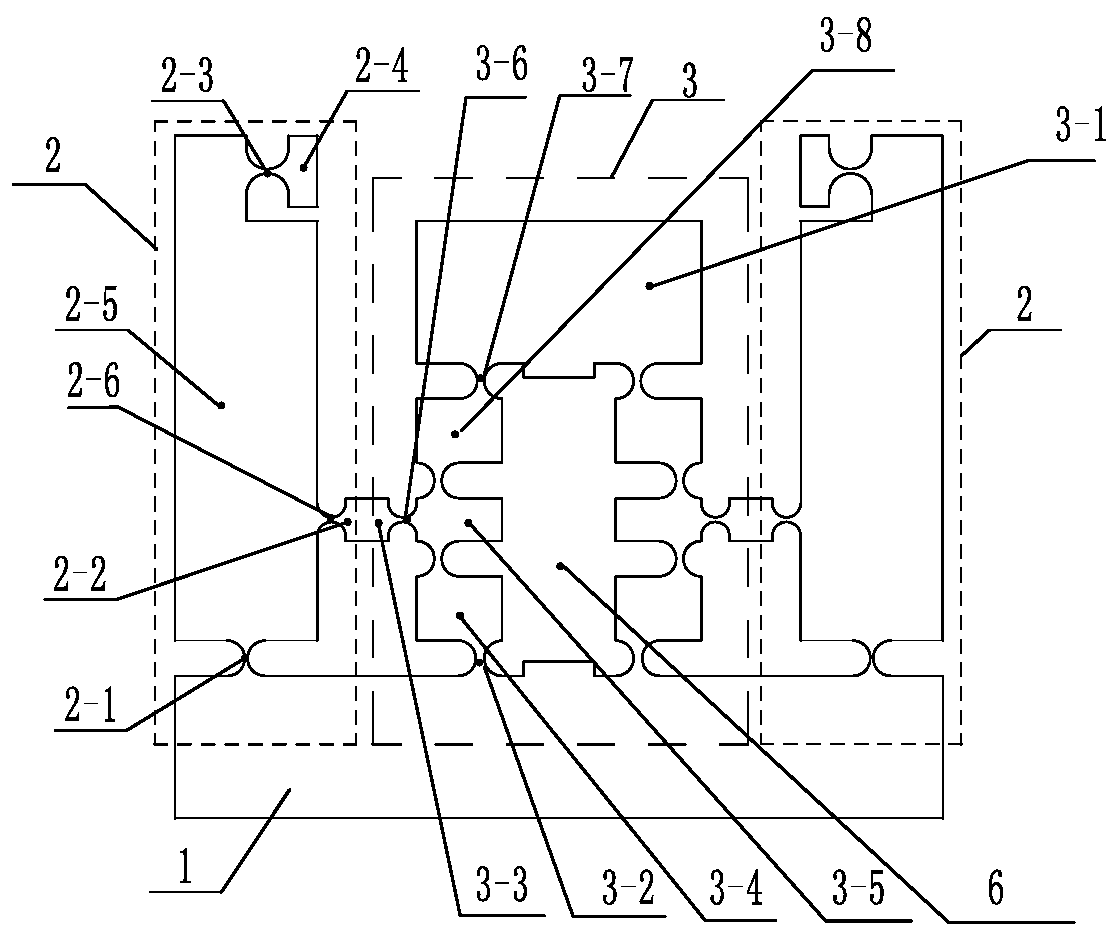

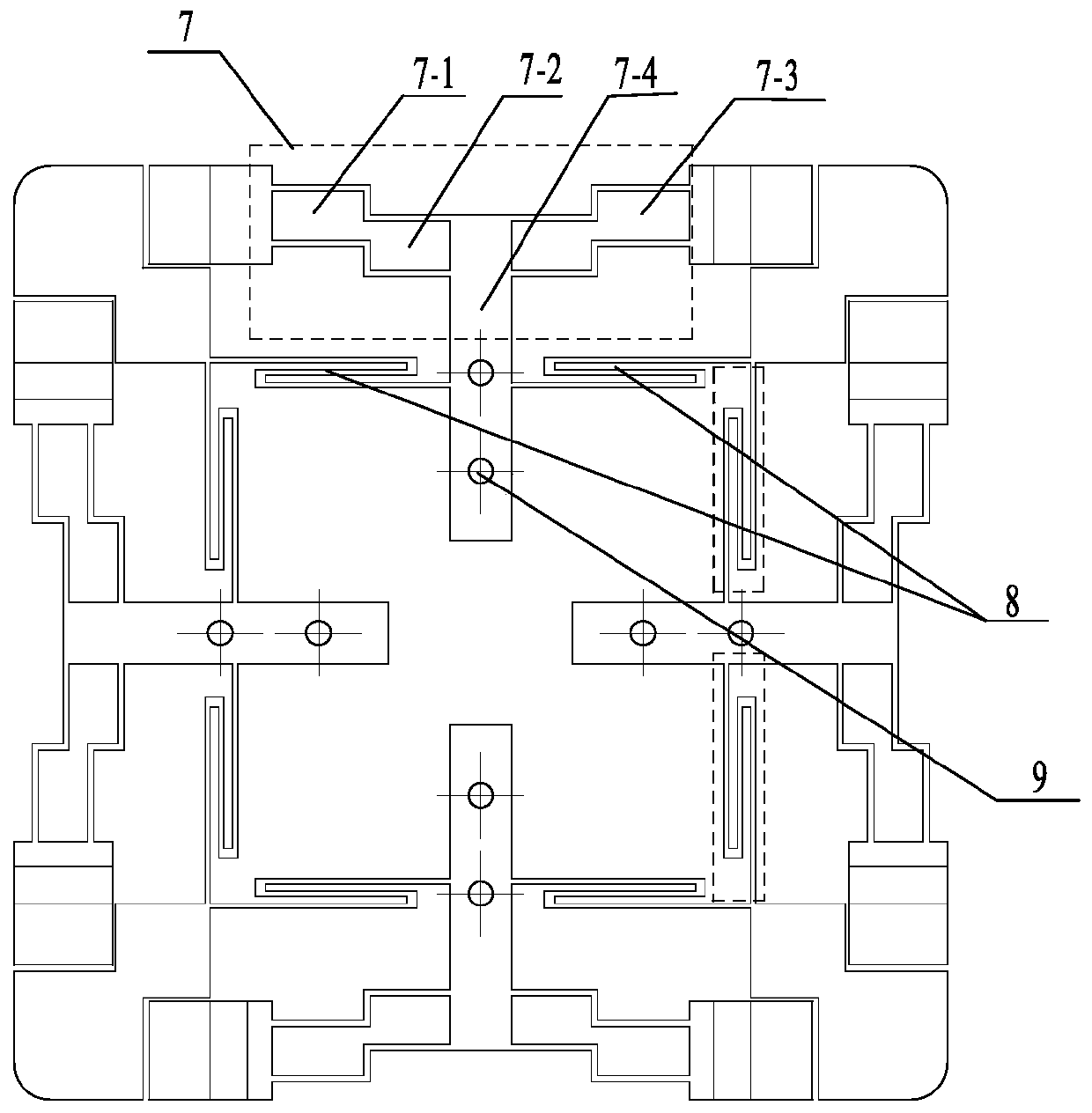

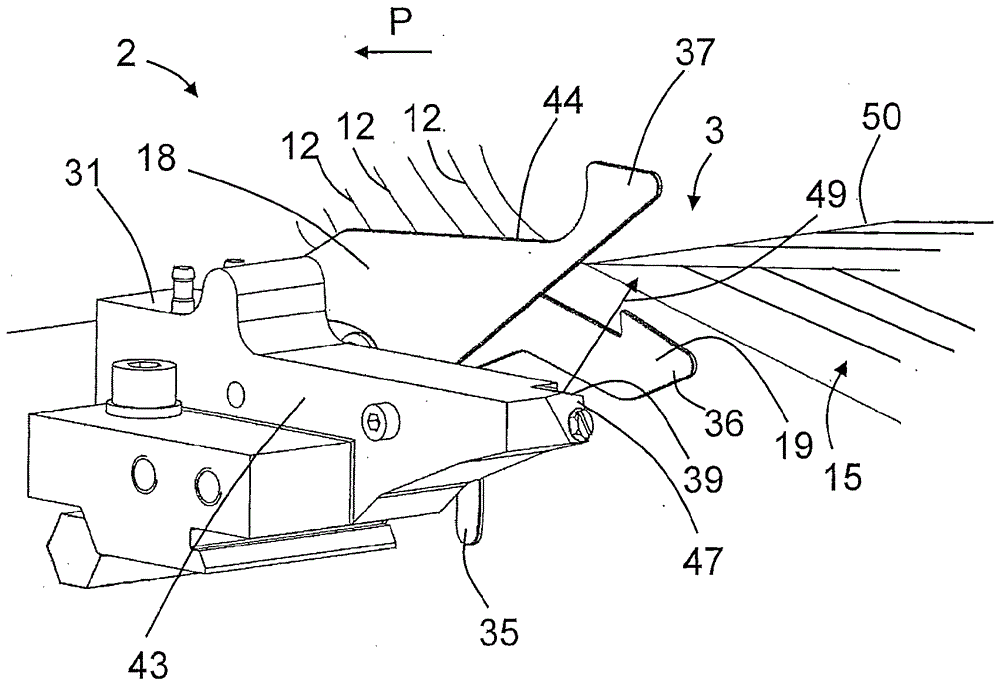

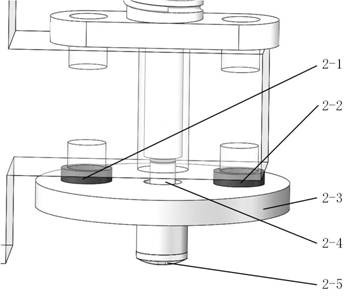

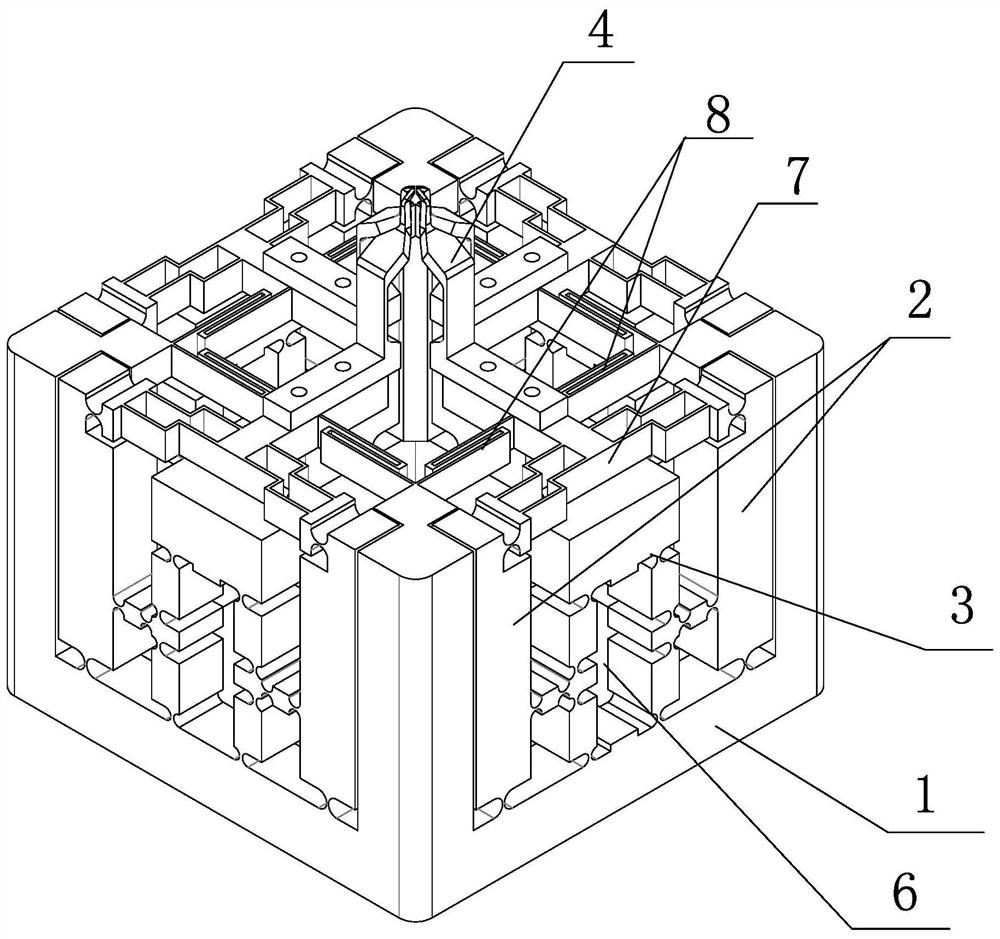

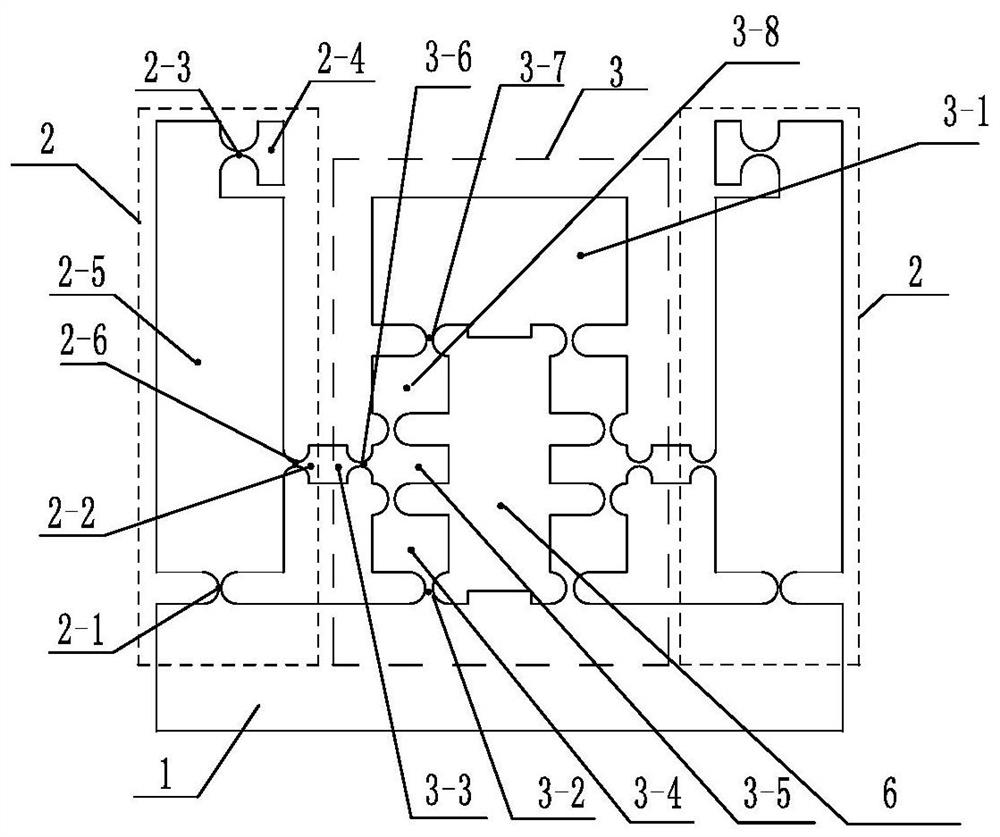

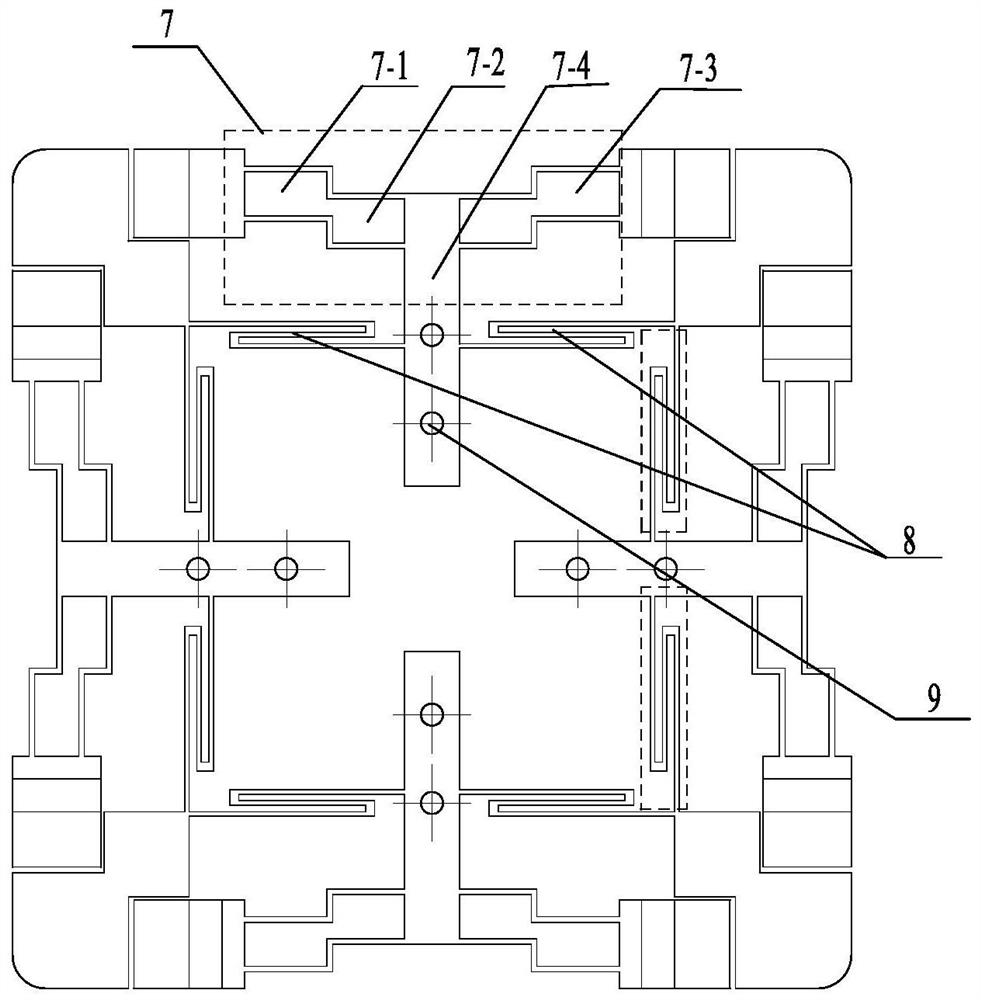

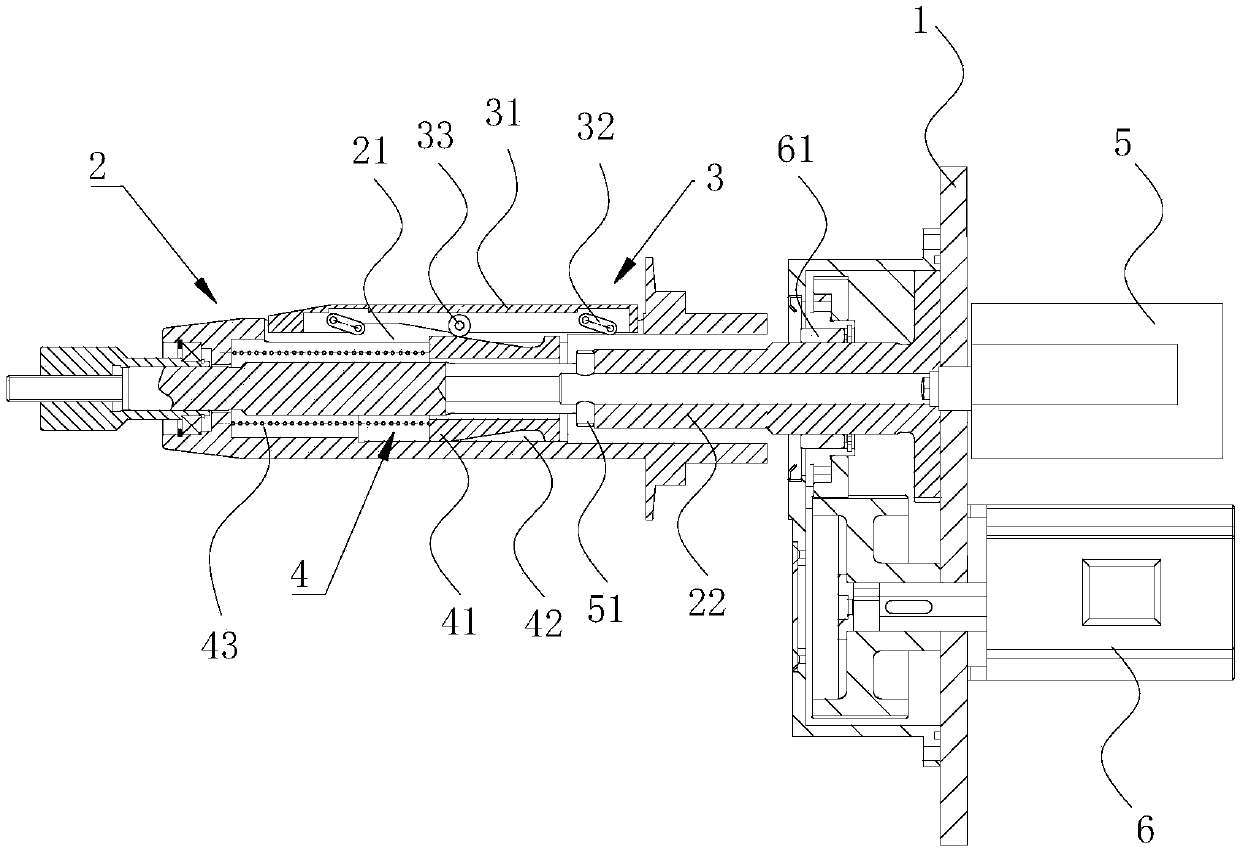

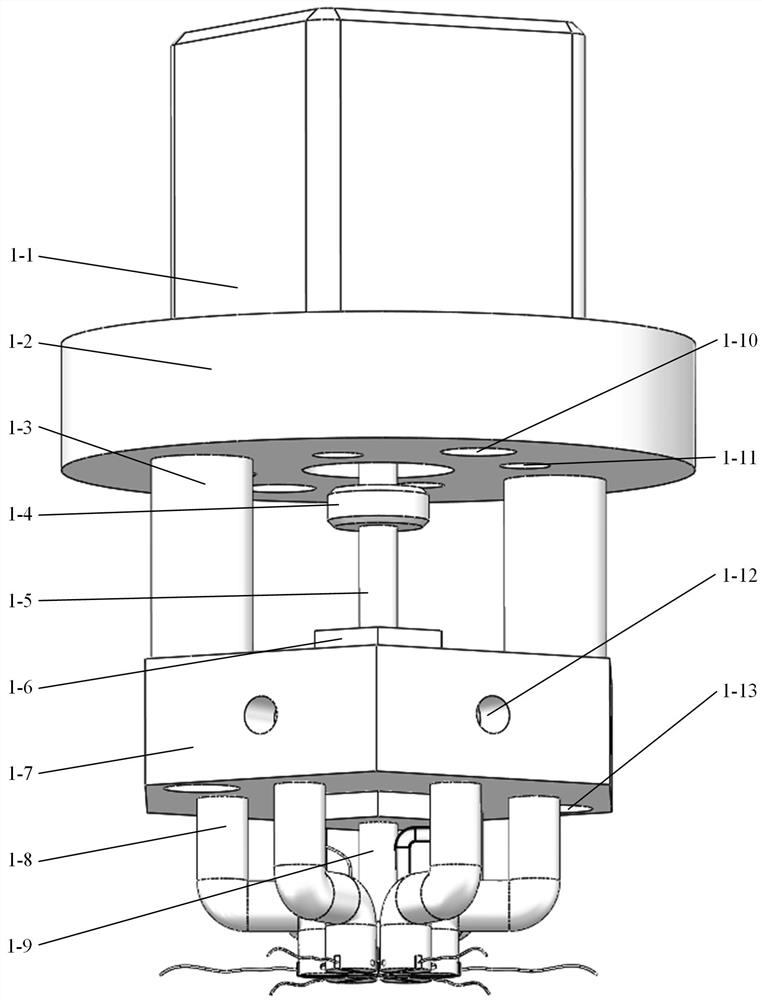

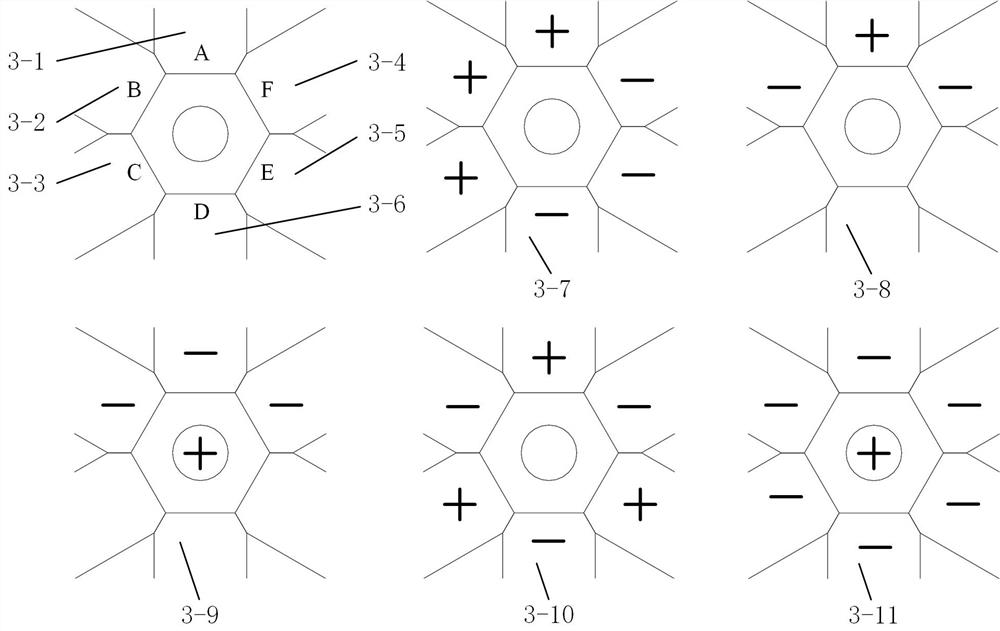

Symmetric spatial three-dimensional micro manipulator with three-stage motion amplifying mechanism

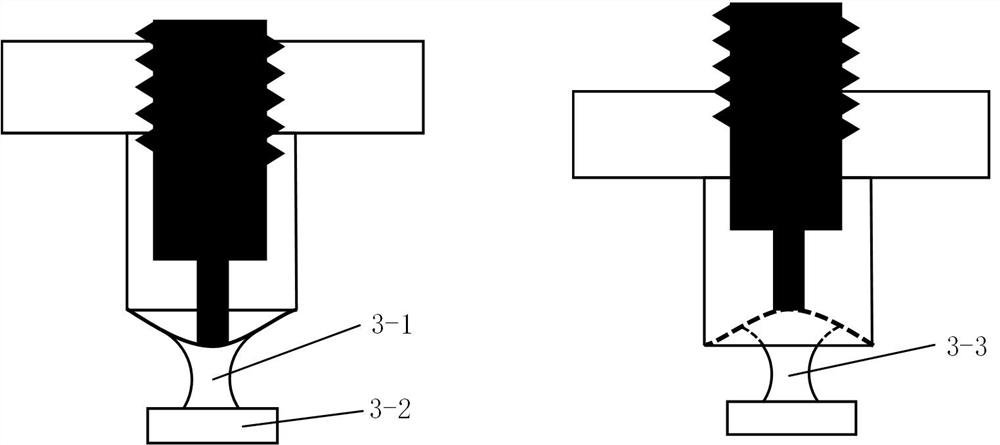

ActiveCN109909976AFirmly connectedActive releaseProgramme-controlled manipulatorGripping headsShaped beamThree stage

The invention discloses a symmetric spatial three-dimensional micro manipulator with a three-stage motion amplifying mechanism. The micro manipulator is small in size, compact in structure, stable andreliable in clamping force and high in movement precision. The micro manipulator is composed of a base and a plurality of amplification clamping modules, wherein each amplification clamping module comprises a piezoelectric ceramic driver, a bridge type displacement amplification mechanism, two lever displacement amplification mechanisms, a Z-shaped beam displacement amplification mechanism, two flexible guide mechanisms and a clamping jaw; the piezoelectric ceramic driver is arranged between the base and the movable end of the bridge type displacement amplification mechanism; and the piezoelectric ceramic driver drives the movable end of the bridge type displacement amplification mechanism, the output end of the bridge type displacement amplification mechanism drives the input ends of thelever displacement amplification mechanisms, the output end of each lever displacement amplification mechanism drives the input end of the Z-shaped beam displacement amplification mechanism, and theoutput end of the Z-shaped beam displacement amplification mechanism is fixedly connected with the clamping jaw. The micro manipulator is compact in structure, stable and reliable in clamping force, low in cost and high in movement precision.

Owner:TIANJIN UNIV

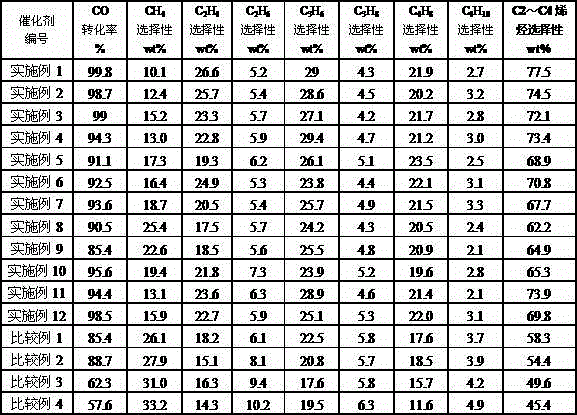

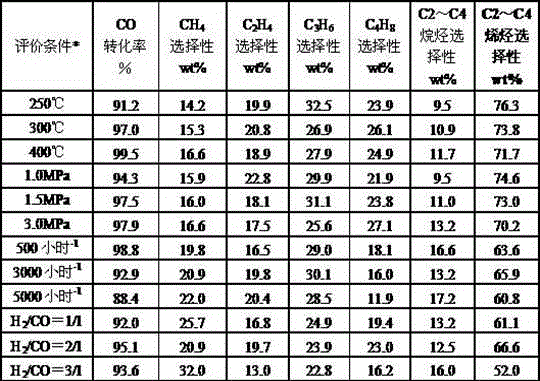

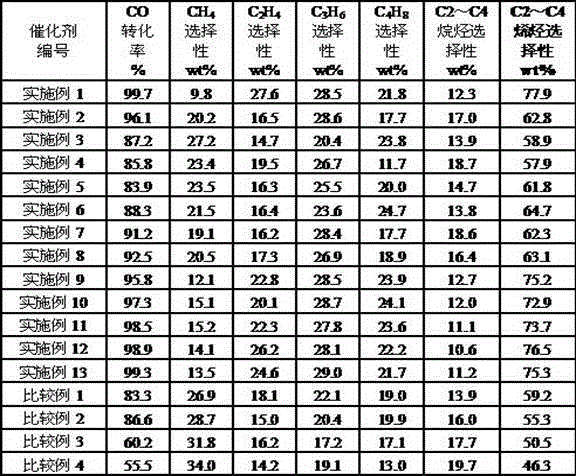

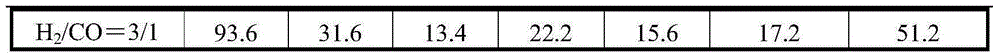

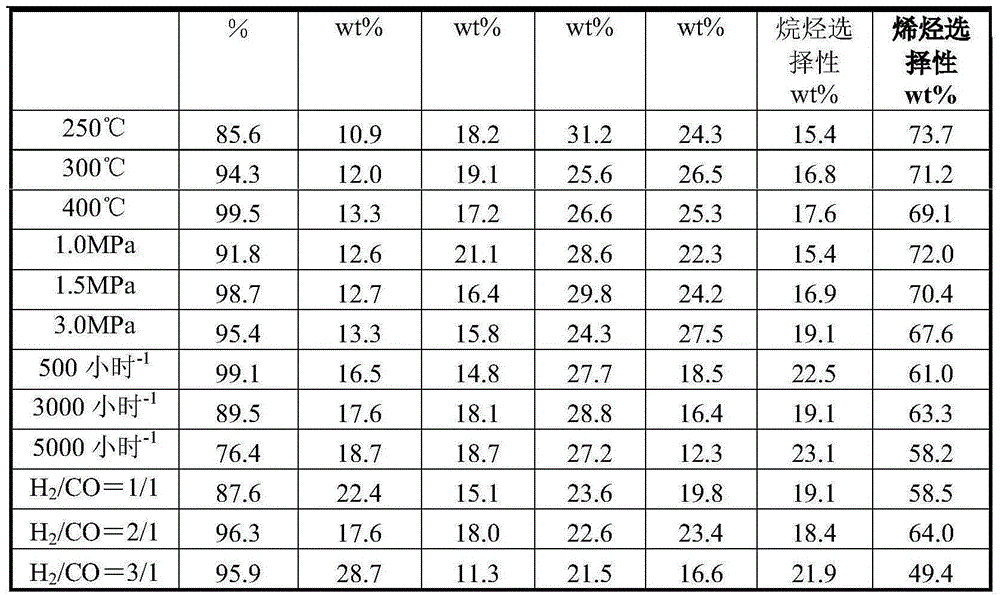

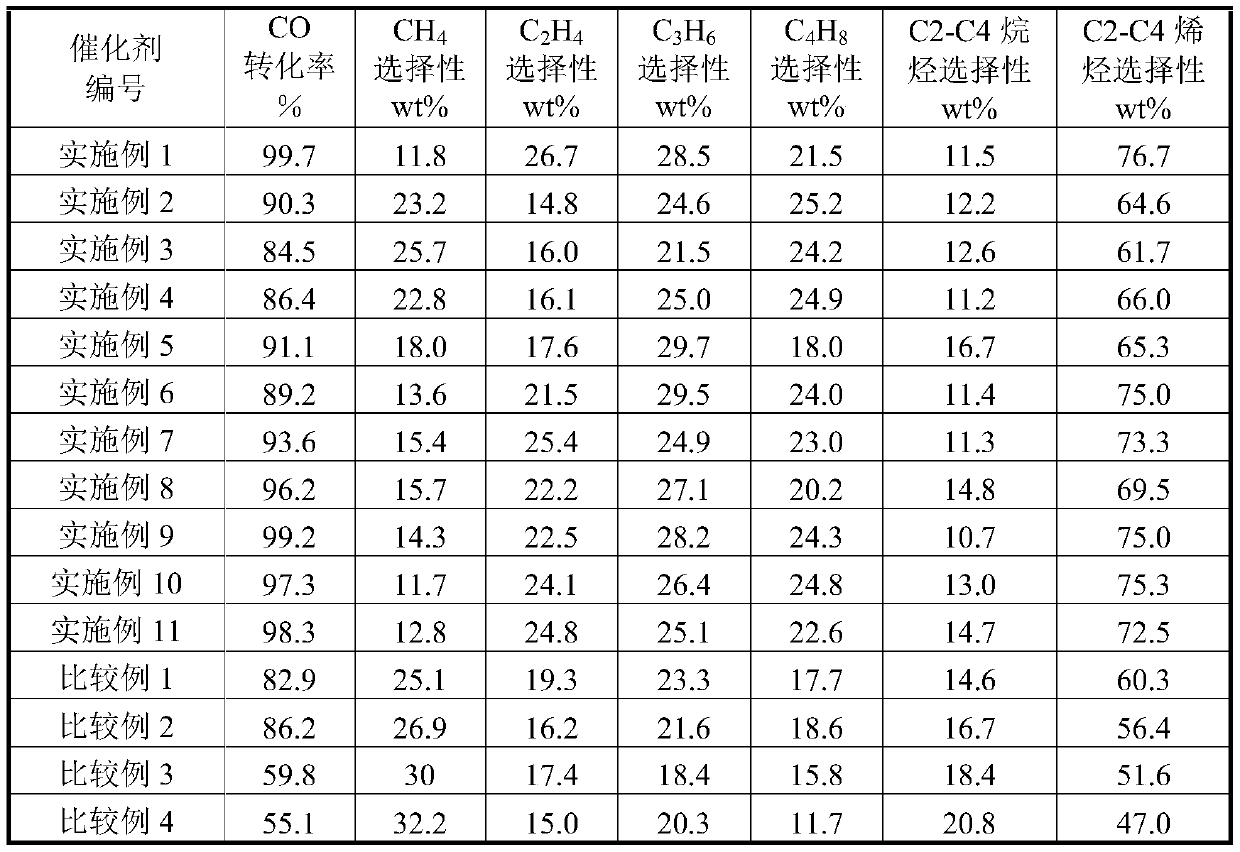

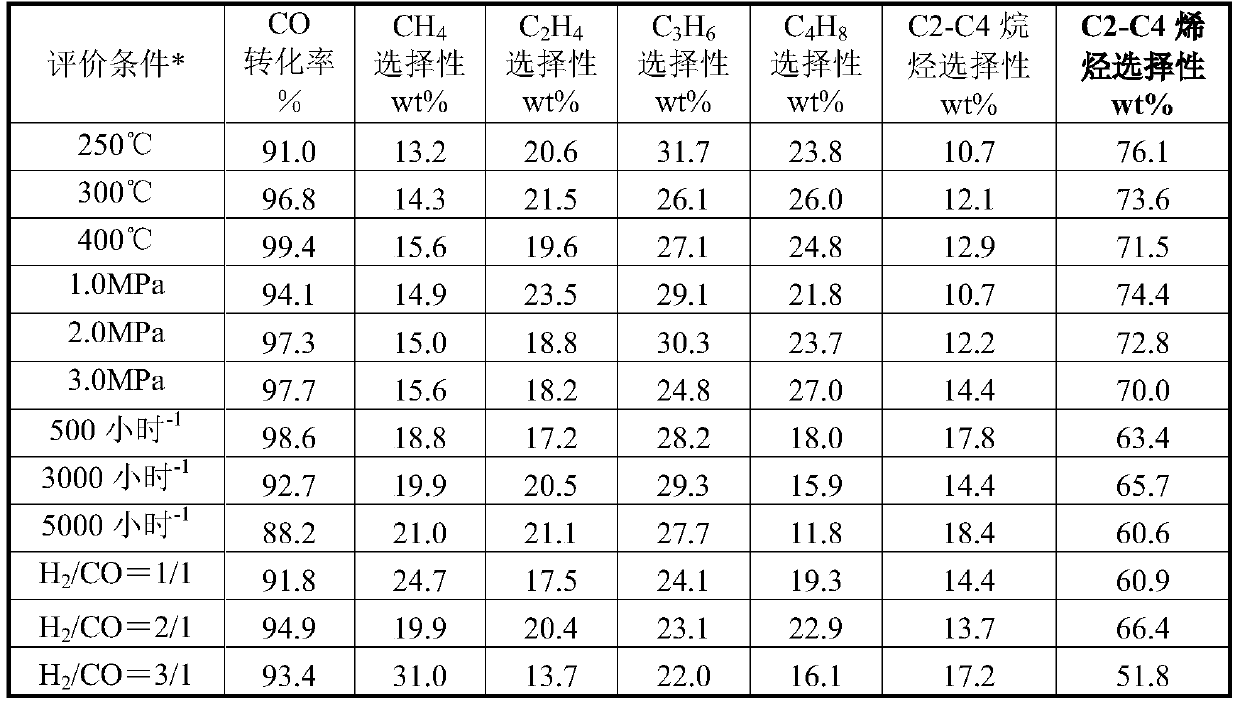

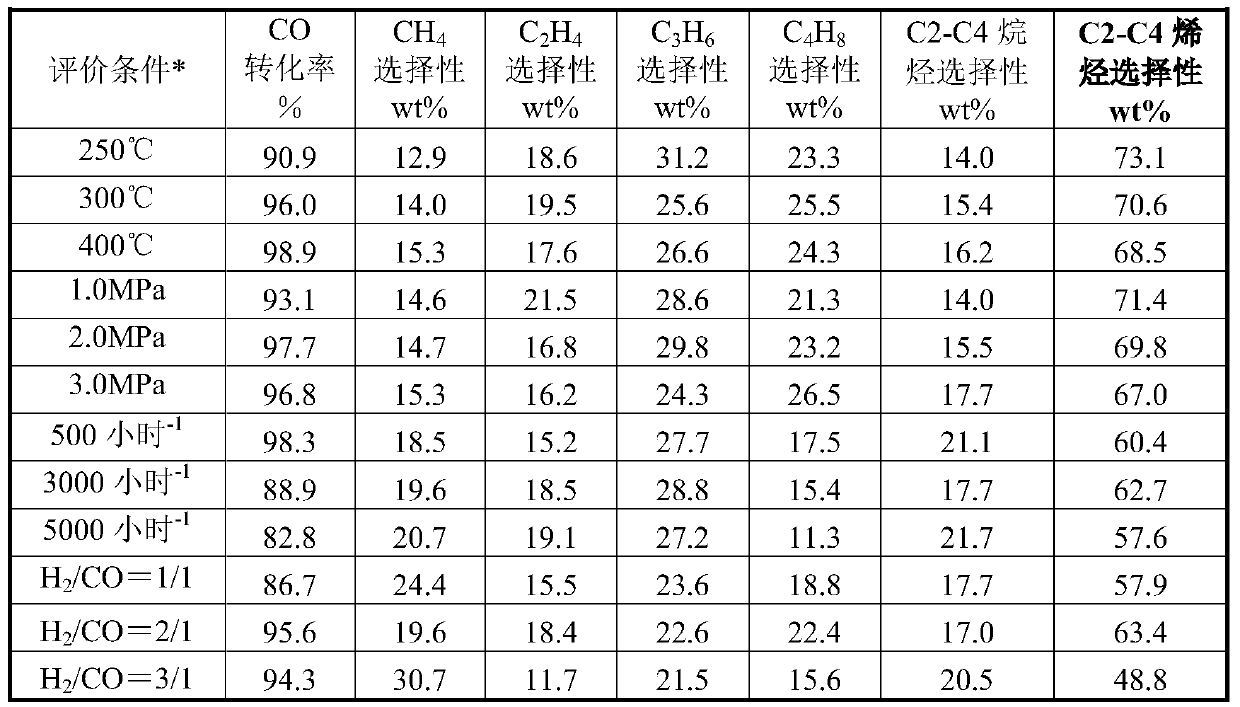

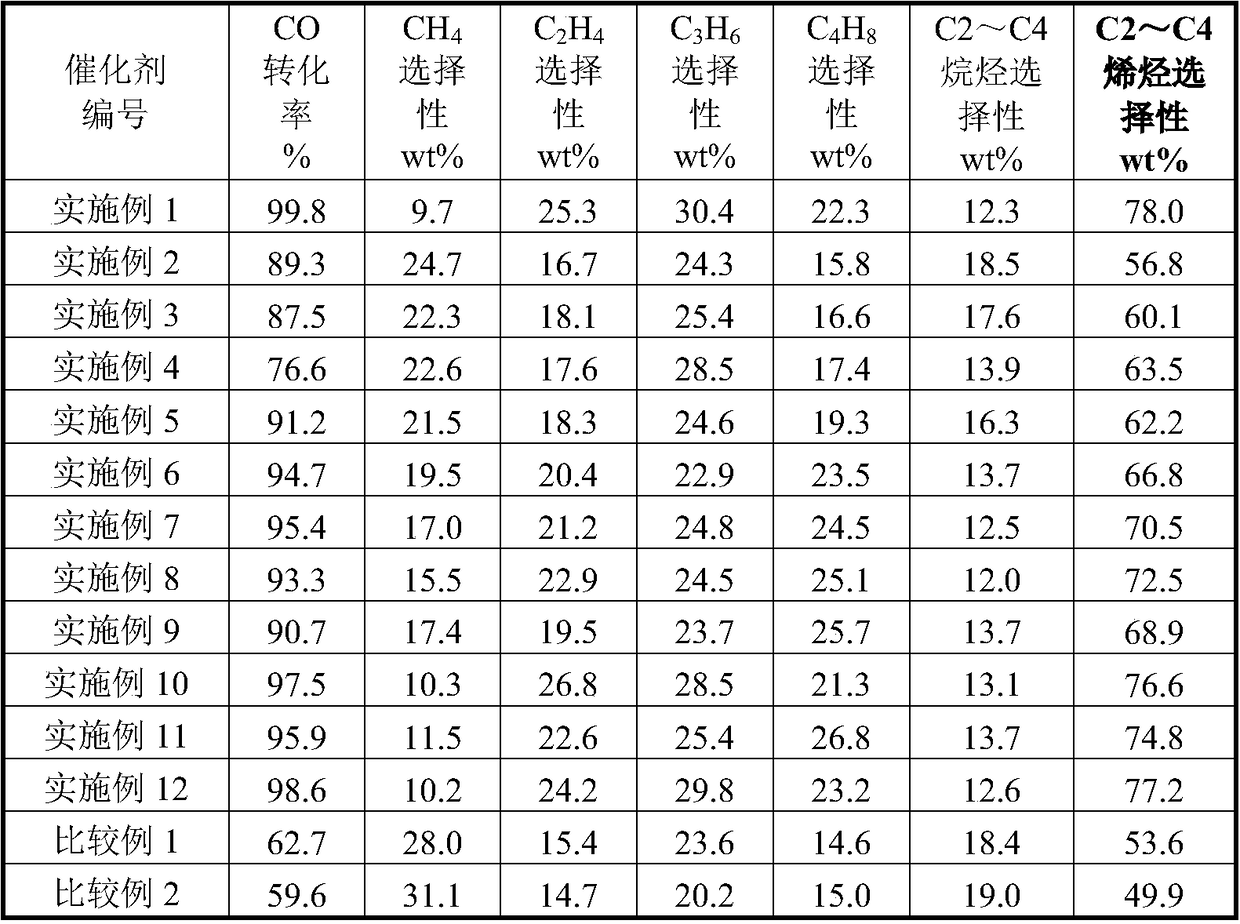

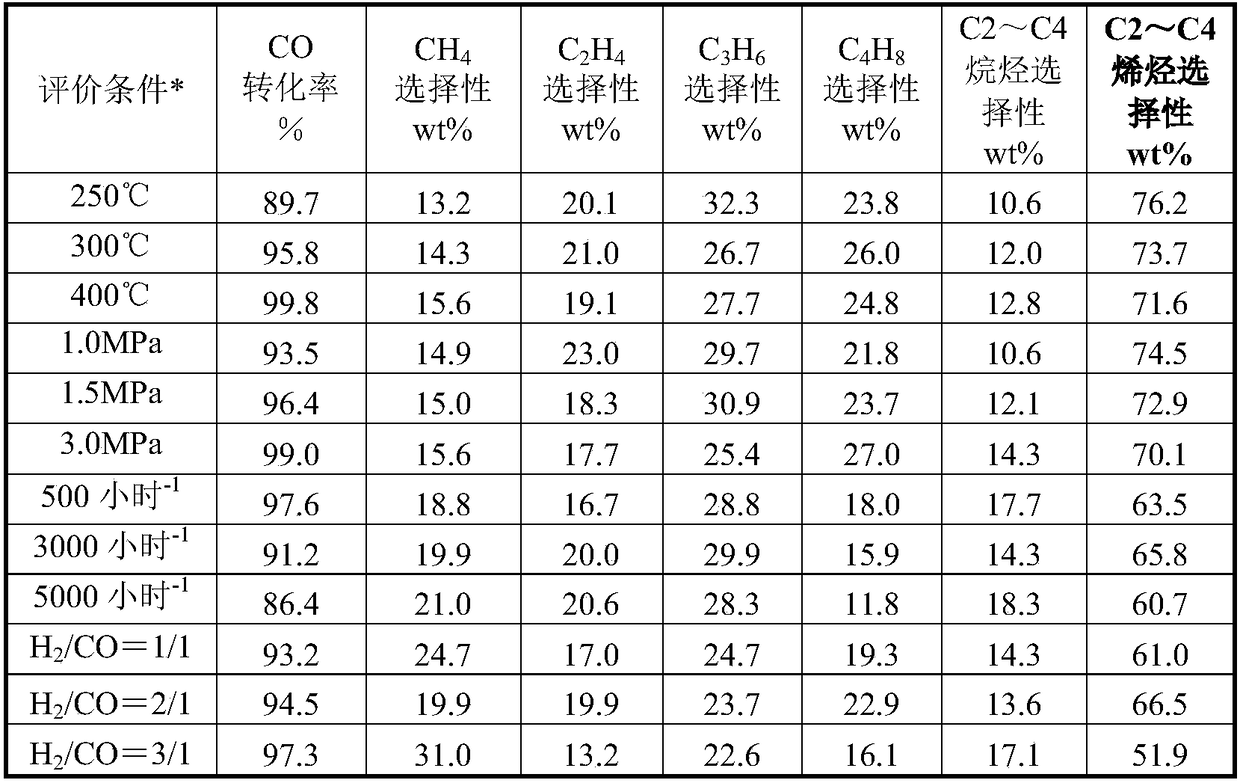

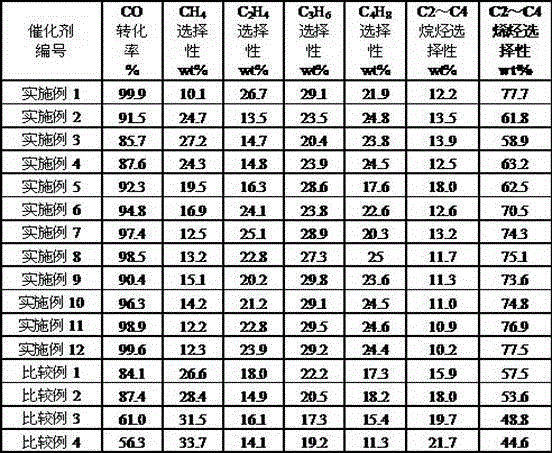

Iron catalyst for preparing light olefins by use of synthesis gas and preparation method of iron catalyst

ActiveCN104549342AHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsNiobiumLanthanum

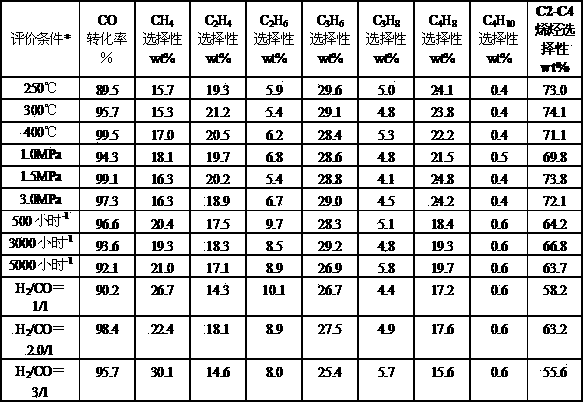

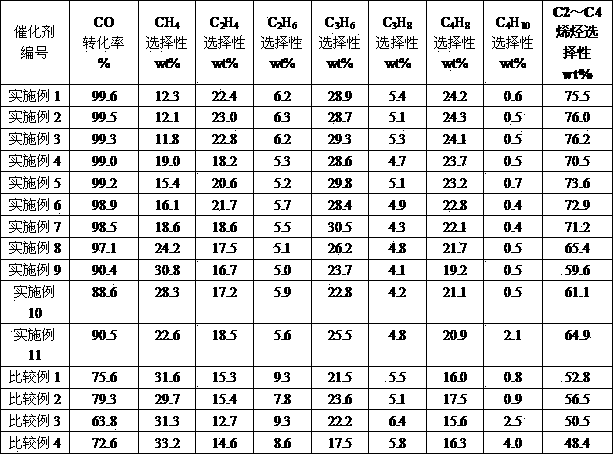

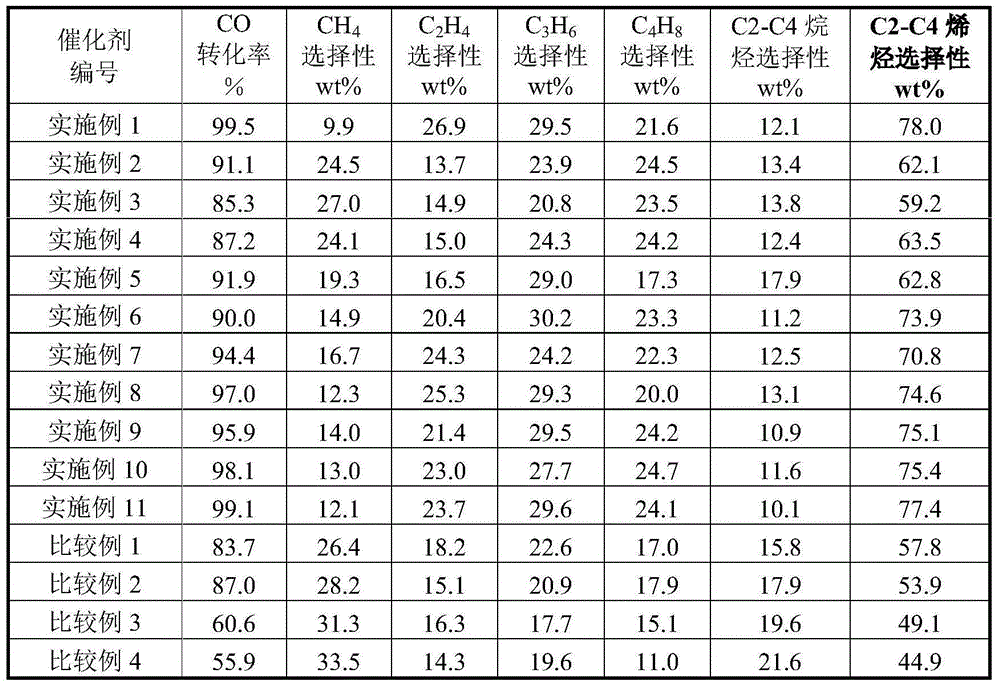

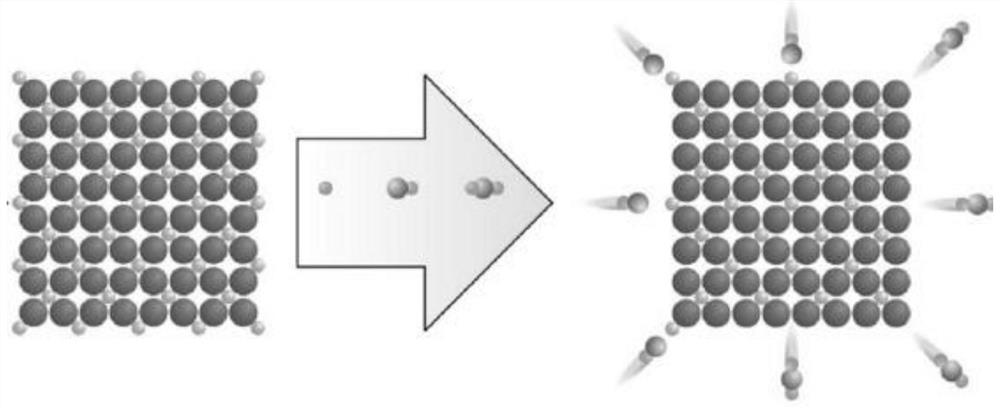

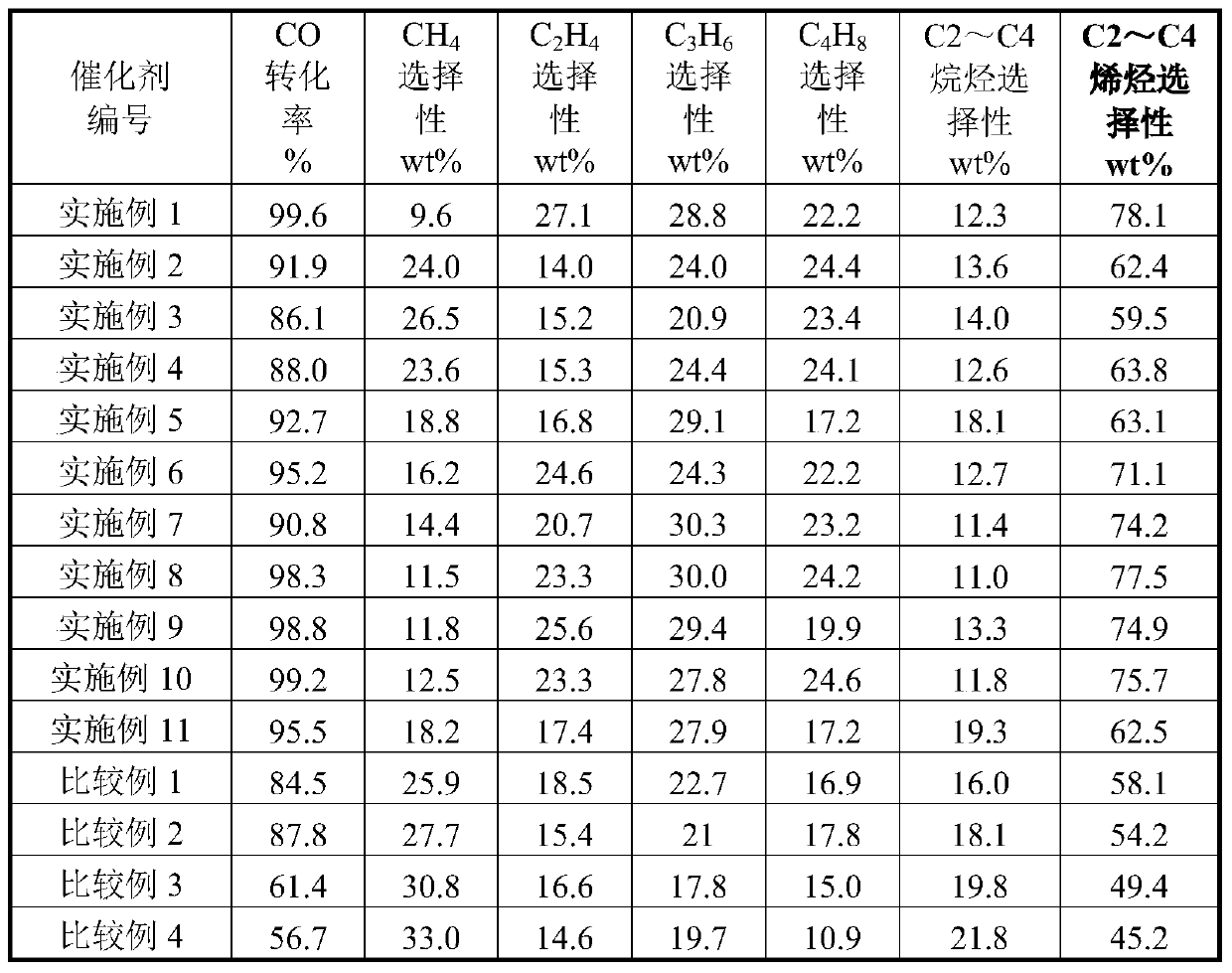

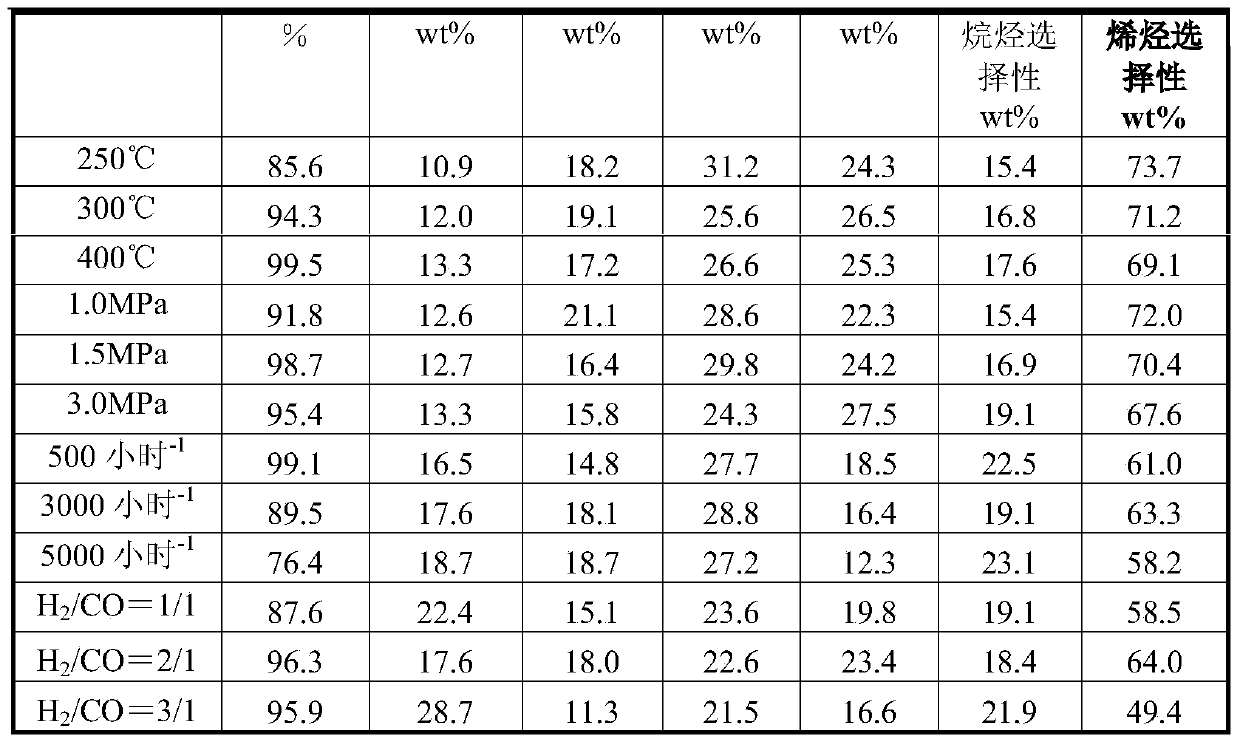

The invention relates to an iron catalyst for preparing light olefins by use of synthesis gas and a preparation method of the iron catalyst, aiming at solving the problems that CO conversion rate is low, the light olefin selectivity is low, and the catalyst has low strength and poor stability under a using condition when the synthesis gas is used for preparing the light olefins in the prior art. The iron catalyst is prepared from the following components in parts by weight: (a) 35-90 parts of iron element or oxide thereof; (b) 5-30 parts of at least one element of titanium and zirconium or oxide of at least one of titanium and zirconium; (c) 5-30 parts of at least one element of molybdenum and tungsten or oxide of at least one of molybdenum and tungsten; (d) 0.1-10 parts of at least one element of vanadium and niobium or oxide of at least one of vanadium and niobium; (e) 0.1-10 parts of at least one element of lanthanum and samarium or oxide of at least one of lanthanum and samarium; and (f) 0.5-5 parts of tin or oxide thereof. The iron catalyst can solve the above problems well and can be used for industrial production for preparing light olefins through Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing low carbon olefin by fixed bed, preparation method as well as use thereof

ActiveCN104437532AImprove conversion rateHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsFixed bedCerium

The invention relates to a catalyst for preparing low carbon olefin by a fixed bed, a preparation method as well as use thereof, which mainly solves the problem that the CO conversion ratio is low and low carbon olefin selectivity is low in synthesis gas to low carbon reaction in the prior art and the catalyst is poor in intensity and thermal stability under a using condition. By adopting the technical scheme that the catalyst provided by the invention comprises the following components in parts by weight: a) 30-80 parts of iron element and oxides thereof; b) 10-40 parts of at least one element selected from manganese and chromium or oxides thereof; c) 10-40 parts of at least one element selected from copper and zinc or oxides thereof; d) 0.9-20 parts of at least one element selected from potassium and cesium or oxides thereof; e) 0.9-20 parts of at least one element selected from cerium and neodymium or oxides thereof; and f) 0.5-10 parts of an antimony element or oxides thereof, the problem is better solved, and the catalyst can be used for industrial production of Fischer-Tropsch synthesis to prepare low carbon olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

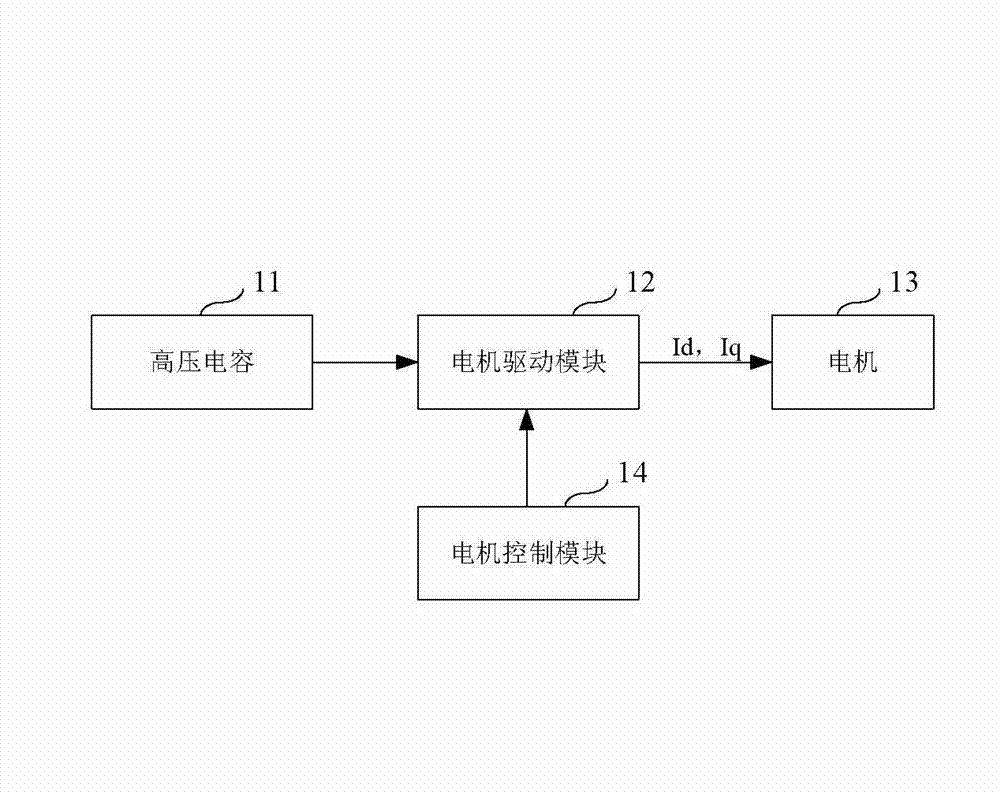

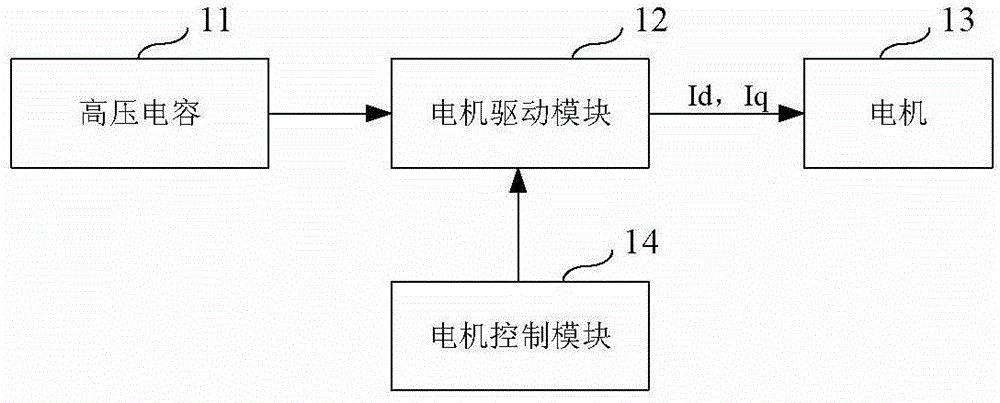

High-voltage capacitor discharging device, method thereof and vehicle

A high-voltage capacitor discharging device comprises a motor control module, a motor driving module and a motor, wherein the motor driving module is connected with a high-voltage capacitor, the motor control module and the motor respectively. The motor control module is used for controlling the motor driving module to enable the high-voltage capacitor to output q-shaft current Iq and d-shaft current Id upon reception of a high-voltage outage signal, and the output q-shaft current Iq and the output d-shaft current Id enable the motor not to be in a rotating state. The high-voltage capacitor discharging device enables the charge of the high-voltage capacitor to be automatically discharged via consumption of the motor, but does not lead the motor to run.

Owner:BYD CO LTD

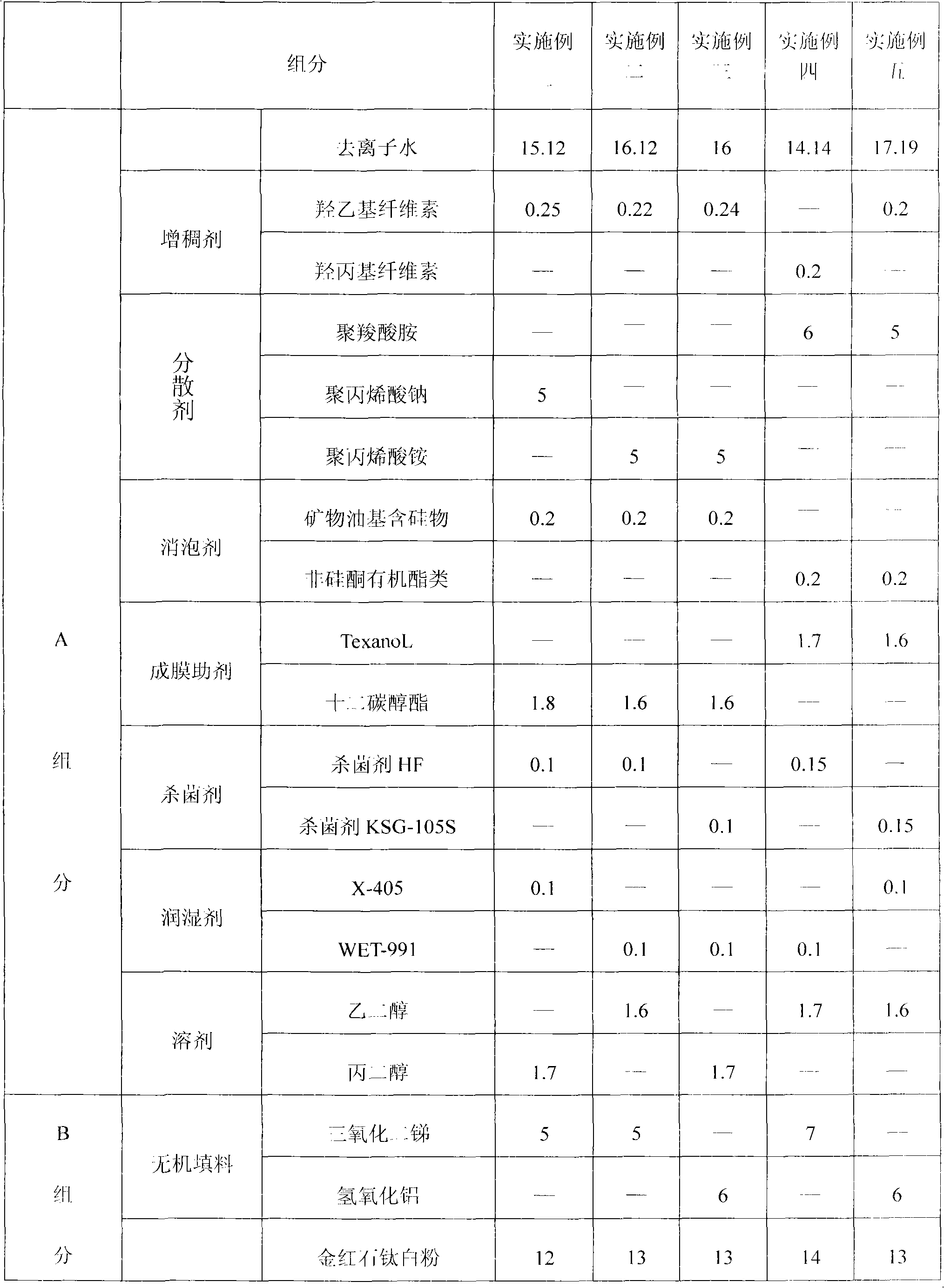

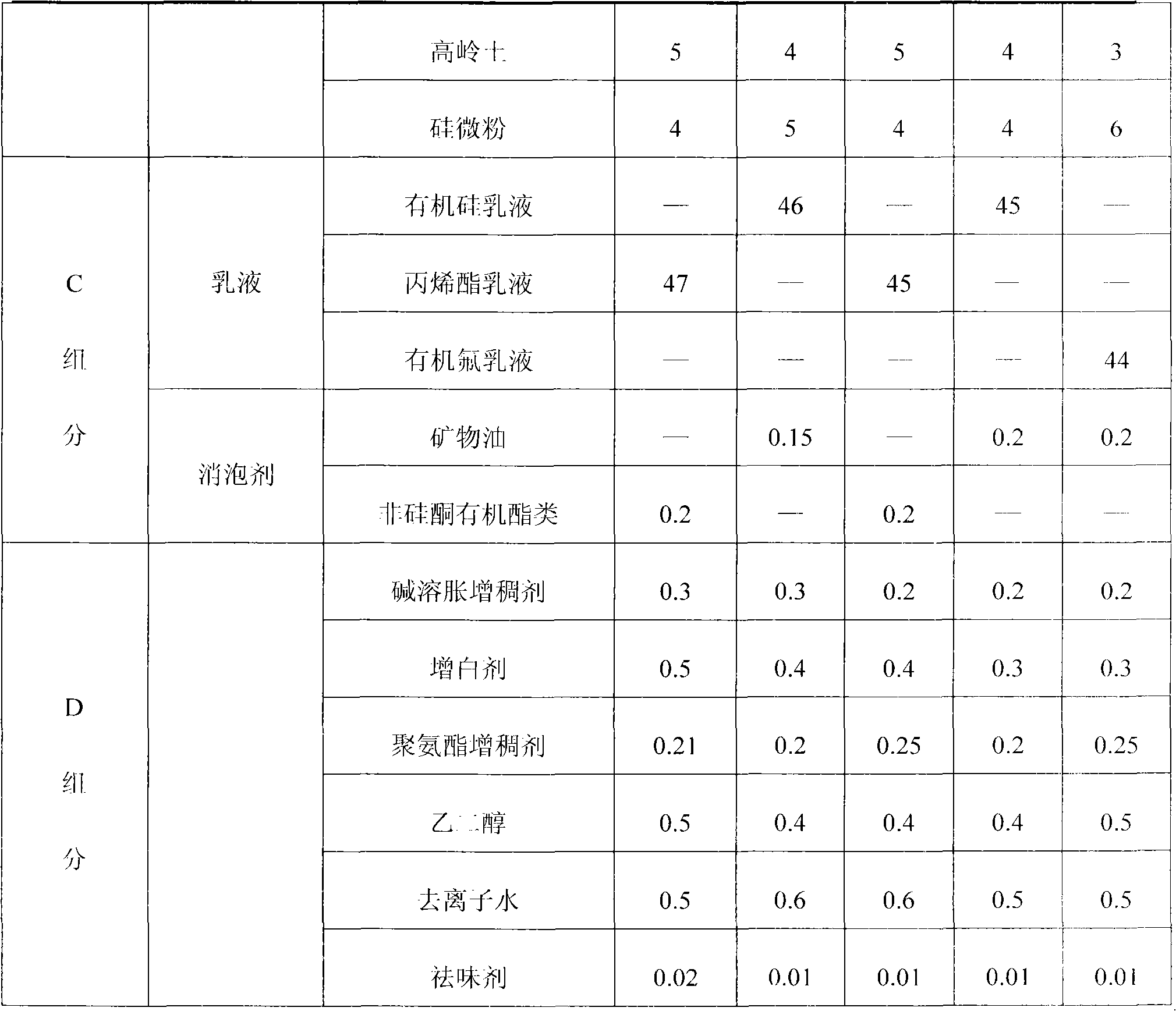

Low carbon wallpaper paint and preparation method thereof

InactiveCN101880987AActive releaseLow VOC contentSpecial visual effect coatingsCoatingsEmulsionOrganic Ester

The invention discloses a low carbon wallpaper paint which comprises the following components in parts by weight: a component A, a component B and a component C, wherein the component A comprises 0.2-0.3 part of thickening agent, 4-7 parts of dispersing agent, 0.1-0.3 part of defoaming agent, 1.5-2.5 parts of film-forming agent, 0.1-0.2 part of sterilizing agent, 0.1-0.2 part of wetting agent, 1-2 parts of solvent and 15-20 parts of water; the component B comprises 4-7 parts of powder, 10-15 parts of titanium white, 2-5 parts of kaoline and 4-7 parts of silica micropowder; the component C comprises 40-60 parts of emulsion, 0.1-0.2 part of deforming agent, 0.2-0.4 part of film-forming agent and 0.1-0.2 part of non-silicone organic ester deforming agent. The low carbon wallpaper paint reaches the international environmental-protection standard, can effectively make up the wall thin cracks, and has excellent scrubbing resisting property, yellowing resisting property and long service life.

Owner:贺佑康

Iron-based catalyst for preparing low-carbon alkane as well as preparation method and using method of iron-based catalyst for preparing low-carbon alkane

ActiveCN104437524AHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAlkanePtru catalyst

The invention relates to an iron-based catalyst for preparing low-carbon alkane as well as a preparation method and a using method of the iron-based catalyst for preparing the low-carbon alkane. The iron-based catalyst for preparing the low-carbon alkane is mainly used for solving the problems that the reaction of preparing low-carbon alkane from a synthesis gas in the prior art is low in CO conversion rate and low in low-carbon alkane selectivity, and the catalyst is poor in strength and thermal stability under a using condition. The problems are solved very well by adopting a technical scheme that the catalyst comprises the following components in parts by weight: a) 20-80 parts of an iron element or oxides thereof; b) 1-15 parts of a cobalt element and oxides thereof; c) 10-30 parts of at least one element selected from molybdenum and vanadium or oxides thereof; d) 5-20 parts of at least one element selected from magnesium and barium or oxides thereof; e) 5-20 parts of at least one element selected from tin and aluminum or oxides thereof; and f) 0.5-10 parts of a scandium element or oxides thereof. The catalyst can be used for industrial production of preparing low-carbon alkane from the synthesis gas by virtue of a one-step process.

Owner:CHINA PETROLEUM & CHEM CORP +1

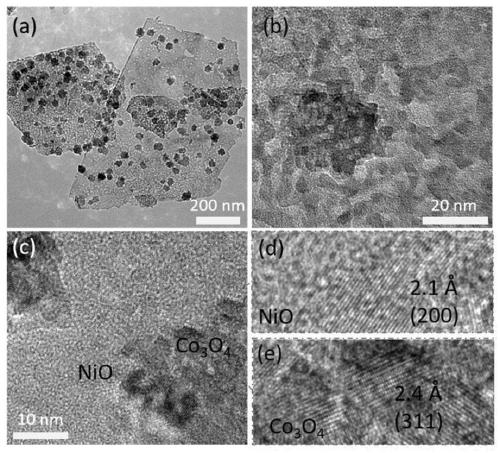

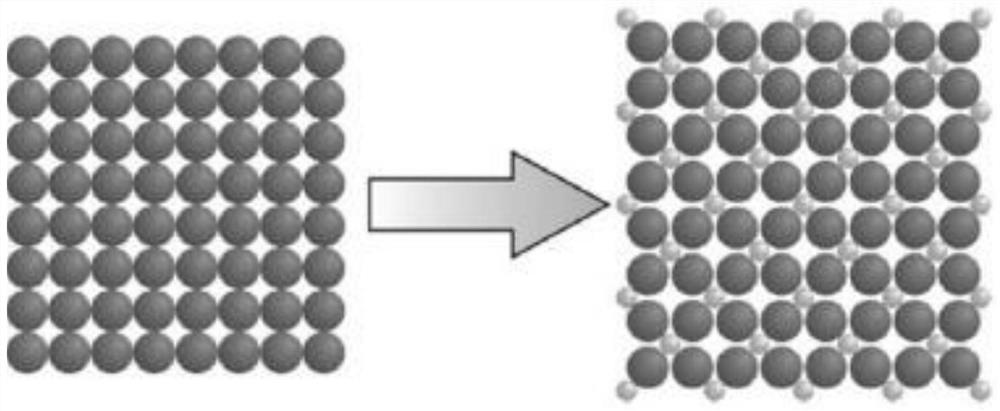

Preparation method and application of NiO/Co3O4

ActiveCN111195518AHigh activityShorten the electron transport pathMetal/metal-oxides/metal-hydroxide catalystsElectrodesAmmonium fluorideCobalt acetate

The invention discloses a preparation method of a nickel oxide-cobaltosic oxide (NiO / Co3O4) composite electrode material based on foamed nickel growth. The process comprises the following steps of: firstly, preparing a precursor of nickel oxide through a hydrothermal method by taking nickel nitrate and urea as raw materials, ammonium fluoride as a morphology control agent and foamed nickel as a substrate, carrying out low-temperature annealing on the precursor in air to obtain pure NiO, and then taking the nickel oxide as a substrate material, adding a cobalt acetate solution and ammonia water, and carrying out a second-step hydrothermal reaction to obtain the NiO / Co3O4 two-phase composite electrocatalyst material growing on a foamed nickel substrate. A plurality of interfaces and defectsbeneficial to catalytic reaction appear in the material, and compared with a single-phase catalyst, the catalytic activity is greatly improved. And meanwhile, due to the use of the foamed nickel substrate, the addition of a conductive agent and an adhesive in the electrocatalysis process can be avoided, the implementation process of the catalytic reaction is simplified, and the electrode impedanceis also reduced.

Owner:LANZHOU UNIVERSITY

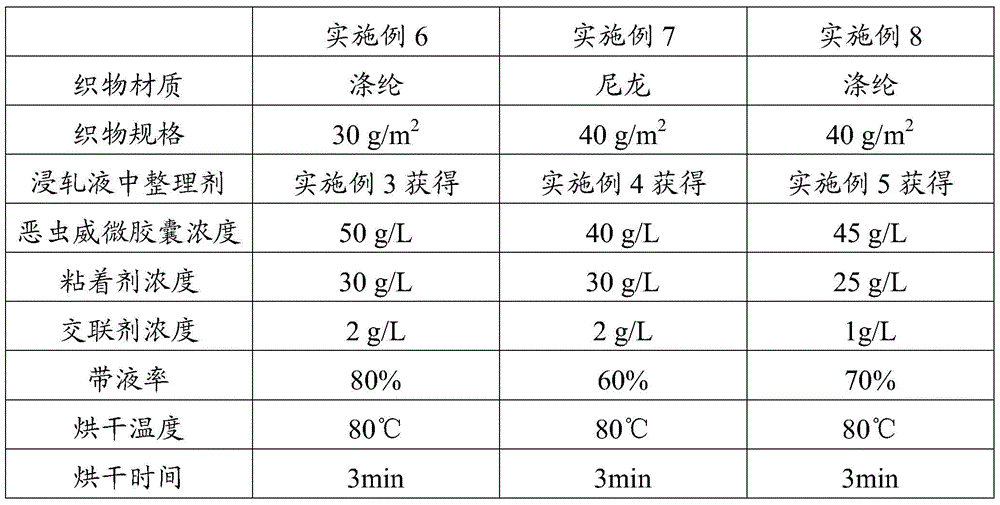

Finishing agent containing bendiocarb microcapsules and application of finishing agent

InactiveCN105696329AStable structureSimple processing methodFibre typesInsect netsCross-linkAfter treatment

The invention relates to the field of anti-mosquito fabrics, in particular to a finishing agent containing bendiocarb microcapsules and application of the finishing agent. The finishing agent containing the bendiocarb microcapsules is prepared from the following components of the bendiocarb microcapsules, an adhesive and a cross-linking agent, wherein the bendiocarb microcapsules comprise capsule walls and capsule cores; the capsule cores are bendiocarb or compositions containing the bendiocarb. The fabric is subjected to after treatment in padding liquid containing the finishing agent containing the bendiocarb microcapsules, so that a long-acting anti-mosquito fabric can be obtained. The fabric can be used for producing a mosquito net. According to the technical scheme provided by the invention, a bendiocarb active substance with an anti-mosquito effect is firmly and stably attached to the surface of the fabric by preparing the proper finishing agent, no special requirement on materials needs to be met, a processing method is simple and the cost is low; the bendiocarb existing in a form of the microcapsules is stable in structure, and the activity of the bendiocarb can be slowly released; the produced fabric is washable and can maintain a long-acting anti-mosquito function; the finishing agent containing the bendiocarb microcapsules is used for processing the mosquito net and has a broad market prospect.

Owner:然晟(上海)实业发展有限公司

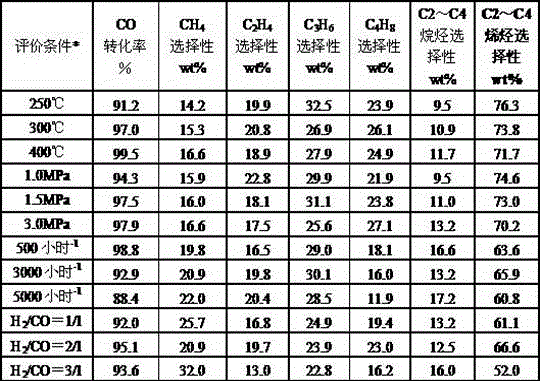

High-temperature sintering type catalyst for preparing light olefins from synthetic gas and preparation method thereof

ActiveCN104275189AHigh activityActive releaseHydrocarbon from carbon oxidesCatalyst activation/preparationPotassiumTitanium

The invention relates to a high-temperature sintering type catalyst for preparing light olefins from synthetic gas and a preparation method thereof. According to the invention, the problem that CO conversion rate is low and selectivity of light olefins is low during a reaction of preparing light olefins from synthetic gas in the prior art is mainly solved. The catalyst provided by the invention contains the following components, by weight, a) 10-40 parts of iron or its oxide, b) 0.5-10 parts of at least one element selected from titanium and chromium or an oxide thereof; c) 1-10 parts of at least one element selected from magnesium and calcium or an oxide thereof; d) 0.5-10 parts of potassium or its oxide; and e) 30-88 parts of a carrier alpha-aluminium oxide. By the technical scheme, the above problem is solved well. The catalyst can be used in industrial production of Fischer-Tropsch synthesis for preparation of light olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low-carbon olefins by using fixed bed

ActiveCN106607048AHighly uniform dispersionIncrease the number ofHydrocarbon from oxygen organic compoundsEthylene productionPotassiumCopper

The invention relates to a method for producing low-carbon olefins by using a fixed bed. The method mainly solves the problems of a low conversion rate of CO and low selectivity of the low-carbon olefins in the reaction process of producing the low-carbon olefins from synthesis gas by using the fixed bed in the prior art. According to the technical scheme, a catalyst adopted by the method comprises the following components, by weight percentage, a) 10-50% of Fe or an oxide thereof, b) 1-5% of Rh or an oxide thereof, c) 9-30% of at least one element selected from Cu and Zn or at least one oxide thereof, d) 9-30% of at least one element selected from K and Cs or at least one oxide thereof, e) 1-5% of Pr or an oxide thereof, and f) 30-70% of a carrier which comprises the following components, based on the weight of the carrier, (1) 20-70 parts of titanium oxide, and (2) 30-80 parts of silicon dioxide. The problems can be well solved through the above technical scheme, and the method can be applied to industrial production of preparing the low-carbon olefins from the synthesis gas by using the fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-temperature sintering type sulfur-containing iron-based catalyst and preparation method thereof

ActiveCN106607052AHigh activityActive releaseHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSulfur containingChromium

The present invention relates to a high-temperature sintering type sulfur-containing iron-based catalyst and a preparation method thereof. A purpose of the present invention is to mainly solve the problems of low CO conversion rate and low low-carbon olefin selectivity in the low-carbon olefin preparation reaction with synthesis gas, and poor strength and poor thermal stability of the catalyst under the use condition in the prior art. The catalyst comprises, by weight, a) 5-50 parts of iron or an oxide thereof; b) 1-15 parts of ruthenium or an oxide thereof; c) 10-30 parts of calcium or an oxide thereof; d) 10-30 parts of at least one element selected from vanadium and chromium, or an oxide thereof; e) 10-75 parts of aluminum or an oxide thereof; and f) added trace amount calcium sulfate, wherein the catalyst contains 20-200 ppm sulfur based on the total weight of the iron-based catalyst. With the technical scheme, the problems in the prior art are well solved. The catalyst of the present invention can be used for the low-carbon olefin preparation with synthesis gas in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

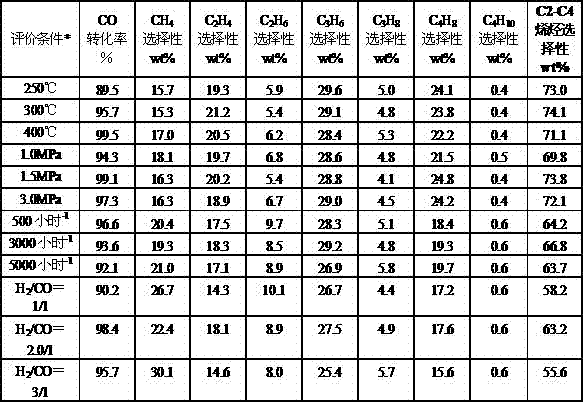

Iron-Based Catalysts for Direct Synthesis of Light Olefins from Syngas

ActiveCN107913718BHigh activityActive releaseHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsPtru catalystManganese

The invention relates to an iron-based catalyst for direct synthesis of low-carbon olefin from synthesis gas and mainly solves the problems of low CO conversion rate and low-carbon olefin selectivityin reactions for direct synthesis of low-carbon olefin from synthesis gas in the prior art. The iron-based catalyst for direct synthesis of low-carbon olefin from synthesis gas is prepared from components in parts by weight as follows: a) 18-50 parts of an iron element or oxide thereof; b) 10-25 parts of at least one element of manganese and zinc or oxide thereof; c) 10-25 parts of at least one element of magnesium and strontium or oxide thereof; d) 20-60 parts of an aluminum element or oxide thereof; e) 1-5 parts of a niobium element or oxide thereof; and f) 1-5 parts of a tantalum element oroxide thereof. With the adoption of the technical scheme, the problems are better solved and the catalyst can be applied to industrial production of direct synthesis of low-carbon olefin from the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

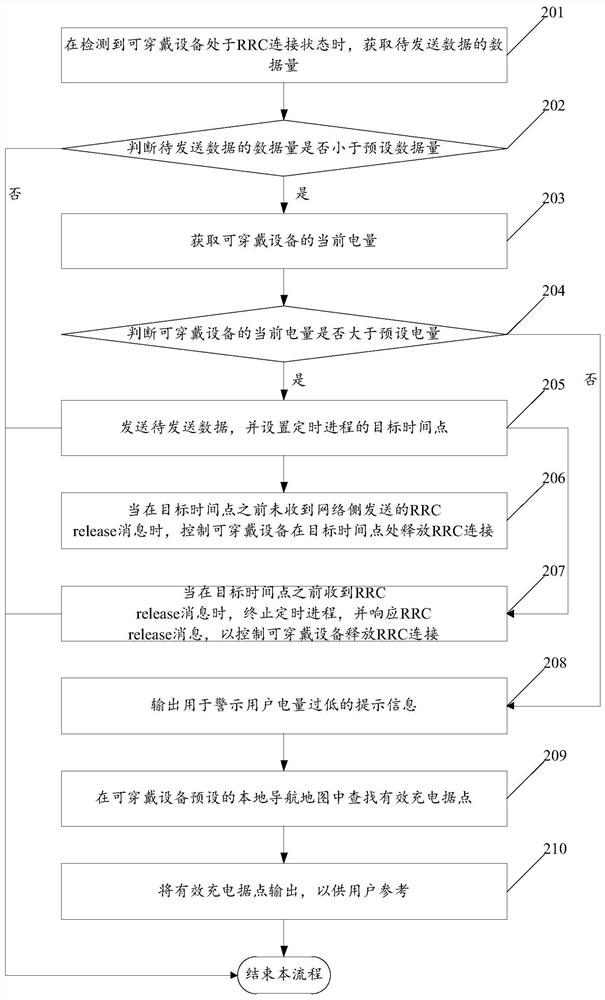

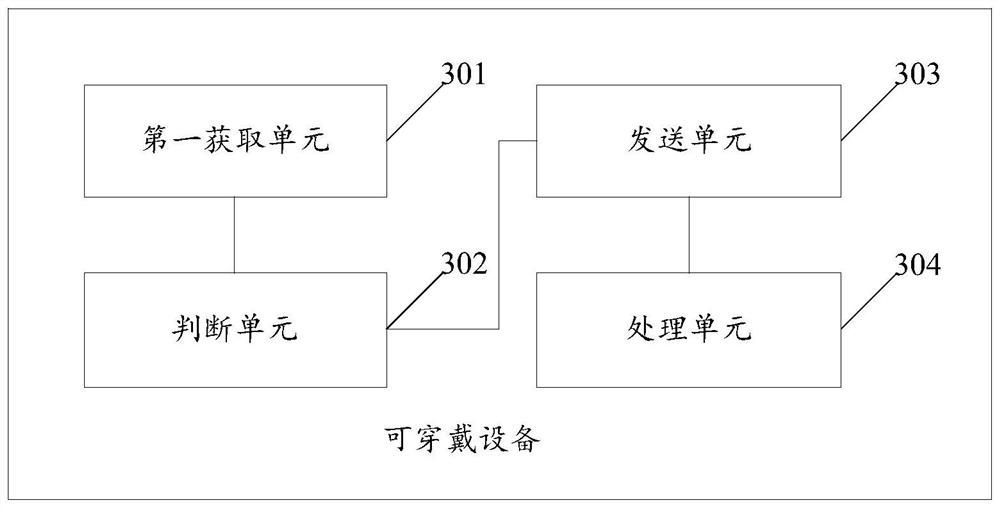

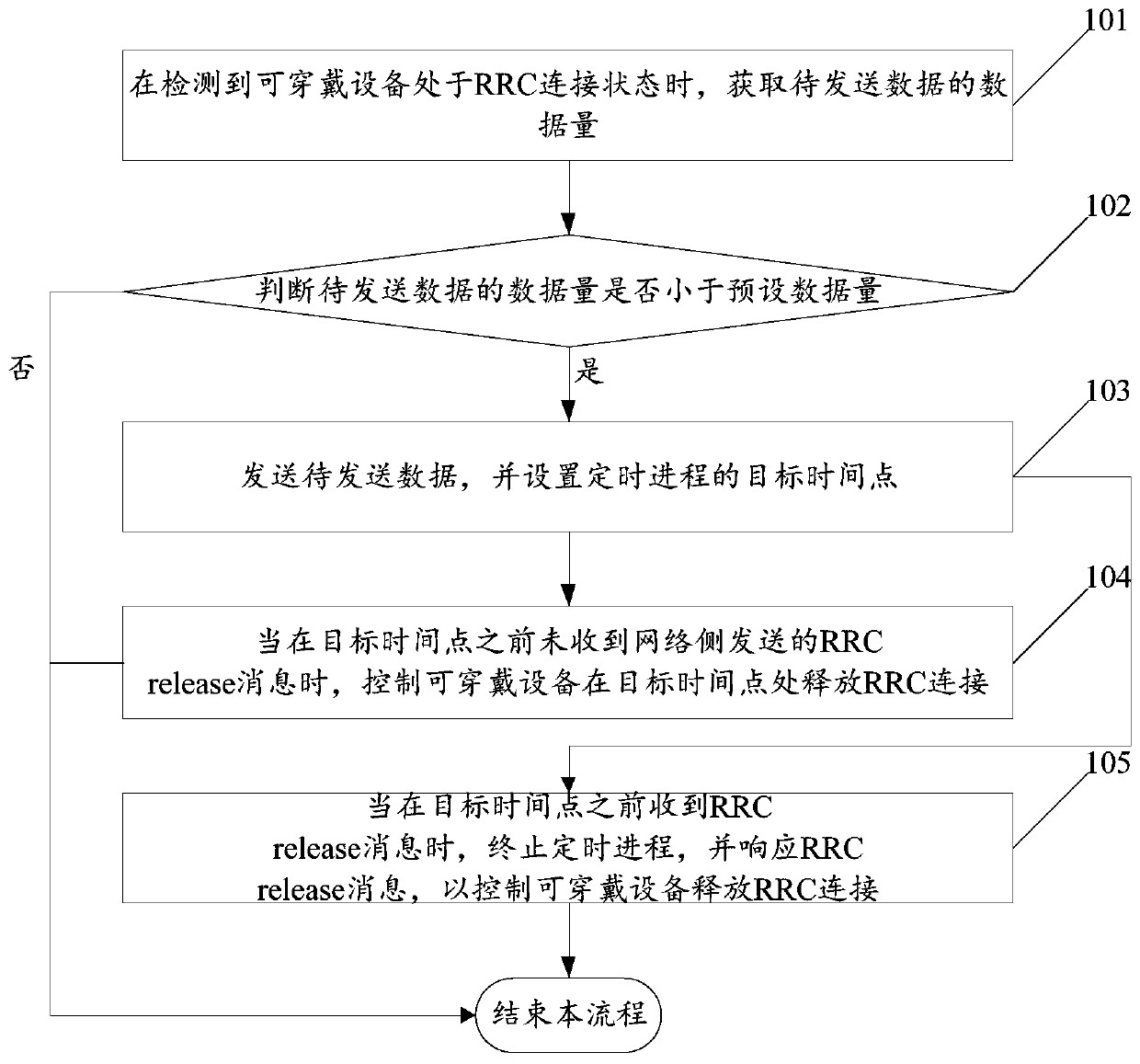

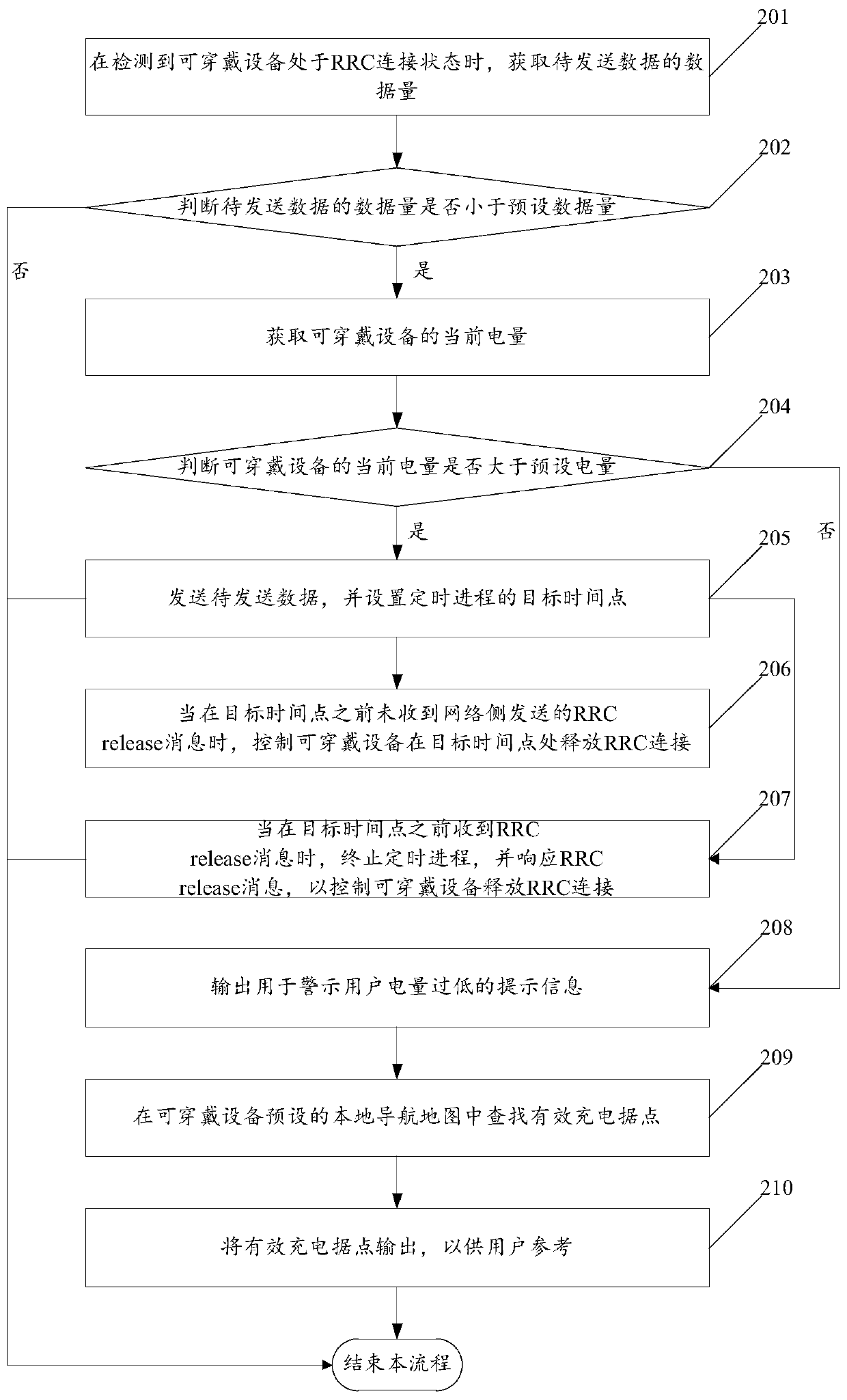

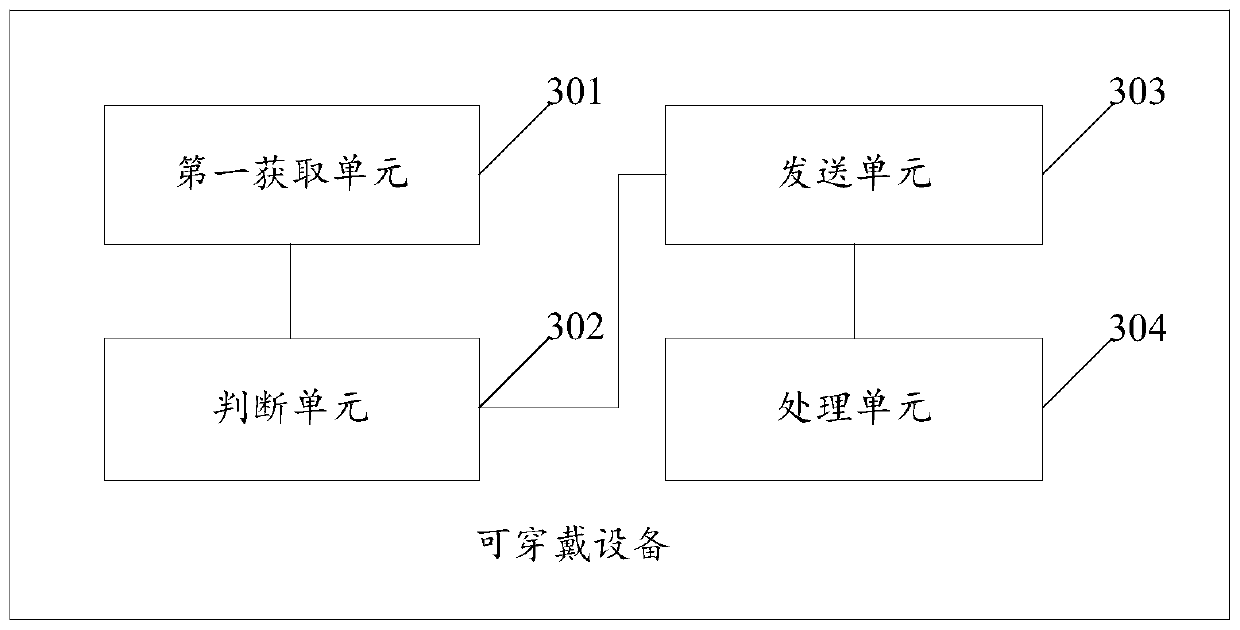

A wearable device-based data transmission method and wearable device

ActiveCN111148194BActive releaseReduce lossPower managementConnection managementData transmissionEmbedded system

The embodiment of the present invention discloses a data transmission method based on a wearable device and a wearable device. The method includes: when it is detected that the wearable device is in an RRC connection state, acquiring the data amount of the data to be sent; and judging whether the data amount is not less than the preset data amount; if less than the preset data amount, send the data to be sent, and set the target time point of the timing process; and when the RRC release message sent by the network side is not received before the target time point, control the wearable device Release the RRC connection at the target time point; and when the RRC release message is received before the target time point, terminate the timing process and respond to the RRC release message to control the wearable device to release the RRC connection. By implementing the embodiments of the present invention, power consumption can be effectively reduced, and user experience can be improved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

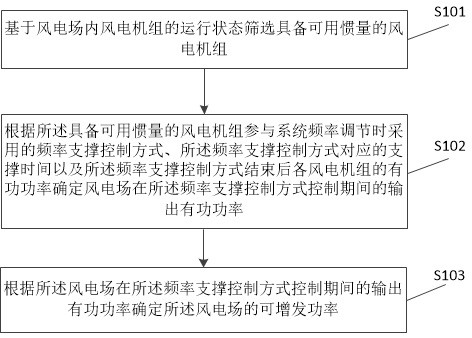

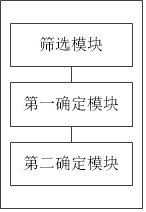

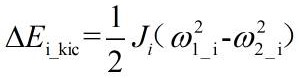

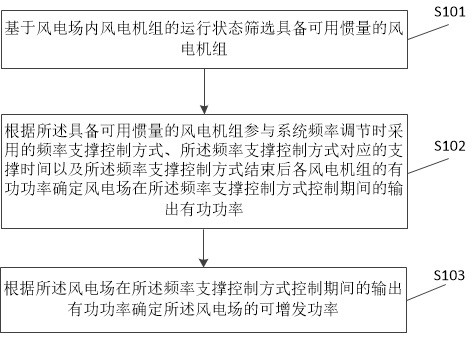

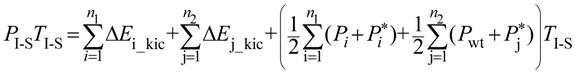

On-line calculation method and device for wind power plant additional power under frequency disturbance working condition

ActiveCN112600259AReduce calculation errorsActive releaseSingle network parallel feeding arrangementsWind energy generationNew energyControl engineering

The invention relates to the technical field of new energy access and control, particularly provides an on-line calculation method and device for wind power plant additional power under a frequency disturbance working condition, and aims to solve the technical problem of inaccurate calculation of the increasable power of the wind power plant. In the calculation process of the additional power of the wind power plant, according to a frequency support control mode which is adopted when a wind turbine generator participates in system frequency adjustment, support time corresponding to the frequency support control mode and the active power of each wind turbine generator after the frequency support control mode is finished, the method determines the output active power of the wind power plantin the control period of the frequency support control mode, and further calculates the additional power of the wind power plant. According to the scheme, on the basis of considering the active powerof each wind turbine generator after the frequency support control mode is ended, the additional power of the wind power plant in the frequency support process is calculated from two perspectives of inertia response and primary frequency modulation, and the calculation error of the additional power of the wind power plant is reduced.

Owner:CHINA ELECTRIC POWER RES INST

Online Calculation Method and Device for Increased Power Generation of Wind Farms Under Frequency Disturbance Conditions

ActiveCN112600259BReduce calculation errorsActive releaseSingle network parallel feeding arrangementsWind energy generationNew energyControl engineering

Owner:CHINA ELECTRIC POWER RES INST

A hydrogen storage nano-palladium photothermal effect targeted release liposome functional group and its preparation method and application

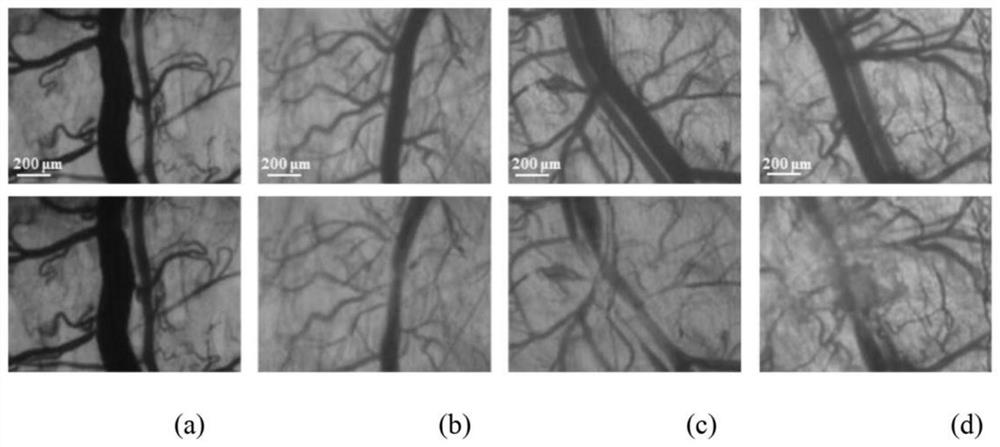

ActiveCN112168786BAbsorption wavelength adjustableGood absorption wavelength tunableSenses disorderDrug photocleavageThrombusLiposome

The invention discloses a hydrogen storage nano palladium photothermal effect targeted release liposome functional group and its preparation method and application, comprising polymer modified liposomes, hydrogen storage nano palladium particles, the hydrogen storage nano palladium particles are arranged on the liposome plastid. The invention effectively combines the photothermal effect and hemodynamic response, and the hydrogen gas generated by the hydrogen storage nano-palladium particles effectively reduces the active oxygen level of cells to realize anti-oxidation treatment; at the same time, the local photothermal effect promotes the polymerization of liposomes with a diameter of 90-240 μm The vesicles can effectively block the blood vessels, and use the physical characteristics of the lipid membrane to realize the targeted release and retention of hydrogen gas, accelerate the formation of thrombus, and ensure the complete blockage of blood vessels.

Owner:XI AN JIAOTONG UNIV

High-temperature sintered sulfur-containing iron-based catalyst and preparation method thereof

ActiveCN106607052BHigh activityActive releaseHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionPtru catalystSulfate

The present invention relates to a high-temperature sintering type sulfur-containing iron-based catalyst and a preparation method thereof. A purpose of the present invention is to mainly solve the problems of low CO conversion rate and low low-carbon olefin selectivity in the low-carbon olefin preparation reaction with synthesis gas, and poor strength and poor thermal stability of the catalyst under the use condition in the prior art. The catalyst comprises, by weight, a) 5-50 parts of iron or an oxide thereof; b) 1-15 parts of ruthenium or an oxide thereof; c) 10-30 parts of calcium or an oxide thereof; d) 10-30 parts of at least one element selected from vanadium and chromium, or an oxide thereof; e) 10-75 parts of aluminum or an oxide thereof; and f) added trace amount calcium sulfate, wherein the catalyst contains 20-200 ppm sulfur based on the total weight of the iron-based catalyst. With the technical scheme, the problems in the prior art are well solved. The catalyst of the present invention can be used for the low-carbon olefin preparation with synthesis gas in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

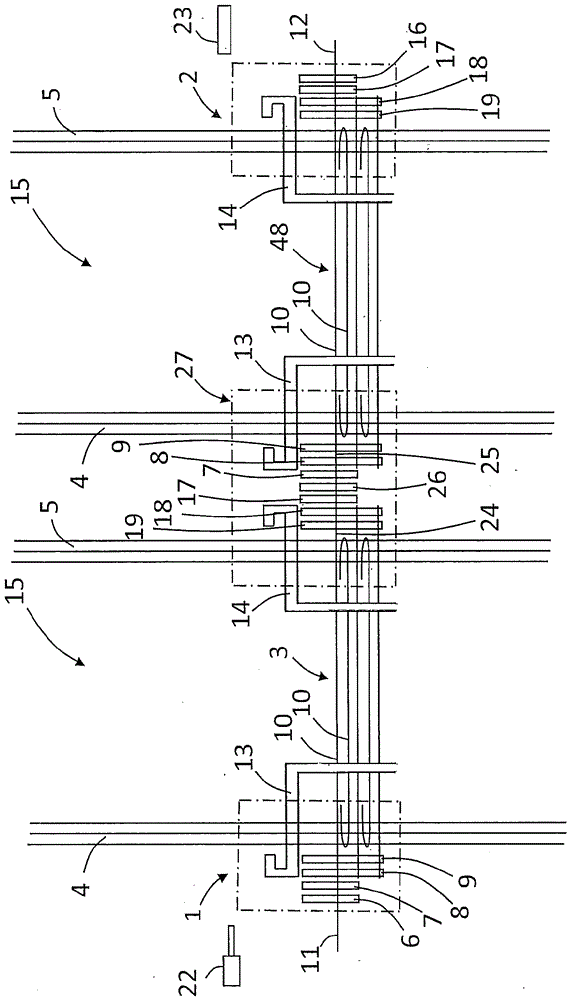

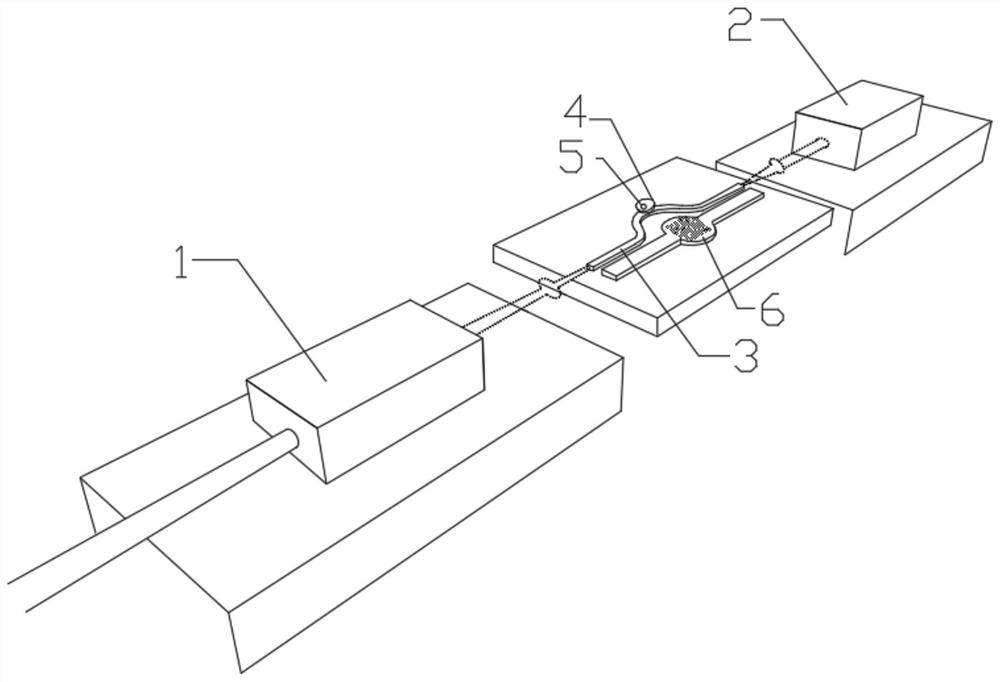

Selvedge forming device for a weft thread

Weaving machine, device and method for tucking a thread end (11, 12, 24, 25) of a weft thread (10) into a subsequent shed (15), which thread end (11, 12,24,25) extends outside a shed (15), wherein thread ends (11, 12, 24, 25) are tucked into a subsequent shed (15) by means of a tucking device (13, 14,28,29), wherein a thread end (11, 12, 24, 25) is selectively moved by means of a moveable arm (9, 19), and wherein the thread end (11, 12,24,25) moved by the moveable arm (9, 19) beyond the separator element (8, 18) is separated by the separator element (8, 18) from the working area of the tucking device (13, 14, 28, 29).

Owner:PICANOL SUZHOU IND PARK TEXTILE MACHINERY

Iron-based catalyst for producing low-carbon olefins from synthesis gas and its application

ActiveCN106607047BHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIridiumSyngas

The invention relates to a method for preparing low-carbon olefins from synthesis gas on an iron-based catalyst and mainly solves the problems that in the prior art, in a reaction of preparation of the low-carbon olefins from the synthesis gas by using a fixed bed, the CO conversion rate is low, and low-carbon olefin selectivity is low. The iron-based catalyst comprises, by weight, 20-70 parts of the iron element or an oxide of the iron element, 4-20 parts of at least one element selected from copper and manganese or an oxide of the at least one element, 4-20 parts of at least one element selected from zinc and zirconium or an oxide of the at least one element, 20-40 parts of the silicon element or an oxide of the silicon element, 1-10 parts of the germanium element or an oxide of the germanium element and 1-10 parts of the iridium element or an oxide of the iridium element. The problems are well solved through adoption of the above technical scheme, and the iron-based catalyst can be used for industrial production of preparing the low-carbon olefins from the synthesis gas by using the fixed bed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Micro component picking and placing device and method controlled by liquid medium

ActiveCN113581849AActive releaseTo achieve fit and fixConveyor partsMagnetic tension forceLiquid medium

The invention discloses a micro component picking and placing device and method controlled by a liquid medium, and relates to micro component operation in the fields of microelectronics, micro assembly and the like. The micro component picking and placing device controlled by liquid medium comprises a mounting frame, a micro driving motor, a coupler, a ball screw, a screw nut, a long connecting plate, a connecting piece, an electromagnet, an iron attracting head, a spring, a spring fixing seat, a heat conducting plate, two fixing bolts, a four-hole connecting piece, two fixing baffles, an electric heating piece, a refrigerating piece, a water cooling head, a hose, a gasket A, a gasket B, a posture adjusting plate, a probe, an elastic film, a long connecting plate and a ball screw in clearance fit with the mounting frame, and the connecting piece, the electromagnet, the magnet head, the spring, an inner hole of the spring fixing base, an inner hole of the heat conducting plate and the probe are coaxially arranged. The electromagnet and the magnet head are arranged in a spaced mode, a magnetic force is generated under excitation of an external current field, the electromagnet is connected with the magnet head in an adsorption mode, and after the external current field disappears, the electromagnet and the magnet head are disconnected instantly. The device is used for flexibly picking a micro member, adjusting a posture of the micro member and performing a release operation.

Owner:SHANDONG UNIV OF TECH

Sintered catalyst for producing low-carbon olefins from syngas and preparation method thereof

ActiveCN105582936BHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIndiumTitanium

The invention relates to a sintered catalyst for producing low-carbon olefins from syngas and a preparation method thereof, which mainly solves the low conversion rate of CO and low selectivity of low-carbon olefins in the reaction of producing low-carbon olefins from syngas in the prior art. The problem of poor strength and poor thermal stability under certain conditions. The catalyst used in the present invention includes the following components in parts by weight: a) 10-70 parts of iron element or its oxide; b) 1-10 parts of cobalt element or its oxide; c) 5-20 parts selected from calcium and at least one element of magnesium or its oxide; d) 5-20 parts of at least one element selected from silicon and zirconium or its oxide; e) 15-45 parts of titanium or its oxide; f) 1 The technical scheme of ~10 indium elements or their oxides solves this problem well and can be used in the industrial production of low-carbon olefins from syngas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Symmetrical three-dimensional micromanipulator with three-stage motion amplification mechanism

ActiveCN109909976BFirmly connectedActive releaseProgramme-controlled manipulatorGripping headsMicromachineryManipulator

Owner:TIANJIN UNIV

Data transmission method based on wearable equipment and wearable equipment

ActiveCN111148194AActive releaseReduce lossPower managementConnection managementData transmissionEmbedded system

The embodiment of the invention discloses a data transmission method based on wearable equipment and the wearable equipment, and the method comprises the steps: obtaining the data volume of to-be-transmitted data when the wearable equipment is detected to be in an RRC connection state; judging whether the data volume is smaller than a preset data volume or not; if the data volume is smaller than the preset data volume, sending the to-be-sent data, and setting the target time point of the timing process; and when the RRC release message sent by the network side is not received before the targettime point, controlling the wearable equipment to release the RRC connection at the target time point; and when the RRC release message is received before the target time point, terminating the timing process, and responding to the RRC release message to control the wearable equipment to release the RRC connection. With implementing of the embodiment of the invention, the electric quantity loss can be effectively reduced, and the user experience is improved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

Driving method, device of on-chip micro-nano object based on light force, and application

ActiveCN113534348AIncreased precision and freedomWide range of regulationCoupling light guidesPhysicsElectrical and Electronics engineering

The invention provides a driving method and device of an on-chip micro-nano object based on light force and application. According to the scheme, a micro-nano container is placed on an on-chip waveguide, a micro-nano object is placed in the micro-nano container, and translation, swing and transportation of the micro-nano container are achieved through conversion of light energy and mechanical energy. According to the scheme, the on-chip micro-nano object can be driven based on light force in a non-liquid environment, and the problems that the controllability of existing on-chip micro-nano object driving transportation is poor, and a reaction field in the liquid environment is prone to being polluted are solved in a targeted mode.

Owner:WESTLAKE UNIV

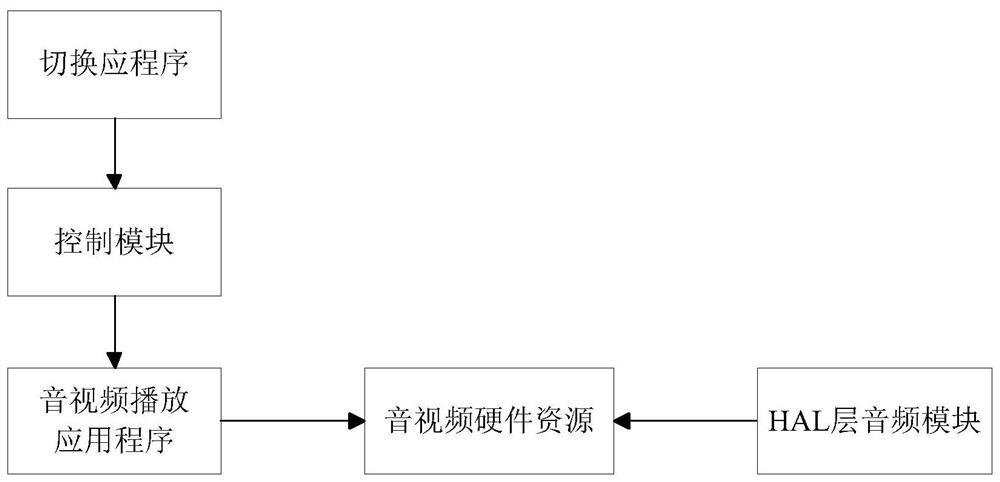

Method and device for operating system switching with dual Android terminals

The present application discloses a method for switching operating systems with dual Android terminals, comprising: for an audio and video playback application currently running in an operating system that is about to be switched to the background in the dual Android terminals, suspending all audio and video playback applications by means of system broadcasting. The audio and video playback application; the audio and video playback application pauses the audio and video playback according to the system broadcast, and releases the audio and video hardware resources occupied by the audio and video playback application. Corresponding to the above method, the present application also discloses a dual Android terminal device. The application of the technical solution disclosed in the present application can ensure the normal operation of the upper-layer application program when the operating system is switched.

Owner:CHENGDU TD TECH LTD

Paper disc frame with active discharging function

The invention relates to the field of cigarette production equipment, in particular to a paper disc frame with an active discharging function. The paper disc frame with the active discharging functioncan realize active release of a paper disc, and avoids the uncontrolled discharging speed due to the large inertia of a rotating material when the material weight is higher. The paper disc frame is characterized by comprising a wall panel, a supporting shaft located on one side of the wall panel and perpendicular to the wall panel, the supporting shaft is rotatably connected with the wall panel,a driving motor for driving the supporting shaft to rotate is arranged on the side wall of the wall panel, a connecting rod mechanism and a driving component for driving the connecting rod mechanism to extend out of the side wall of the supporting shaft are arranged in the supporting shaft, a connecting rod cavity is formed in the side wall of the supporting shaft in the axial direction of the supporting shaft, the connecting rod mechanism comprises a tension arm movably arranged in the connecting rod cavity, the two ends of the tension arm are hinged to the side wall of the connecting rod cavity through a swing rod, and the tension arm can rotate along with the swing rod and extends out of the connecting rod cavity.

Owner:XIANGYANG SHENGUAN MECHANICAL & ELECTRICAL TECH CO LTD

High-voltage capacitor discharging device, method thereof and vehicle

A high-voltage capacitor discharging device comprises a motor control module, a motor driving module and a motor, wherein the motor driving module is connected with a high-voltage capacitor, the motor control module and the motor respectively. The motor control module is used for controlling the motor driving module to enable the high-voltage capacitor to output q-shaft current Iq and d-shaft current Id upon reception of a high-voltage outage signal, and the output q-shaft current Iq and the output d-shaft current Id enable the motor not to be in a rotating state. The high-voltage capacitor discharging device enables the charge of the high-voltage capacitor to be automatically discharged via consumption of the motor, but does not lead the motor to run.

Owner:BYD CO LTD

Fixed-bed low-carbon olefin catalyst, preparation method and use thereof

ActiveCN104437532BHigh activityActive releaseHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFixed bed

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing low-carbon olefins from high-temperature sintered syngas and preparation method thereof

ActiveCN104275189BHigh activityActive releaseHydrocarbon from carbon oxidesCatalyst activation/preparationPotassiumTitanium

The invention relates to a high-temperature sintering type catalyst for preparing light olefins from synthetic gas and a preparation method thereof. According to the invention, the problem that CO conversion rate is low and selectivity of light olefins is low during a reaction of preparing light olefins from synthetic gas in the prior art is mainly solved. The catalyst provided by the invention contains the following components, by weight, a) 10-40 parts of iron or its oxide, b) 0.5-10 parts of at least one element selected from titanium and chromium or an oxide thereof; c) 1-10 parts of at least one element selected from magnesium and calcium or an oxide thereof; d) 0.5-10 parts of potassium or its oxide; and e) 30-88 parts of a carrier alpha-aluminium oxide. By the technical scheme, the above problem is solved well. The catalyst can be used in industrial production of Fischer-Tropsch synthesis for preparation of light olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electrolytically-controlled micro-component picking and placing device and method

InactiveCN113733045ARealize attitude adjustmentActive releaseElectrolysis componentsMicromanipulatorElectrolysisBall screw

The invention discloses an electrolytically-controlled micro-component picking and placing device and method, relates to micro-component control in the field of micro-assembly, and aims to solve the key problem that active release of micro-components is difficult to realize in the micro-component operation process. The device comprises a micro-driving motor, a mounting frame, two sleeves, a coupler, a ball screw, a connecting nut, a hexagonal mounting frame, six fixing frames, a long connecting rod, a hose, an electrode connecting piece, a movable electrode and six inert electrodes, wherein the mounting frame and the micro-driving motor are connected through four through hole bolts, the lower end of the long connecting rod is in threaded connection with the electrode connecting piece, the upper ends of the fixing frames are fixed in holes of the hexagonal mounting frame through screws, the six inert electrodes are fixed in grooves in the lower ends of the fixing frames through screws respectively and are tightly attached to the six side faces of the movable electrode, and the six inert electrodes are tightly attached to one another. The device is used for lossless pickup, posture adjustment and active release operation of the micro-components.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com