Micro component picking and placing device and method controlled by liquid medium

A liquid medium, pick-and-place device technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve problems such as difficulty in ensuring release accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

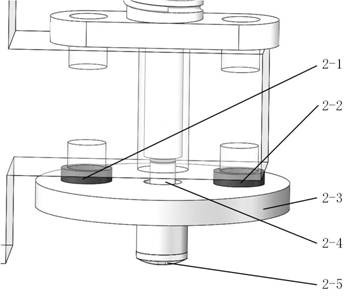

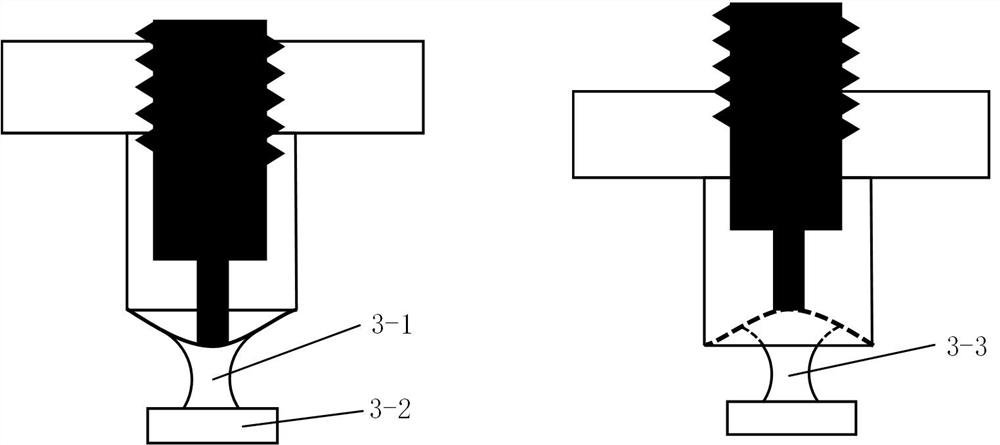

[0018] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Illustrates that a micro-component pick-and-place device controlled by a liquid medium in this embodiment includes a displacement control module, an inertia release module, a temperature control module, and an end effector module. The displacement control module includes a mounting frame 1-1, a micro-drive Motor 1-2, coupling 1-3, ball screw 1-4, screw nut 1-5, long connecting plate 1-6, inertia release module including connecting piece 1-7, electromagnet 1-8, suction Iron head 1-9, spring 1-10, spring holder 1-11, temperature control module includes heat conduction plate 1-12, two fixing bolts 1-13, four-hole connector 1-16, two fixing baffles 1 -17, electric heater 1-18, cooling plate 1-19, water cooling head 1-20, hose 1-21, end effector module including gasket A 2-1, gasket B 2-2, attitude adjustment plate 2-3 , probe 2-4, elastic film 2-5, the mounting frame 1-1 and the micr...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 It is explained that the long connecting plate 1-6 and the ball screw 1-4 in this embodiment are respectively in clearance fit with the mounting frame 1-1. Such arrangement can ensure the smooth movement of the long connecting plate up and down without frictional hindrance, and is conducive to the radial fixation of the ball screw. The other components and connections are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 , figure 2 , image 3 and Figure 4 Description, the connector 1-7, the electromagnet 1-8, the iron head 1-9, the spring 1-10, the inner hole of the spring holder 1-11, the inner hole of the heat conducting plate 1-12 and the Probe 2-4 coaxial setup. Such an arrangement is convenient for assembly and unobstructed up and down movement of the probes 2-4, and other components and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com