Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

224results about How to "Good light diffusion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycarbonate combination and preparation method thereof

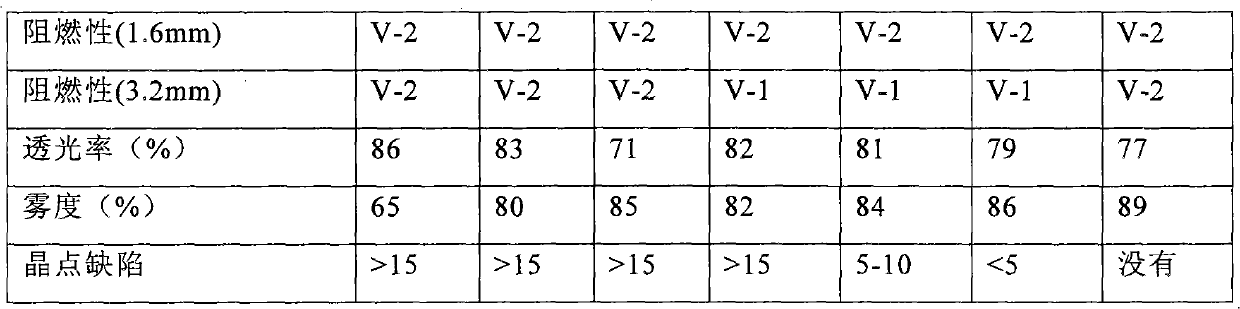

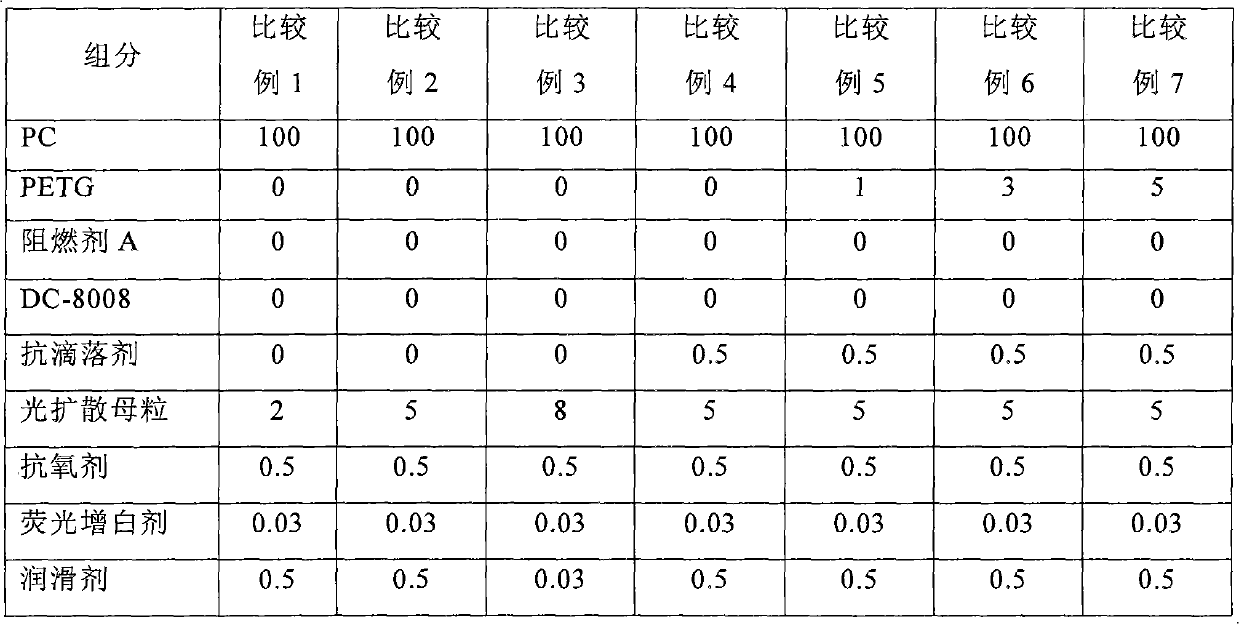

The invention provides a polycarbonate combination and a preparation method thereof. In terms of 100 parts of polycarbonate materials by weight, the polycarbonate combination comprises the following components in parts by weight: 100 parts of polycarbonate, 1-10 parts of copolyester, 0.01-0.5 part of aromatic sulphosalts fire retardant, 0.05-0.35 part of organic silicon fire retardant, 0.05-5 parts of anti-dripping agent, 1-15 parts of photodiffusion agent master batches and 0.05-5 parts of antioxidant. The preparation method of the polycarbonate combination comprises the following steps: adding the components of the polycarbonate combination as required into a blender mixer, and evenly stirring and mixing; and carrying out melt mixing, extrusion and granulation on the evenly mixed raw materials in eight temperature areas of a double-screw extruder. The polycarbonate combination provided by the invention has excellent photodiffusion performance, high light transmittance, excellent flame retardant property, safety, environmental protection, favorable heat resistance, easy molding and reduced crystal point defect.

Owner:SINOPLAST NEW MATERIAL

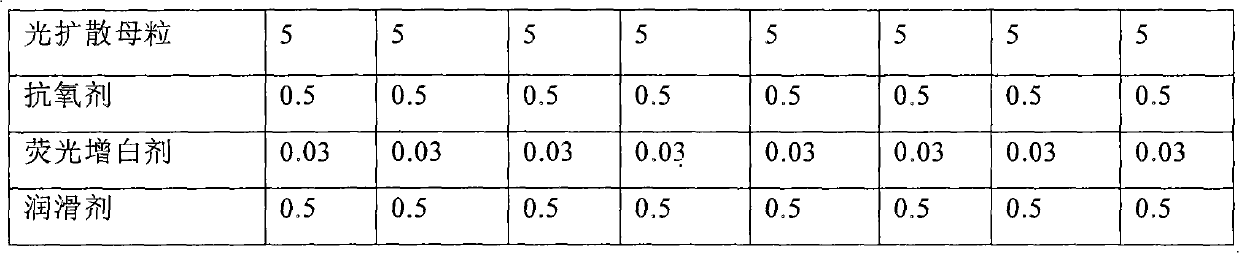

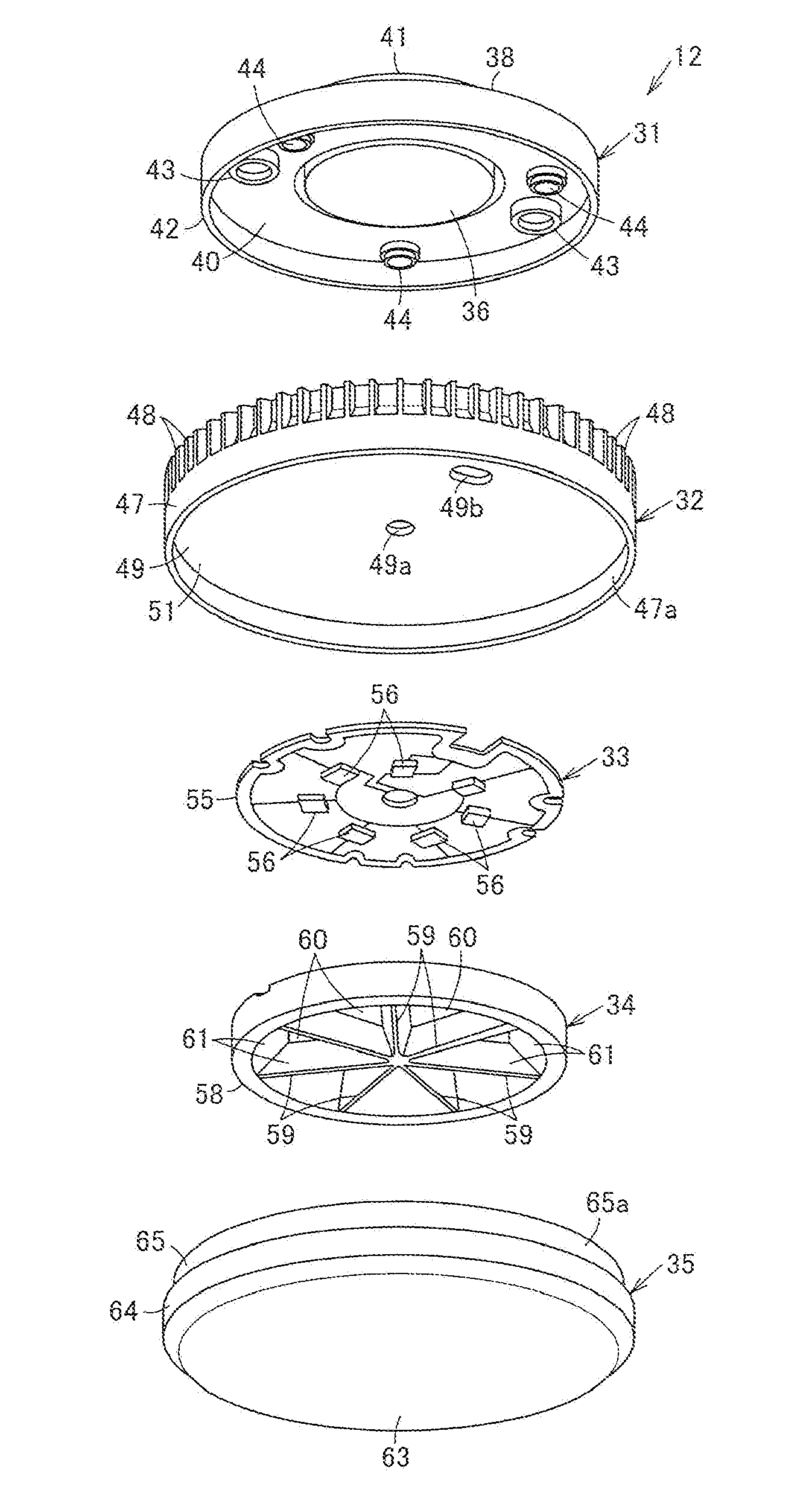

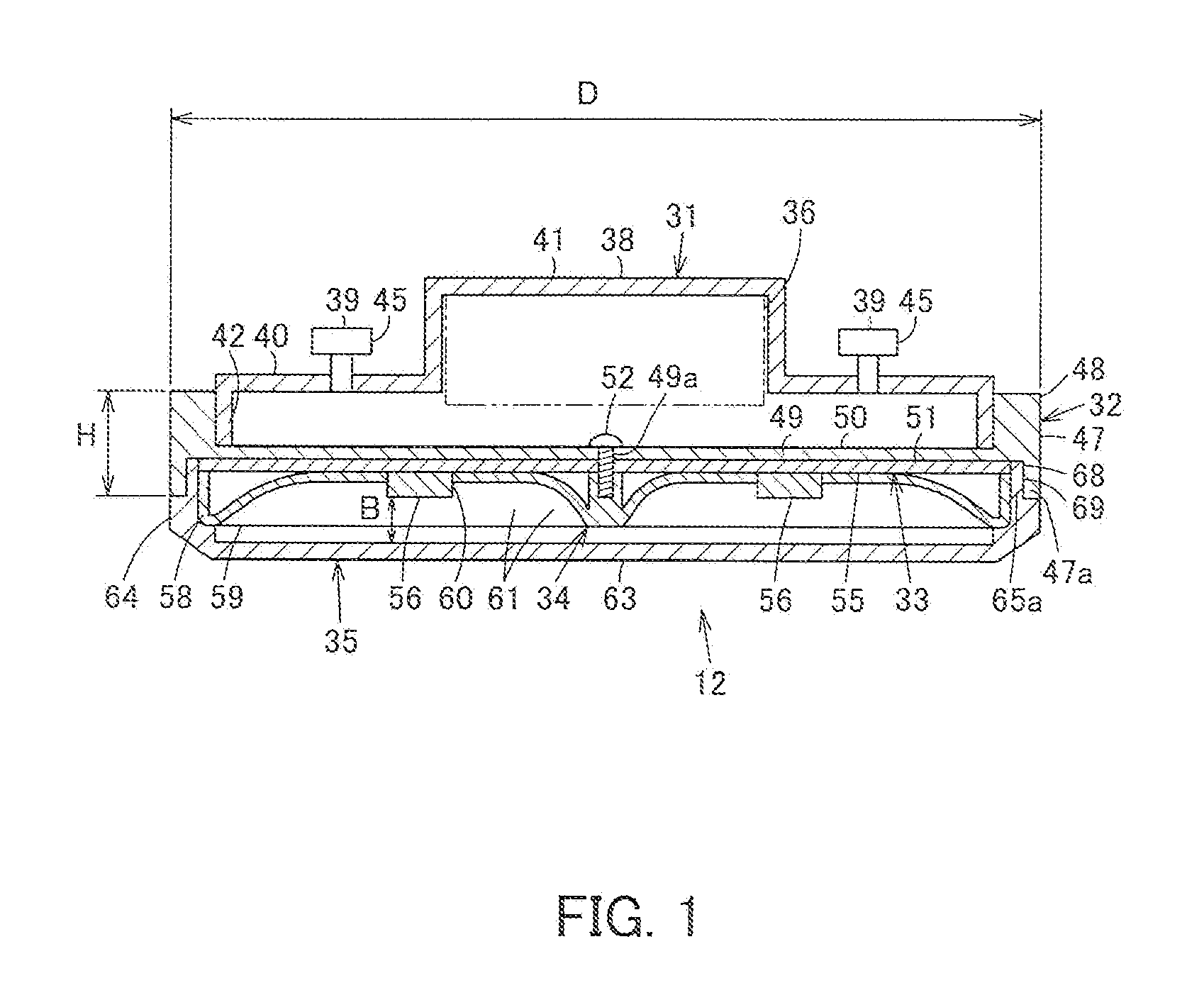

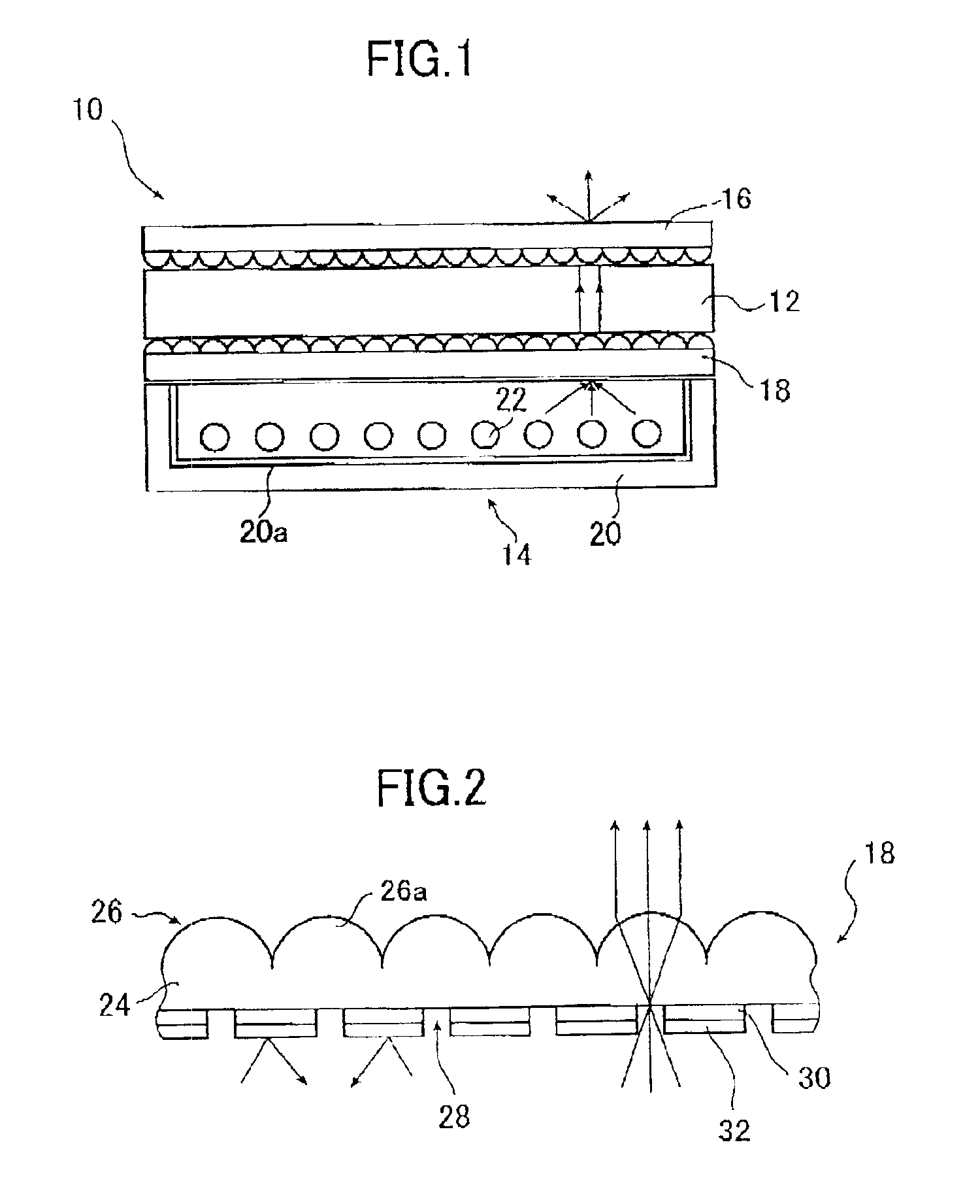

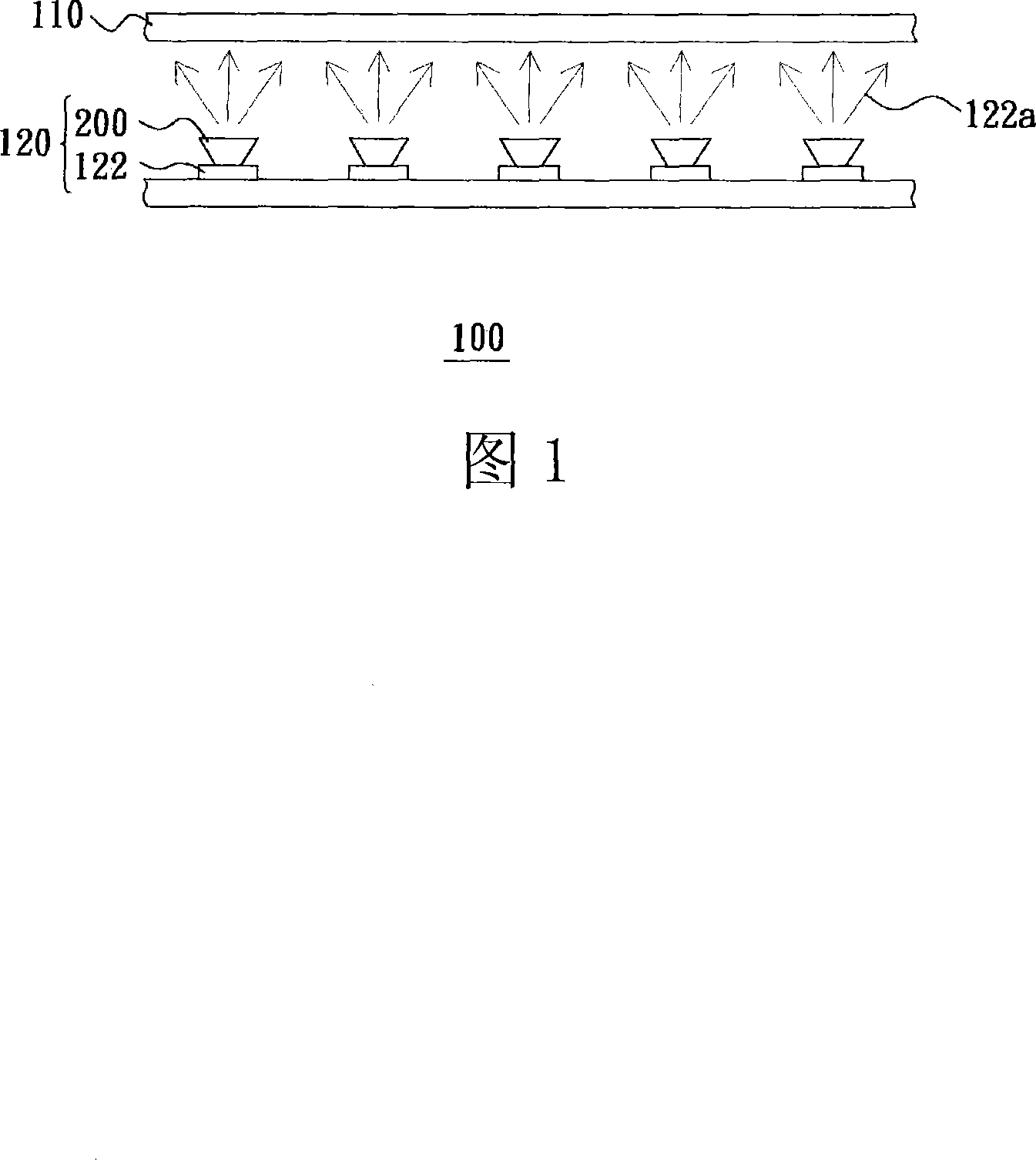

Lamp system and lighting apparatus

InactiveUS20100208473A1Long life-timeEffective coolingPoint-like light sourceLighting support devicesEngineeringRadiation

A lamp system which can improve radiation performance is provided. A metallic heat conduction part provided along a peripheral portion of a metallic cover is fitted with a resin heat conduction part provided along a peripheral portion of a transparent cover so as to thermally contact each other. Heat generated by an LED is radiated into air from the metallic cover and at the same time is efficiently conducted from the metallic cover to the transparent cover to be radiated into air from the transparent cover.

Owner:TOSHIBA LIGHTING & TECH CORP +1

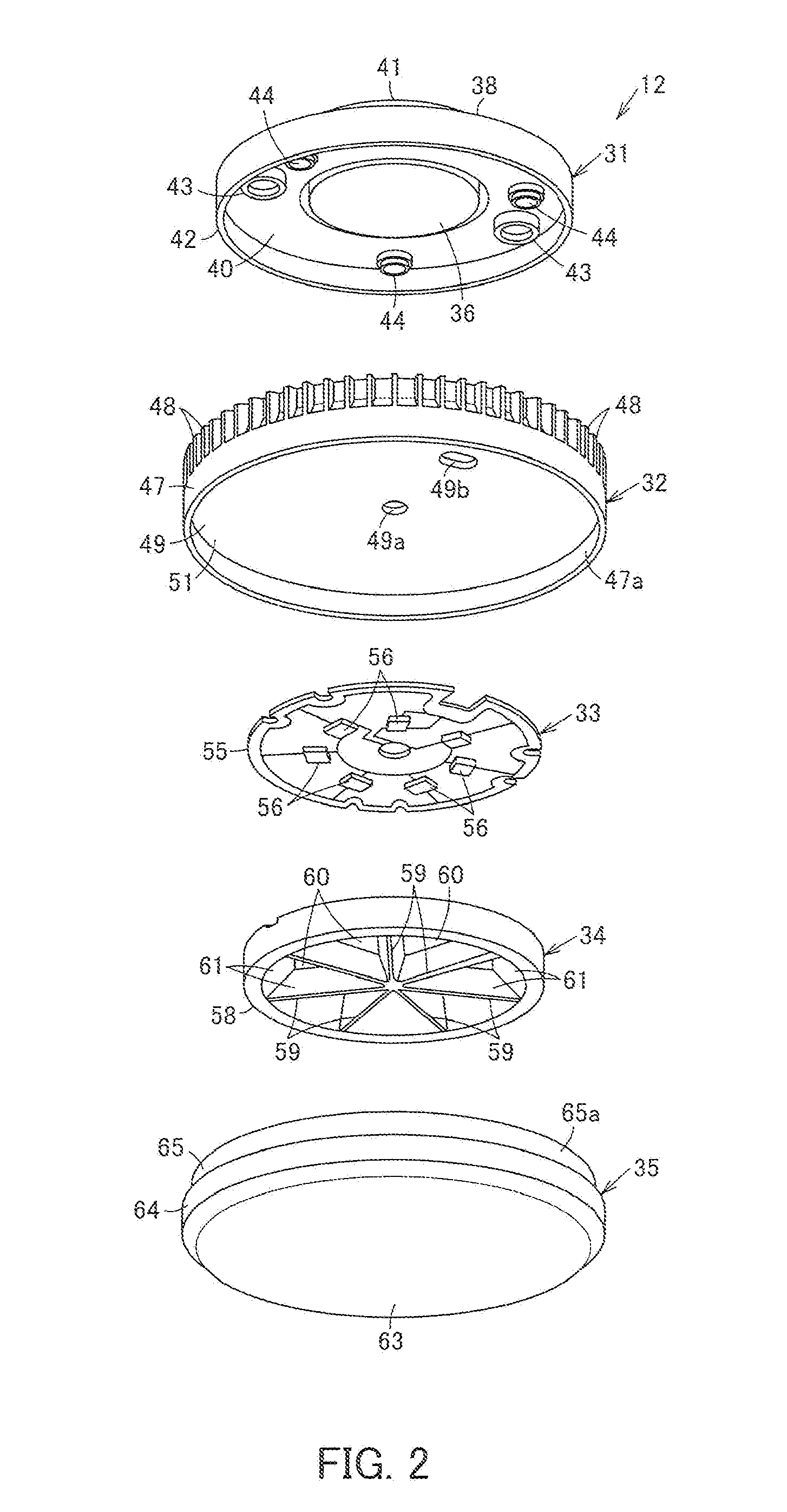

Polycarbonate composite material suitable for LED (light-emitting diode) lamp cover and preparation method thereof

ActiveCN102532857AGood light diffusion effectEvenly dispersedPoint-like light sourceGlobesLight guideEngineering plastic

The invention discloses a polycarbonate composite material suitable for an LED (light-emitting diode) lamp cover and a preparation method thereof. Based on the 100 weight parts PHR (parts per hundreds of rubber or resin) of a substrate polycarbonate material, the composition of the composite comprises the following components in PHR: 100PHR of polycarbonate, 5-15PHR of light scattering master batch, 0.2-1.0PHR of flame retardant, 1-3PHR of nano master batch and 0.2-1.0PHR of other additives. In the method, engineering plastic polycarbonate is used as a main body; and the light scattering master batch and the nano additive master batch are firstly prepared through an internal mixer and then smashed at high speed, and finally, the light scattering master batch and other raw materials are subjected to blending, extruding and granulating by adopting a side feeding method. By using the method, the problem that the dispersion of a light dispersing agent and other additives is not uniform issolved, and the obtained light dispersing material has high transmissivity and haze. The polycarbonate composite material disclosed by the invention can be used for preparation of related products inthe optical field, is environment-friendly, high in safety and excellent in various physical and mechanical properties, and is suitable for preparing the LED lamp covers and other light guiding materials.

Owner:SHANGHAI UNIV

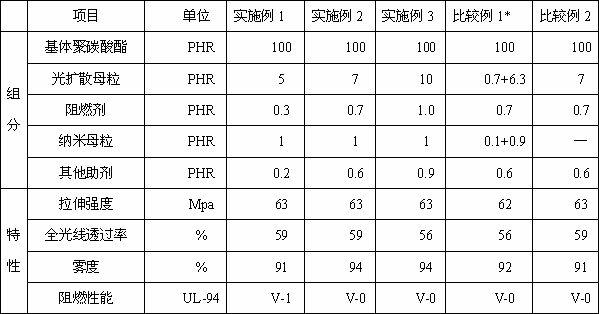

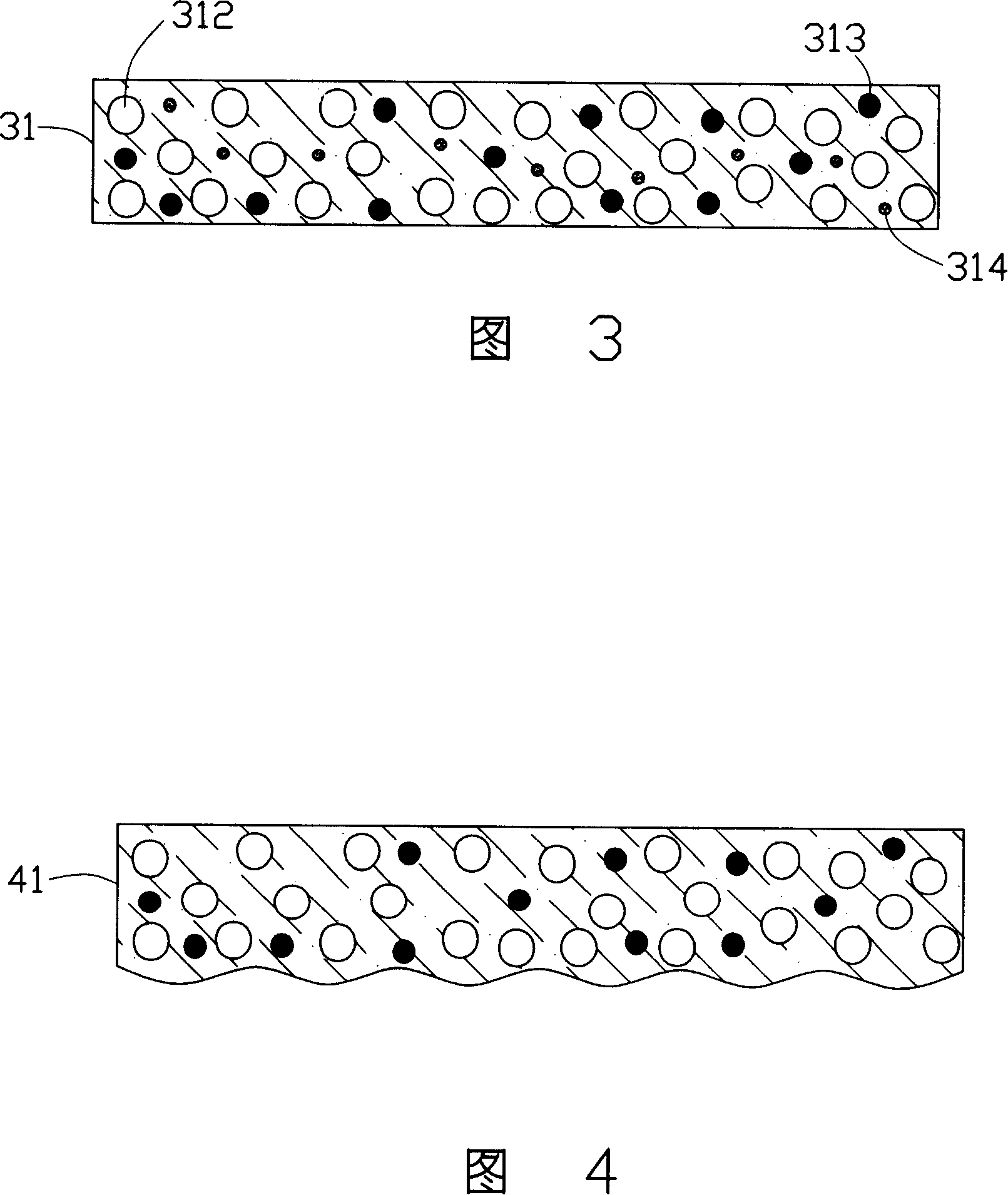

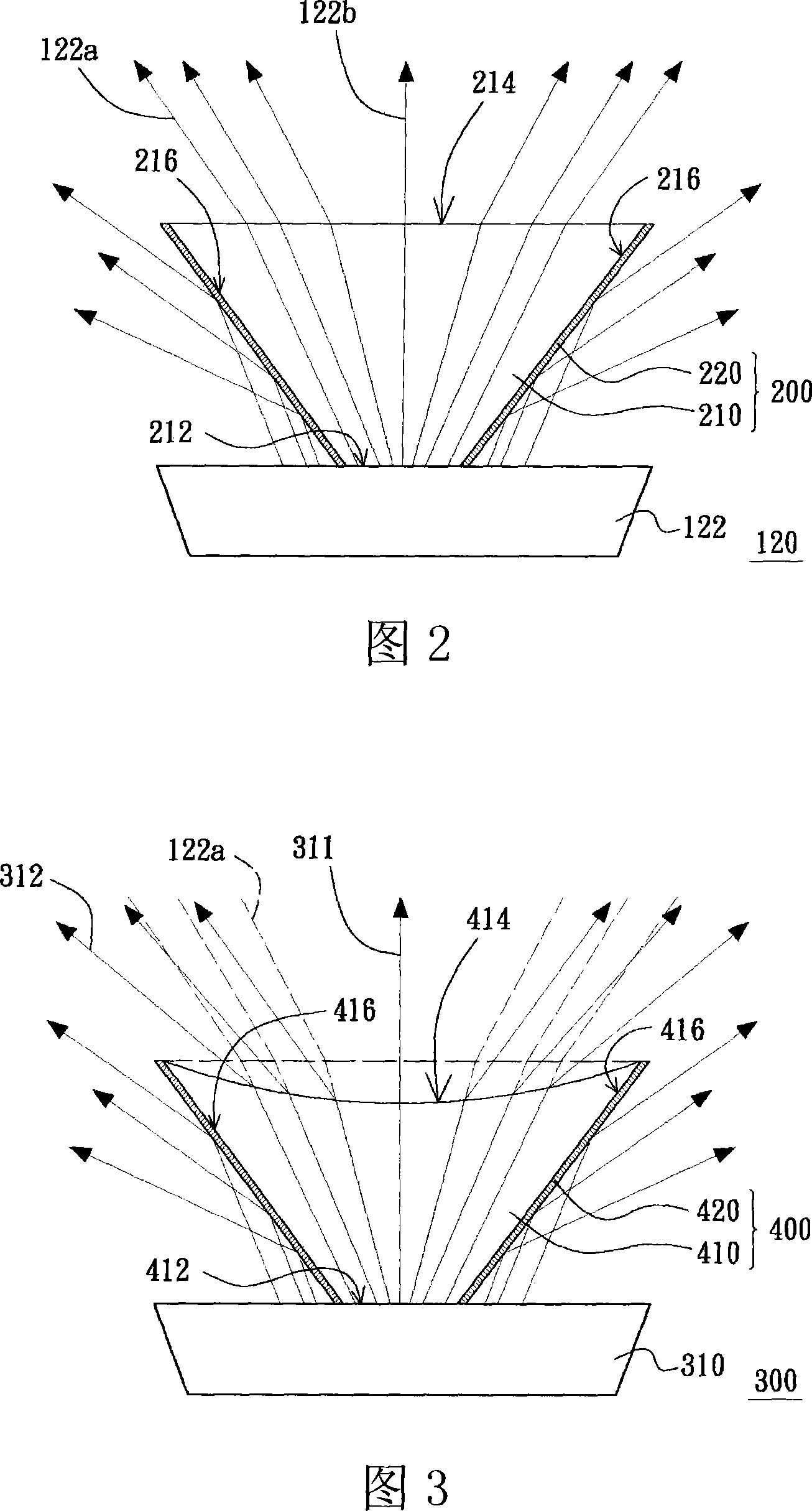

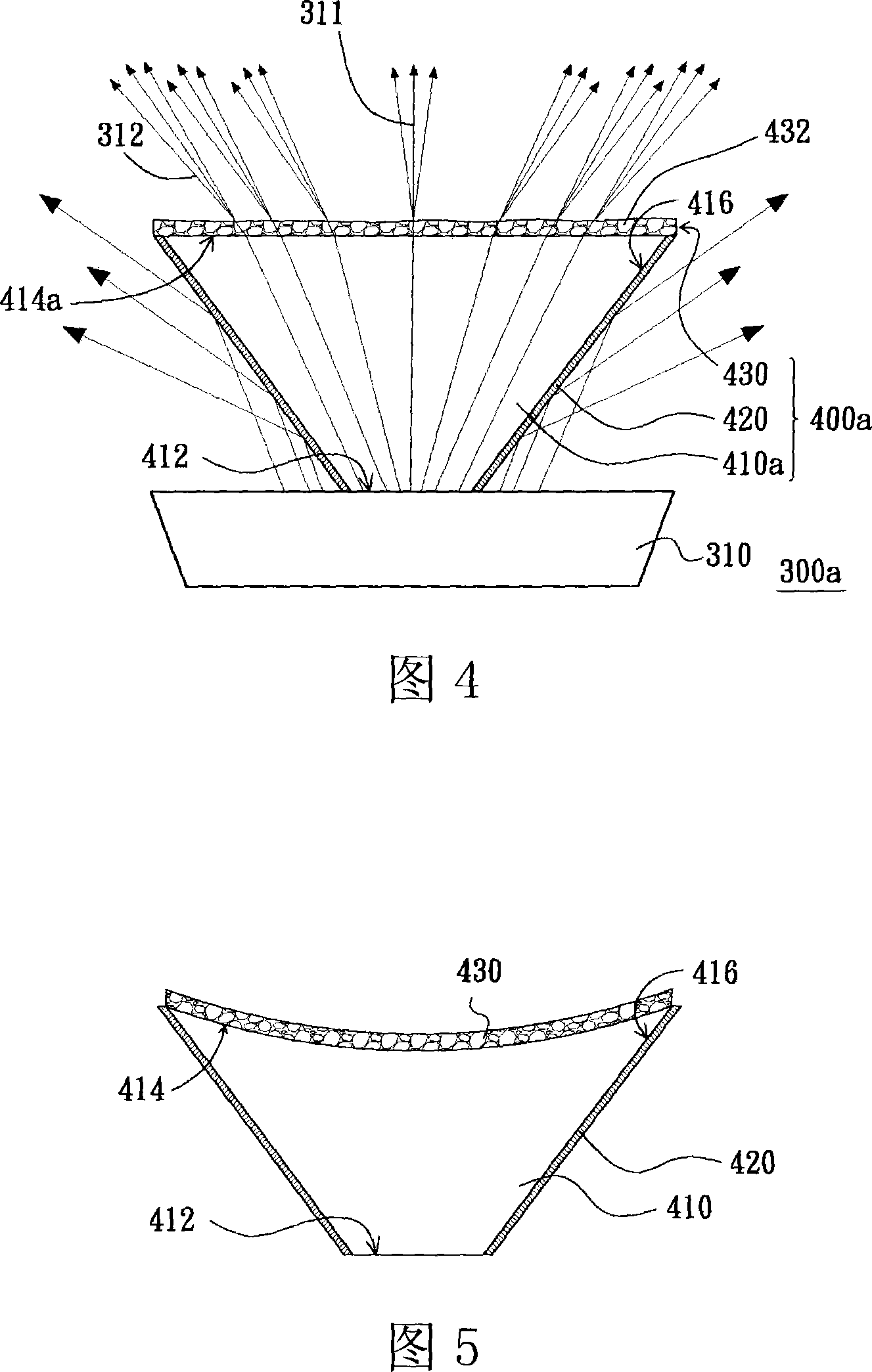

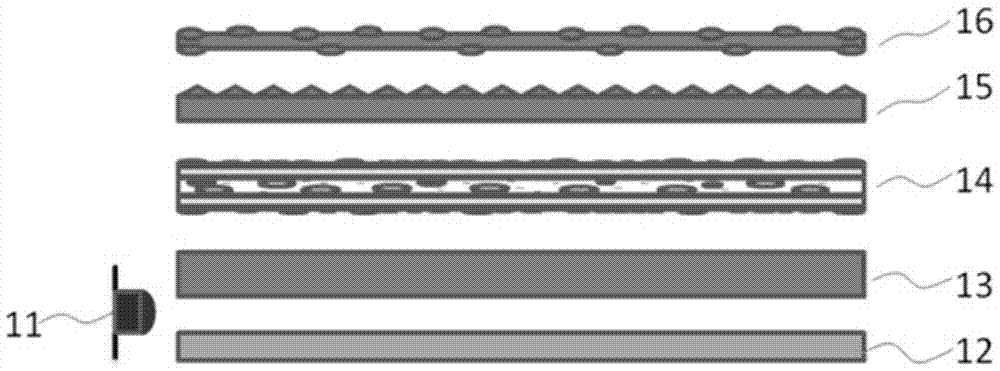

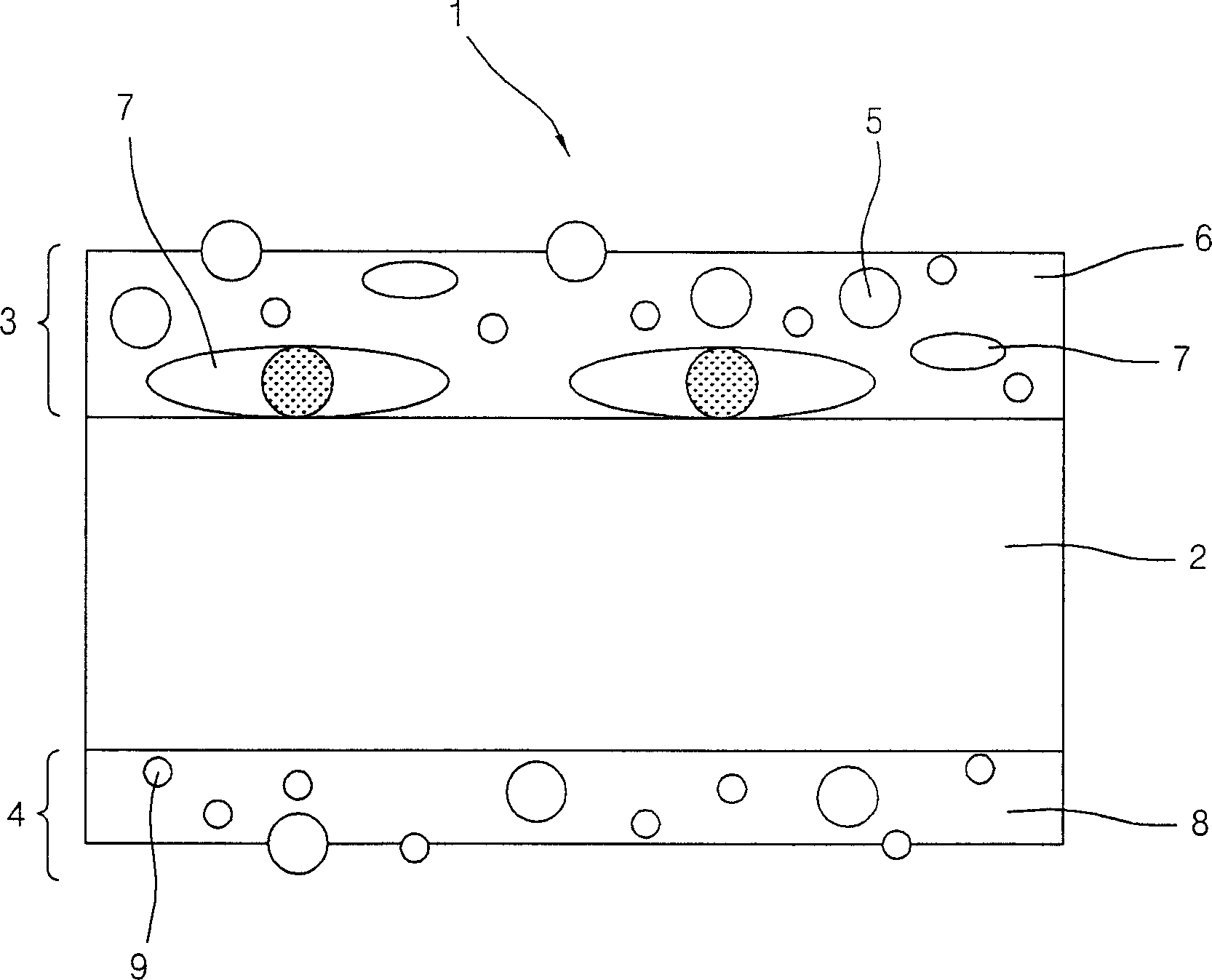

Pervasion piece

InactiveCN101118291AHigh refractive indexSpread evenlyDiffusing elementsSynthetic resin layered productsRefractive indexDiffusion layer

The present invention discloses a diffusion piece and comprises a diffusion layer. The diffusion layer consists of a transparent resin parent metal, as well as a first scattering particle and a second scattering particle doping in the transparent resin parent metal. The refractive index of the first scattering particle is smaller than the refractive index of the second scattering particle. The light diffusion effect of the diffusion piece is strong.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

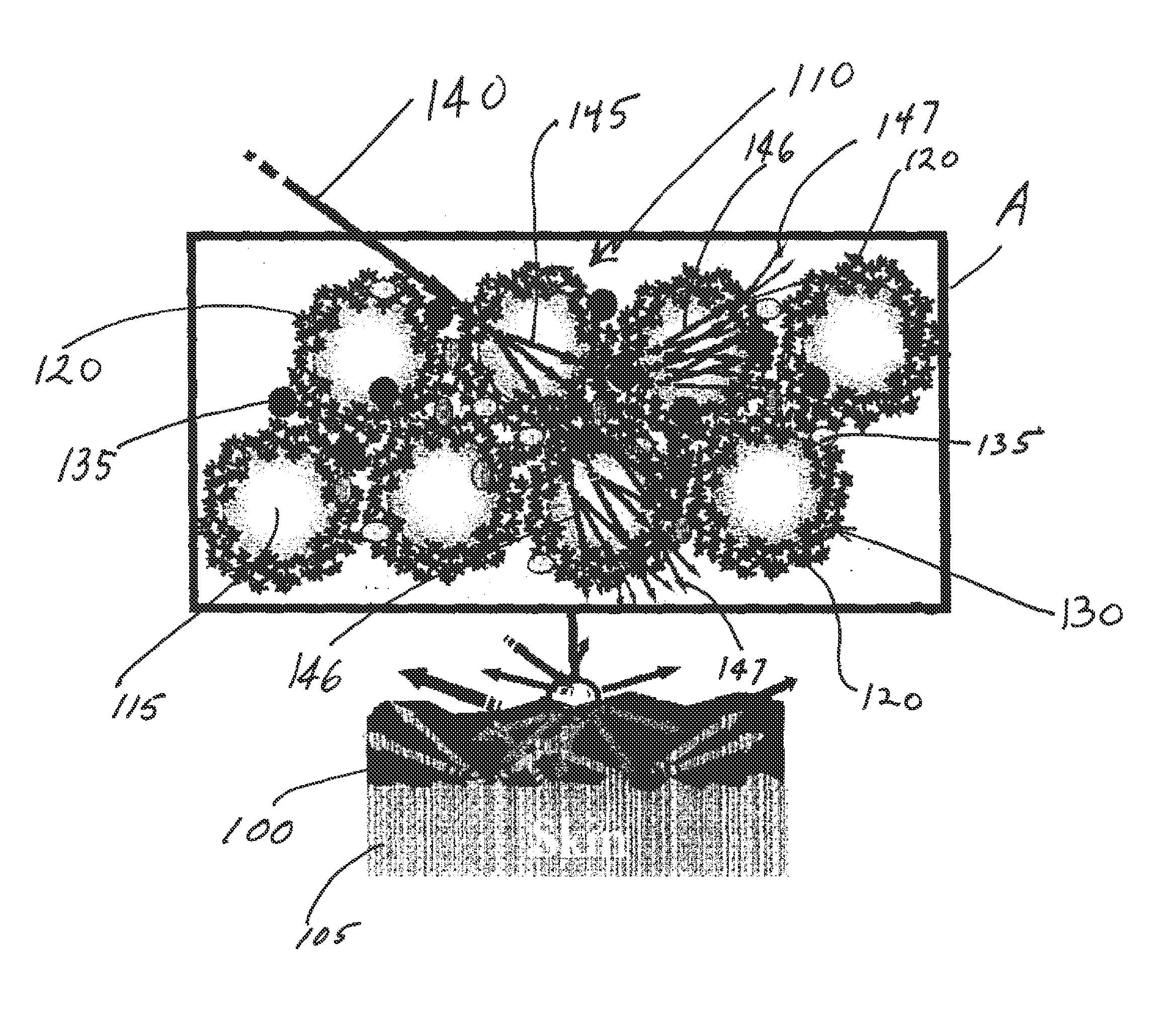

Gel Technology Suitable for Use in Cosmetic Compositions

InactiveUS20100266649A1Optimize optical diffusion effectIncrease interfacial areaBiocideHeavy metal active ingredientsWrinkleFine grain

A gel system comprising a fractal network of nanoparticles and macroscopic particles is disclosed. The gel system is capable of forming an “optical gel” effective to blurrfine lines and wrinkles as a consequence of the size domain differences between the fractal particles and the macroscopic particles. Cosmetic compositions comprising such gels and methods for their use are also disclosed.

Owner:AVON PROD INC

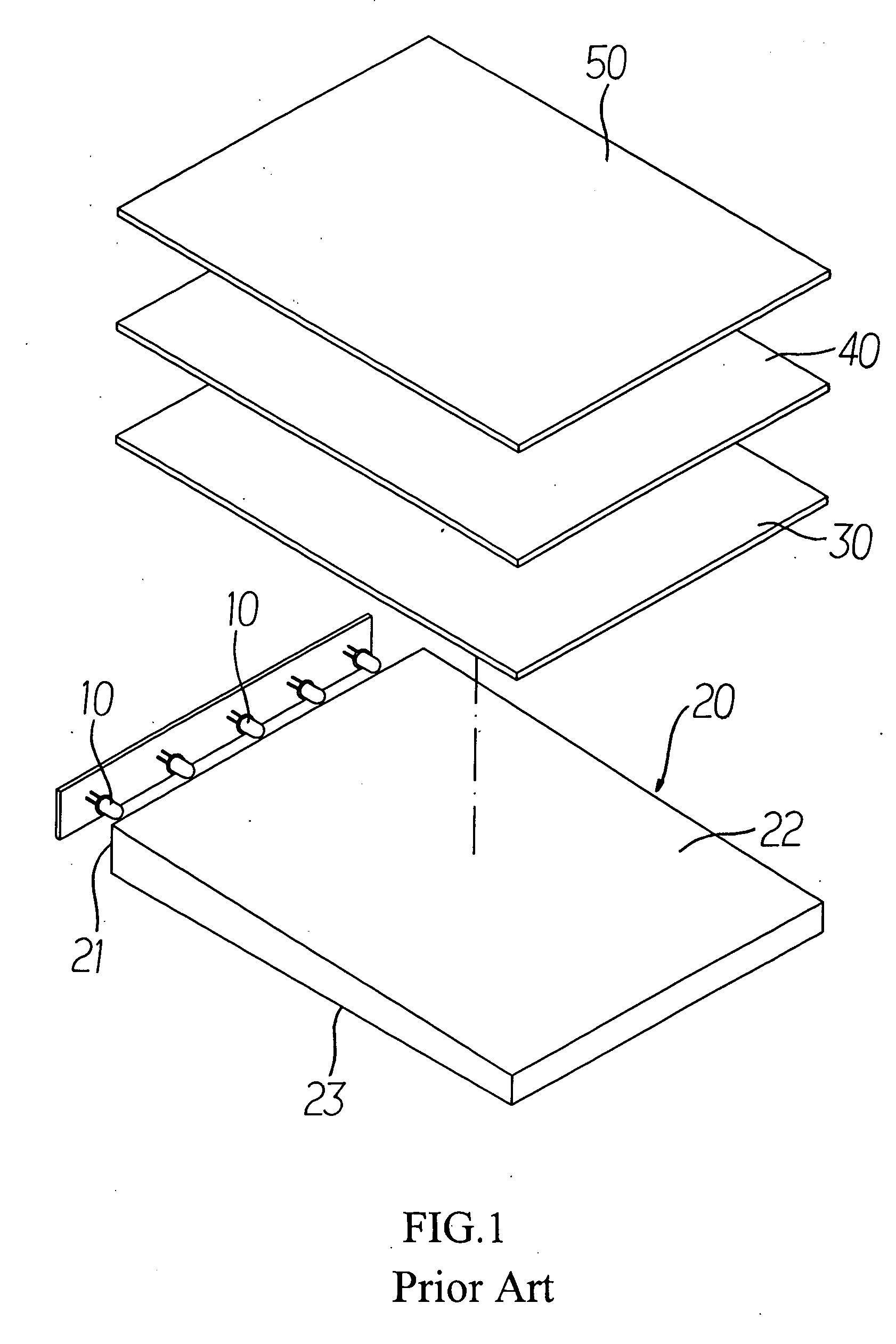

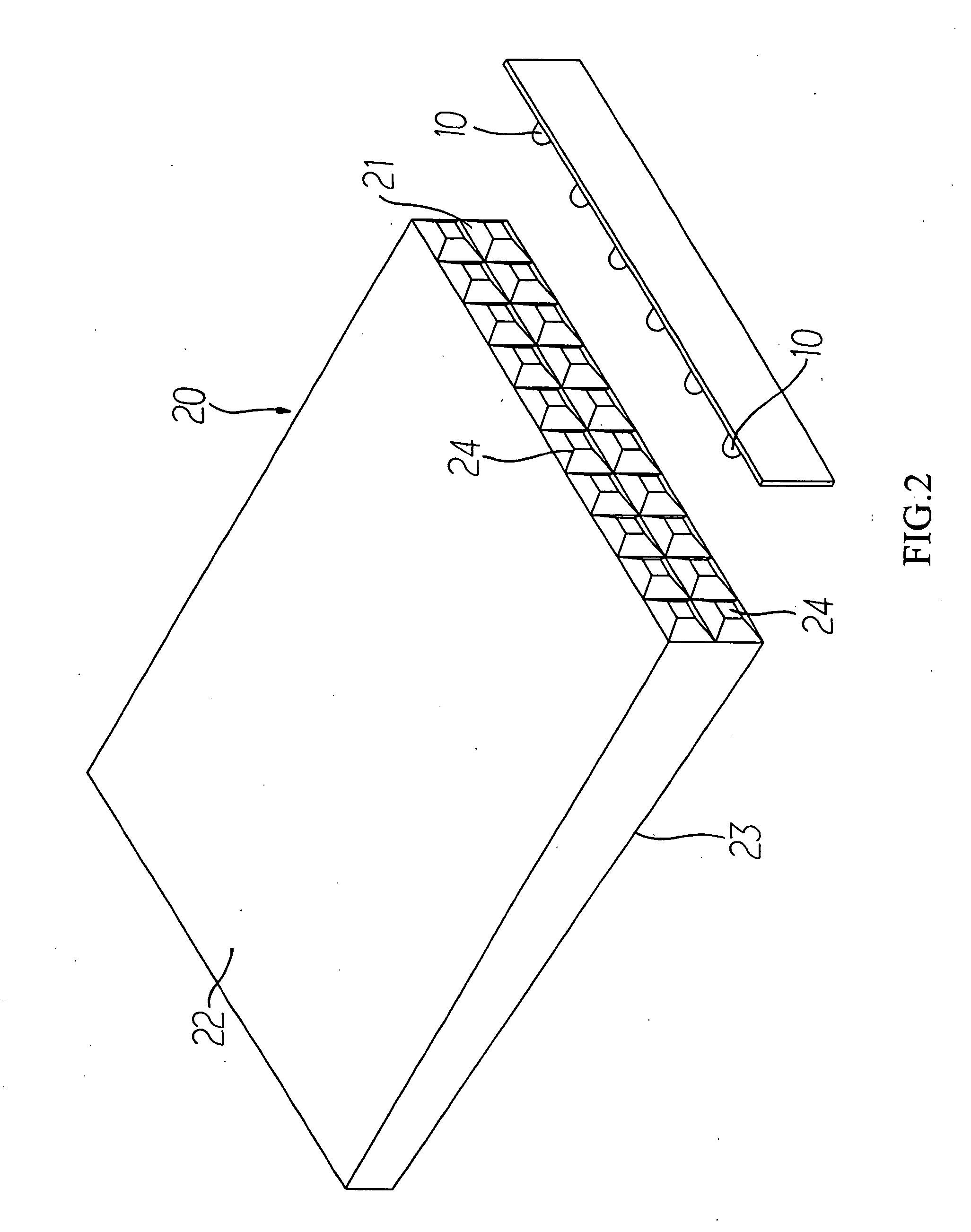

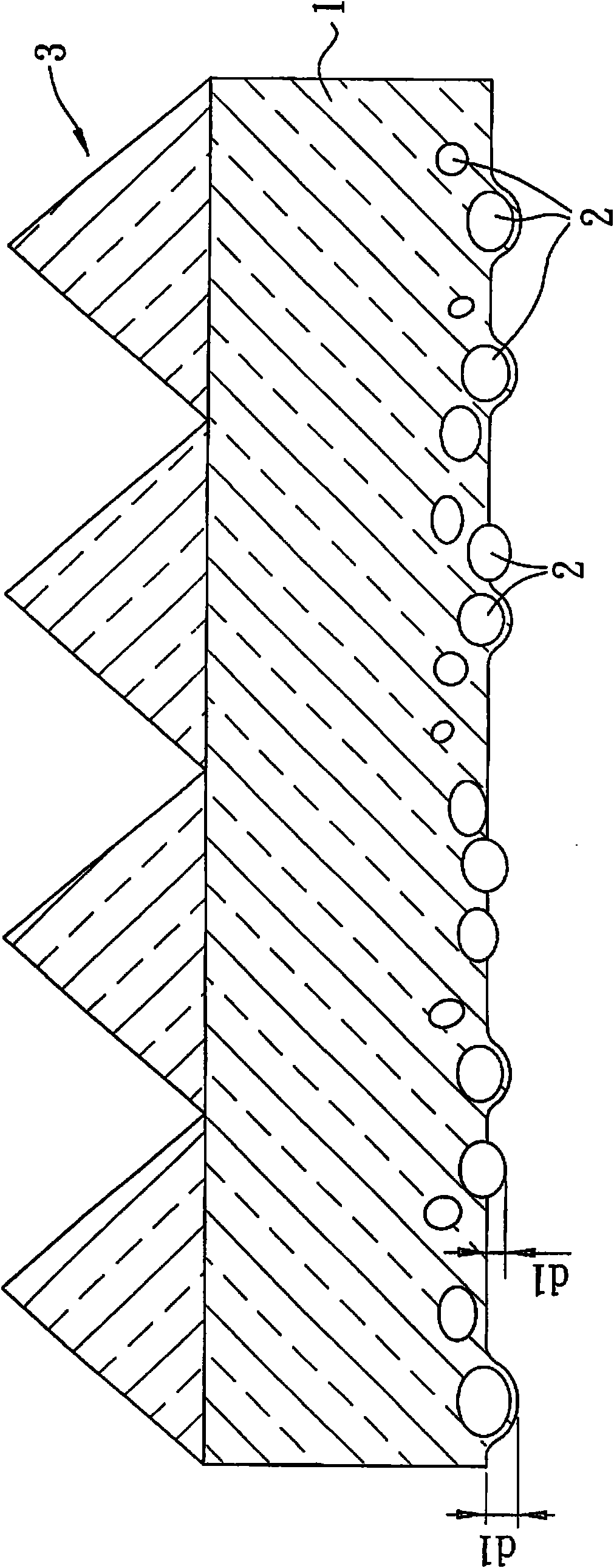

Incident assembly of light guide plate

InactiveUS20060203511A1Increase light sourceEven projectionOptical beam guiding meansPlanar/plate-like light guidesLight guideLight emitting device

A light guide plate includes an incident plane for receiving a light source of a light emitting device, a bottom surface connected to the incident plane, and an emergent plane corresponding to the bottom surface for outputting the light source of the light emitting device, and the light emitting device is installed on one side of the incident plane of the light guide plate; wherein the incident plane of the light guide plate has a structure consisted of a plurality of polyhedrons, such that an incident light of the light emitting device passes through the polyhedron structure to improve the light diffusion effect and make the light produced by the light emitting device evenly diffused towards the emergent plane of the light guide plate.

Owner:K-BRIDGE ELECTRONICS CO LTD

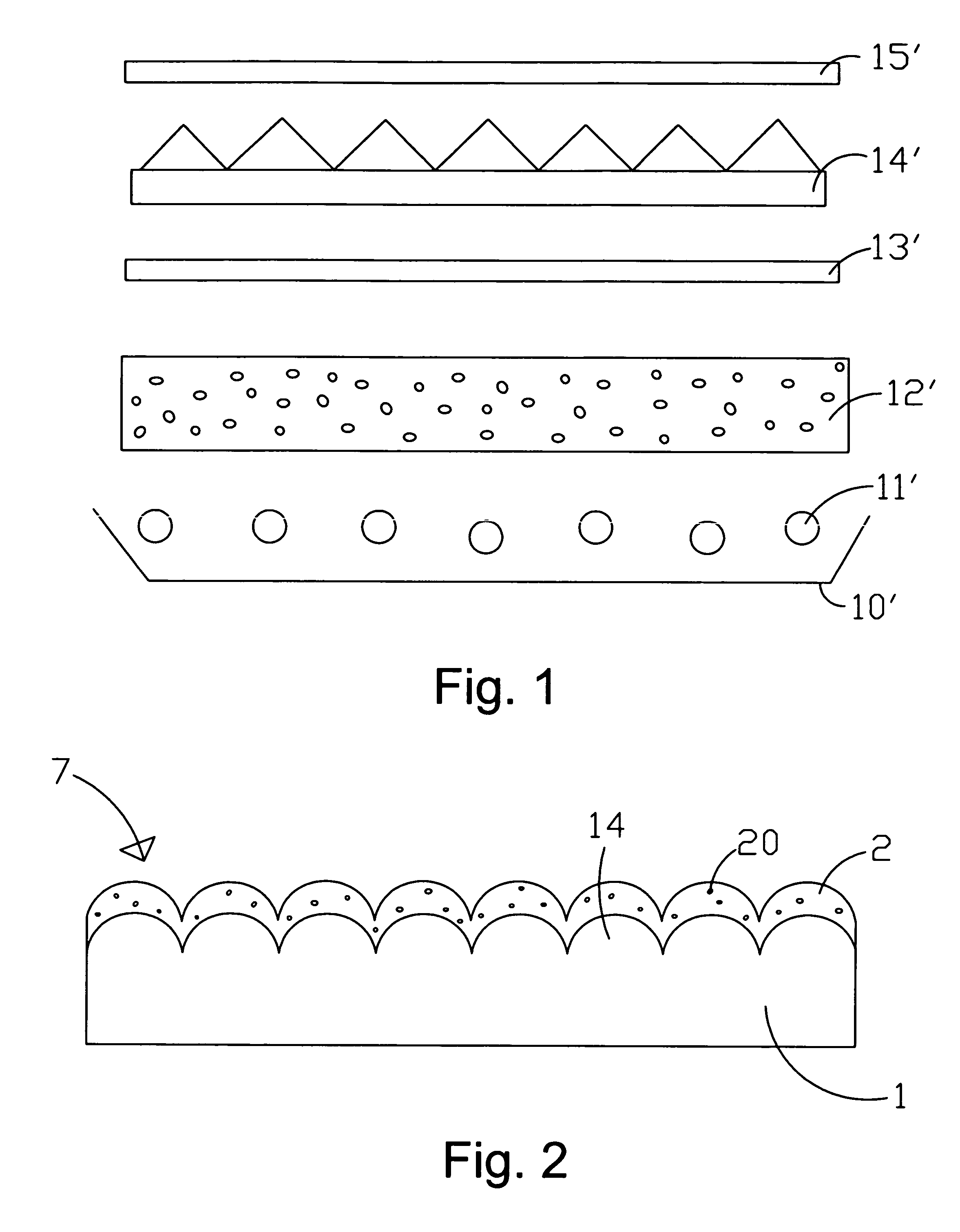

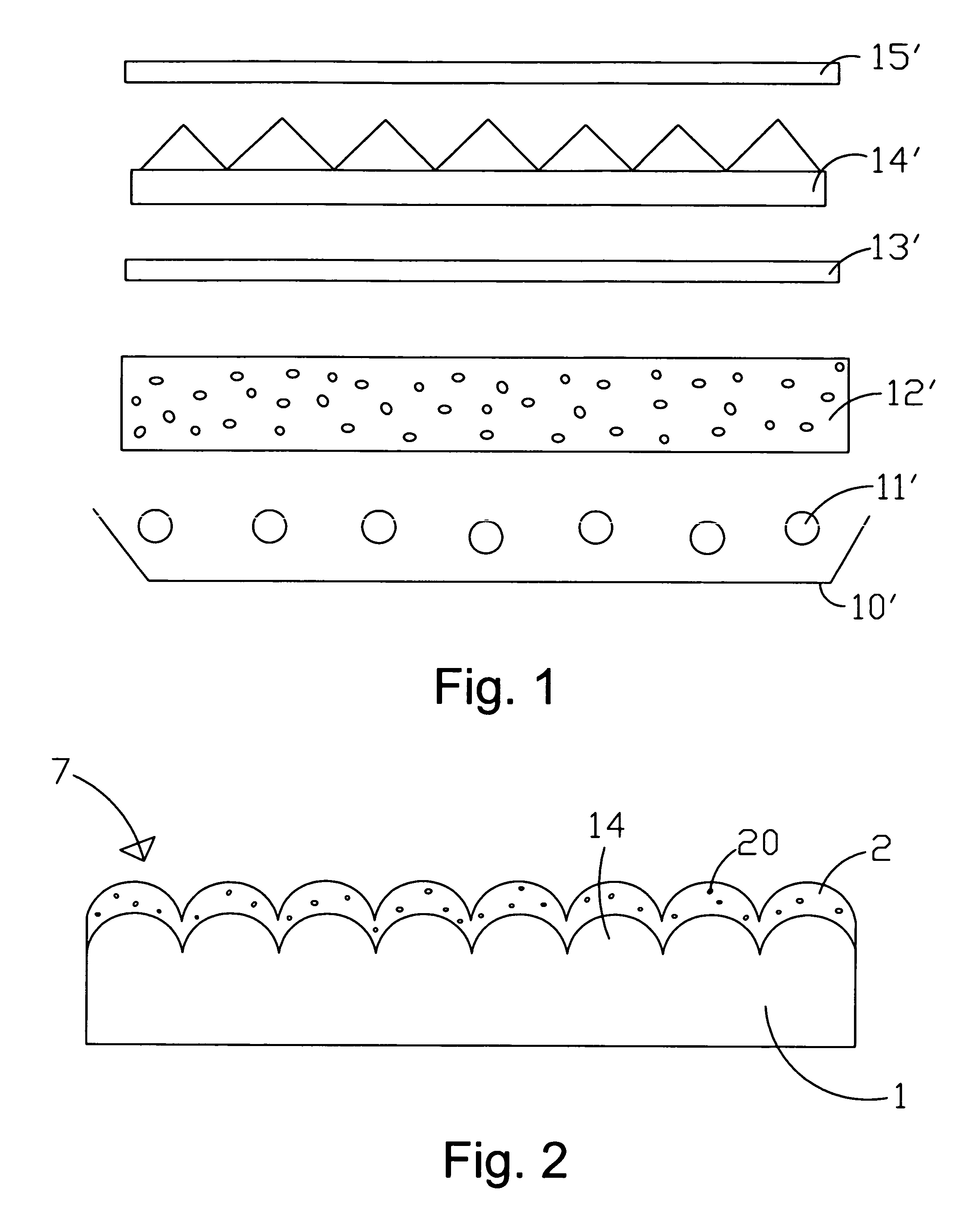

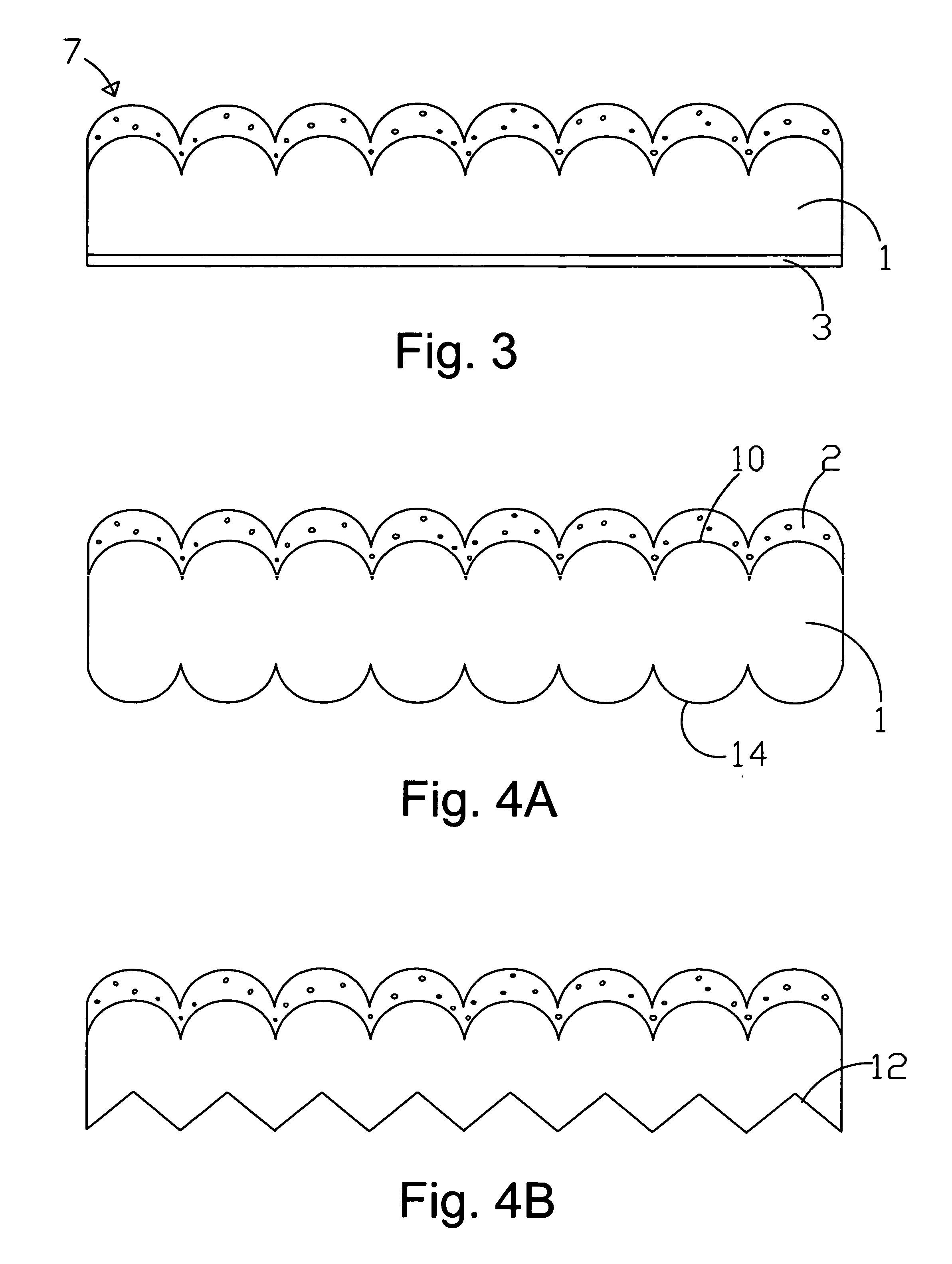

Diffuser plate with higher light diffusion efficiency and brightness

ActiveUS20070159699A1Improve diffusion efficiencyIncrease brightnessPrismsDiffusing elementsDiffusionLenticular lens

A diffuser plate with higher light diffusion efficiency and brightness applied to backlight module of Liquid Crystal Display TV (LCD TV) for providing uniform light is disclosed. An optical lens with a diffusion layer is disposed on one side of the substrate. The diffusion layer is arranged above the optical lens for enhancing diffusion effect. The other side of the diffuser plate can be a plane or having a lens structure. By Lenticular lens, the homogeneity of emitted light is improved so as to reduce the amount of diffusion particles being added into the diffusion plate Therefore, the light transmission is increased and the brightness is enhanced. Meanwhile, ability of shielding lamps is considered and Moiré effect is eliminated. Moreover, the diffusion layer is co-extruded on surface of the Lenticular lens together with the substrate so that the device is easy to be produced.

Owner:ENTIRE TECH CO LTD

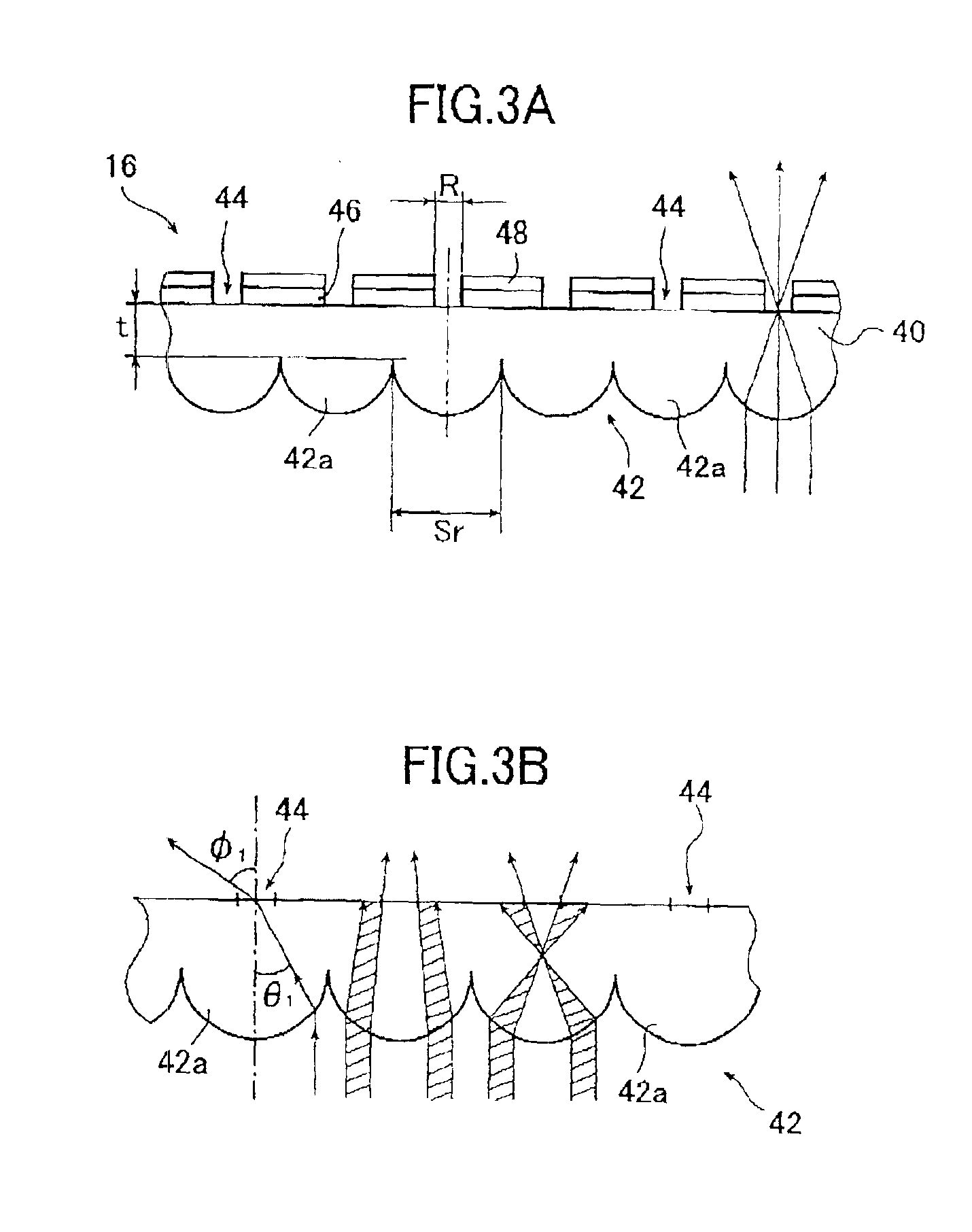

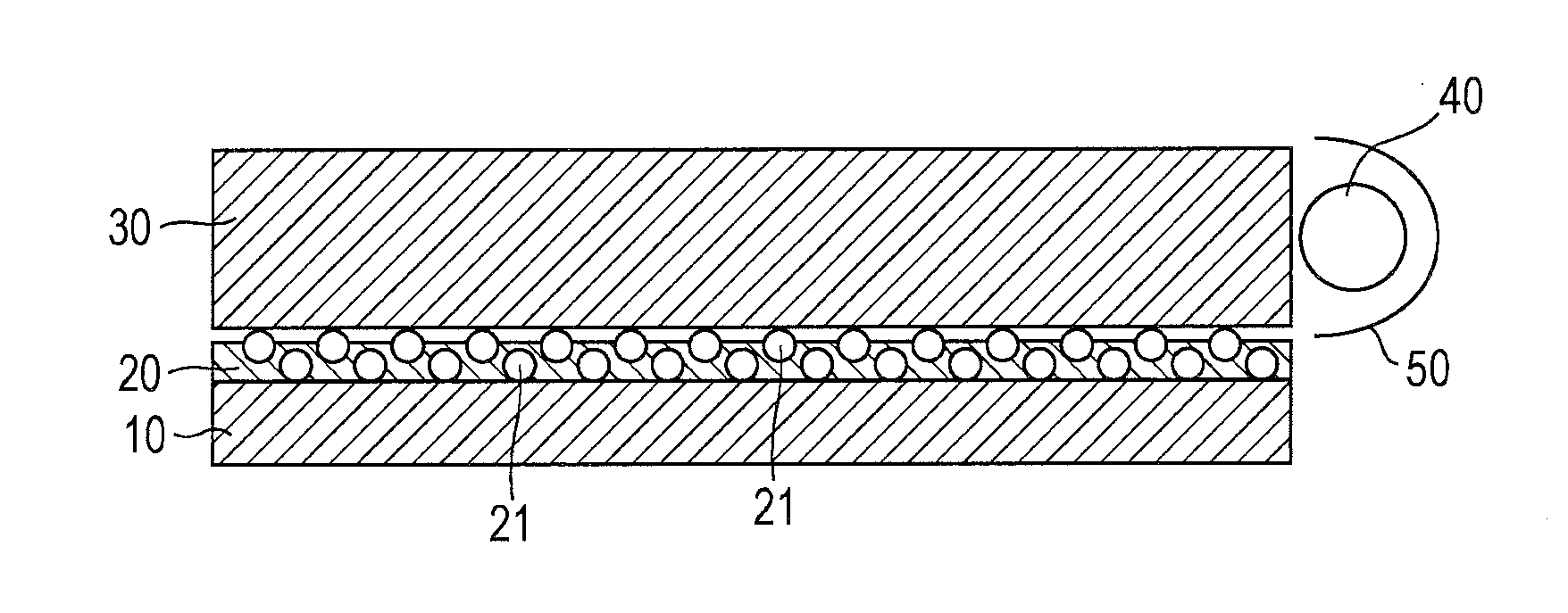

Light diffusing plate, liquid crystal display apparatus and rear projection apparatus

InactiveUS6897911B2Excellent light diffuse capabilityHigh contrastDiffusing elementsNon-linear opticsMicrolensLiquid-crystal display

The light diffusing plate includes a lens substrate, a plurality of microlenses disposed on a surface of the lens substrate, a plurality of light exit areas, each having a circular or rectangular form a center of which is coincident with an optical axis of the microlens, and a light shield layer formed on another surface of the lens substrate, and covering other area than the light exit areas. When n and t are a refractive index and a thickness of the lens substrate, respectively, and C (R; diameter, A, B; sides of rectangle) is a size of light exit area, a size of the microlens Sr satisfies the following formula in the light diffusing plate: Sr≧2t×tan θ+C (with the proviso that θ=sin−1(1 / n)). Or, a form of the microlens in the light diffusing plate is a part of an ellipsoid shown in the following formula X2 / a2+y2 / a2+z2 / c2=1 (x and y represent axis on the surface of the lens substrate, z represents the optical axis), it's eccentricity ε is shown in the following formula ε=(c2−a2)1 / 2 / c=1 / n and it's far focal point is coincident with a position of the light exit area. The liquid crystal display apparatus and the rear projection apparatus use the light diffusing plate.

Owner:FUJIFILM CORP +1

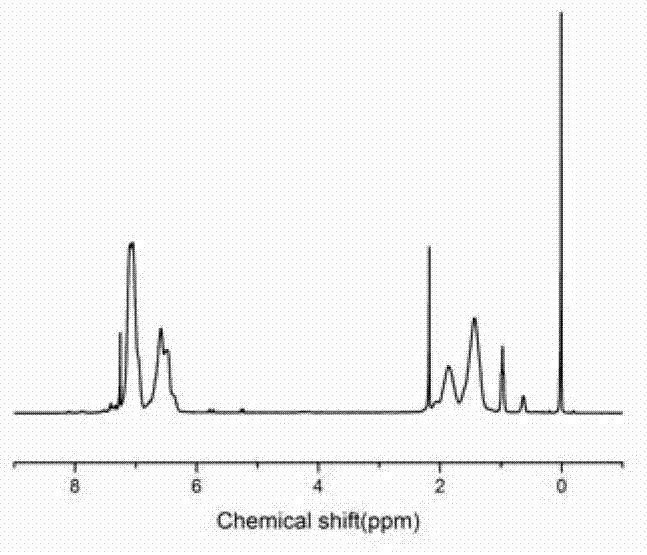

Light diffusing agent, PMMA (polymethyl methacrylate) light diffusing plate and manufacturing method thereof

ActiveCN103193915AImprove performanceImprove mechanical propertiesDiffusing elementsOligomerRefractive index

The invention relates to a light diffusing agent, a PMMA (polymethyl methacrylate) light diffusing plate and a manufacturing method thereof. The light diffusing agent is a random copolymer of styrene (St) and methacryloxypropylisobutyl polyhedral oligomer silsesquioxane (MAiBuPOSS). The PMMA light diffusing plate comprises the following components in percentage by weight: 97.0-99.5% of polymethyl methacrylate and 0.5-3.0% of light diffusing agent. The refractive indexes of the styrene component and the MAiBuPOSS component in the light diffusing agent differ from the refractive index of PMMA; when passing through a material, a light ray is refracted for many times and becomes bright and soft after passing through a substrate. Meanwhile, the MAiBuPOSS component ensures that the dispersibility of PS (Poly Styrene) in PMMA is remarkably improved, excellent light transmission and light scattering are obtained, and the optical efficacy is high. The PMMA light diffusing plate manufactured by the invention can be used for LED (Light Emitting Diode) illumination lamps, such as a plate lamp, an advertising lamp box, a professional film viewer, a down lamp and the like.

Owner:石狮市天生化工有限公司 +1

High light-transmittance and high light-shielding polystyrene composition and preparation method of composition

The invention relates to the technical field of polystyrene composition, particularly to high light-transmittance and high light-shielding polystyrene composition. The high light-transmittance and high light-shielding polystyrene composition is prepared from the following materials by weight: 98.2%-99.6% of polystyrene, 0-1% of silicon light diffusing agent, 0.1-0.2% of a lubricating agent, 0.1-0.2% of a dispersing agent, 0.1-0.3% of antioxidant A and 0.1-0.2% of antioxidant B. The preparation method comprises the steps of uniformly agitating the constituents except for polystyrene by a high-speed mixer; putting the polystyrene and the uniformly mixed materials into the high-speed mixer to carry out three-segment agitation, and extruding and pelletizing the uniformly mixed materials by a double-screw extruder. The polystyrene composition disclosed by the invention is high in light transmittance, high in light shielding property, good in impact strength, good in balance of haze and light transmittance, high in structure strength of the prepared product, simple in process, low in production cost and beneficial for generalization and application.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

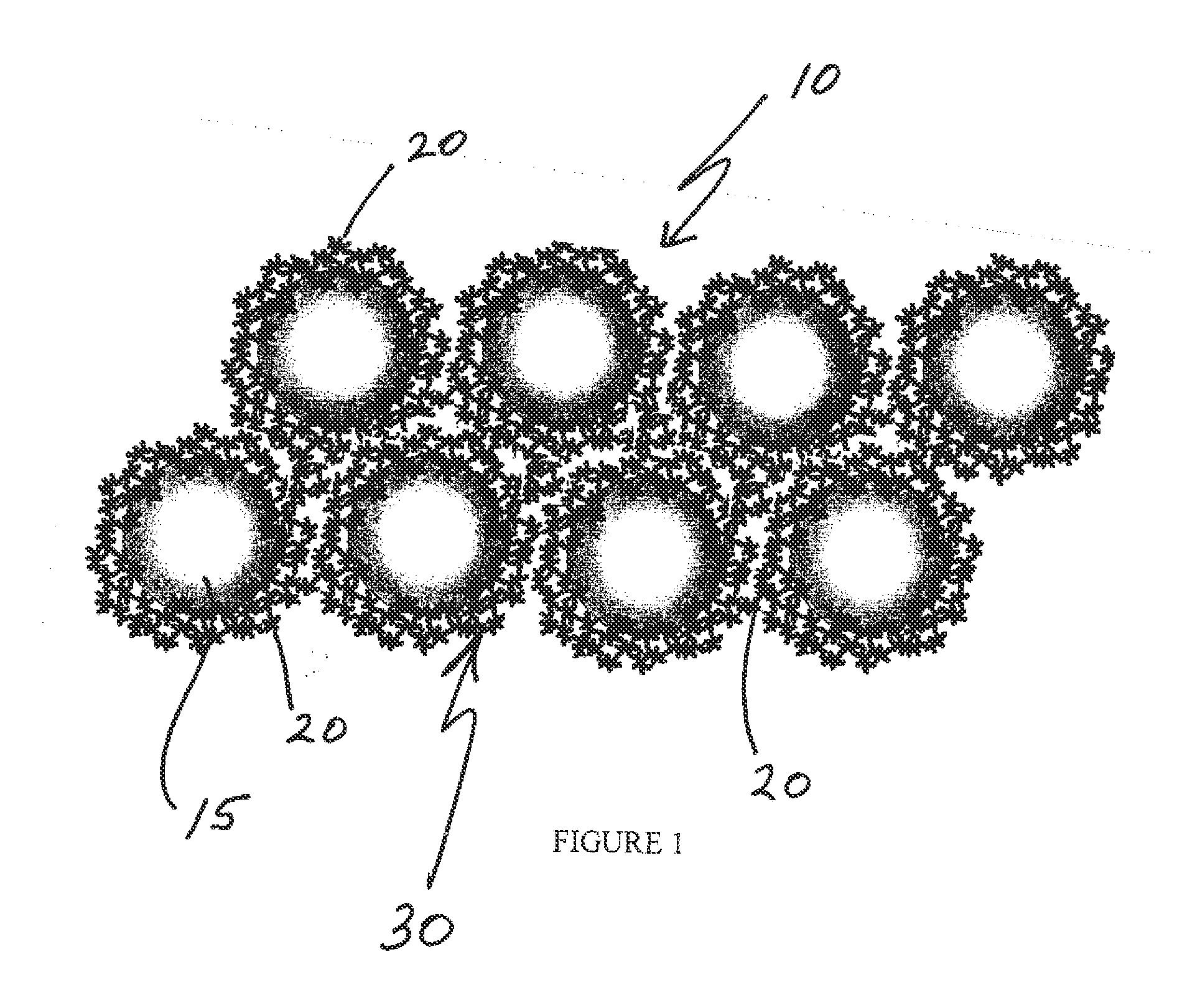

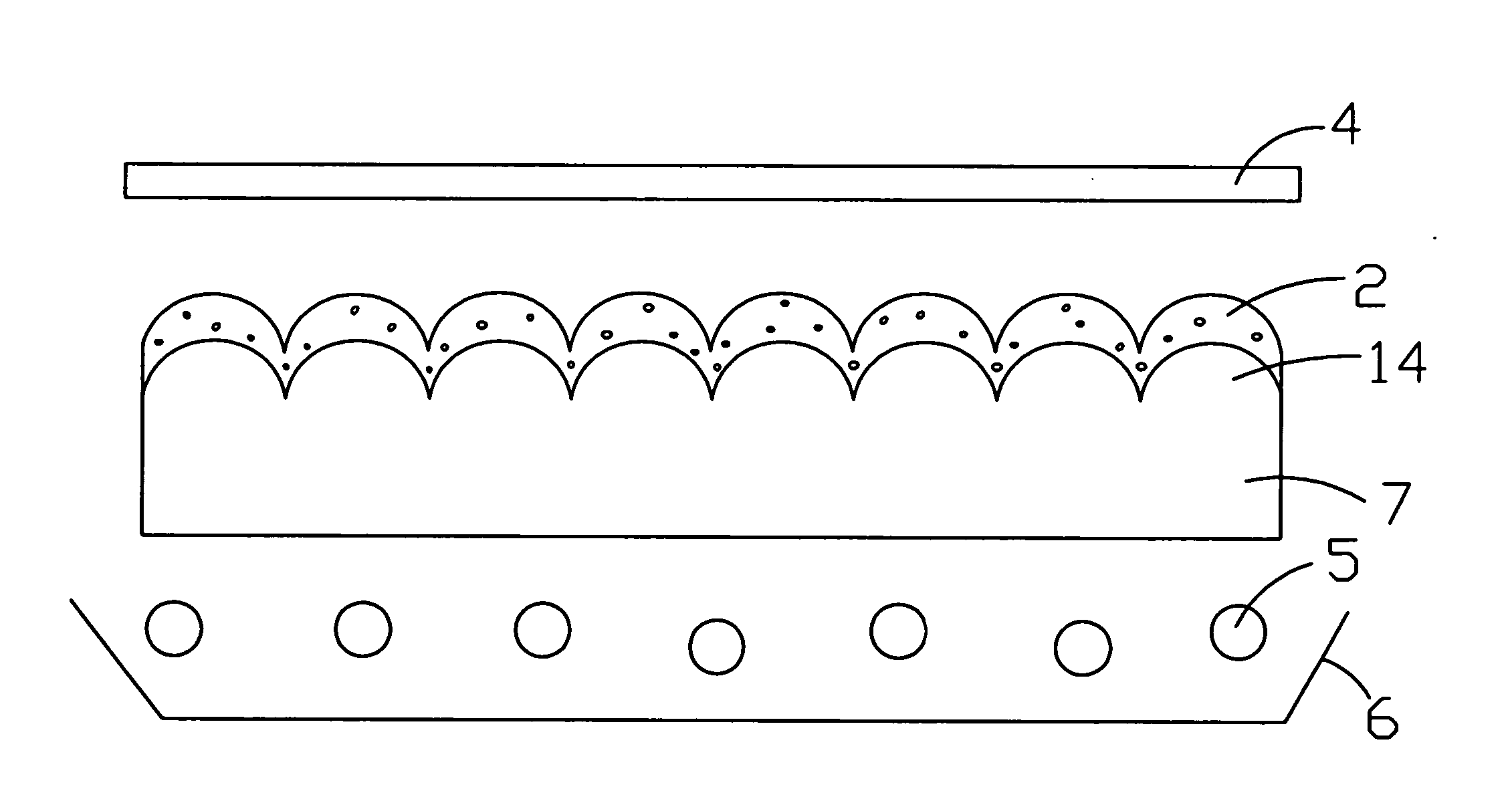

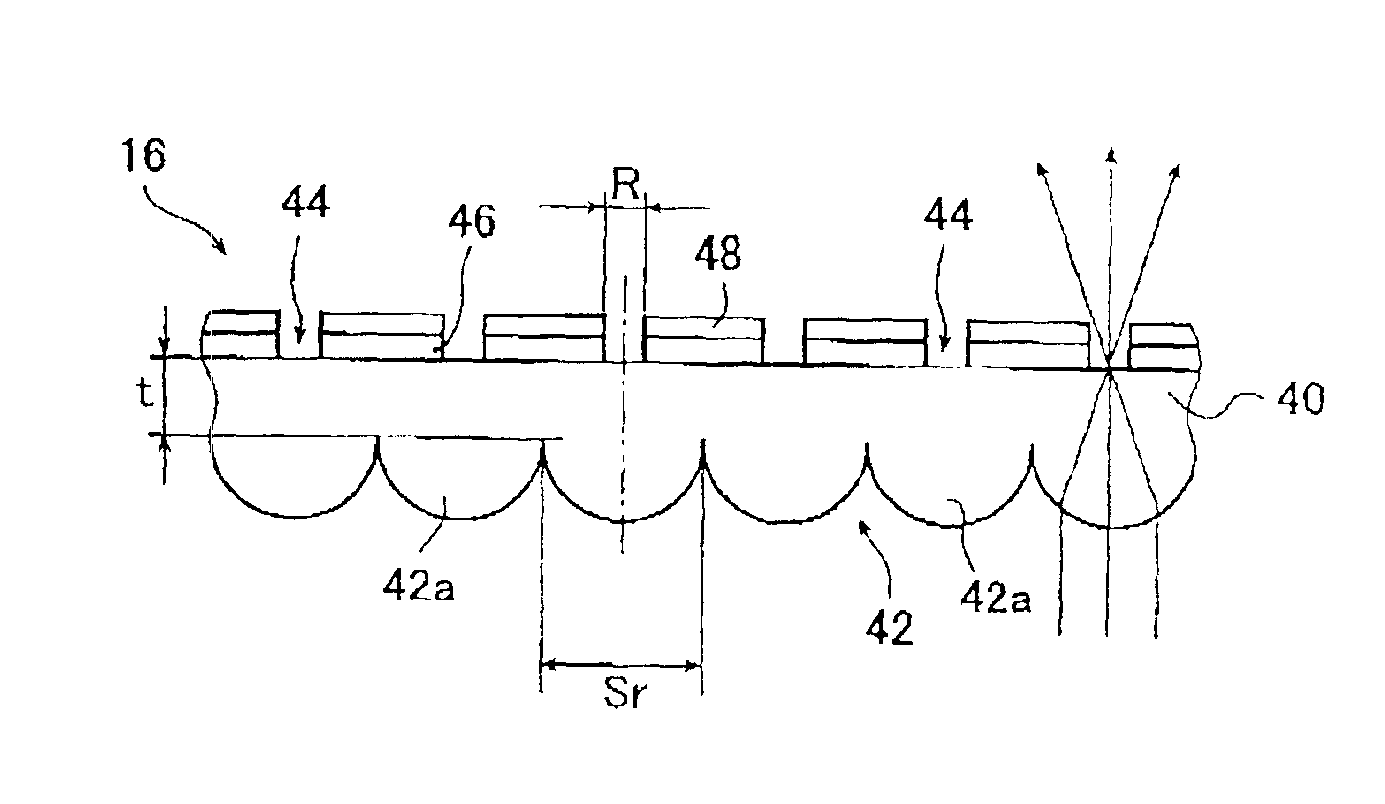

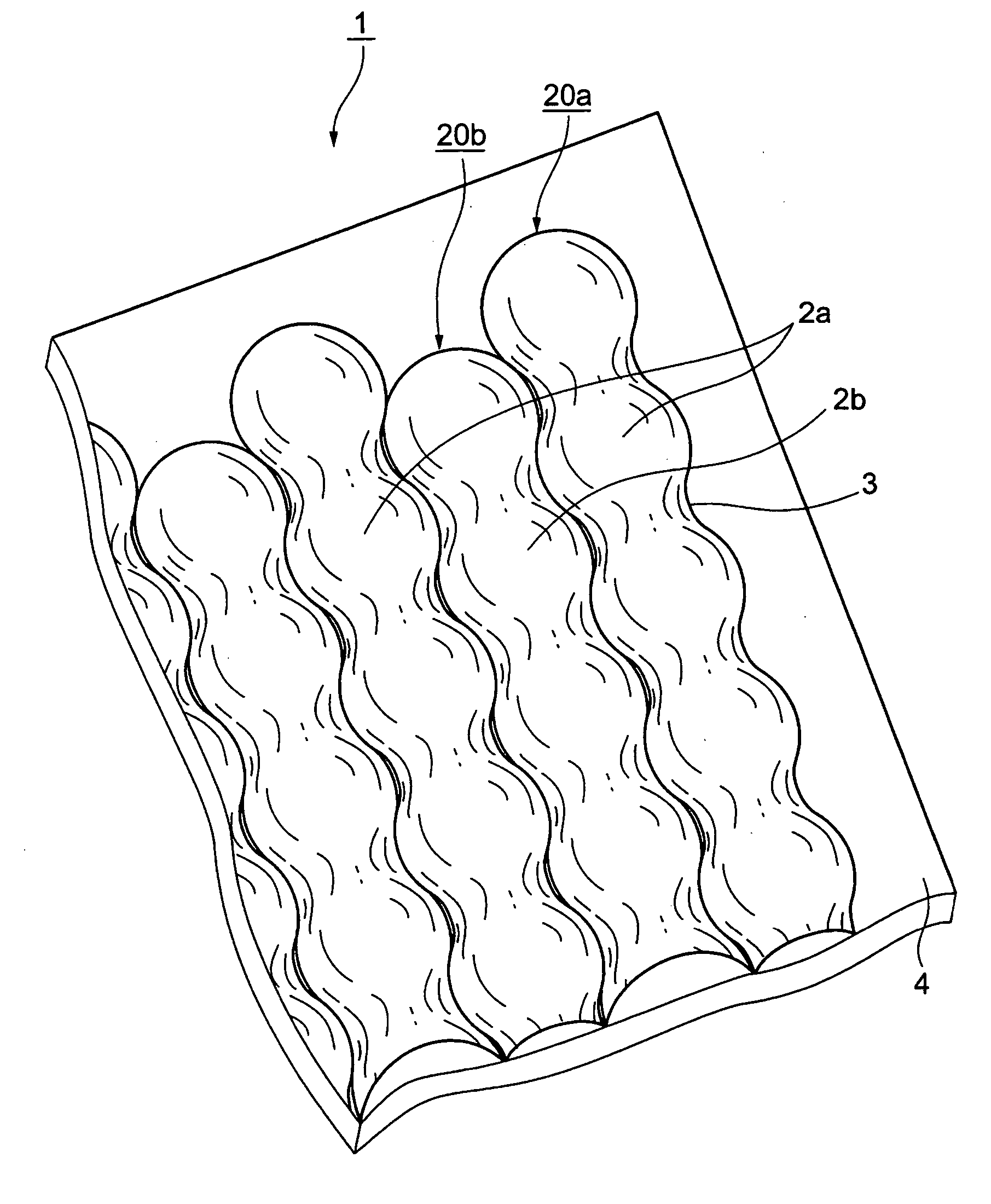

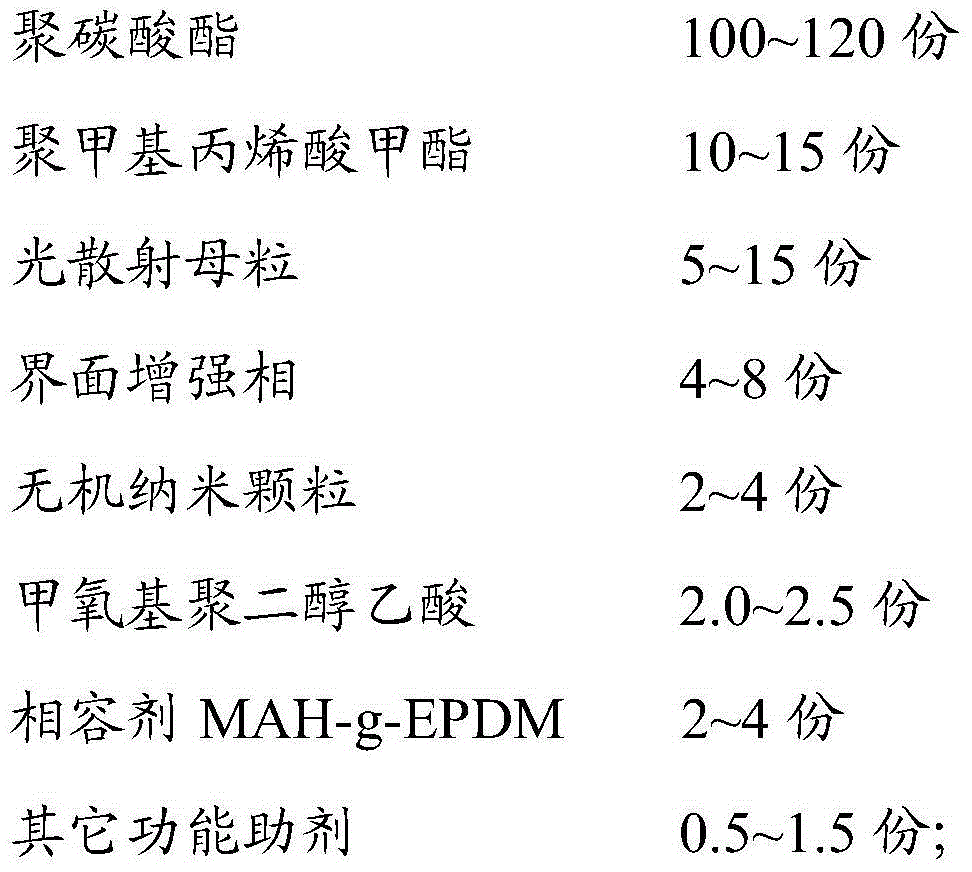

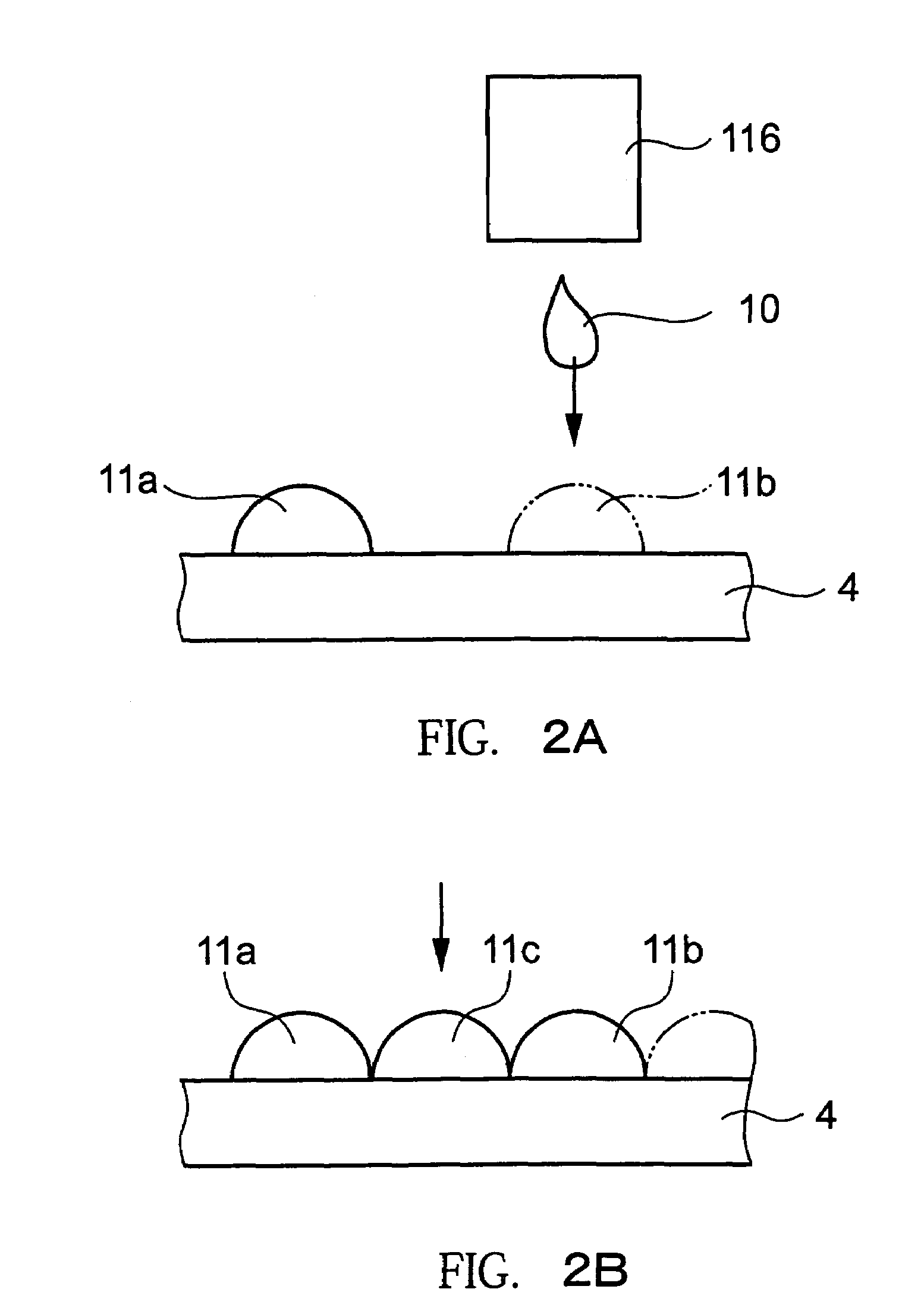

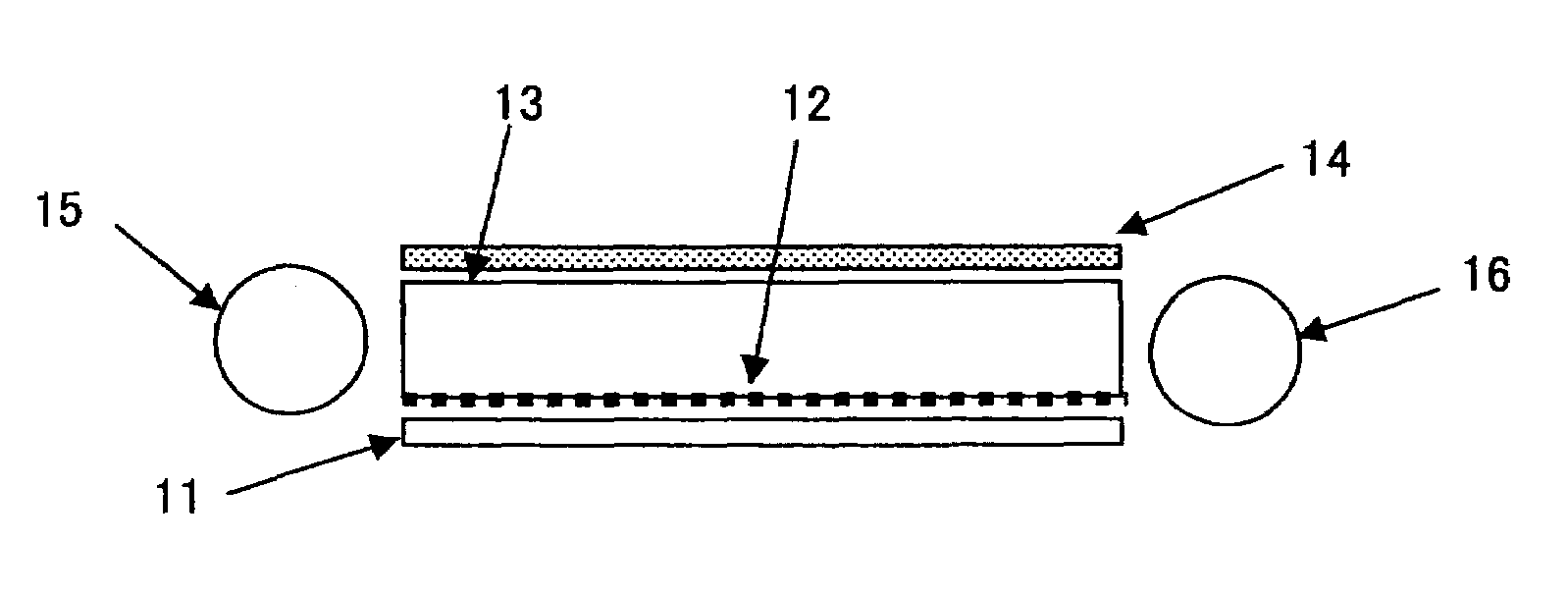

Method of manufacturing microlens, microlens, optical film, screen for projection, and projector system

InactiveUS20050088750A1Shape can be reduced and preventedAccurate shapeProjectorsOptical articlesEngineeringMicrolens

Exemplary embodiments of the present invention provide an optimal manufacturing method of a microlens to diffuse light. According to exemplary embodiments, a manufacturing method of microlens includes forming a generally convex shaped lens portions made from a light transmissive resin on a substrate having light transmissivity, and curing the lens portions, forming the lens portions being a process in which a plurality of the lens portions are formed so as to be coupled on the substrate.

Owner:SEIKO EPSON CORP

Diffuser plate with higher light diffusion efficiency and brightness

ActiveUS7474464B2Improve efficiencyIncrease brightnessPrismsDiffusing elementsDiffusionLiquid-crystal display

A diffuser plate with higher light diffusion efficiency and brightness applied to backlight module of Liquid Crystal Display TV (LCD TV) for providing uniform light is disclosed. An optical lens with a diffusion layer is disposed on one side of the substrate. The diffusion layer is arranged above the optical lens for enhancing diffusion effect. The other side of the diffuser plate can be a plane or having a lens structure. By Lenticular lens, the homogeneity of emitted light is improved so as to reduce the amount of diffusion particles being added into the diffusion plate Therefore, the light transmission is increased and the brightness is enhanced. Meanwhile, ability of shielding lamps is considered and Moiré effect is eliminated. Moreover, the diffusion layer is co-extruded on surface of the Lenticular lens together with the substrate so that the device is easy to be produced.

Owner:ENTIRE TECH CO LTD

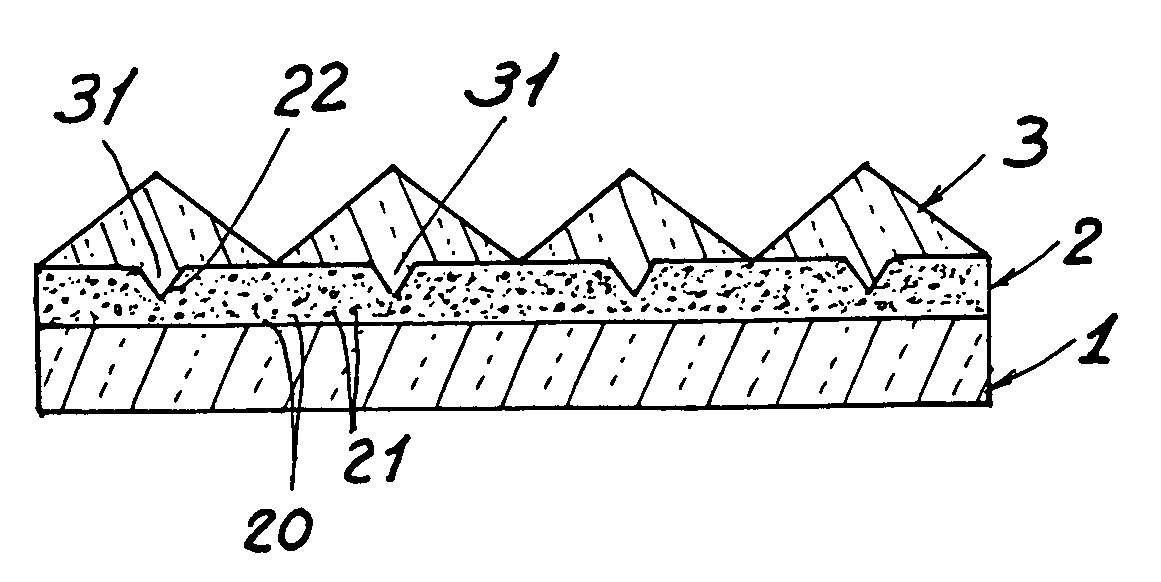

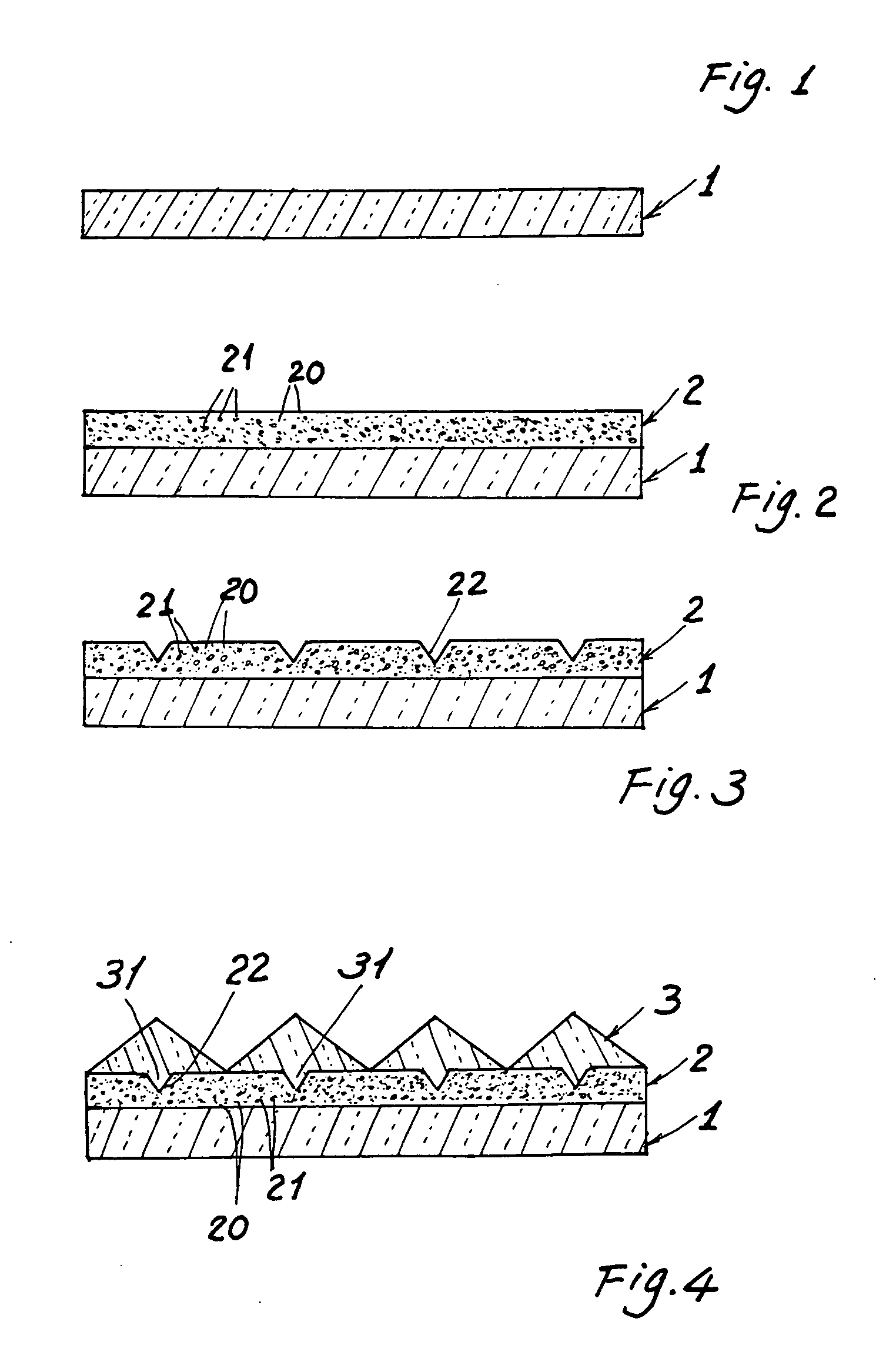

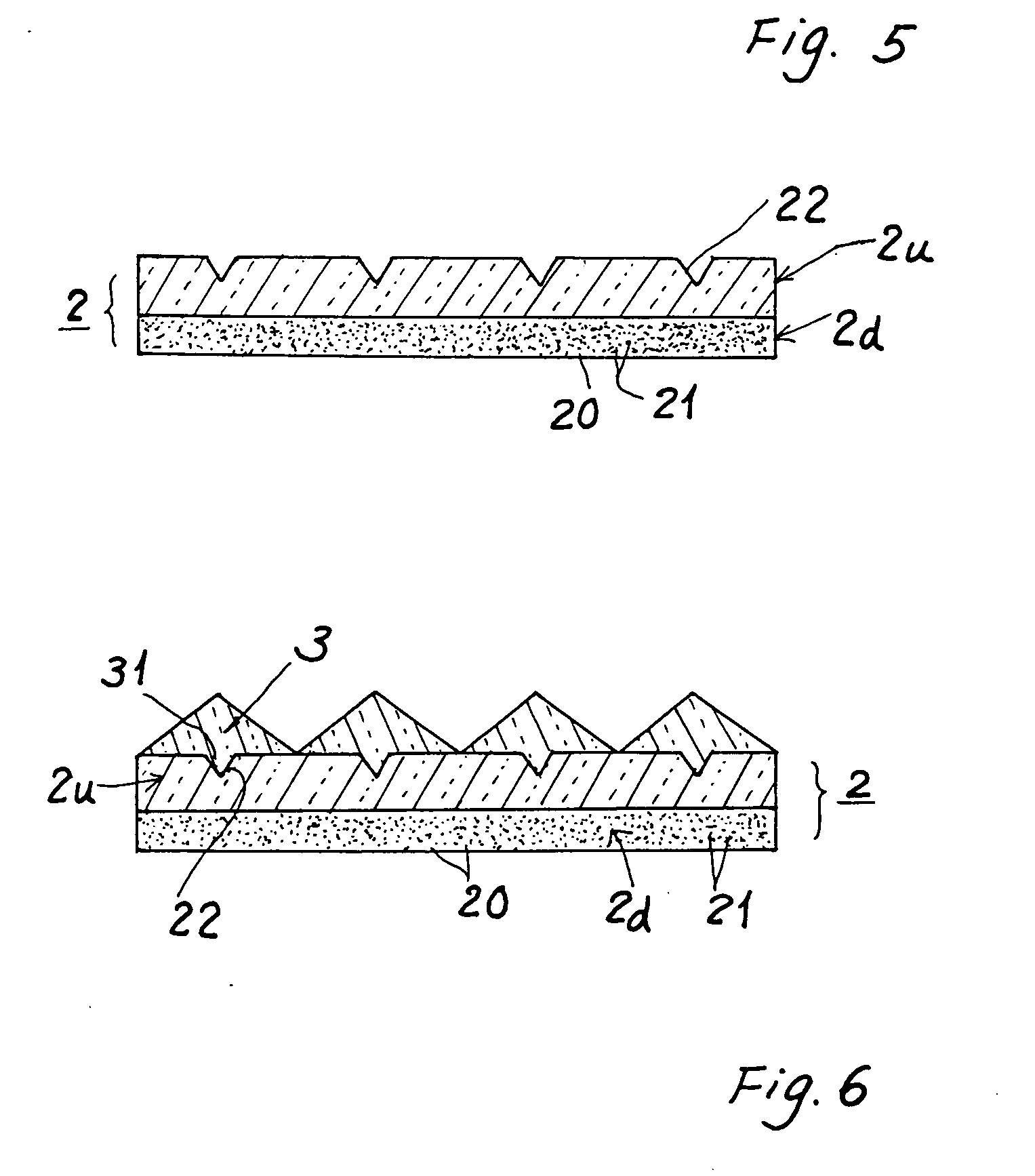

Multiple-layer optical film having light concentrating and diffusing functions

InactiveUS20070285785A1Good light diffusion effectLight stabilityPrismsDiffusing elementsResin matrixPrism

A multiple-layer optical film comprising: a transparent base layer, a diffusion layer formed on the base layer, and an upper prismatic layer formed on the diffusion layer having a plurality of root portions protruding downwardly from the upper prismatic layer to be respectively engaged with a plurality of recesses as recessed in the diffusion layer for firmly interlocking the upper prismatic layer with the diffusion layer. The diffusion layer includes nano or micron particles homogeneously dispersed in a resin matrix to obtain a composite layer having better light diffusibility; and the upper prismatic layer having nice light concentrating effect, thereby cooperatively synergetically forming a multiple-layer optical film having enhanced brightness, light uniformity, and dimensional stability.

Owner:LIN CHING BIN

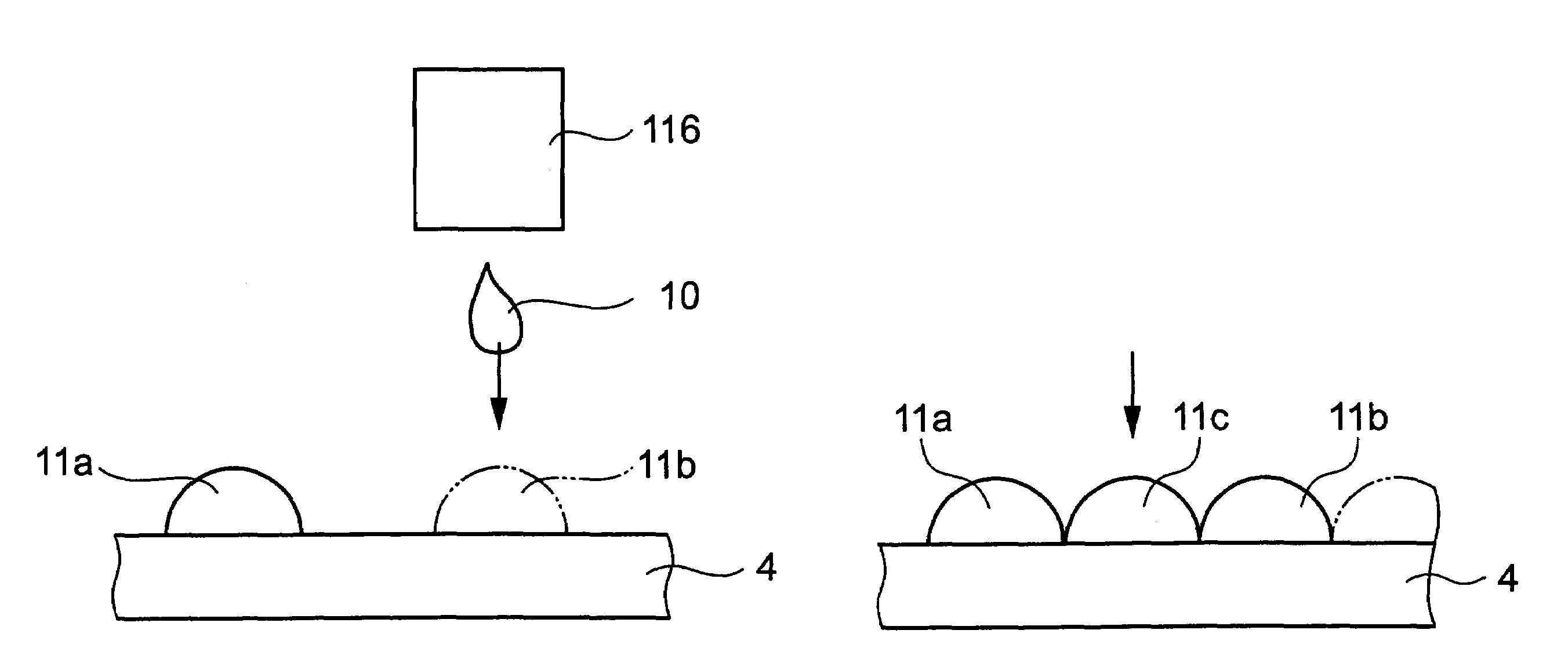

Photodiffusion film and preparation method thereof

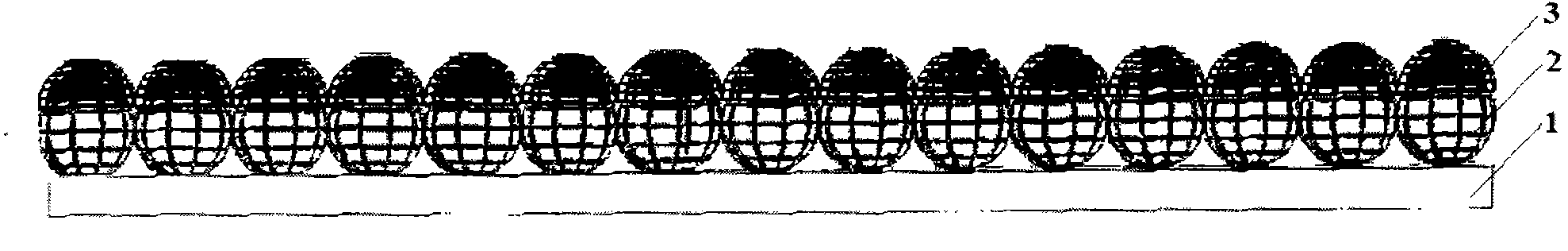

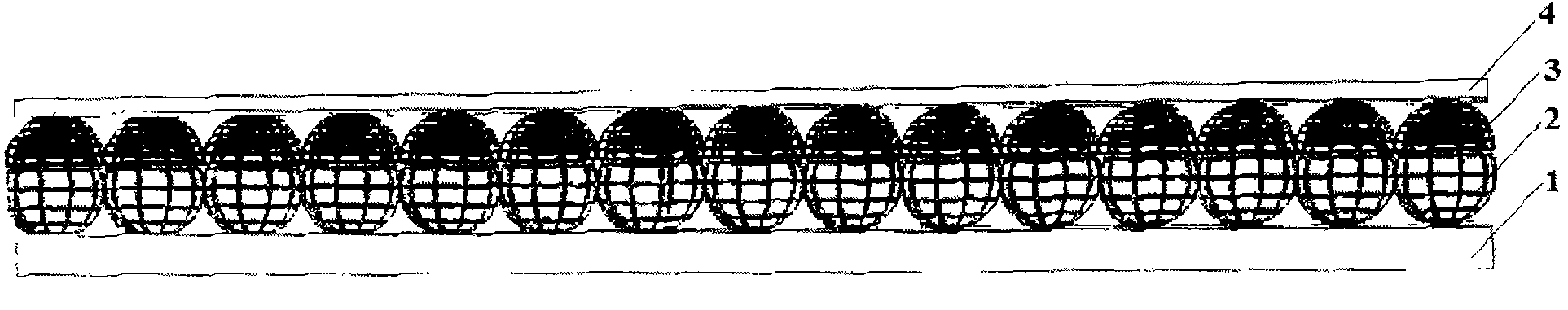

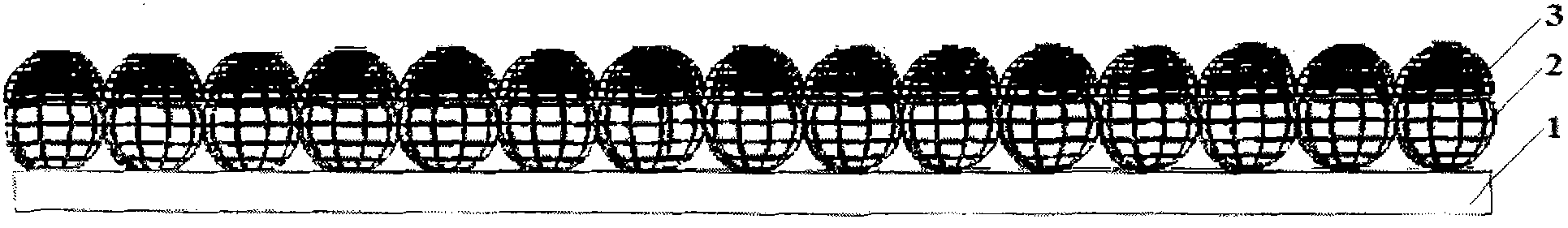

ActiveCN102109624AGood light diffusion effectDiffusion stableDiffusing elementsNon-linear opticsSelf-assemblyDiffusion layer

The invention provides a photodiffusion film. The photodiffusion film comprises transparent substrates, a first diffusion layer and a second diffusion layer which are stacked sequentially, wherein the first diffusion layer is formed by spherical diffusion particles, whose average particle diameter ranges from 0.1 to 5 micron, and the first diffusion layer is coated with the second diffusion layer. The invention further provides a preparation method of a photodiffusion film. The method comprises the following steps: a first diffusion layer and a second diffusion layer are sequentially formed on one surface of transparent substrates, the first diffusion layer is formed by spherical diffusion particles, whose average particle diameter ranges from 0.1 to 5 micron, by virtue of a method of self-assembly film forming, and the first diffusion layer is coated with the second diffusion layer. The photodiffusion film provided by the invention has excellent photodiffusion performance; moreover, by the adoption of the preparation method for preparing the photodiffusion film, the photodiffusion film can be prepared and has the advantages that the thickness of a photodiffusion layer is less than 10 micron, and the photodiffusion performance can be remarkably improved.

Owner:BYD CO LTD

Fluorescent microsphere and preparation method and application thereof

ActiveCN104046350AWith fluorescent whitening effectGood ballMicroballoon preparationLuminescent compositionsColored whiteBright-white

The invention relates to a fluorescent microsphere and its preparation method. Particle size of the fluorescent microsphere is within the range of 0.1-10 micrometer. The fluorescent microsphere has good sphericity and narrow particle size distribution and also has fluorescent brightening groups. The fluorescent brightening groups are uniformly or randomly distributed in a polysiloxane microsphere or on the surface of the polysiloxane microsphere such that the polysiloxane microsphere has a fluorescent brightening effect, has high light fastness, has excellent heat resistance and high chemical stability, can absorb ultraviolet rays to prevent aging of a product, is especially suitable for an originally yellowish product, endows a product with bright white appearance, can make a colored product more dazzlingly beautiful when used in the colored product, and can enhance brightness of a product when used in a black product. The invention, on the other hand, provides a preparation method of the above fluorescent microsphere and a prepared photodiffusion material.

Owner:GUANGZHOU SHINE POLYMER TECH

Light diffuser board integrated with high transmittance, high haze and high toughness in one body

InactiveCN103645525AGood light diffusion effectImprove uniformityDiffusing elementsPolystyreneStabilizing Agents

The invention discloses a light diffuser board integrated with high transmittance, high haze and high toughness in one body. A fiber-level GPPS such as transparent and blue-background polystyrene is taken as a main material, glass beads are taken as a silicon diffusion agent, and a high haze flexibilizer SCBS is innovatively added. Based on the diffuser board having functions of light collection, light diffusion and light reflection, a product formula is improved and added, auxiliary agents such as a diffusion agent, a light stabilizing agent and a high haze flexibilizer are added to a raw material, and thereby functions of light refraction, light reflection and light diffusion are realized in products, not only can quite high light diffusion and emergent light uniformity be realized, but also a utilization rate of the power source is high, anti-folding performance and shielding performance are good, a penetration rate of products can reach 93%+ / -5%, and the haze can reach 99%+ / -1%.

Owner:HUIZHOU YUETAIXIANG TECH

Lens structure and light emitting unit

InactiveCN101235953AImprove light diffusion effectGood light diffusion effectPoint-like light sourceNon-linear opticsConcave surfaceLight reflection

Disclosed is a lens structure, which comprises a lens body, and the lens body is provided with a light incidence plane, a light emergence plane and a light reflection plane. The light incidence plane is opposite with the light emergence plane, the light reflection plane is in cone shape and is connected with the middle of the light incidence plane and the light emergence plane. The area of the light incidence plane is smaller than that of the light emergence plane, and the light emergence plane is a concave surface and / or is provided with a microdiffusion particle layer. The lens structure is provided with a fine photodiffusion effect. Further, the invention also provides a luminous unit with the above-mentioned lens structure.

Owner:AU OPTRONICS CORP

Aromatic polycarbonate resin composition with light diffusibility

ActiveCN101525483AGood light diffusion effectHigh light transmittanceDiffusing elementsGlobesPolycarbonateCalorimetry

The objective of the present invention is to provide excellent thermostable aromatic polycarbonate resin composition with high light diffusibility and high light permeation rate simultaneously, without generation of silver plaque and resin speckle. The resin composition according to the invention has light diffusibility, relative to 100 parts by weight of aromatic polycarbonate resin (A ingredient), containing 0.01-3.0 parts by weight of crosslinking (methyl) acrylic polymer particles (B ingredient), which are not compatible with the aromatic polycarbonate resin, and reduces 5% of weight detected by calorimetry device when temperature is above 300 DEG C.

Owner:TEIJIN LTD

Acrylic polyurethane coating and preparation method and application thereof

ActiveCN107216792AGood light transmissionGood light diffusion effectDiffusing elementsPolyurea/polyurethane coatingsPlasticizerAcrylic resin

The invention discloses an acrylic polyurethane coating and a preparation method and application thereof in manufacture of a connecting material or a protective coating. The acrylic polyurethane coating is prepared by mixing hydroxyl acrylic resin, a hydroxyl polyurethane plasticizer and a polyisocyanate curing agent. The acrylic polyurethane coating is mainly used for making the resin connecting material of an optical diffusion film, and the coating after the film formation has good light transmittance and light diffusion property and high scratch resistance, and has the advantages of prevention of falling off of resin micro beads in a diffusion layer. The acrylic polyurethane coating can also be used for making optical films such as brightening films and reflecting films, and the ratio of the three components can be adjusted according to the use and the substrate characteristics of different optical films so as to achieve the coating performances required by different purposes.

Owner:周建明

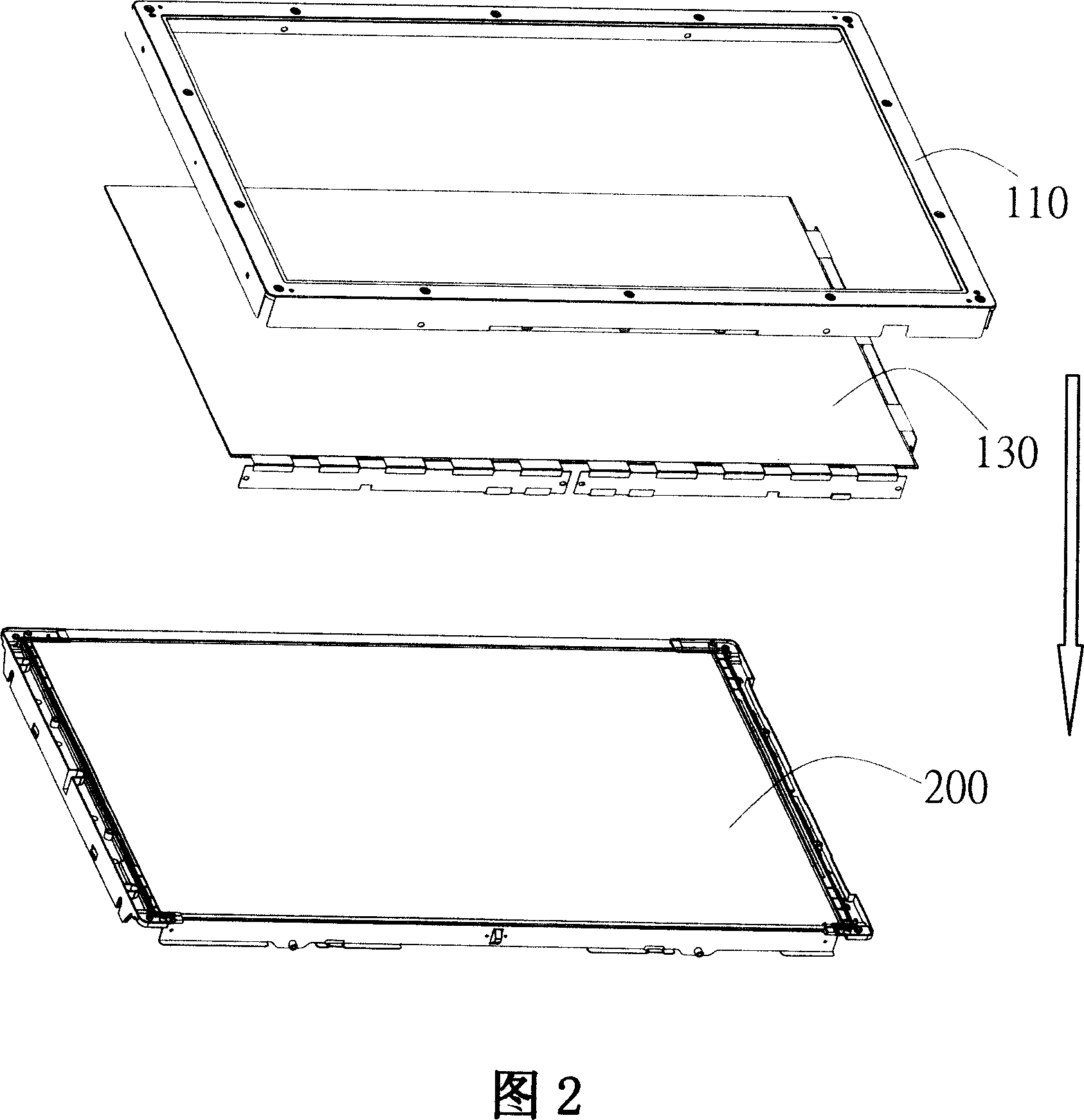

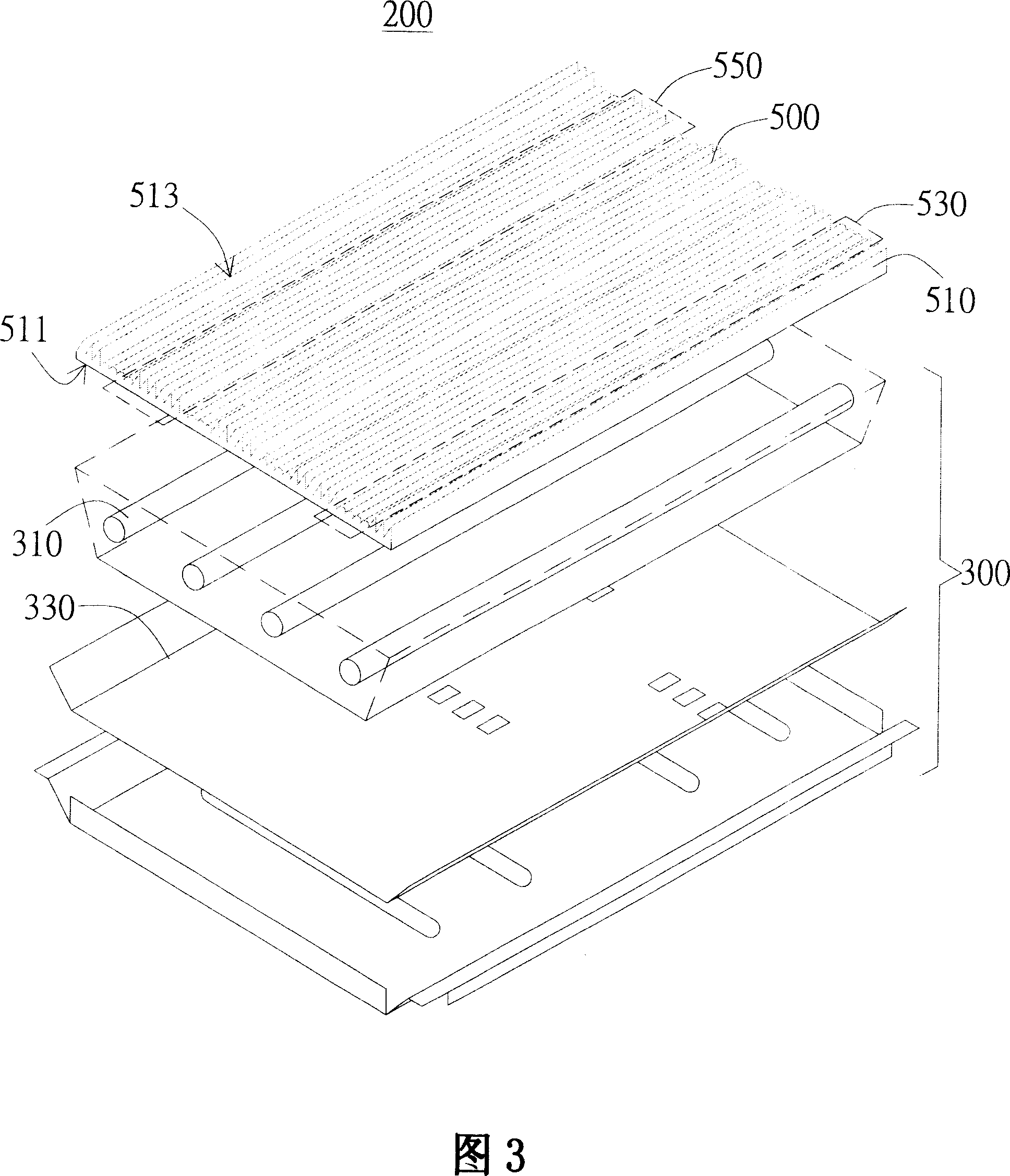

Backlight module and diffusion board structure used thereby

The invention discloses a negative phototropism module and its pervasion plate structure. The negative phototropism module mainly contains lamp-house module equipped with light source and pervasion plate structure located on the upper of the lamp-house module. The pervasion plate structure includes board, several astigmatic microstructures and condensing microstructures. The astigmatic microstructures and condensing microstructures are radial arranged on out-light surface or in-light surface of the board. Astigmatic microstructures contain several cambered surface transmission microstructures, each of the cambered surface transmission microstructures possess an arc convex surface. Condensing microstructures possess several convex prism microstructures. The microstructures of convex prism have two corresponding side surfaces which has an included angle theta.

Owner:AU OPTRONICS CORP

Green quantum dot film and backlight module thereof

InactiveCN107966855AImprove stabilityAvoid fluorescence quenchingNon-linear opticsDiffusionLight irradiation

The invention discloses a green quantum dot film and a preparation method of a backlight module thereof. The method performs functional design on the protective layer of the green quantum dot film; the outer surface of the protective layer has a good light diffusion effect after being coated, and inorganic diffusion particles in the coated layer play a role in blocking light in some bands, thus the light damage caused by long-time light irradiation on the quantum dot is slowed down. The invention also provides a using method of the green quantum dot film, the using method matches the green quantum dot film and a blue chip with red phosphor to make a novel LED light source, and the using method improves the stability of the quantum dot film while greatly increasing the color gamut coverageof the LCD.

Owner:NINGBO DXC NEW MATERIAL TECH

Light reflection plate

InactiveUS20130314796A1High light reflection performanceHigh light diffusibilityDiffusing elementsNon-linear opticsPolyolefinTitanium oxide

There is provided a light reflection plate that can uniformly exhibit high light diffusibility. The light reflection plate includes 100 parts by weight of a polyolefin-based resin and 20 to 120 parts by weight of a coated titanium oxide that is obtained by coating a surface of titanium oxide with a coating layer containing aluminum oxide and silicon oxide. The coated titanium oxide is constituted by primary particles having a particle size of 0.10 to 0.39 μm and agglomerated particles which are formed by agglomeration of the primary particles and have a particle size of 0.4 μm or more. The number of the agglomerated particles in a cross section of the light reflection plate in a thickness direction is 0.1 to 4.5 / 900 μm2 and the number of the primary particles, which are not agglomerated, in the cross section of the light reflection plate in the thickness direction is 1.5 to 11.0 / 900 μm2.

Owner:SEKISUI PLASTICS CO LTD

Light-diffusing film having pores

InactiveCN1847955AHigh light transmittanceGood light diffusion effectLayered productsDiffusing elementsLiquid-crystal displayThin-film-transistor liquid-crystal display

The disclosed diffuser film with pores is used in the backlighting unit of a thin-film transistor liquid crystal display. The diffuser film with pores of the present invention includes a substrate of synthetic resin; a diffuser layer with pores on the surface of the substrate has pores, wherein The air hole is formed by coating a composition comprising light-scattering resin and light-scattering particles contained in the light-scattering resin under the synthetic application pressure of 1-5MPa and the moving speed of the substrate at 10-200m / min; And forming an anti-adhesion layer on the other surface of the substrate. The diffusion plate of the present invention may be applied to the back lighting unit of the thin film transistor liquid crystal display.

Owner:TORAY SAEHAN

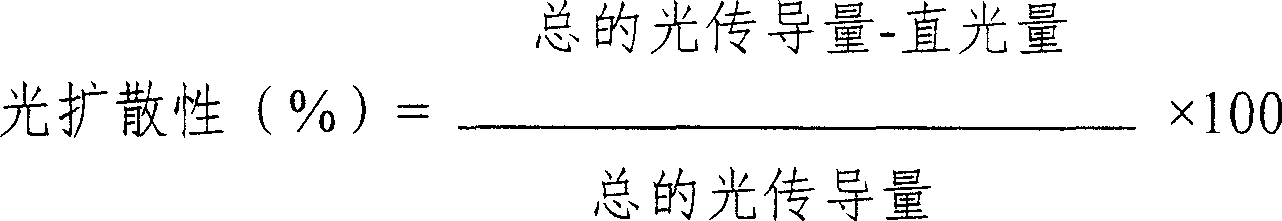

Polycarbonate material composition of reinforced LED lamp shade and preparation method and LED lamp shade

ActiveCN104356626AHigh light transmittanceGood light diffusion effectGlobesNano al2o3Polymethyl methacrylate

The invention provides a polycarbonate material composition of a reinforced LED lamp shade. The polycarbonate material composition comprises 100-120 parts of polycarbonate, 10-15 parts of polymethyl methacrylate, 5-15 parts of light scattering master batch, 4-8 parts of interface reinforcing phase, 2-4 parts of inorganic nanoparticles, 2.0-2.5 parts of methoxyl polyglycol acetic acid, 2-4 parts of a compatilizer MAH-g-EPDM and 0.5-1.5 parts of other functional additives, wherein the interface reinforcing phase is at least one of nanometer aluminum oxide crystal particles or crystal whiskers. The polycarbonate material composition of the reinforced LED lamp shade, which is provided by the invention, is relatively excellent in light permeability and light scattering property, is capable of eliminating the phenomena of halo or dark spot generated from the dispersibility, and is also relatively excellent in mechanical property.

Owner:惠州市沃特新材料有限公司

Preparation method of perovskite quantum dot composite

PendingCN109054809ASimple methodImprove light diffusion effectMaterial nanotechnologyNanoopticsQuantum dotComputational chemistry

The invention discloses a preparation method of a perovskite quantum dot composite, comprising the following steps: S1, mixing a first precursor and a second precursor with an organic solvent to obtain a perovskite precursor mixed liquid; S2, mixing the perovskite precursor mixed liquid in S1 with polymer microspheres to obtain a mixture of perovskite quantum dot polymer microspheres; S3, and subjecting the mixture of perovskite quantum dot polymer microspheres in S2 to solvent removal treatment to obtain the perovskite quantum dot composite. The preparation method of the perovskite quantum dot composite is simple, rapid, efficient and easy to operate, and can produce a perovskite quantum dot composite which is stable in air, is not easily quenched during light emitting, and can be furtherdirectly applied.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Method of manufacturing microlens, microlens, optical film, screen for projection, and projector system

InactiveUS7265907B2Shape can be reduced and preventedAccurate shapeProjectorsOptical articlesEngineeringMicrolens

Exemplary embodiments of the present invention provide an optimal manufacturing method of a microlens to diffuse light. According to exemplary embodiments, a manufacturing method of microlens includes forming a generally convex shaped lens portions made from a light transmissive resin on a substrate having light transmissivity, and curing the lens portions, forming the lens portions being a process in which a plurality of the lens portions are formed so as to be coupled on the substrate.

Owner:SEIKO EPSON CORP

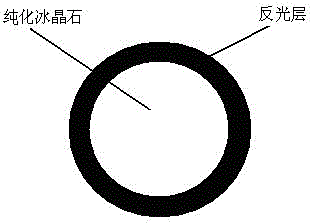

Light-transmitting inorganic light diffusion agent and preparation method thereof

InactiveCN104059246ALarge luminous surfaceLess light lossInorganic pigment treatmentPhysicsPotassium feldspar

The invention discloses a light-transmitting inorganic light diffusion agent which is characterized by comprising the following components by weight percent: 85%-94% of cryolite, 3%-8% of pyrophyllite, 2%-5% of kaolin, 0.5%-1% of potassium feldspar and 0.2%-1% of brucite. A fluidized bed is coated with cryolite, a powdery material is mixed with heated hot air in a rotational-flow dynamic calcining furnace, the specific surface of the cryolite is instantly calcined and molten and is spheroidized, and the surface of cryolite is covered with a reflection layer, so that cryolite has good light transmitting and reflectivity. The light diffusion agent is high in micro-particle sphericity and good in flowing dispersity, can be used at a high temperature of 800 DEG C or above, has excellent high temperature resistance, has a reflectivity different from most transparent resins, can be uniformly dispersed in resin so that a point light source is changed into an area light source, light transmitting and dodging effects are achieved, and therefore high light transmittance is ensured and good haze is achieved.

Owner:江门市金德丰塑业科技有限公司

Brightening light diffusion material and preparation method thereof

InactiveCN102363667AHigh light transmittanceImprove light diffusion effectDiffusing elementsFluorescenceOptical transmittance

The invention which belongs to the technical field of the material chemistry relates to a brightening light diffusion material and a preparation method thereof. The brightening light diffusion material is characterized in that the brightening light diffusion material comprises the following components, by weight, 0.005-1% of a photoluminescent material, 0.02-5% of a light diffusant, and the balance transparent material. Compared with a case that only the light diffusant is added to a base material which treats the transparent material as a main component, the photoluminescent material and the light diffusant are added to the base material which treats the transparent material as a main component in the invention, so the light transmittance of the transparent material is improved and the light diffusion effect is improved.

Owner:SHENZHEN HALCYON NEW MATERIALS

Light reflector and planar light source device

ActiveUS7548372B2Effective diffusionImprove reflectivityMechanical apparatusMirrorsLight reflectionSurface roughness

A light reflector including a laminate film having a light-diffusive layer on one surface of a substrate layer, wherein the surface roughness index of the light-reflective surface is at least 1, the reflectance thereof is at least 95%, and the regular reflectance thereof is at most 3%. The light reflector has higher brightness and higher reflectivity.

Owner:MITSUBISHI CHEM CORP

Optical film and manufacturing method thereof

ActiveCN101833126AReduce in quantityQuantity reachedDiffusing elementsOptical light guidesMolten stateOptical film

The invention relates to an optical film and a manufacturing method thereof, which comprises a light-permeable base material, a plurality of diffusion micro-particles distributed on the base material and a light collection layer arranged on the surface of the base material. Part of the diffusion micro-particles lead at least one surface of the base material to form bulges, and the protrusive height of part of the bulges is larger than or equal to 0.5 mu m. The manufacturing method of the optical film mainly comprises the following steps: heating the base material for leading the base material to be in molten state, adding the diffusion micro-particles on the surface of the base material, curing the base material for forming the base material, and finally forming the light collection layer on the surface of the base material. The optical film only contains the double-layer structure of the base material and the light collection layer, and can still achieve the effects of light collection and light diffusion atomization while reducing the number of film layers, so that the manufacturing method has the advantages of easy manufacture and reduced cost.

Owner:ZHEJIANG JINHUI OPTOELECTRONIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com