Ultra-gasoline resistant aqueous varnish and preparation method thereof

A gasoline and water-resistant technology, applied in the field of coatings, can solve problems such as unsatisfactory drying speed and antibacterial properties, and achieve the effects of improving scratch resistance, improving wettability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

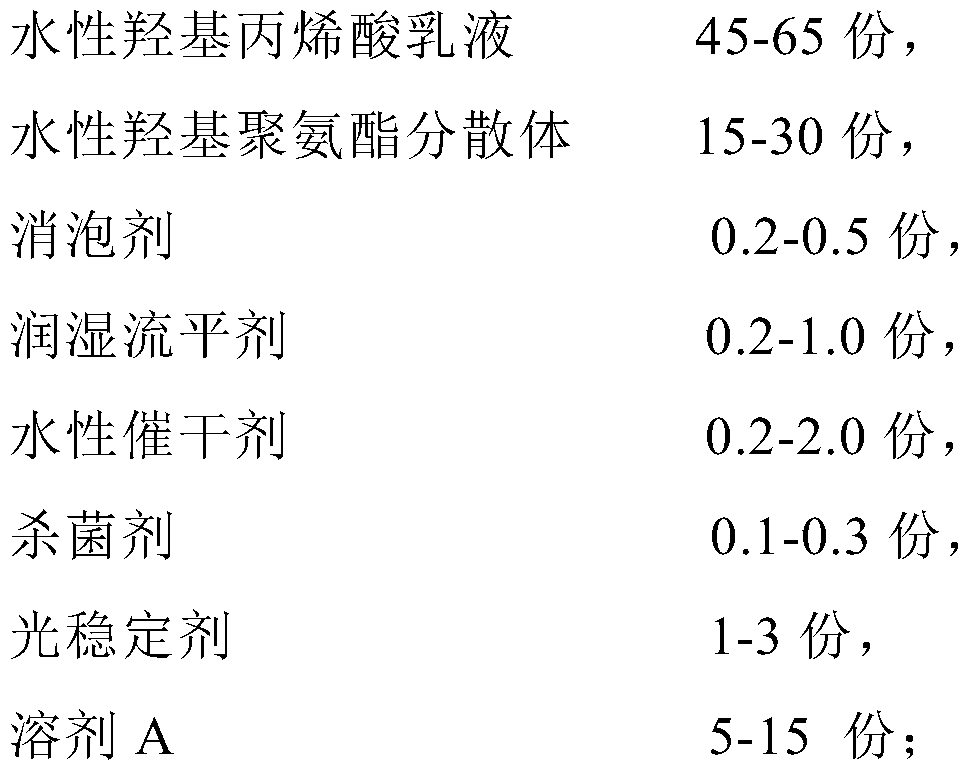

[0049] A super gasoline-resistant water-based varnish, which is composed of a component A resin paint and a component B curing agent in a weight ratio of 3:1. The specific formula is shown in Table 1. The preparation method of water-based varnish specifically comprises the following steps:

[0050] (1) Add the hydroxyacrylic acid emulsion and the hydroxypolyurethane dispersion into the dispersion tank in parts by weight, stir evenly, then add the defoamer, solvent A, stir at a low speed for 5-10min, moisten the leveling agent, water-based drier, Bactericide and light stabilizer, stir at medium speed for 10-15 minutes, adjust the viscosity to 30-40s, filter to obtain component A resin paint;

[0051] (2) Add the curing agent to the solvent B in parts by weight, and stir evenly to obtain the curing agent of component B;

[0052] (3) Mix the resin paint of component A and the curing agent of component B in a weight ratio of 3:1 to obtain the water-based varnish.

Embodiment 1

[0053] The coating of Example 1 and the commercially available water-based varnish were constructed simultaneously on the ABS of spray-coated paint (surface dry), and the test results of paint film properties are shown in Table 2.

[0054] Table 2 Paint film performance test results

[0055]

[0056] From Table 2, we can see that the water-based varnish of the present invention has excellent gasoline resistance, and has excellent properties such as fast drying, long activation time, and good gloss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com