Improved P-RC APMP (preconditioning-refining chemical alkaline peroxide mechanical pulp) new flow path

A process and wood chip technology, applied in the field of improved P-RC APMP pulping new process, can solve the problems of heavy washing load, anion waste retention, unstable operation of wet end, etc., to reduce washing load, reduce steam consumption, The effect of high solid content of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

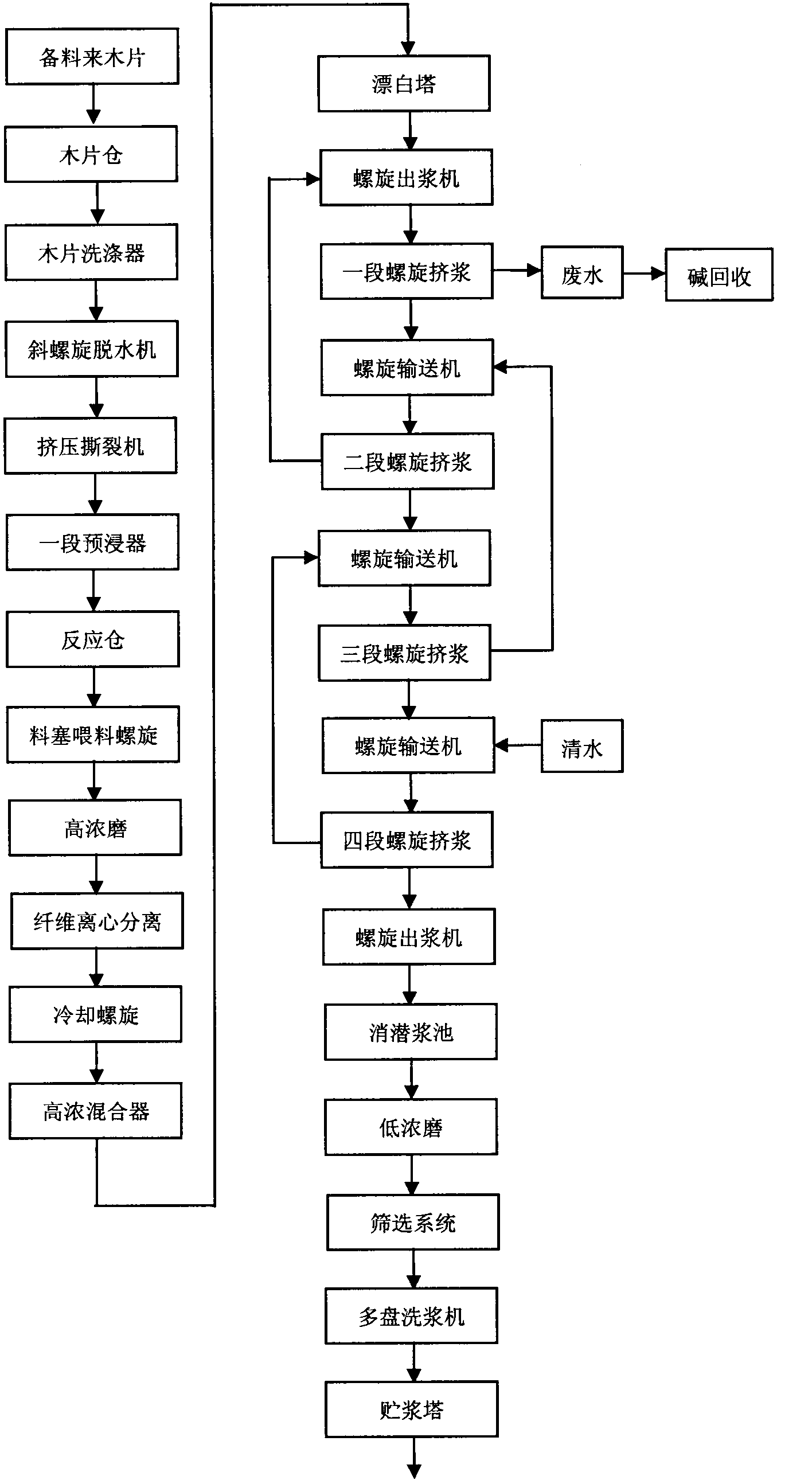

[0017] Embodiment one: the new flow process of the improved P-RC APMP process of the present invention is combined figure 1 described as follows:

[0018] 1. Washing of wood chips: Wash wood chips with a length of 15-20mm, a thickness of 3-5mm, and a width of less than 10mm to remove sediment;

[0019] 2. Dehydration, extrusion and tearing of wood chips: Use an oblique spiral dehydrator to make the dryness of wood chips reach 35-40%; use an extrusion tearing machine with a compression ratio of 1:4.0 to extrude the wood chips into wood filaments;

[0020] 3. One-stage impregnation: impregnate the extruded wood chips in an alkaline hydrogen peroxide solution containing 20-40% of the total amount of chelating agent (DTPA), magnesium sulfate, and sodium silicate, and enter the reaction chamber to react for 30-60 minutes;

[0021] 4. One-stage high-consistency refining: After the reaction chamber, the slurry is subjected to a high-consistency refining at a concentration of 35-40%...

Embodiment 2

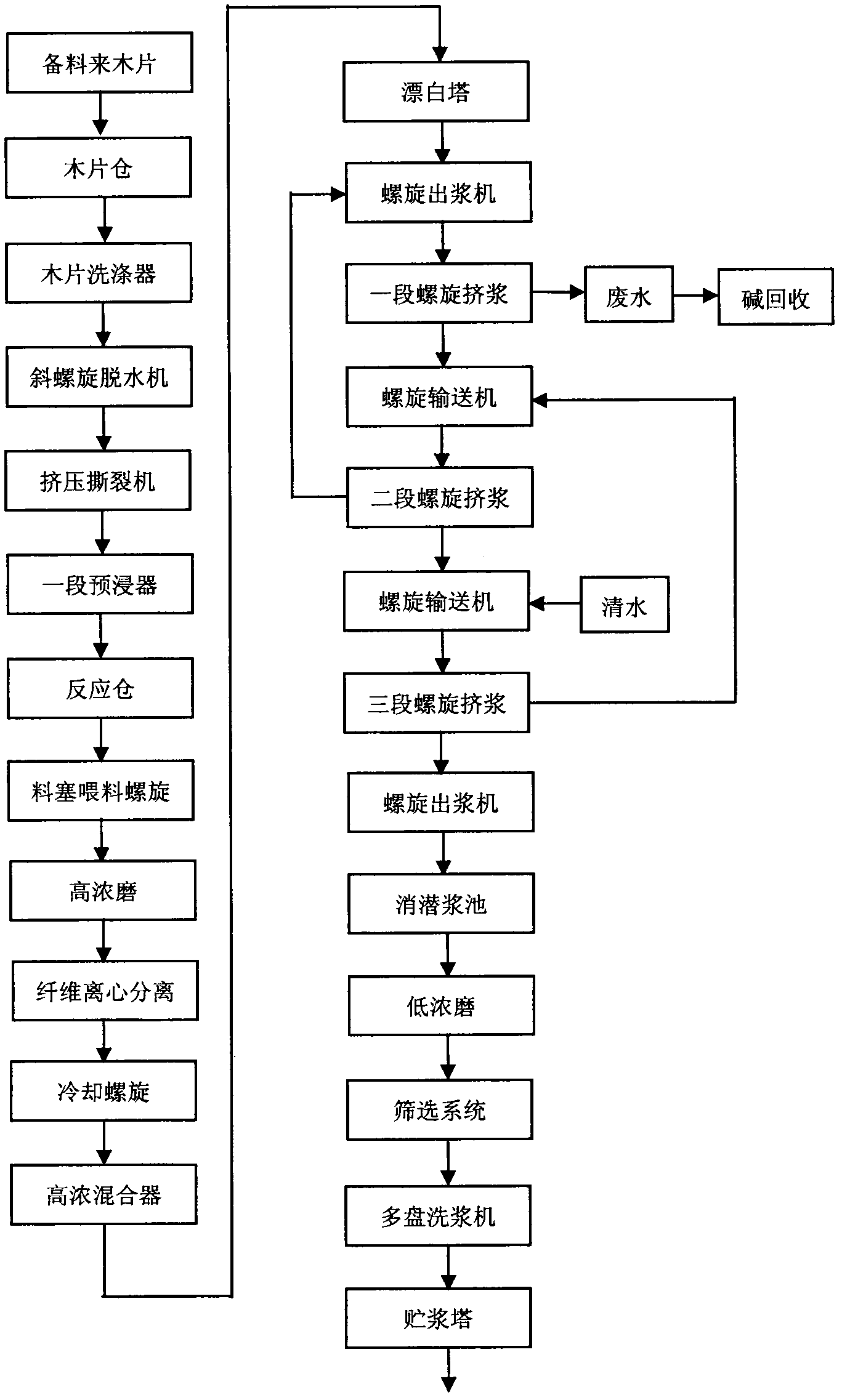

[0028] Embodiment two: the new flow process of the improved P-RC APMP technique of the present invention is combined figure 2 described as follows:

[0029] 1. Washing of wood chips: Wash wood chips with a length of 15-20mm, a thickness of 3-5mm, and a width of less than 10mm to remove sediment;

[0030] 2. Dehydration, extrusion and tearing of wood chips: Use an oblique spiral dehydrator to make the dryness of wood chips reach 35-40%; use an extrusion tearing machine with a compression ratio of 1:4.0 to extrude the wood chips into wood filaments;

[0031] 3. One-stage impregnation: impregnate the extruded wood chips in an alkaline hydrogen peroxide solution containing 20-40% of the total amount of chelating agent (DTPA), magnesium sulfate, and sodium silicate, and enter the reaction chamber to react for 30-60 minutes;

[0032] 4. One-stage high-consistency refining: After the reaction chamber, the slurry is subjected to a high-consistency refining at a concentration of 35-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com