Method and device for treating organic cyanide wastewater

A treatment method and treatment device technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high cost, equipment corrosion, and highly toxic cyanide, and achieve Effects of preventing highly toxic hydrogen cyanide gas, reducing biological toxicity, and simple operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

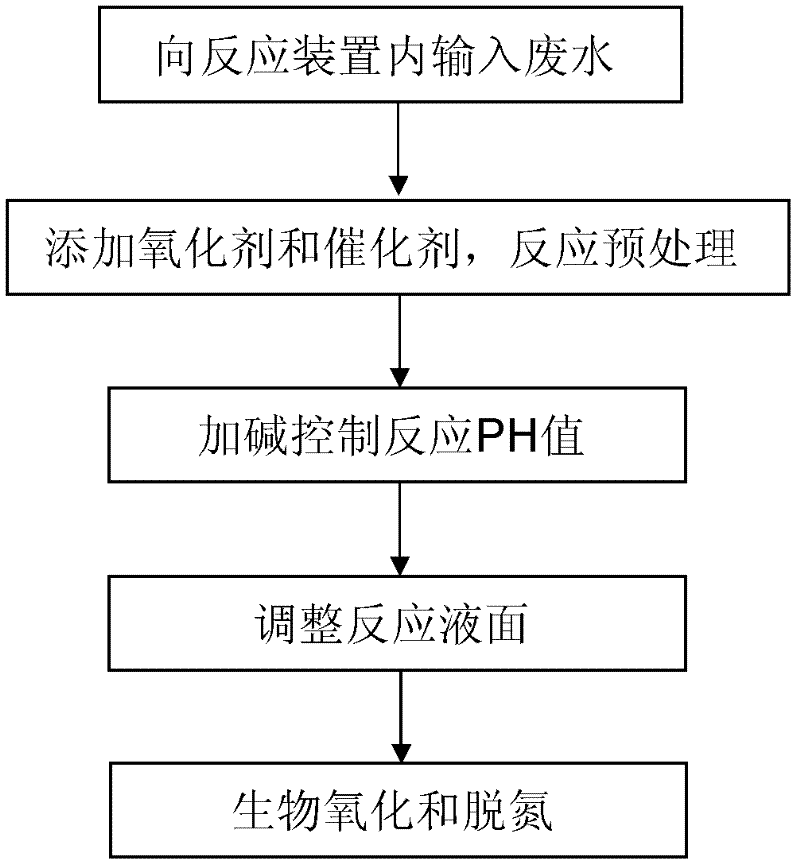

Method used

Image

Examples

Embodiment 1

[0036] The organic cyanide-containing wastewater discharged from a production facility contains a large amount of organic nitriles (3-cyanopyridine, succinonitrile, etc.), with a COD of 2963 mg / L and a cyanide concentration of 3.76 mg / L. Operating conditions: Wastewater treatment capacity is 1m3 / h, the dosage of 30% hydrogen peroxide is 50ml / min, the upper limit of pH controller 14 is set to 9, the lower limit is 8.2, the reaction residence time is controlled at 2 hours, the COD of oxidized water is 2100mg / L, and the concentration of cyanide It is 0.24mg / L. After biochemical treatment, the COD of the final effluent is 84mg / L, and the concentration of cyanide is 0.02mg / L (see Table 1).

[0037] Table 1

[0038] reaction stage

Embodiment 2

[0040] The organic cyanide-containing wastewater discharged from a production facility contains a large amount of organic nitriles (3-cyanopyridine, succinonitrile, etc.), the COD is 3215mg / L, and the cyanide concentration is 4.9mg / L. Operating conditions: Wastewater treatment capacity is 1m 3 / h, the dosage of 30% hydrogen peroxide is 45ml / min, the upper limit of pH controller 14 is set to 10, the lower limit is 9, the reaction residence time is controlled at 2 hours, the COD of oxidized water is 1865mg / L, and the concentration of cyanide It is 0.12mg / L. After biochemical treatment, the COD of the final effluent is 75mg / L, and the cyanide concentration is 0.01mg / L (see Table 2).

[0041] Table 2

[0042] reaction stage

Embodiment 3

[0044] The organic wastewater of a synthesis plant contains a certain concentration of toluene and benzaldehyde, the influent COD is 560mg / L, the cyanide concentration is 25mg / L, the pH is 10, the dosage of hydrogen peroxide is 5g / L, and the catalyst copper sulfate is Under the operating condition of 8mg / L, the reaction was carried out for 1 hour, and the cyanide in the effluent was 0.13mg / L, and the removal rate was 99.5%. After biochemical treatment, the final effluent COD is 50mg / L, and the cyanide concentration is 0.02mg / L.

[0045] In summary, the method and device for treating organic cyanide-containing wastewater of the present invention can fully meet the treatment requirements of organic cyanide-containing wastewater in the petrochemical industry, and has the following advantages:

[0046] 1. As an ideal and clean oxidant, hydrogen peroxide will not cause secondary pollution.

[0047] 2. The pH value of the reaction is controlled to be alkaline, which can effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com