Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Hydrogen cyanide gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen Cyanide is one of the many chemicals found in cigarettes. Hydrogen Cyanide is the chemical whose formula is HCN. Pure hydrogen cyanide is a colourless, highly poisonous, and volatile liquid that boils slightly above room temperature at 26 °C, becoming hydrogen cyanide gas.

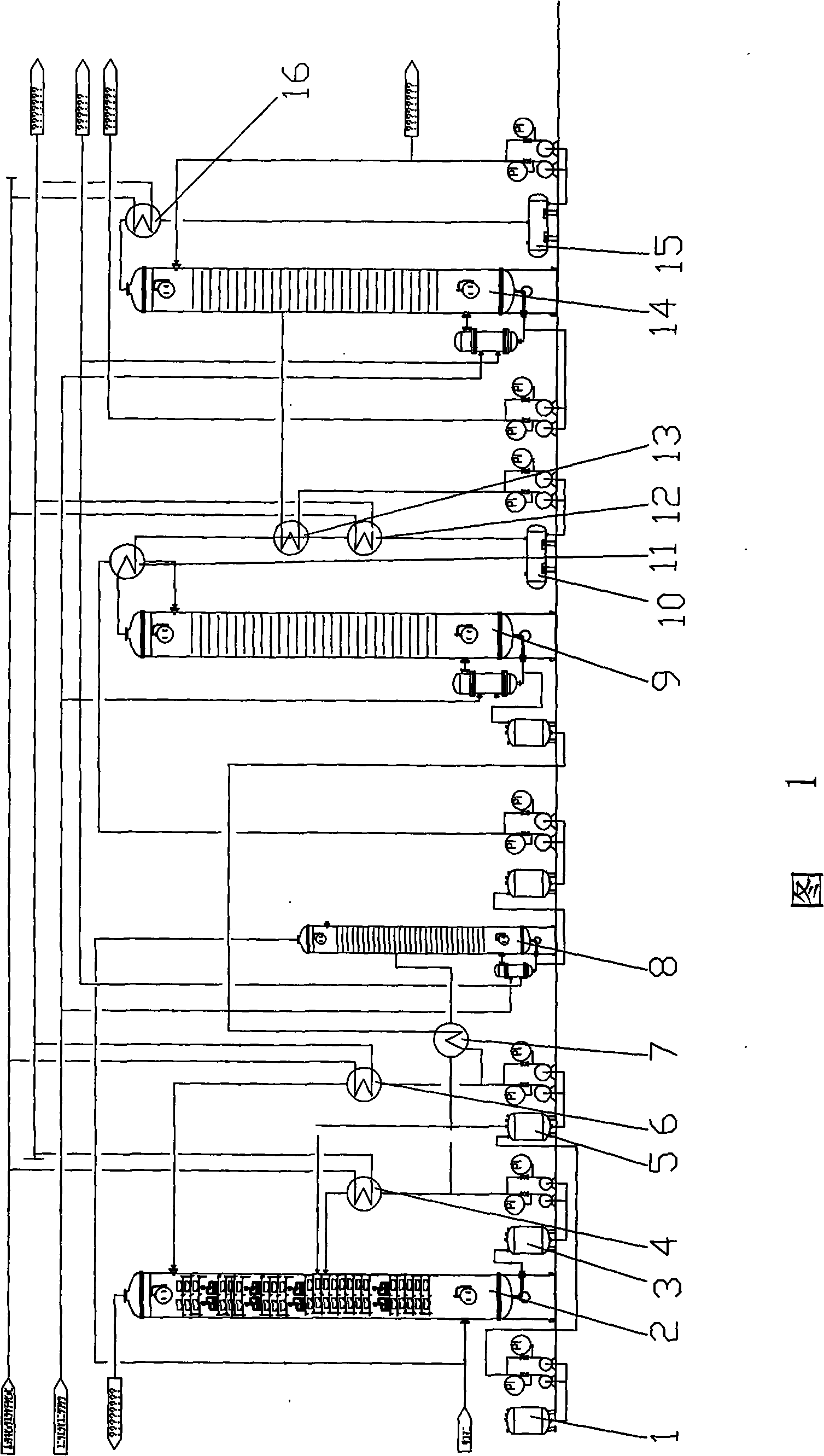

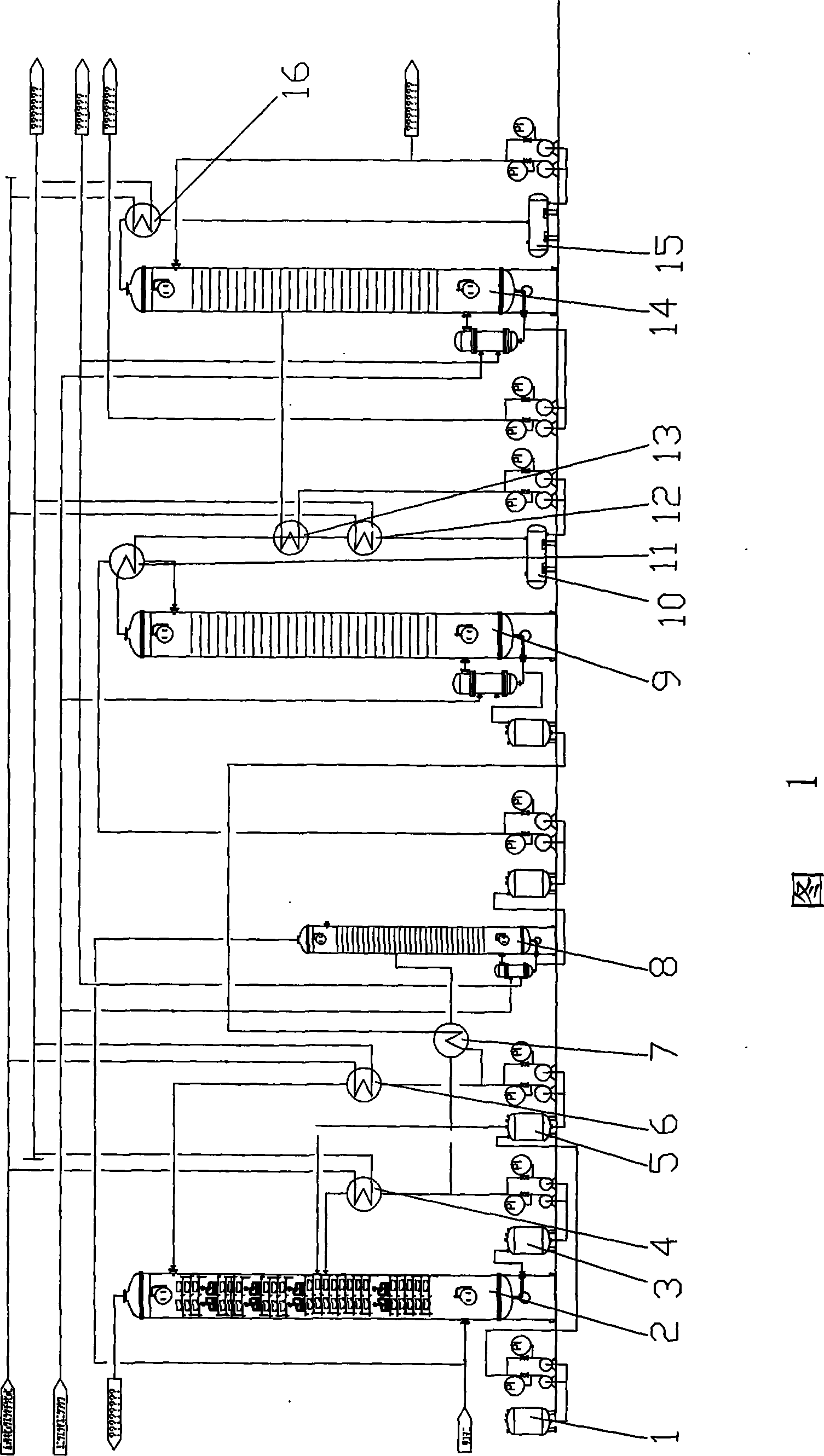

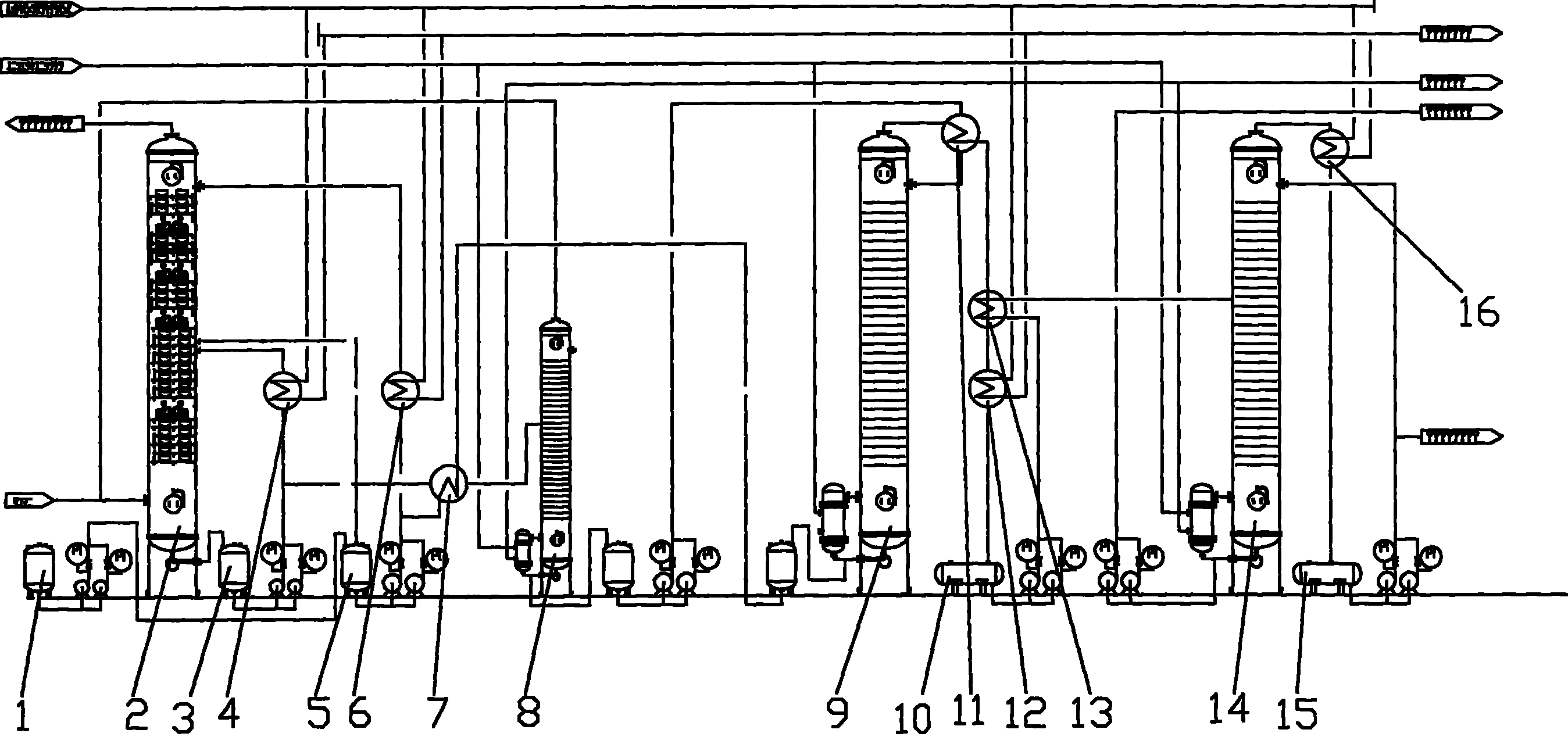

Ammonia recovery method for gas mixture in hydrogen cyanide production

ActiveCN101264901AAvoid lossReduce manufacturing costHydrogen cyanide preparation/purification/separationAmmonia preparation/separationRecovery methodDesorption

The invention discloses an ammonia recovery method from the mixing gas produced in the process of hydrogen cyanide production, comprising ammonia absorption process, decyanation process, desorption process and rectifying process for solving the technical problem. The invention is characterized in that decyanation process is set separately to recovery hydrogen cyanide gas, avoiding the loss of hydrogen cyanide caused by a large amount of acid gas like hydrocyanic acid contained in the ammonium phosphate solution directly steamed in Versum method, reducing production cost of hydrogen cyanide, reducing the emission of the harmful acid gas like hydrogen cyanide, and avoiding the serious pollution of peripheral enviroment. Besides, the ammonium phosphate solution contains a much smaller amout of hydrocyanic acid after hydrogen cyanide is recovered, which can not influence production process and make the production process more safety.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

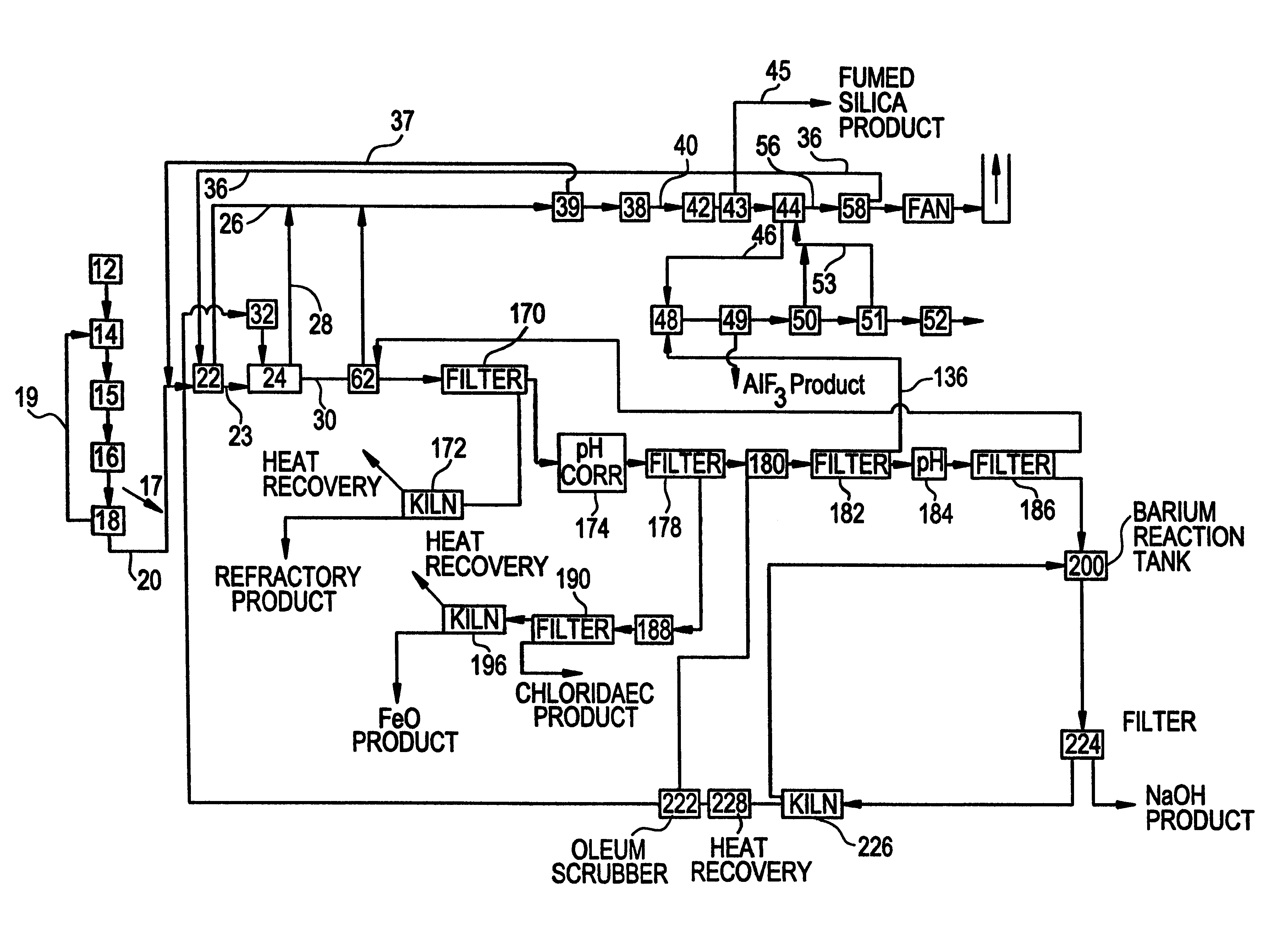

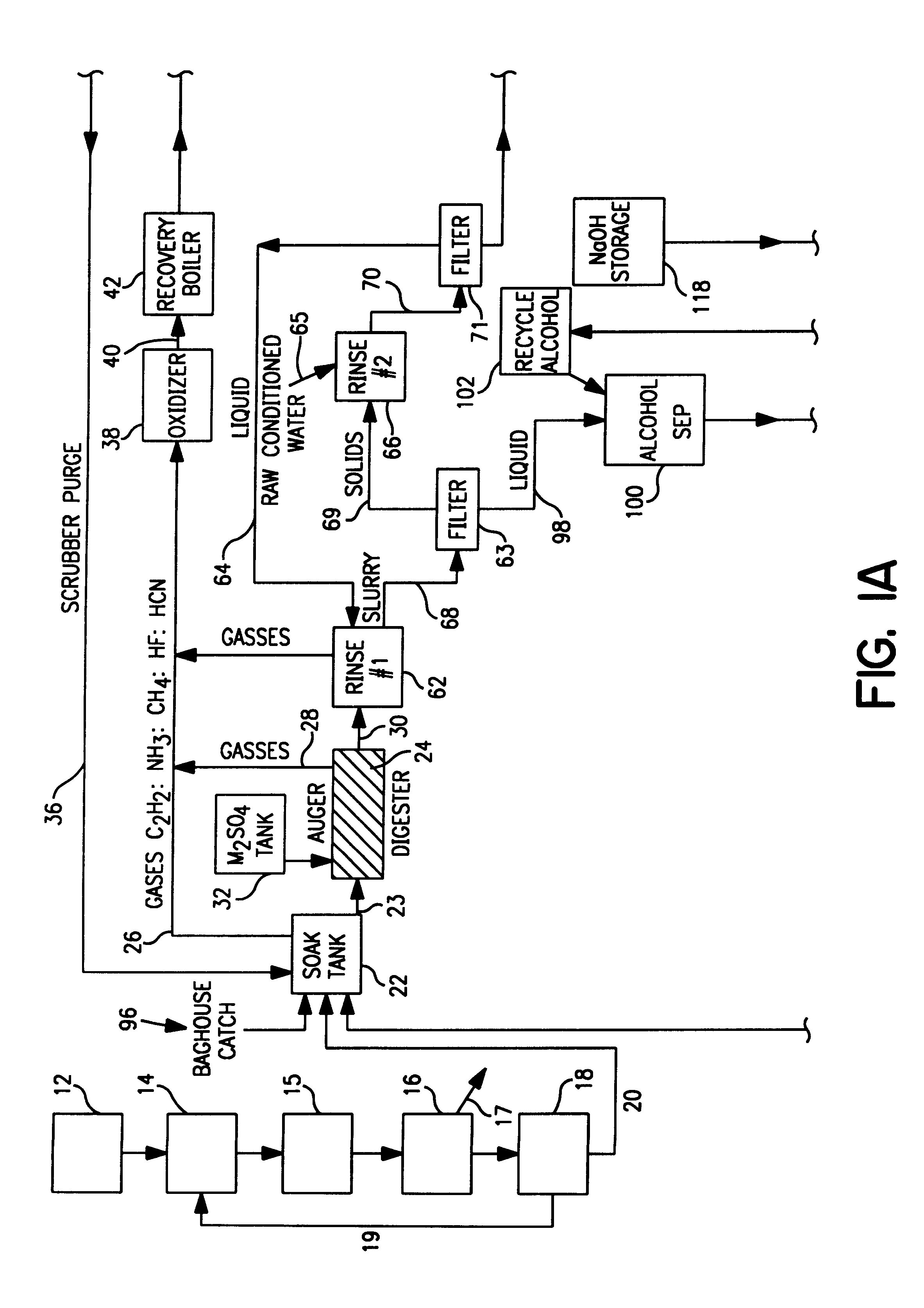

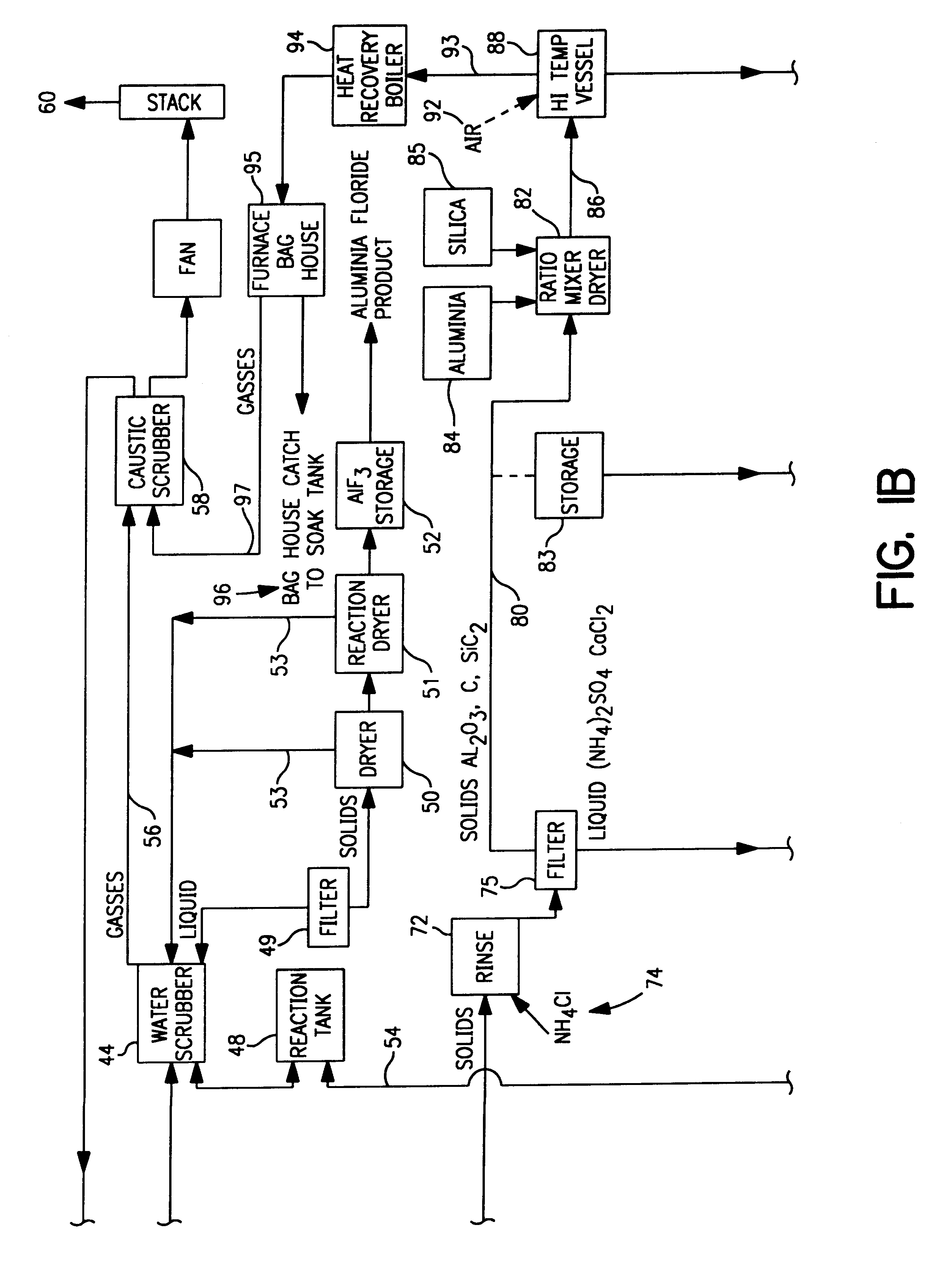

Method of recovering fumed silica from spent potliner

Spent potliner from an aluminum reduction cell is subject to an acid digest and the digest may be adjusted to produce a first gas component comprised of at least one material selected from the group consisting of silicon tetrafluoride, hydrogen fluoride, hydrogen cyanide gas and water vapor, and a slurry component comprised of at least one material selected from the group consisting of carbon, silica, alumina, and sodium, iron, calcium and magnesium compounds. The first gas component is removed from the digester and heated to a temperature sufficiently high to convert said silicon tetrafluoride to fumed silica and hydrogen fluoride. Thereafter, the fumed silica is separated from the hydrogen fluoride to recover fumed silica from spent potliner material.

Owner:GOLDENDALE ALUMINIUM CO

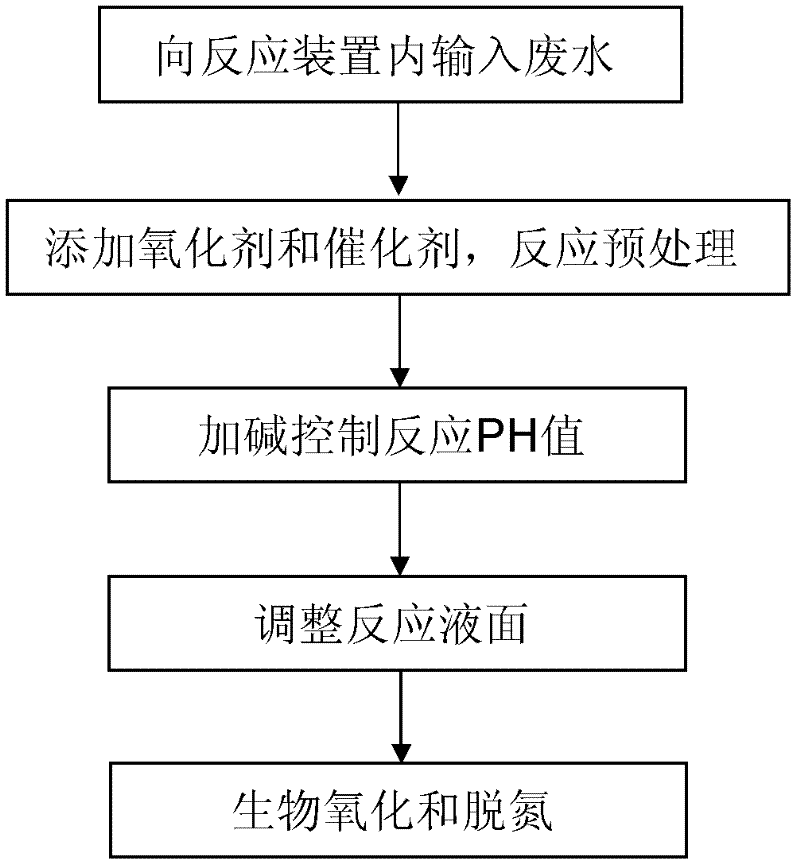

Method and device for treating organic cyanide wastewater

InactiveCN102642986AEasy to handleLow biological toxicityWater contaminantsMultistage water/sewage treatmentNitrogen removalBiological oxidation

The invention discloses a method for treating organic cyanide wastewater. The organic cyanide wastewater is pretreated by reaction using the alkaline peroxide advanced oxidation method, and the pretreated wastewater is subjected to biological oxidation and nitrogen removal by the biological A / O (Anoxic / Oxic) process to obtain effluent water meeting the discharge standards of China and to realize effective treatment of organic cyanide wastewater. The invention further discloses a device for treating the organic cyanide wastewater. As an ideal and clean oxidant, peroxide does not cause secondary pollution, and can reduce biological toxicity of wastewater as well as improve the biodegradability of wastewater, the pH value is controlled in the alkaline range, and highly toxic cyanide gas can be effectively prevented from escaping; and in addition, the operation conditions are simple, and the operation can be carried out at normal temperature and normal pressure.

Owner:SHANGHAI CHEM IND PARK SINO FRENCH WATERDEV

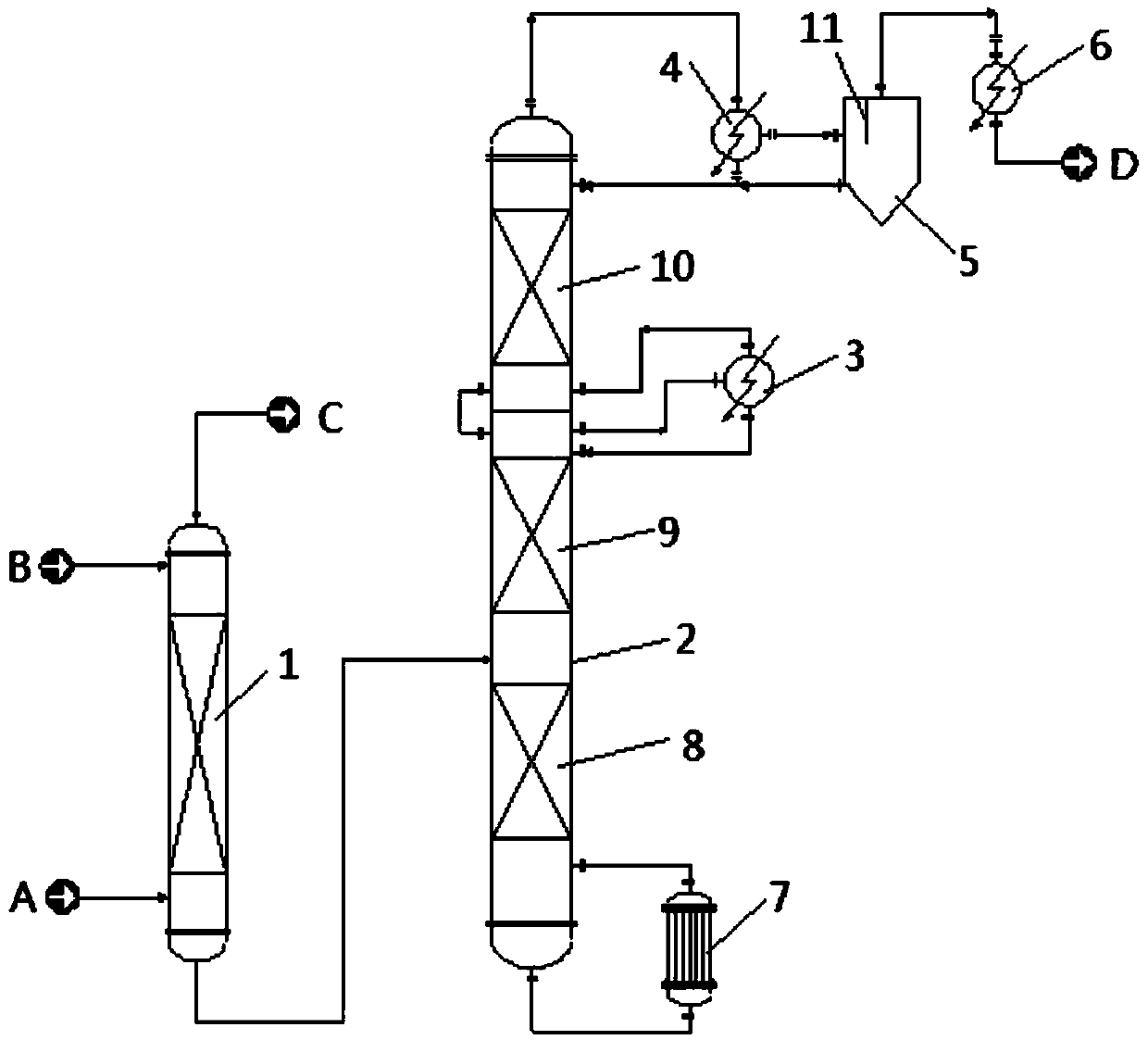

Process and system for preparing high-purity liquid hydrogen cyanide

ActiveCN105366692AImprove absorption efficiencyReduce loadHydrogen cyanide preparation/purification/separationEnvironmental resistanceVapor–liquid separator

The present invention provides a method for producing a high-purity liquid hydrogen cyanide for hydrogen cyanide gas obtained by ammoxidation. The liquid hydrogen cyanide of a low water content is obtained by absorption of low-temperature water in an absorbing tower and operation of a three-stage distillation tower and a gas-liquid separator. The process and method have the beneficial effects that by virtue of adoption by low-temperature water, the absorption efficiency of HCN gas is improved, the load on subsequent exhaust gas processing facilitates is alleviated, and the environmental protection pressure is relieved. Refined by the process disclosed by the invention, the content of a finished product hydrogen cyanide water can reach below 50 ppm, thereby sufficiently satisfying the using requirements on downstream users; the leakage risk of the hydrogen cyanide is effectively avoided, thereby more facilitating the safe production; and self-polymerization of hydrogen cyanide can be further slowed, so that production is more smooth and the production efficiency is improved.

Owner:CHINA TIANCHEN ENG +1

Nano sensitive material for monitoring hydrogen cyanide

InactiveCN102807862AUniform growthSmall particle size distribution rangeChemiluminescene/bioluminescenceLuminescent compositionsHydrogen cyanide gasTrace Amounts

The invention relates to a nano sensitive material for monitoring hydrogen cyanide. The nano sensitive material is characterized by consisting of the following components in percentage by weight: 25 to 35 percent of NiO, 30 to 40 percent of V2O5 and 32 to 42 percent of Al2O3 nano powder. The particle size of the nano sensitive material is between 25 and 40nm. A hydrogen cyanide air sensor made of the nano sensitive material has the advantages of wide linear range, high selectivity and high sensitivity, and can monitor a trace amount of hydrogen cyanide on line without being influenced by coexisting substances.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

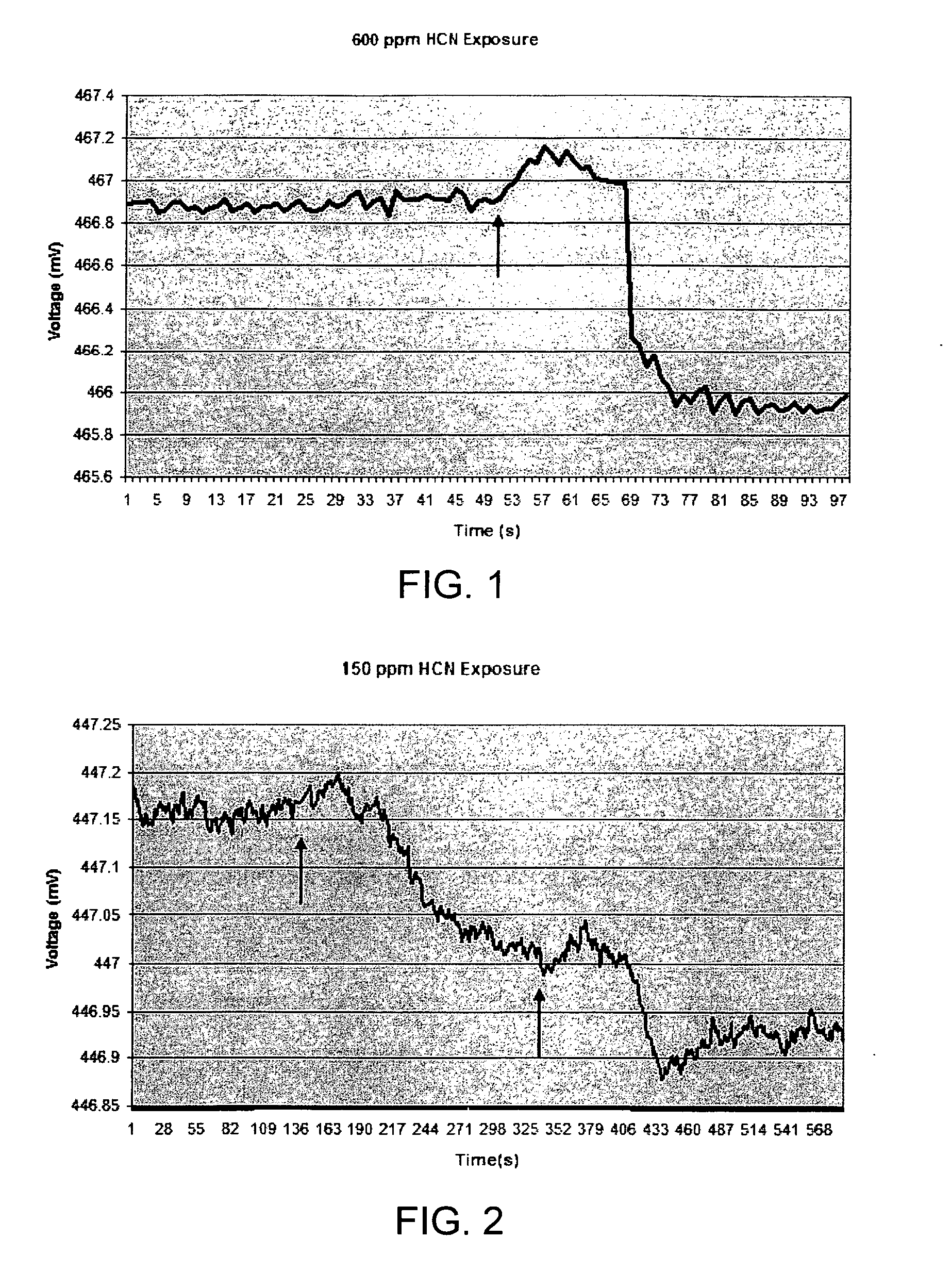

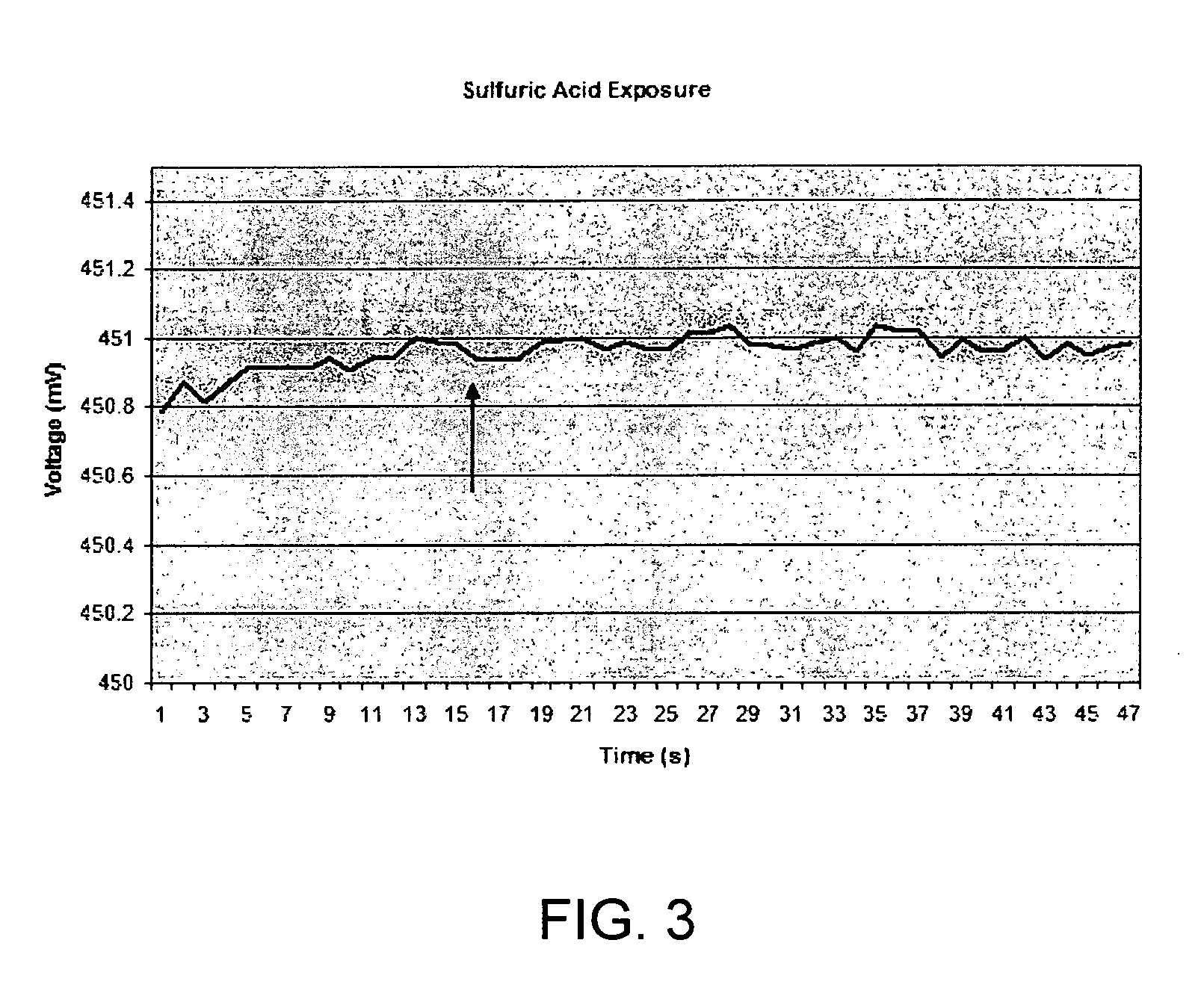

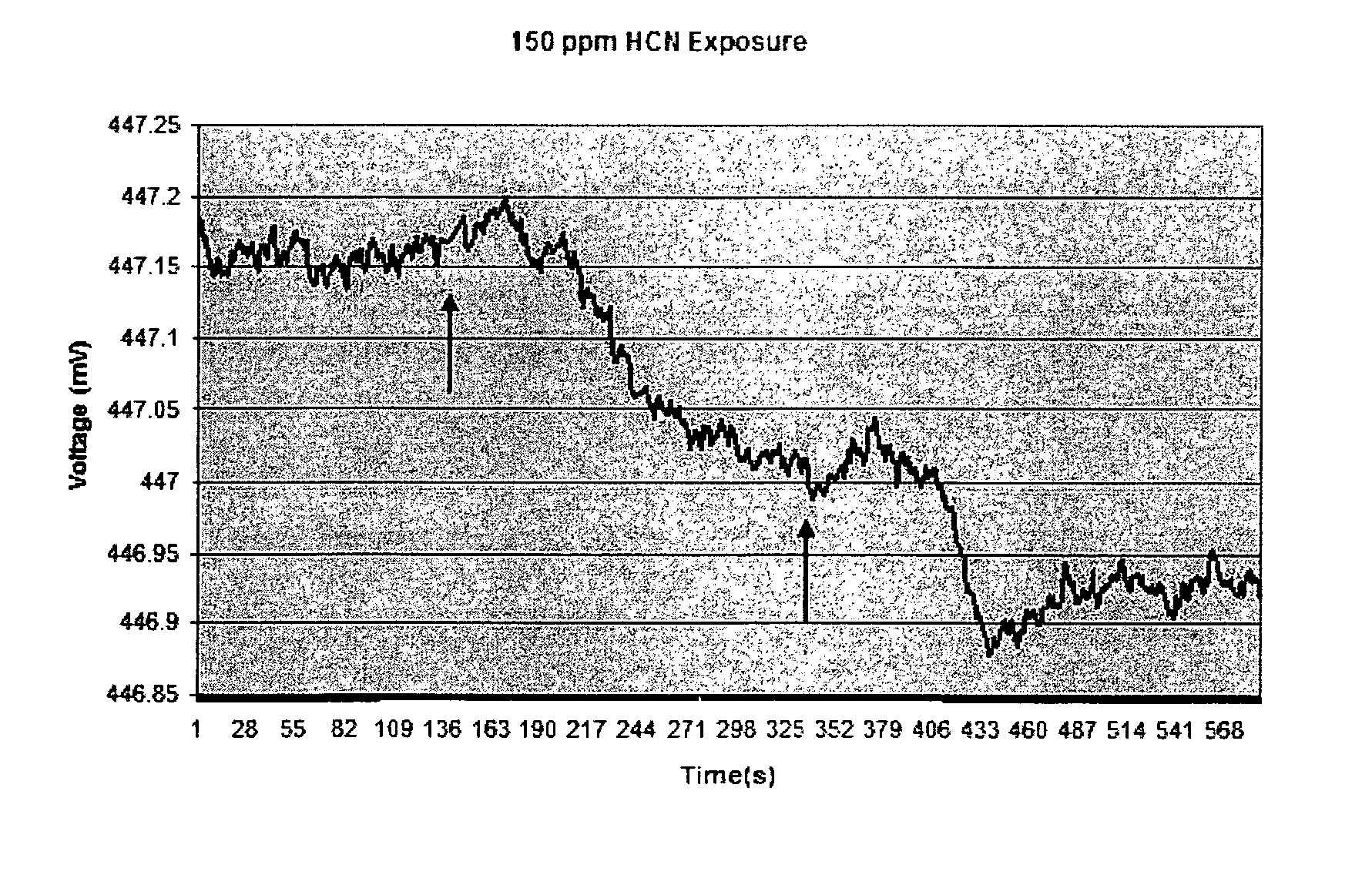

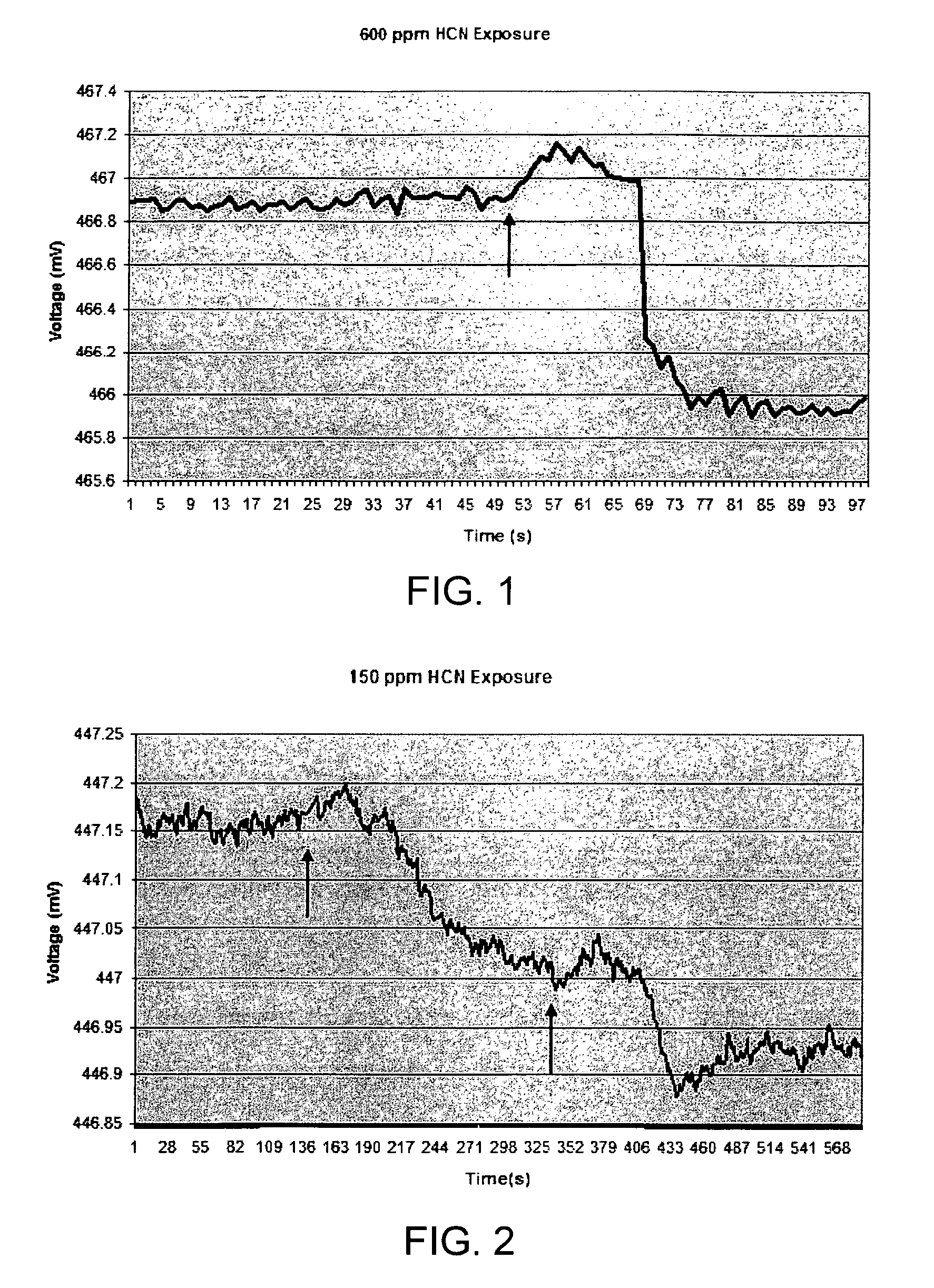

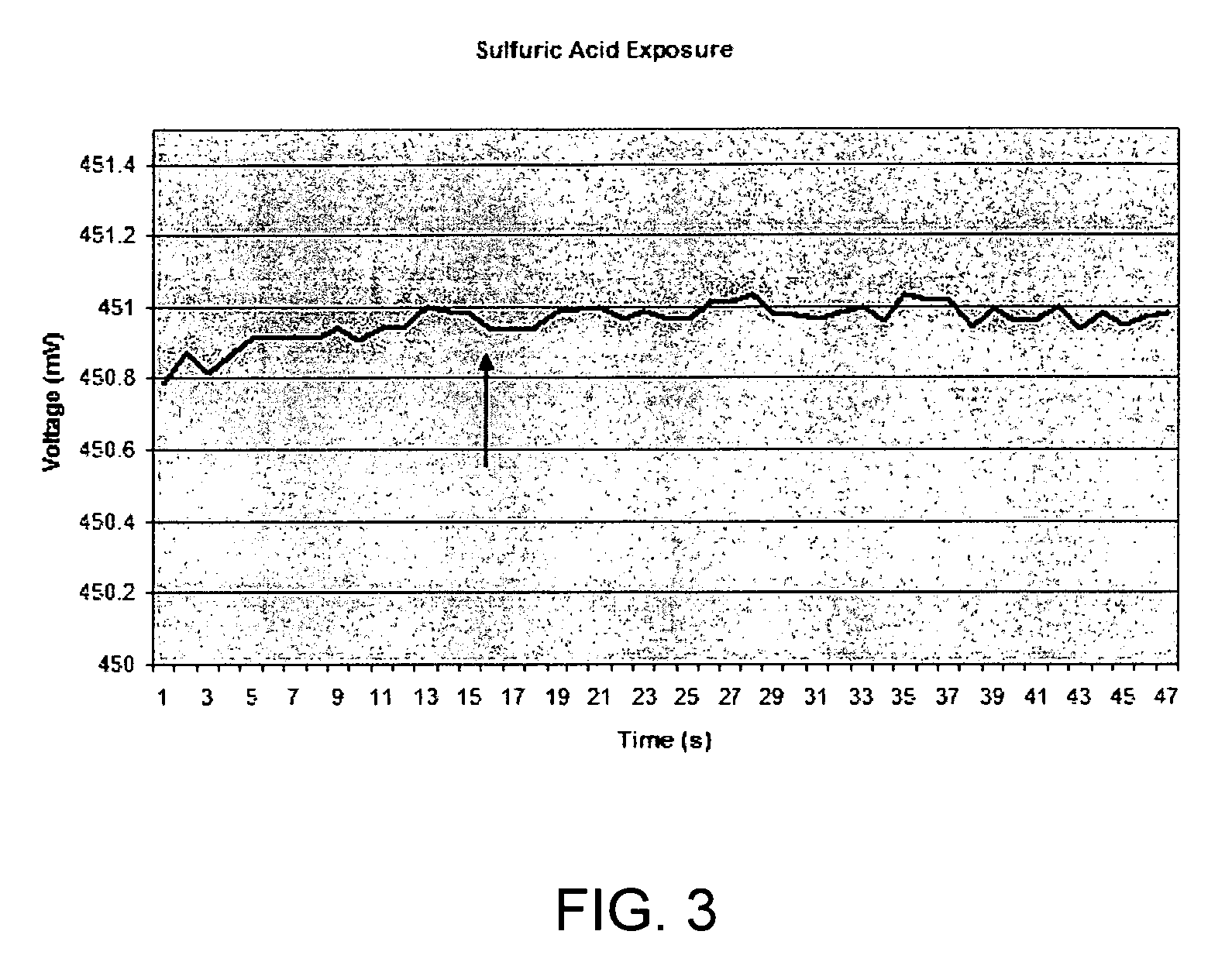

Microsensor material and methods for analyte detection

InactiveUS20100203648A1Increased free volumeFree volumeMaterial analysis using sonic/ultrasonic/infrasonic wavesBiological testingInorganic particleAnalyte

The compositions and methods relate to an organic polymer-inorganic particle sensor material for detecting analytes. Interactions between the polymer and the particles are affected by the presence of analyte, which displaces the polymer and increases its free volume. This change in free volume can be detected, e.g., using an embedded piezoresistive microcantilever (EPM) sensor. Analytes that can be detected include noxious substances, such as hydrogen cyanide gas and carbon monoxide.

Owner:CANTIMER +1

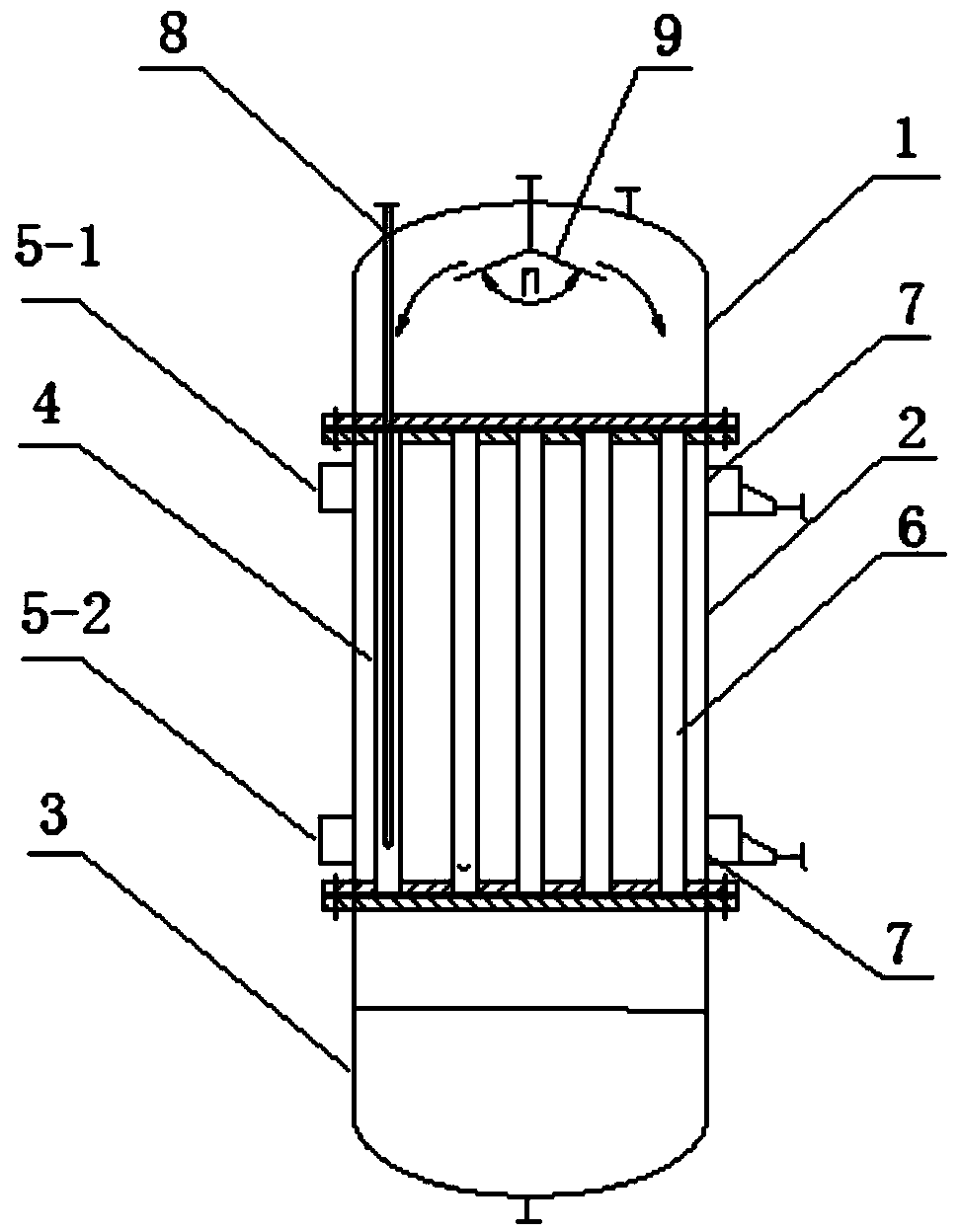

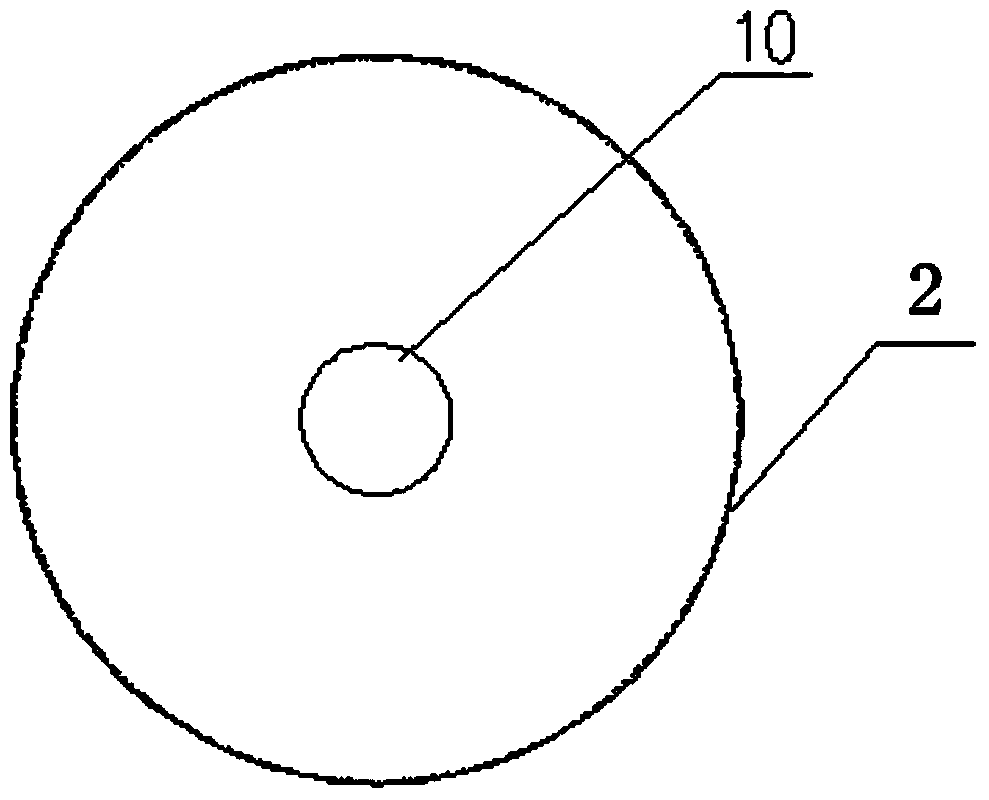

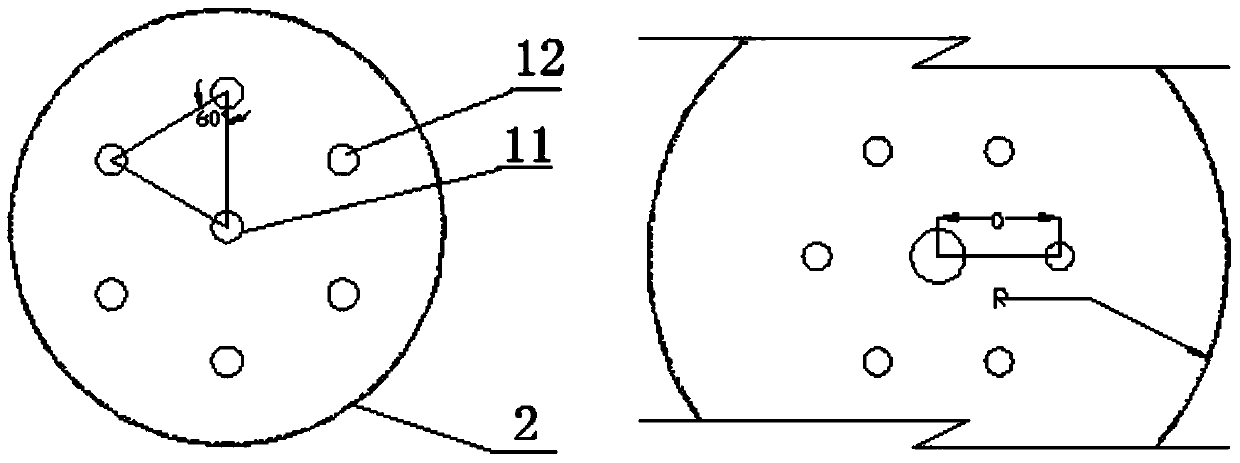

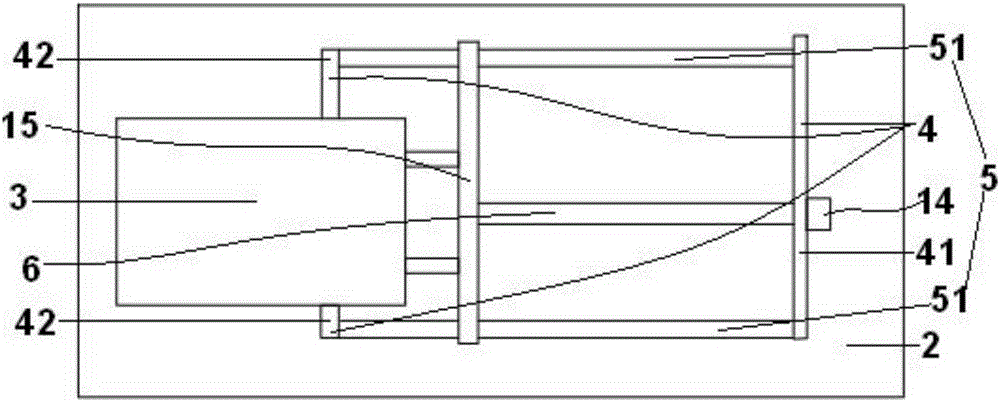

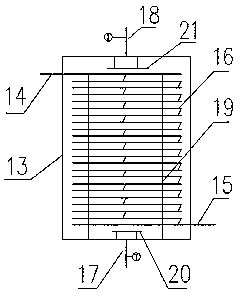

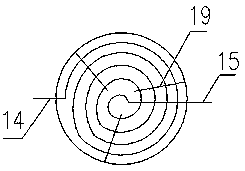

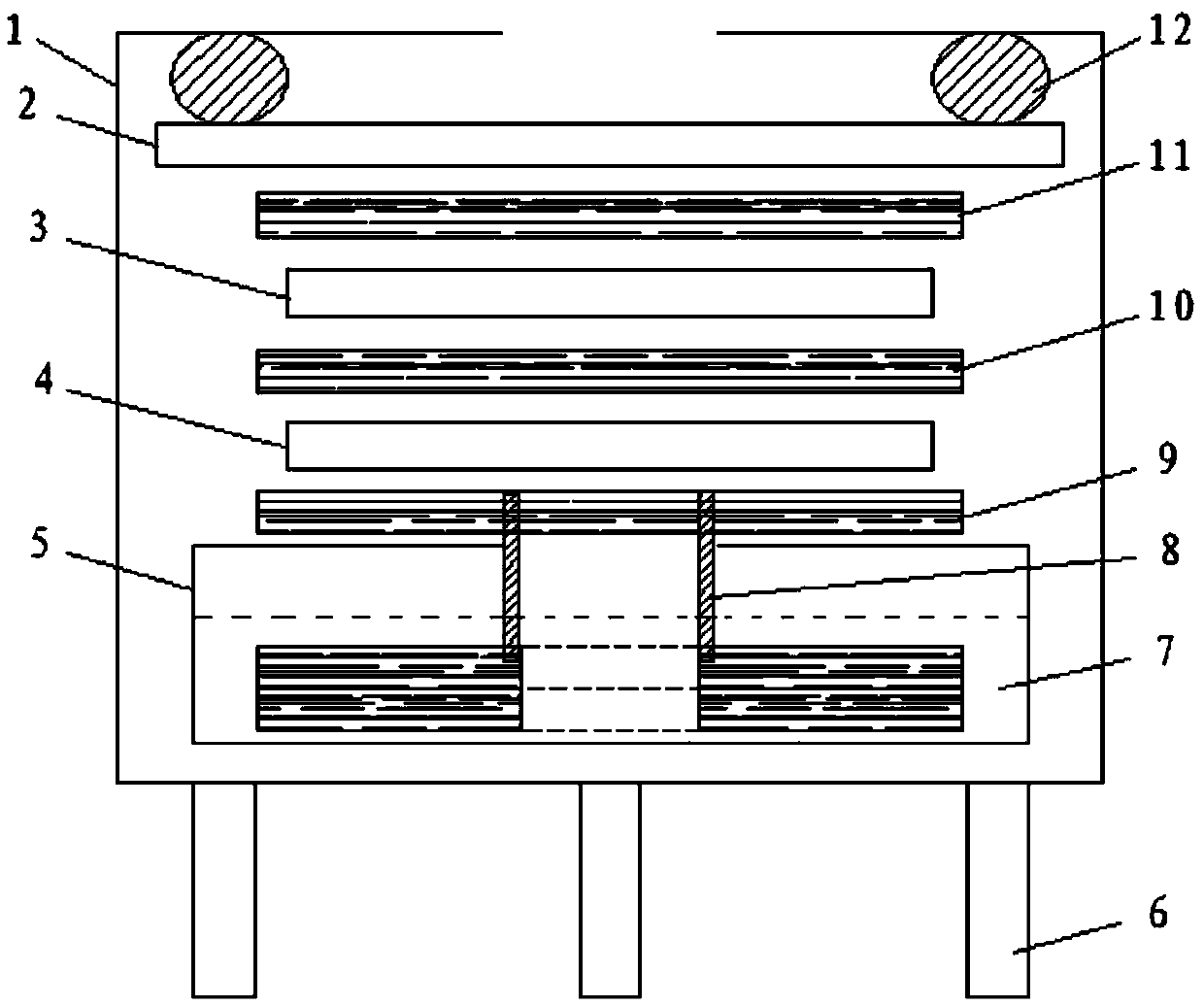

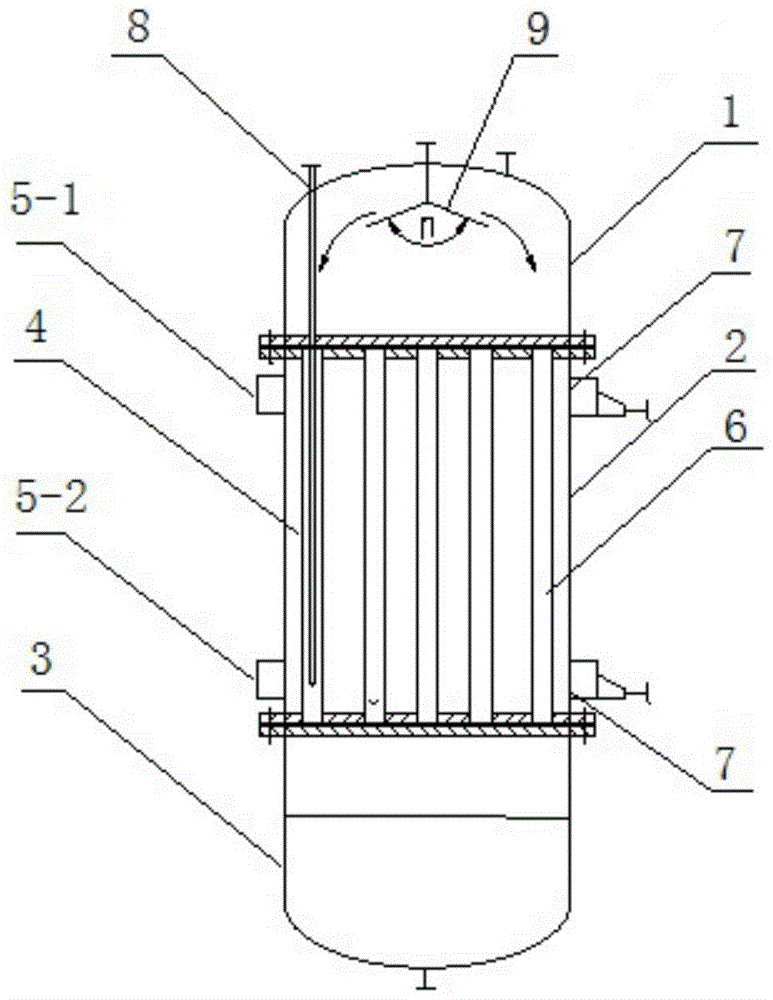

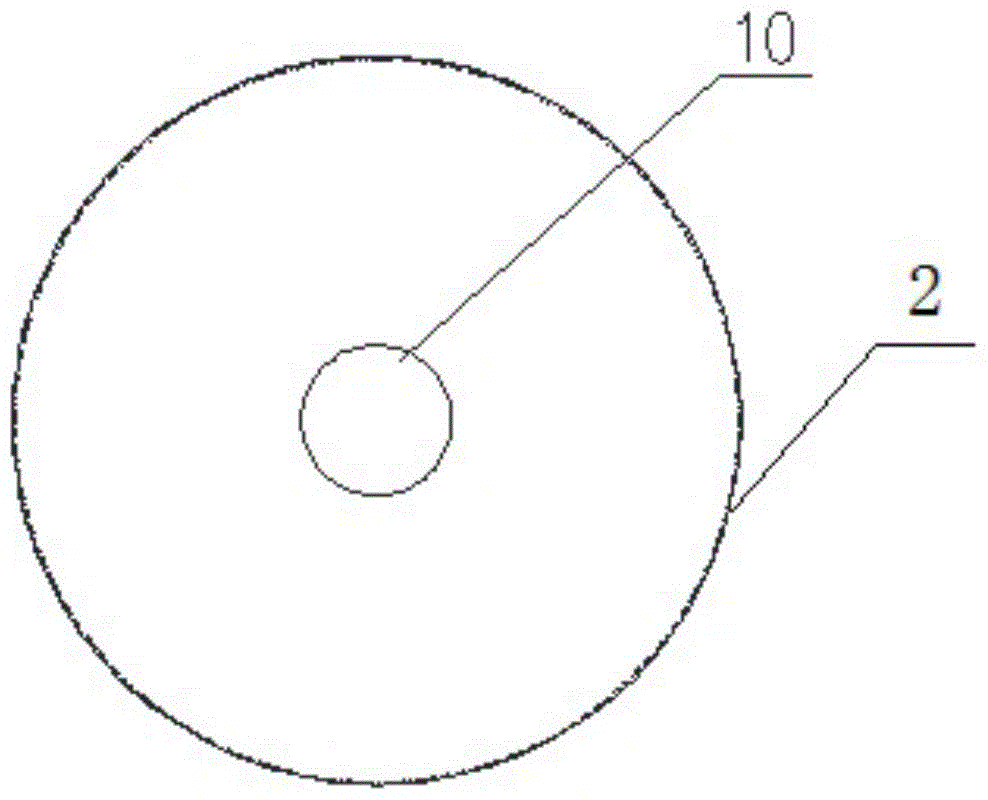

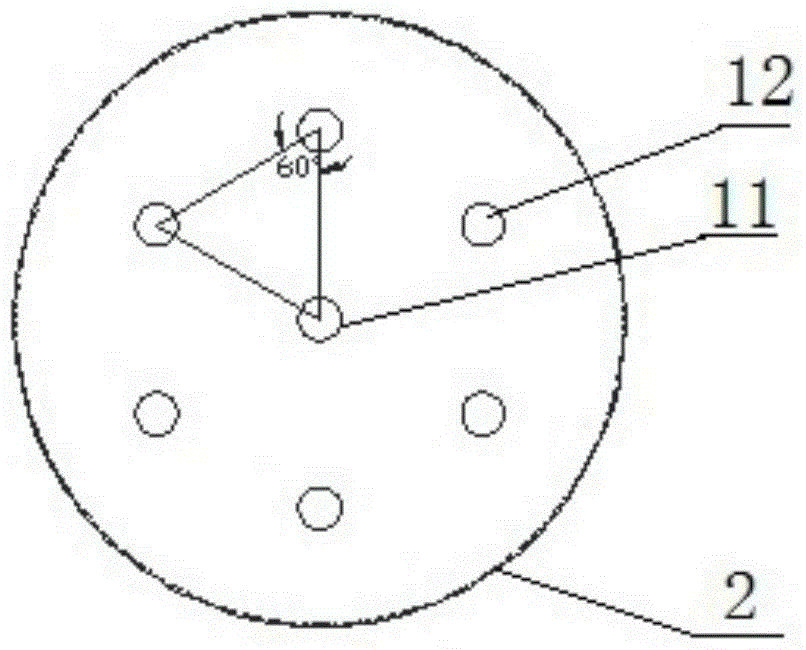

Reactor used for preparing gas-phase hydrogen cyanide

ActiveCN104190328AStable and effective withdrawalImprove distributionChemical/physical processesHydrogen cyanide preparation/purification/separationGas phaseReaction temperature

The invention discloses a reactor used for preparing gas-phase hydrogen cyanide. The reactor used for preparing gas-phase hydrogen cyanide comprises an upper sealing head, a lower sealing head, a shell side and reaction tubes, wherein the reaction tubes are arranged in the shell side; the upper sealing head and the lower sealing head are respectively and correspondingly mounted at the upper end and the lower end of the shell side; the reactor used for preparing gas-phase hydrogen cyanide also comprises a feed gas distribution device, a temperature monitoring device, a heat-transfer medium flow guide device and a hollow flow guide cylinder; the feed gas distribution device is mounted in the top end of a main body structure of the tubular reactor; the temperature monitoring device is inserted from the top end of the main body structure of the tubular reactor; the heat-transfer medium flow guide device is mounted on the outer part of the shell side; flow guide holes are formed in an inner wall surface, being in contact with the heat-transfer medium flow guide device, of the shell side; the hollow flow guide cylinder and the reaction tubes are mounted in the shell side in a mixing manner. The reactor used for preparing gas-phase hydrogen cyanide has the beneficial effects of being capable of generating easily-separated hydrogen cyanide gas and stably and effectively dissipating reaction heat, an accurate reaction temperature monitoring system is arranged, the feed gas distribution effect is good, the reaction conversion rate is high; a catalyst is low in loss during use and long in service life.

Owner:CHINA TIANCHEN ENG +2

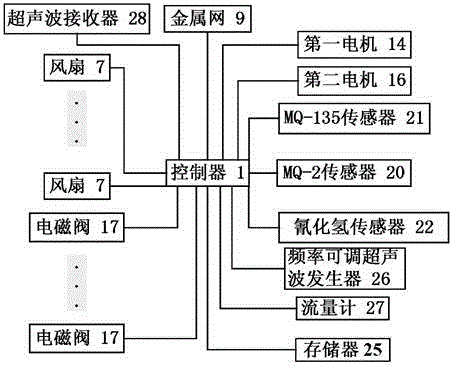

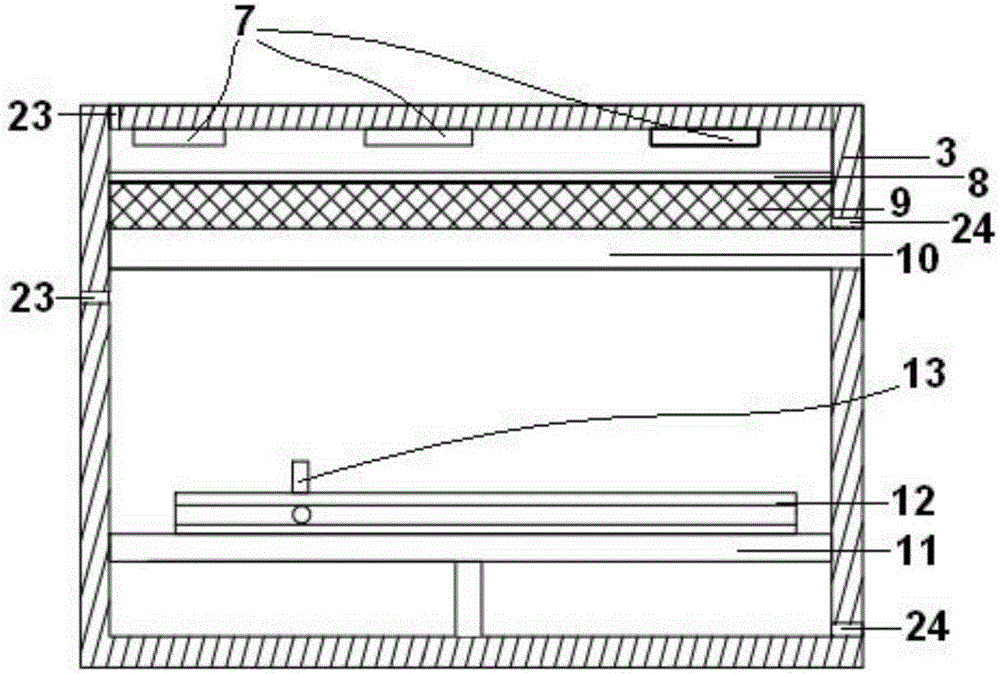

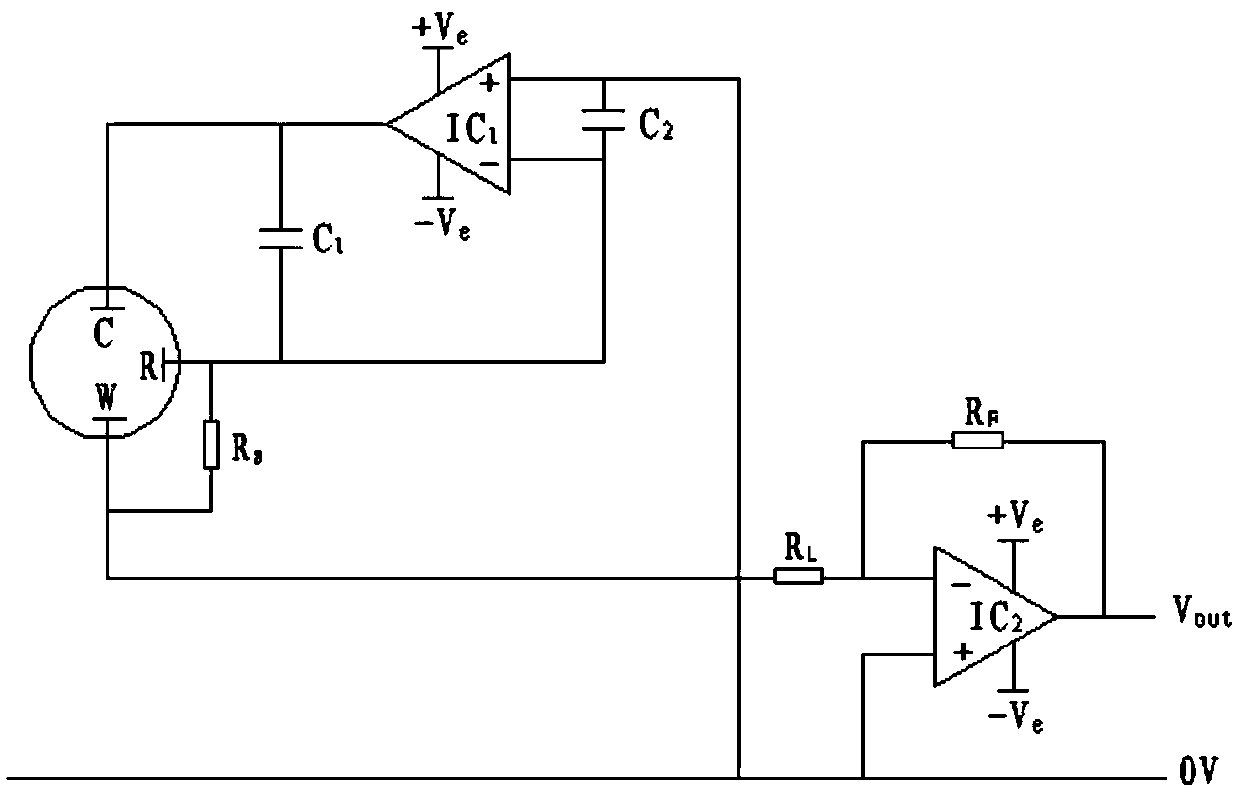

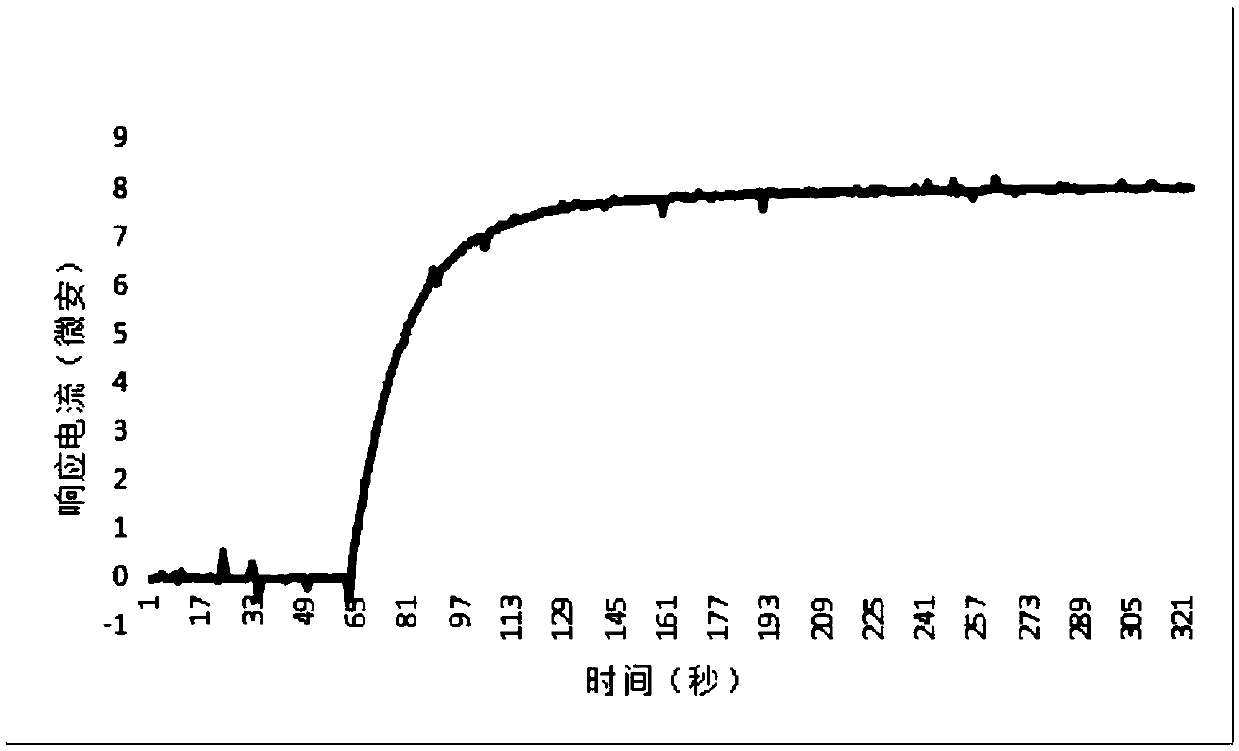

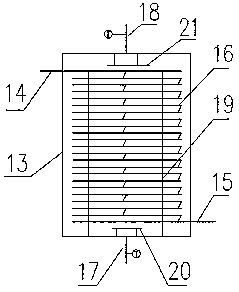

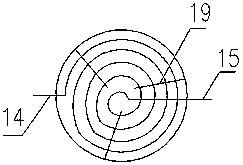

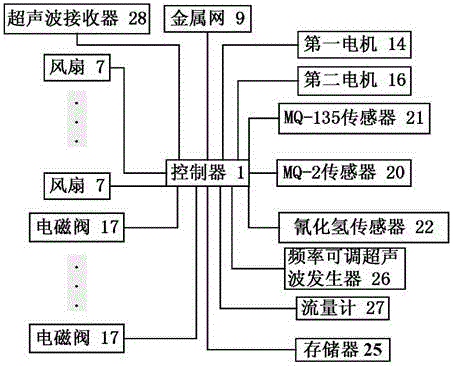

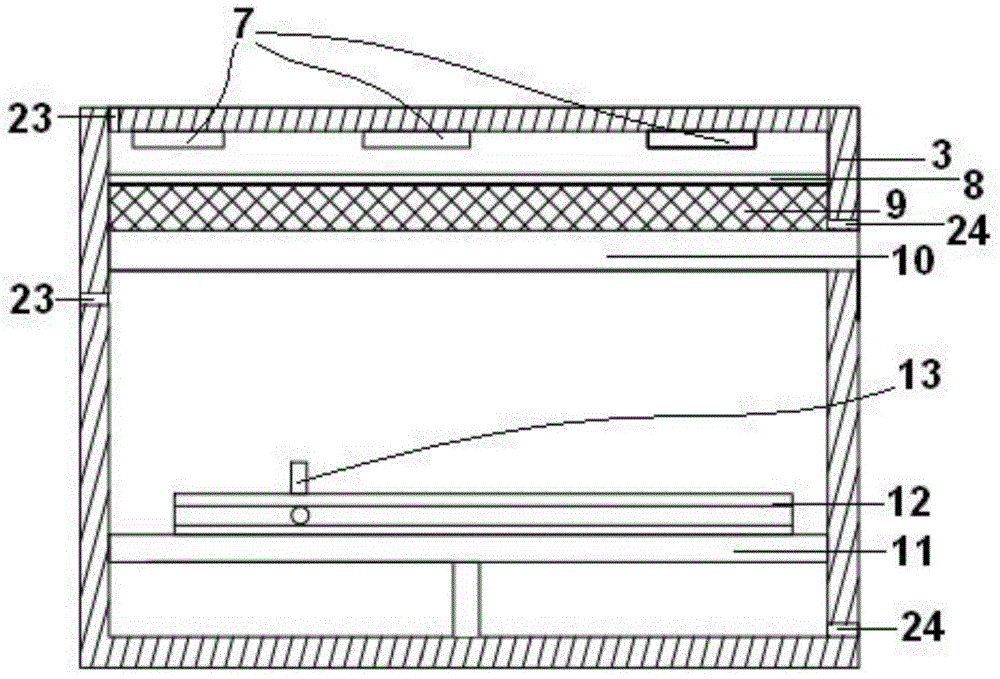

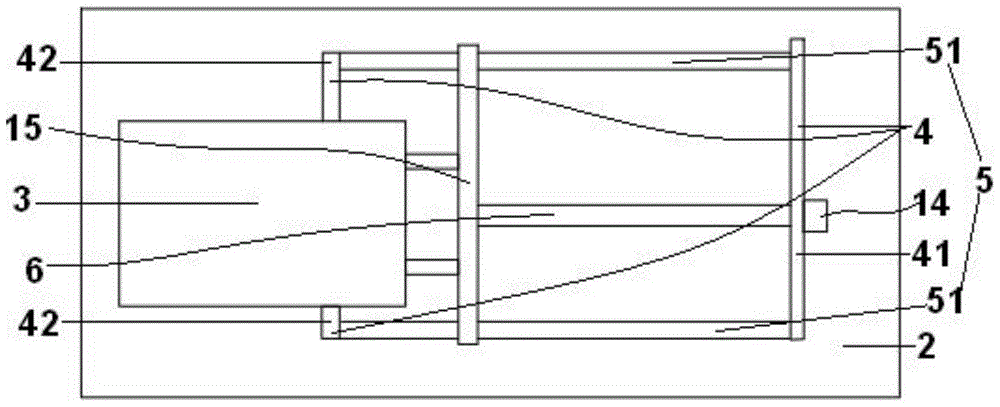

Detection apparatus and detection method for hydrogen cyanide in research lab

InactiveCN105223313AKeep detection informationPreserve signal difference informationMaterial analysisPhysical well beingEngineering

The invention discloses a detection apparatus and detection method for hydrogen cyanide in a research lab. The detection apparatus comprises a controller, a memory, a base plate, a rectangular cross section equipped air chamber and a support frame arranged on the base plate, and a guide structure and a cross lead screw arranged on the support frame. The inner wall top of the air chamber is provided with an ultrasonic generator and several fans for blowing down, the inner side wall of the air chamber is equipped with a gas sensitive film, a metal net composed by heating wires and for supporting the gas sensitive film, a horizontal separator plate that is located below the metal net and separating the inside of the air chamber into an upper part and a lower part from top down in order, and the air chamber is internally provided with an ultrasonic receiver, a support plate, a detection head and a track spirally distributed along the upper surface of the support plate. The detection apparatus provided by the invention has the characteristics of high sensitivity, good stability and short response time, good selectivity to hydrogen cyanide, and ability to detect lower concentration trace hydrogen cyanide gas, thus effectively guaranteeing people good health.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Technological method for jointly preparing liquid hydrogen cyanide and hydroxynitrile

ActiveCN104725269AIncrease profitReduce purification energy consumptionCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystHCN poisoning

The invention provides a technological method for jointly preparing liquid hydrogen cyanide and hydroxynitrile. The technological method comprises the steps that a light oil cracking hydrogen cyanide gas mixture is used as a raw material and undergoes an ammonia removal process and a cryogenic process to obtain liquid hydrogen cyanide, wherein in the ammonia removal process, the hydrogen cyanide gas mixture is absorbed with a sulfuric acid aqueous solution; in the cryogenic process, the hydrogen cyanide gas mixture is cooled to minus 10-minus 20 DEG C, after the hydrogen cyanide gas mixture is cooled, a part of the hydrogen cyanide gas becomes liquid to obtain liquid hydrogen cyanide, and the other part of the hydrogen cyanide gas is the tail gas containing hydrogen cyanide; the tail gas containing hydrogen cyanide, which undergoes cryogenic treatment, is absorbed with a formaldehyde aqueous solution containing a catalyst to prepare a hydroxynitrile aqueous solution, and the tail gas absorbed with the formaldehyde aqueous solution directly enters an incinerator to be incinerated. By adopting the technological method, the purification efficiency and the utilization efficiency of hydrogen cyanide can be obviously improved, meanwhile, the energy consumption in the hydrogen cyanide purification process is greatly reduced and can be reduced by 90% at most, and the utilization rate of hydrogen cyanide is more than 99.9%.

Owner:枣阳市金鹿化工有限公司

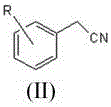

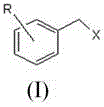

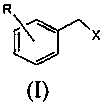

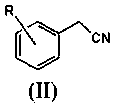

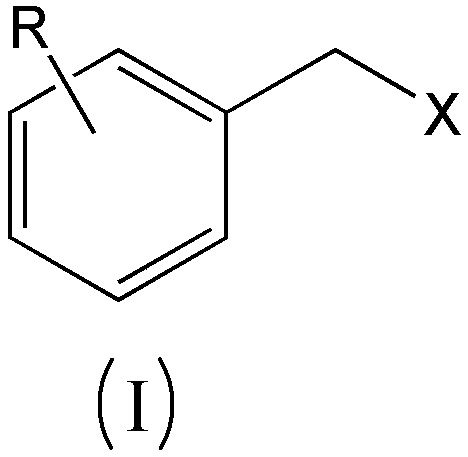

Preparation method of substituted benzyl cyanide

ActiveCN106349105AImprove reaction efficiencyHigh degree of automationPreparation by cyanide reactionSulfonic acid preparationHydrogen halideOrganic synthesis

The invention relates to the technical field of organic synthesis, in particular to a method of continuously preparing a substituted benzyl cyanide compound by using a microchannel reactor, and discloses a preparation method of substituted benzyl cyanide. The preparation method comprises the steps of preheating accurately metered raw materials, namely substituted benzyl halide and hydrogen cyanide gas separately, allowing the raw materials to enter a microchannel reactor after mixing for nucleophilic substitution reaction at 150.0-250.0 DEG C and pressure of 1.0-10.0MPa to generate substituted benzyl cyanide and hydrogen halide, keeping reaction retention time for 10-300s, then cooling for quenching reaction, and post-treating a reaction material to form substituted benzyl cyanide. The method has the advantages of low cost, high production efficiency, continuous production and clean production.

Owner:HEBEI CHENGXIN

Microsensor material and methods for analyte detection

InactiveUS8828733B2Increased free volumeFree volumeAnalysing fluids using sonic/ultrasonic/infrasonic wavesBiological testingInorganic particleAnalyte

The compositions and methods relate to an organic polymer-inorganic particle sensor material for detecting analytes. Interactions between the polymer and the particles are affected by the presence of analyte, which displaces the polymer and increases its free volume. This change in free volume can be detected, e.g., using an embedded piezoresistive microcantilever (EPM) sensor. Analytes that can be detected include noxious substances, such as hydrogen cyanide gas and carbon monoxide.

Owner:CANTIMER +1

DL-mandelic acid preparation process

InactiveCN106986762ALow priceHigh optical purityOrganic compound preparationPreparation from nitrilesActivated carbonBenzaldehyde

The invention discloses a DL-mandelic acid preparation process. The DL-mandelic acid preparation process comprises the following steps: adding benzaldehyde and sodium hydroxide into a three-neck bottle having backflowing and stirring functions, keeping the temperature of the three-neck bottle to 45-60 DEG C, slowly adding ionized water into the three-neck bottle, then slowly adding dichloroacetophenone dropwise, moving to the environment of 65 DEG C to place for 50-55 minutes so as to generate a mixed solution, adding a hydrogen cyanide gas into the mixed solution again, reacting at the same temperature again for 30-45 seconds, adding an acid solution into the mixed solution until a crystal overflows, adding a catalyst for multiple times to obtain a white crystal, adding water to dissolve the white crystal, adding an activated carbon to decolorize, filtering, enabling the solution to recrystallize at the environment of 30-35 DEG C, centrifuging and drying to obtain a finished product, namely the DL-mandelic acid. The cost of the raw materials is effectively reduced, the optical purity of the product is higher, and the product quality is greatly improved.

Owner:枣阳市残联福利生物化工厂

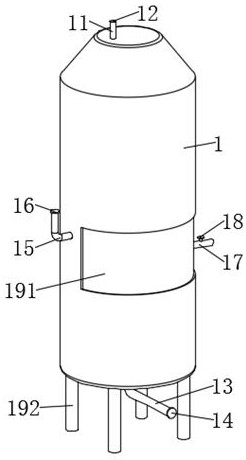

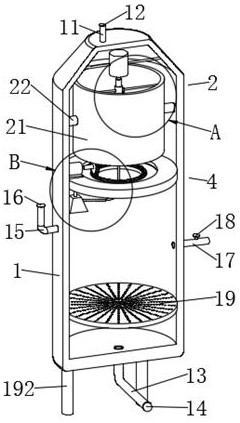

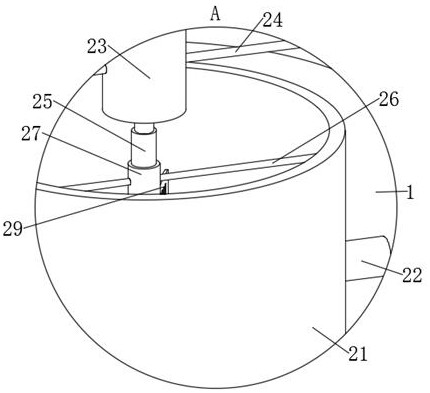

Industrial water-containing hydrogen chloride gas dehydration device and dehydration method

PendingCN114100328AImprove the heating effectStir wellChlorine/hydrogen-chloride purificationRotary stirring mixersThermodynamicsHydrogen cyanide gas

The invention discloses an industrial water-containing hydrogen chloride gas dehydration device and a dehydration method, belongs to the technical field of gas treatment, and aims to solve the problem that in the prior art, when hydrogen chloride gas is subjected to dehydration treatment, purchased dehydration chemical agents are mostly in contact with gas to complete dehydration of the hydrogen chloride gas. The device comprises a dehydrating tower, a feeding pipe is fixedly mounted at the upper end of the dehydrating tower, and a discharging pipe is fixedly mounted on one side, far away from the feeding pipe, of the dehydrating tower; a heating block and a first motor are started, the heating block enables a heat conduction disc to be heated through a heat conduction rod, the heat conduction disc enables various chemical agents to be heated, the first motor enables a first rotating rod to rotate, the first rotating rod enables stirring blades to rotate through a connecting sleeve, the stirring blades stir the various chemical agents, and therefore heating and stirring of the various chemical agents are conveniently completed; therefore, the effect of the prepared dehydration chemical agent is effectively improved.

Owner:HWASU

Ammonia recovery method for gas mixture in hydrogen cyanide production

ActiveCN101264901BAvoid lossReduce manufacturing costHydrogen cyanide preparation/purification/separationAmmonia preparation/separationRecovery methodDesorption

The invention discloses an ammonia recovery method from the mixing gas produced in the process of hydrogen cyanide production, comprising ammonia absorption process, decyanation process, desorption process and rectifying process for solving the technical problem. The invention is characterized in that decyanation process is set separately to recovery hydrogen cyanide gas, avoiding the loss of hydrogen cyanide caused by a large amount of acid gas like hydrocyanic acid contained in the ammonium phosphate solution directly steamed in Versum method, reducing production cost of hydrogen cyanide, reducing the emission of the harmful acid gas like hydrogen cyanide, and avoiding the serious pollution of peripheral enviroment. Besides, the ammonium phosphate solution contains a much smaller amout of hydrocyanic acid after hydrogen cyanide is recovered, which can not influence production process and make the production process more safety.

Owner:SHIJIAZHUANG GONGDA CHEM EQUIP

Method for treating cyanate ions in benzyl cyanide production wastewater

InactiveCN102107966ACN

<sup>-</sup>

Concentration decreasedReduce concentrationWater contaminantsMultistage water/sewage treatmentWastewaterSodium hypochlorite solution

The invention discloses a method for treating cyanate ions in benzyl cyanide production wastewater. The method comprises the following steps of: throwing cyanogen-containing wastewater into a reaction kettle; adding sodium hydroxide to adjust the pH value to 10; adding sodium hypochlorite solution; sealing an opening of the kettle; heating the reaction kettle to 140 to 150 DEG C; preserving the heat for 1 to 2 hours; cooling to 40 to 50 DEG C; and opening a pump and throwing the solution into a wastewater storage tank after the cyanogen is broken for recovering and reusing. By the method, cyanate ion (CN<->) concentration of the benzyl cyanide wastewater is greatly reduced; and requirements of wastewater standard emission are met through simple system treatment. The technique is small in investment, simple in operation, high in safety because of no hydrogen cyanide gas and low in treatment cost.

Owner:聊城鲁西氯苄化工有限公司

Electrochemical gas sensor for detecting hydrogen cyanide gas

An electrochemical hydrogen cyanide sensor (1) comprises a housing (10) comprising an opening (2) allowing gas to enter the sensor (1); an electrolyte disposed within the housing (10); a plurality ofelectrodes in contact with the electrolyte within the housing (10), wherein the plurality of electrodes comprise a working electrode (5) and a counter electrode (7), and wherein the electrodes comprise a metal catalytic material; and a filter (3) operable to cover the opening (2) of the housing (10), and prevent hydrogen sulfide from reaching the electrodes, wherein the filter (3) comprises silversulfate layered onto a polytetrafluoroethylene support material.

Owner:HONEYWELL INT INC

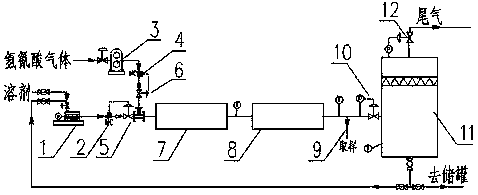

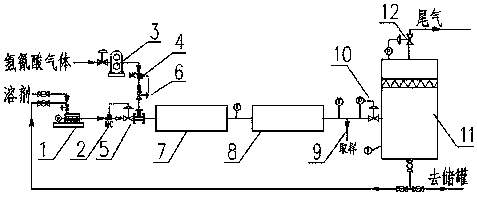

High-quality cyanide solution continuous production process and production system of high-quality cyanide solution

ActiveCN107434253AImprove operational safetyHigh selectivityAlkali metal cyanidesHydrogen cyanide preparation/purification/separationHydrogen cyanide gasAbsorption rate

The invention relates to a high-quality cyanide solution continuous production process and a production system of the high-quality cyanide solution, and belongs to the technical field of cyanide production. The production system comprises a metering pump, a mass flowmeter, a static mixer 7, a tube reactor 8, a gas-liquid separator 11, and pipeline valves and auto control instruments of the production system. A sampling valve 9 and a pressure auto control system 10 are arranged on a pipeline; a demister is installed inside the gas-liquid separator 11; a reaction tail gas discharging opening 12 having auto pressure control is arranged on the top of the gas-liquid separator; and a material discharging pipe and a circulating returning pipeline are arranged at the bottom of the gas-liquid separator. The method is simple; continuous production can be realize; the reaction time is short; the gas-liquid contact has no dead angle; the mass and heat transfer effects are good; the absorption rate of a raw material hydrogen cyanide is close to 100%; the aggregation discoloration caused by partial aggregation of the hydrogen cyanide gas is avoided particularly; the periodic equipment cleaning process in conventional arts is avoided especially; the labor intensity of workers is decreased; the labor force is saved; the product quality is notably improved as well; the cost is reduced by a certain degree; and accordingly the production process and the production system provided by the invention have good economic and social benefits.

Owner:HEBEI CHENGXIN

Technological method for jointly preparing liquid hydrogen cyanide and bisisobutyronitrile hydrazine

ActiveCN104724726AIncrease profitReduce purification energy consumptionCyanic/isocyanic acidPreparation by hydrogen cyanide additionHCN poisoningHydrogen cyanide gas

The invention provides a technological method for jointly preparing liquid hydrogen cyanide and bisisobutyronitrile hydrazine. The technological method comprises the steps that a light oil cracking hydrogen cyanide gas mixture is used as a raw material and undergoes an ammonia removal process and a cryogenic process to obtain liquid hydrogen cyanide, wherein in the ammonia removal process, the hydrogen cyanide gas mixture is absorbed with a sulfuric acid aqueous solution; in the cryogenic process, the hydrogen cyanide gas mixture is cooled to minus 10-minus 20 DEG C, after the hydrogen cyanide gas mixture is cooled, a part of the hydrogen cyanide gas becomes liquid to obtain liquid hydrogen cyanide, and the other part of the hydrogen cyanide gas is the tail gas containing hydrogen cyanide; the tail gas containing hydrogen cyanide, which undergoes cryogenic treatment, is absorbed with a ketazine aqueous solution to obtain an aqueous solution containing bisisobutyronitrile hydrazine, and the aqueous solution containing bisisobutyronitrile hydrazine undergoes cooling, crystallization and centrifugal filtration to obtain a bisisobutyronitrile hydrazine crystalline solid. By adopting the technological method, the purification efficiency and the utilization efficiency of hydrogen cyanide can be obviously improved, meanwhile, the energy consumption in the hydrogen cyanide purification process is greatly reduced and can be reduced by 90% at most, and the utilization rate of hydrogen cyanide is more than 99.9%.

Owner:枣阳市金鹿化工有限公司

Electrochemical hydrogen cyanide gas sensor

InactiveCN109596693AConcentration real-time monitoringGuaranteed concentrationMaterial analysis by electric/magnetic meansPropylene carbonateHydrogen cyanide gas

The invention relates to an electrochemical hydrogen cyanide gas sensor. The sensor comprises a shell, electrolyte, as well as a working electrode, a reference electrode and a counter electrode, whichare used for forming an ionic conduction in the electrolyte; each of the working electrode, the reference electrode and the counter electrode comprises an electrode membrane and a mixture adsorbed onthe electrode membrane; the mixture on the working electrode includes a first nanometer material and polytetrafluoroethylene particles; the mixture on the reference electrode includes a second nanometer material and the polytetrafluoroethylene particles; the mixture on the counter electrode includes a third nanometer material and the polytetrafluoroethylene particles; the electrolyte is the propylene carbonate solution; and, the lithium perchlorate and the triethanolamine are dissolved in the propylene carbonate solution. The gas sensor provided by the technical scheme of the invention precisely and quickly measures the concentration of the hydrogen cyanide gas, and monitors the concentration of the hydrogen cyanide gas in real time.

Owner:JINGZHOU AERITECH CO LTD

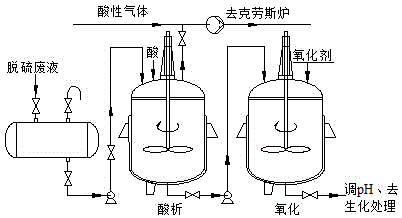

Method of treating vacuum potassium carbonate desulfurization waste liquid through acidic separation-out/oxidization process

ActiveCN105130099AReduce consumptionReduce processing costsSulfur preparation/purificationMultistage water/sewage treatmentChemical treatmentSulfide

The invention discloses a method of treating a vacuum potassium carbonate desulfurization waste liquid through an acidic separation-out / oxidization process. In the invention, the vacuum potassium carbonate desulfurization waste liquid is added by an acid to perform acid-out, wherein the separated hydrogen sulfide and hydrogen cyanide gases are mixed with acidic gas come out from a vacuum potassium carbonate desulfurization and regeneration column. The mixed gas is fed into a Claus furnace to recycle sulfur. The waste liquid after the acidic separation is added with an oxidizing agent to remove the residual sulfides and cyanides in the waste liquid. The treated waste liquid, after pH regulation, is discharged into a coking phenolic and cyanide wastewater bio-chemical treatment system to perform bio-chemical treatment. The method utilizes a vacuum system arranged on the top of the original vacuum potassium carbonate desulfurization and regeneration column. The method is short in technical process and less in equipment. By means of the process of firstly acid-out and then oxidization, the consumption of the oxidizing agent is less, so that the method is low in operation cost.

Owner:WUHAN UNIV OF SCI & TECH

Nano sensitive material for monitoring hydrogen cyanide

InactiveCN102807862BUniform growthSmall particle size distribution rangeChemiluminescene/bioluminescenceLuminescent compositionsHydrogen cyanide gasTrace Amounts

The invention relates to a nano sensitive material for monitoring hydrogen cyanide. The nano sensitive material is characterized by consisting of the following components in percentage by weight: 25 to 35 percent of NiO, 30 to 40 percent of V2O5 and 32 to 42 percent of Al2O3 nano powder. The particle size of the nano sensitive material is between 25 and 40nm. A hydrogen cyanide air sensor made of the nano sensitive material has the advantages of wide linear range, high selectivity and high sensitivity, and can monitor a trace amount of hydrogen cyanide on line without being influenced by coexisting substances.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

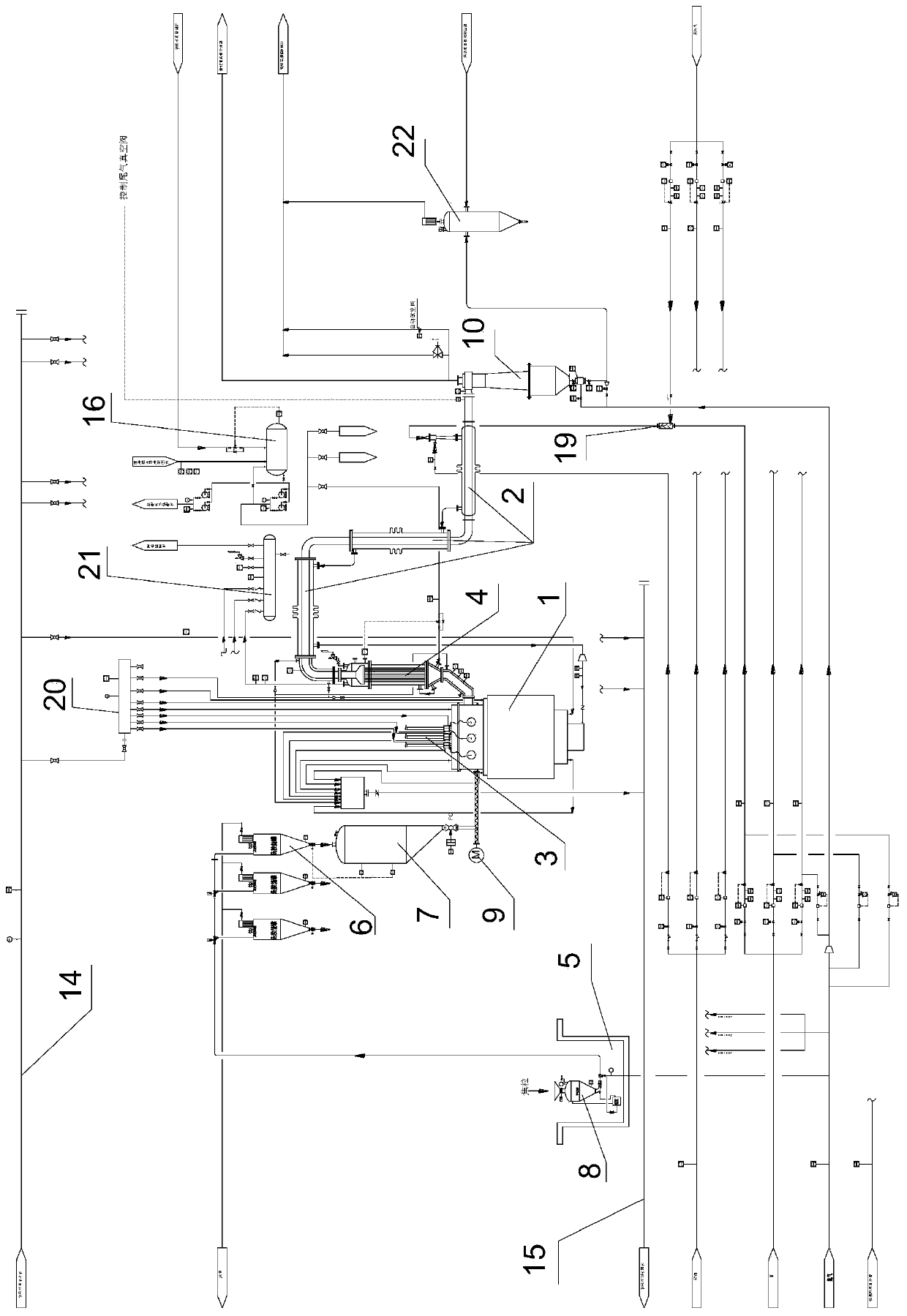

Method and device for producing sodium cyanide through mixed pyrolysis of ammonia, light oil and natural gas

ActiveCN110589852ASolve procurement difficultiesNo excessive consumption costsAlkali metal cyanidesHydrogen separationDehydrogenationSodium cyanide

The invention belongs to the technical field of energy saving and environmental protection, and particularly provides a method and device for producing sodium cyanide through mixed pyrolysis of ammonia, light oil and natural gas. After the ammonia, the light oil and the natural gas are mixed according to a certain ratio and preheated, with scorched particles as conductive carriers, under the discharge action of pyrolysis electricity, a pyrolysis reaction is carried out to generate hydrogen cyanide gas, the hydrogen cyanide gas is absorbed by alkali liquid to generate the sodium cyanide, and hydrogen-containing tail gas is recovered after being subjected to dehydrogenation and deamination. According to the method and device for producing the sodium cyanide through mixed pyrolysis of the ammonia, the light oil and the natural gas, the natural gas and the light oil are mixed, an obtained mixture and the ammonia are subjected to pyrolysis to generate the sodium cyanide, the effect is significant, a system is made to be stable, and the production cost of the sodium cyanide is greatly reduced.

Owner:营创三征(营口)精细化工有限公司

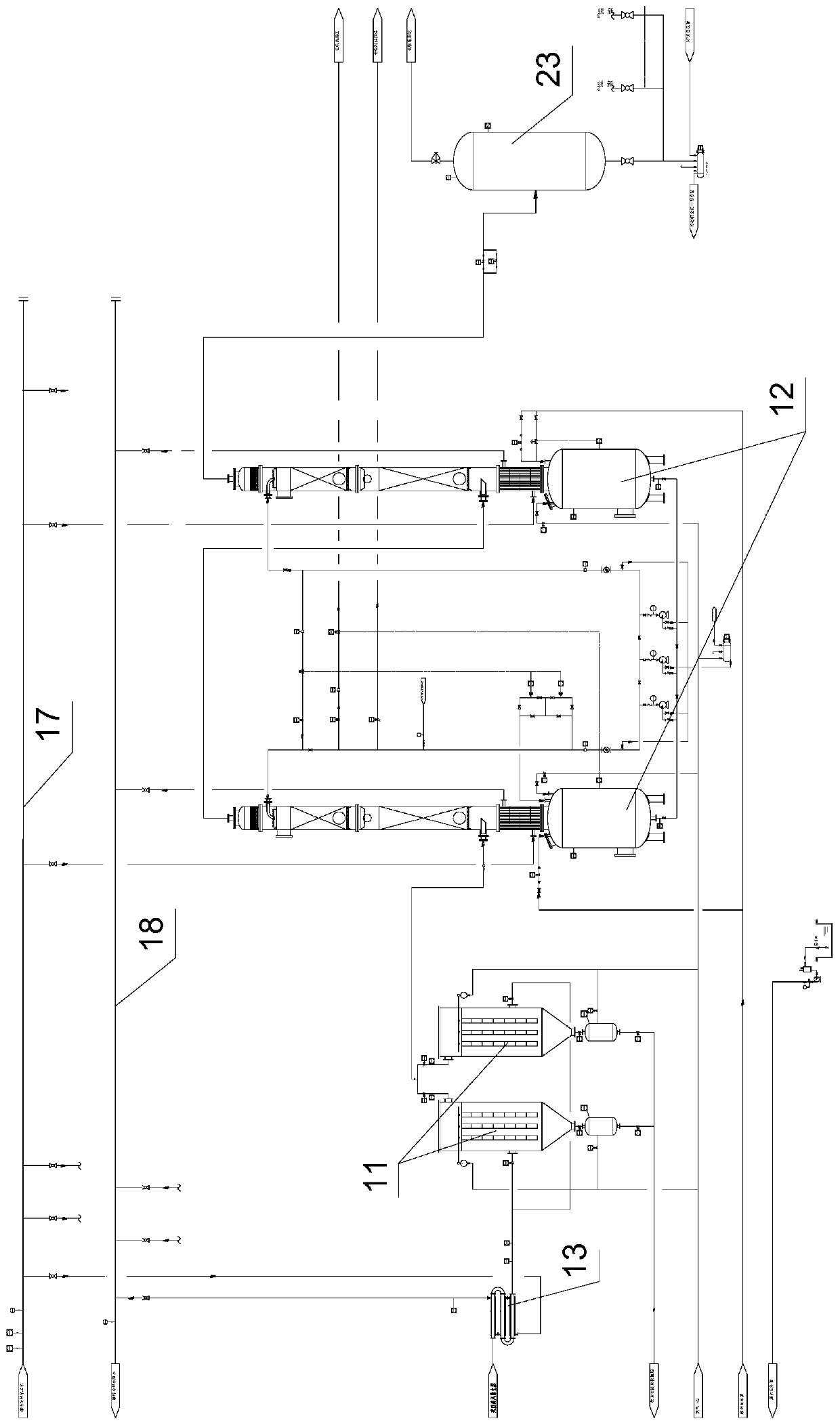

A kind of pretreatment method of vacuum potassium carbonate gas desulfurization waste liquid

ActiveCN104843951BReduce contentSimple process flowSulfur preparation/purificationWaste water treatment from gaseous effluentsLiquid wastePretreatment method

The invention relates to a pretreatment method for a desulfurization waste solution by vacuum potassium carbonate coal gas. The technical scheme is that the pretreatment method comprises the following step: collecting the desulfurization waste solution in a liquid storage tank (1) and acidifying the desulfurization waste solution in the liquid storage tank (1) by virtue of an acidifying tower (7), wherein hydrogen sulfide and hydrogen cyanide generated by acidification and acid gas from a vacuum potassium carbonate desulfurization regeneration tower enter a Claus oven together to recover sulfur, and the acidified desulfurization waste solution is incorporated into a bio-adjustment pool of a bio-treatment system of coking phenol cyanogen wastewater and the pH value is adjusted to 7.0-8.5 for bio-treatment; the acidification comprises the following steps: firstly, adding acids into the acidifying tower (7) through an acid groove (4); then spraying the desulfurization waste solution to the acidifying tower (7) through a sprayer (6) by using a circulating pump (3); introducing compressed air into the acidifying tower (7) by using an air compressor (2); and operating acidification in an intermittent mode. The pretreatment method provided by the invention treats the desulfurization waste solution from the source and has the characteristics of being short in process flow, simple in process, less in equipment, less in investment, low in operating cost and free of secondary pollutants.

Owner:WUHAN UNIV OF SCI & TECH

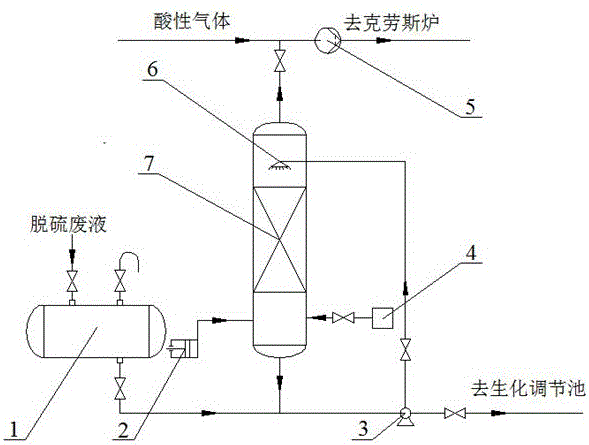

A continuous production process of high-quality cyanide solution and its production system

ActiveCN107434253BImprove operational safetyHigh selectivityAlkali metal cyanidesHydrogen cyanide preparation/purification/separationHydrogen cyanide gasAbsorption rate

The invention relates to a high-quality cyanide solution continuous production process and a production system of the high-quality cyanide solution, and belongs to the technical field of cyanide production. The production system comprises a metering pump, a mass flowmeter, a static mixer 7, a tube reactor 8, a gas-liquid separator 11, and pipeline valves and auto control instruments of the production system. A sampling valve 9 and a pressure auto control system 10 are arranged on a pipeline; a demister is installed inside the gas-liquid separator 11; a reaction tail gas discharging opening 12 having auto pressure control is arranged on the top of the gas-liquid separator; and a material discharging pipe and a circulating returning pipeline are arranged at the bottom of the gas-liquid separator. The method is simple; continuous production can be realize; the reaction time is short; the gas-liquid contact has no dead angle; the mass and heat transfer effects are good; the absorption rate of a raw material hydrogen cyanide is close to 100%; the aggregation discoloration caused by partial aggregation of the hydrogen cyanide gas is avoided particularly; the periodic equipment cleaning process in conventional arts is avoided especially; the labor intensity of workers is decreased; the labor force is saved; the product quality is notably improved as well; the cost is reduced by a certain degree; and accordingly the production process and the production system provided by the invention have good economic and social benefits.

Owner:HEBEI CHENGXIN

Hydrogen cyanide detection device and detection method in research laboratory

InactiveCN105223313BGood choiceHigh sensitivityMaterial analysisPhysical well beingHydrogen cyanide gas

Owner:ZHEJIANG GONGSHANG UNIVERSITY

A kind of reactor that can be used to prepare gas-phase hydrogen cyanide

ActiveCN104190328BStable and effective withdrawalImprove distributionChemical/physical processesHydrogen cyanide preparation/purification/separationGas phaseReaction temperature

The invention discloses a reactor used for preparing gas-phase hydrogen cyanide. The reactor used for preparing gas-phase hydrogen cyanide comprises an upper sealing head, a lower sealing head, a shell side and reaction tubes, wherein the reaction tubes are arranged in the shell side; the upper sealing head and the lower sealing head are respectively and correspondingly mounted at the upper end and the lower end of the shell side; the reactor used for preparing gas-phase hydrogen cyanide also comprises a feed gas distribution device, a temperature monitoring device, a heat-transfer medium flow guide device and a hollow flow guide cylinder; the feed gas distribution device is mounted in the top end of a main body structure of the tubular reactor; the temperature monitoring device is inserted from the top end of the main body structure of the tubular reactor; the heat-transfer medium flow guide device is mounted on the outer part of the shell side; flow guide holes are formed in an inner wall surface, being in contact with the heat-transfer medium flow guide device, of the shell side; the hollow flow guide cylinder and the reaction tubes are mounted in the shell side in a mixing manner. The reactor used for preparing gas-phase hydrogen cyanide has the beneficial effects of being capable of generating easily-separated hydrogen cyanide gas and stably and effectively dissipating reaction heat, an accurate reaction temperature monitoring system is arranged, the feed gas distribution effect is good, the reaction conversion rate is high; a catalyst is low in loss during use and long in service life.

Owner:CHINA TIANCHEN ENG +2

A kind of process method of jointly preparing liquid hydrocyanic acid and diisobutyronitrile hydrazine

ActiveCN104724726BIncrease profitReduce purification energy consumptionCyanic/isocyanic acidPreparation by hydrogen cyanide additionHydrazine compoundLiquid hydrogen

The invention provides a technological method for jointly preparing liquid hydrogen cyanide and bisisobutyronitrile hydrazine. The technological method comprises the steps that a light oil cracking hydrogen cyanide gas mixture is used as a raw material and undergoes an ammonia removal process and a cryogenic process to obtain liquid hydrogen cyanide, wherein in the ammonia removal process, the hydrogen cyanide gas mixture is absorbed with a sulfuric acid aqueous solution; in the cryogenic process, the hydrogen cyanide gas mixture is cooled to minus 10-minus 20 DEG C, after the hydrogen cyanide gas mixture is cooled, a part of the hydrogen cyanide gas becomes liquid to obtain liquid hydrogen cyanide, and the other part of the hydrogen cyanide gas is the tail gas containing hydrogen cyanide; the tail gas containing hydrogen cyanide, which undergoes cryogenic treatment, is absorbed with a ketazine aqueous solution to obtain an aqueous solution containing bisisobutyronitrile hydrazine, and the aqueous solution containing bisisobutyronitrile hydrazine undergoes cooling, crystallization and centrifugal filtration to obtain a bisisobutyronitrile hydrazine crystalline solid. By adopting the technological method, the purification efficiency and the utilization efficiency of hydrogen cyanide can be obviously improved, meanwhile, the energy consumption in the hydrogen cyanide purification process is greatly reduced and can be reduced by 90% at most, and the utilization rate of hydrogen cyanide is more than 99.9%.

Owner:枣阳市金鹿化工有限公司

Harmless method for treating cyanide-containing tailings slurry with biological oxidation solution in gold extraction process in gold industry

ActiveCN108117232BReduce operating costsEasy to handleWater contaminantsTreatment involving filtrationPtru catalystSlag

Owner:CHANGCHUN GOLD RES INST

A kind of preparation method of substituted benzyl nitrile

ActiveCN106349105BImprove reaction efficiencyHigh degree of automationPreparation by cyanide reactionSulfonic acid preparationHydrogen halideOrganic synthesis

The invention relates to the technical field of organic synthesis, in particular to a method of continuously preparing a substituted benzyl cyanide compound by using a microchannel reactor, and discloses a preparation method of substituted benzyl cyanide. The preparation method comprises the steps of preheating accurately metered raw materials, namely substituted benzyl halide and hydrogen cyanide gas separately, allowing the raw materials to enter a microchannel reactor after mixing for nucleophilic substitution reaction at 150.0-250.0 DEG C and pressure of 1.0-10.0MPa to generate substituted benzyl cyanide and hydrogen halide, keeping reaction retention time for 10-300s, then cooling for quenching reaction, and post-treating a reaction material to form substituted benzyl cyanide. The method has the advantages of low cost, high production efficiency, continuous production and clean production.

Owner:HEBEI CHENGXIN

A kind of process method of jointly preparing liquid hydrocyanic acid and hydroxyacetonitrile

ActiveCN104725269BIncrease profitReduce purification energy consumptionCarboxylic acid nitrile preparationOrganic compound preparationLiquid hydrogenHydrogen cyanide gas

The invention provides a technological method for jointly preparing liquid hydrogen cyanide and hydroxynitrile. The technological method comprises the steps that a light oil cracking hydrogen cyanide gas mixture is used as a raw material and undergoes an ammonia removal process and a cryogenic process to obtain liquid hydrogen cyanide, wherein in the ammonia removal process, the hydrogen cyanide gas mixture is absorbed with a sulfuric acid aqueous solution; in the cryogenic process, the hydrogen cyanide gas mixture is cooled to minus 10-minus 20 DEG C, after the hydrogen cyanide gas mixture is cooled, a part of the hydrogen cyanide gas becomes liquid to obtain liquid hydrogen cyanide, and the other part of the hydrogen cyanide gas is the tail gas containing hydrogen cyanide; the tail gas containing hydrogen cyanide, which undergoes cryogenic treatment, is absorbed with a formaldehyde aqueous solution containing a catalyst to prepare a hydroxynitrile aqueous solution, and the tail gas absorbed with the formaldehyde aqueous solution directly enters an incinerator to be incinerated. By adopting the technological method, the purification efficiency and the utilization efficiency of hydrogen cyanide can be obviously improved, meanwhile, the energy consumption in the hydrogen cyanide purification process is greatly reduced and can be reduced by 90% at most, and the utilization rate of hydrogen cyanide is more than 99.9%.

Owner:枣阳市金鹿化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com