Method of treating vacuum potassium carbonate desulfurization waste liquid through acidic separation-out/oxidization process

A technology for vacuum potassium carbonate and desulfurization waste liquid, which is applied in chemical instruments and methods, natural water treatment, sulfur preparation/purification, etc. The effect of low chemical concentration, short process flow and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

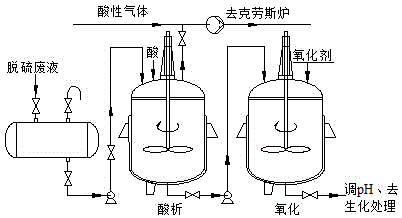

Image

Examples

Embodiment 1

[0017] Vacuum potassium carbonate desulfurization waste liquid is treated by acid precipitation-oxidation process, operated intermittently, with a processing capacity of 10L per batch. The desulfurization waste liquid is a mixture of lean liquid and condensate, and the content of sulfide and cyanide is 5512mg / L and 4638mg / L. Pump the desulfurization waste liquid in the storage tank into the reaction kettle, add 50vol% sulfuric acid for vacuum analysis, add Fenton reagent to the waste liquid after acid analysis, and the content of sulfide and cyanide in the waste liquid after reaction is 35.5mg respectively / L and 26.7mg / L, the desulfurization waste liquid from which sulfide and cyanide have been removed is discharged into coking phenol cyanide wastewater for biochemical treatment.

Embodiment 2

[0019] Vacuum potassium carbonate desulfurization waste liquid is treated by acid precipitation-oxidation process, operated intermittently, with a processing capacity of 10L per batch. The desulfurization waste liquid is a mixture of lean liquid and condensate, and the contents of sulfide and cyanide are respectively 3618mg / L and 3234mg / L. Pump the desulfurization waste liquid in the storage tank into the reaction kettle, add 40vol% nitric acid for vacuum analysis, add ozone oxidation to the waste liquid after acid analysis, the content of sulfide and cyanide in the waste liquid after reaction is 32.2mg / L respectively and 25.1mg / L, the desulfurization waste liquid from which sulfide and cyanide have been removed is discharged into coking phenol cyanide wastewater for biochemical treatment.

Embodiment 3

[0021] Vacuum potassium carbonate desulfurization waste liquid is treated by acid precipitation-oxidation process, operated intermittently, with a processing capacity of 10L per batch. The desulfurization waste liquid is a mixture of lean liquid and condensate, and the content of sulfide and cyanide is 2546mg / L and 2183mg / L. Pump the desulfurization waste liquid in the storage tank into the reaction kettle, add 45vol% sulfuric acid for vacuum analysis, add ozone oxidation to the waste liquid after acid analysis, the content of sulfide and cyanide in the waste liquid after reaction is 30.2mg / L respectively and 23.3mg / L, the desulfurization waste liquid from which sulfide and cyanide have been removed is discharged into coking phenol cyanide wastewater for biochemical treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com