A kind of pretreatment method of vacuum potassium carbonate gas desulfurization waste liquid

A technology for vacuum potassium carbonate and desulfurization waste liquid, which is applied in gaseous discharge wastewater treatment, sulfur preparation/purification, chemical instruments and methods, etc. Furnace equipment and other problems, to achieve the effect of less equipment, simple process and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

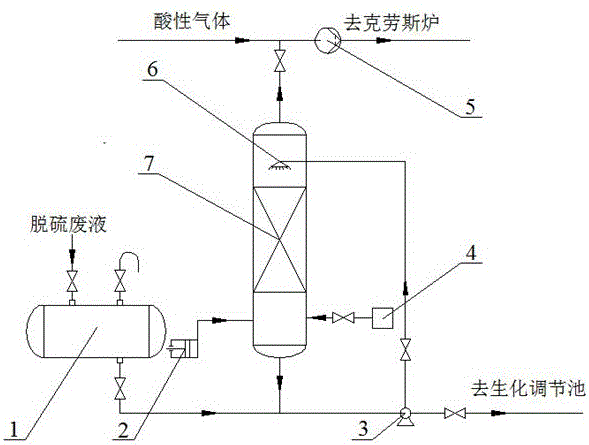

[0018] A pretreatment method for vacuum potassium carbonate gas desulfurization waste liquid. The pretreatment method described is as figure 1 As shown, the desulfurization waste liquid is collected in the liquid storage tank (1), and then the desulfurization waste liquid in the liquid storage tank (1) is carried out acid analysis through the acid analysis tower (7), and the hydrogen sulfide gas and cyanide produced by the acid analysis The hydrogenated gas and the acid gas from the vacuum potassium carbonate desulfurization regeneration tower enter the Claus furnace to recover sulfur; the acid-analyzed desulfurization waste liquid is incorporated into the biochemical adjustment tank of the coking phenol cyanide wastewater biochemical treatment system, and the pH value is adjusted to 7.0~8.5, then carry out biochemical treatment.

[0019] The acid analysis is: first add acid to the acid analysis tower (7) through the acid tank (4), then utilize the circulation pump (3) to spr...

Embodiment 2

[0025] A pretreatment method for vacuum potassium carbonate gas desulfurization waste liquid. Except following technical parameter, all the other are with embodiment 1:

[0026] In the desulfurization waste liquid: the concentration of cyanide is 1800-4500 mg / L, and the concentration of sulfide is 250-5500 mg / L.

[0027] The acid is sulfuric acid with a concentration of 40-50vol%.

[0028] The concentration of cyanide in the desulfurization waste liquid treated in this embodiment is 15-27 mg / L, and the concentration of sulfide is 20-35 mg / L.

Embodiment 3

[0030] A pretreatment method for vacuum potassium carbonate gas desulfurization waste liquid. Except following technical parameter, all the other are with embodiment 1:

[0031] In the desulfurization waste liquid: the concentration of cyanide is 150-1800 mg / L, and the concentration of sulfide is 800-2500 mg / L.

[0032] The acid is nitric acid with a concentration of 30-35vol%.

[0033] The concentration of cyanide in the desulfurization waste liquid treated in this embodiment is 11-18 mg / L, and the concentration of sulfide is 15-26 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com