Reactor used for preparing gas-phase hydrogen cyanide

A reactor, hydrogen cyanide technology, applied in the preparation/purification/separation of hydrogen cyanide, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of not mentioning the details of the reaction process, and achieve the service life Long time, high reaction conversion rate, good distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

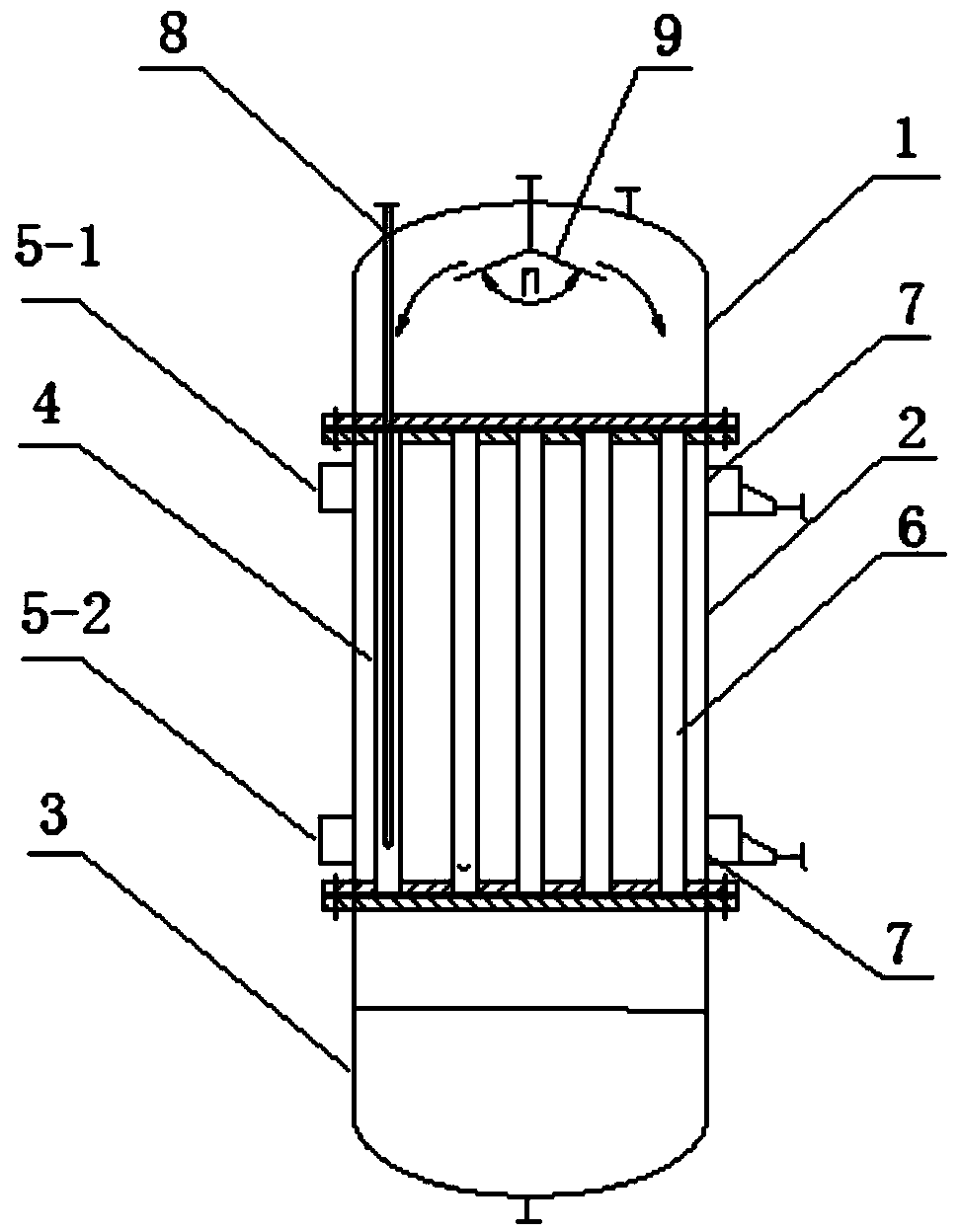

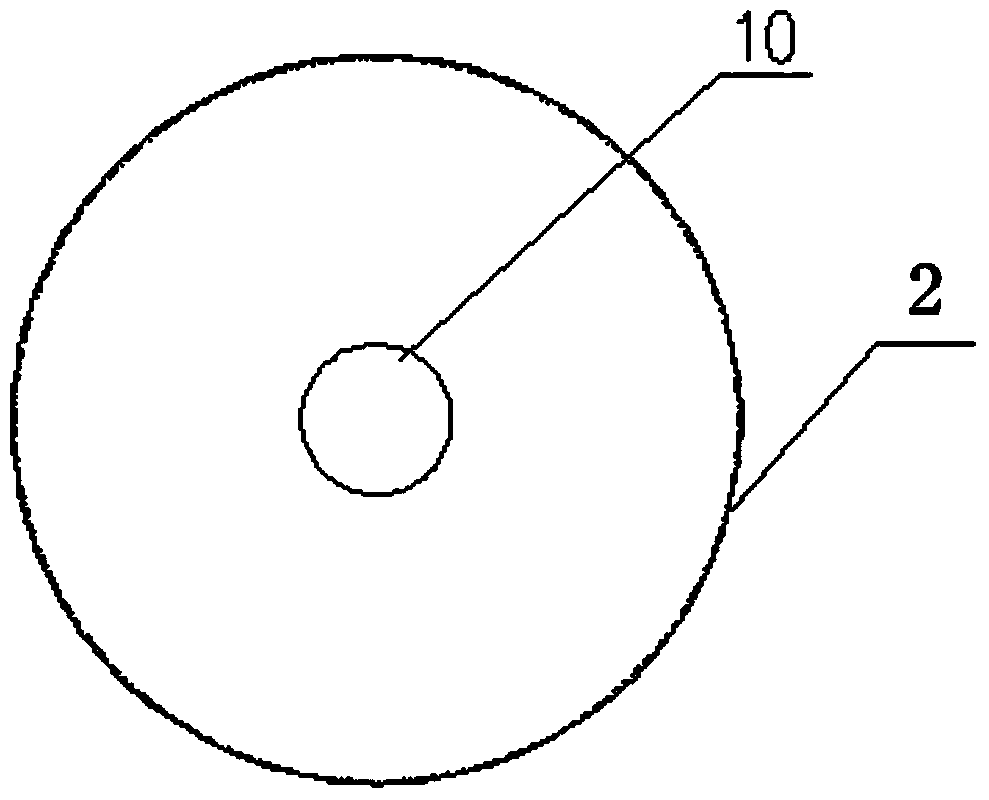

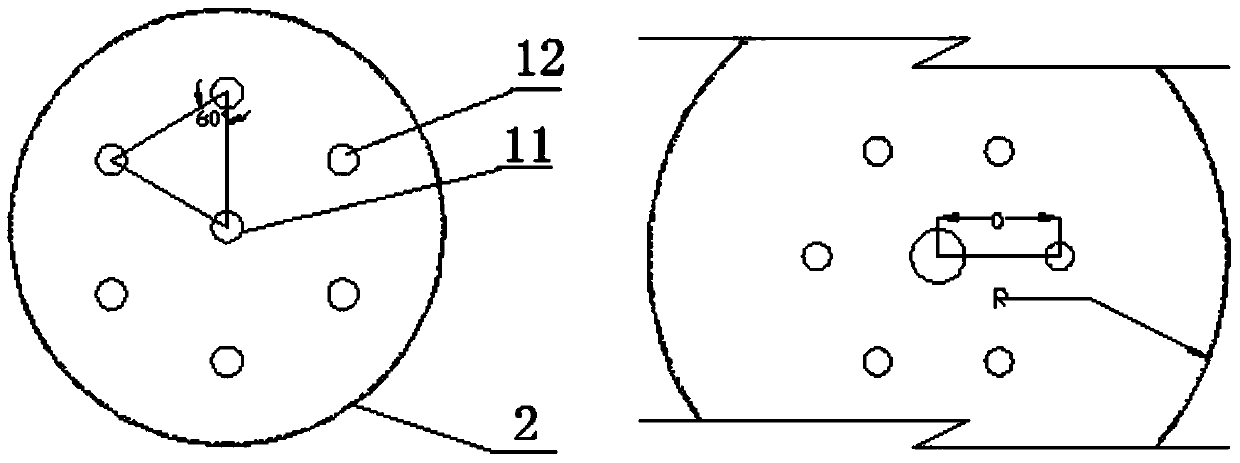

[0050] The reactor shell side 2 has a diameter of 2.5 meters, and contains 2781 reaction tubes 6 with an outer diameter of 35 mm, a wall thickness of 2 mm, and a tube spacing of 44 mm. Each reaction tube 6 is 3 meters long, and 6 casing-type temperature For the temperature measurement point of the detection device 8, three thermocouples are arranged in each group of detection devices. Set a raw material gas distribution device 9 with an opening of 120° at a distance from the upper head of the reactor, and open 4 small holes of 3 mm. The projected area of the concentric circle of the raw material gas distribution device 9 on the outer wall of the reactor shell side 2 is about 0.4D The catalyst is placed in the reaction column tube 6, and the air feed rate can be kept at 18000-20000Nm 3 / h, methanol, ammonia and air enter the reactor when the preheating temperature is above 200°C.

[0051] The diversion device adopts the following settings. The upper diversion device 5-1 is p...

Embodiment 3

[0054] The reactor shell side 2 has a diameter of 2.5 meters, and contains 2751 reaction tubes 6 with an outer diameter of 35 mm, a wall thickness of 2 mm, and a tube spacing of 44 mm. The length of each reaction tube 6 is 3 meters, and 6 casing-type temperature For the temperature measurement point of the detection device 8, three thermocouples are arranged in each group of detection devices. Set a raw material gas distribution device 9 with an opening of 120° at a distance from the upper head of the reactor, and open 4 small holes of 3 mm. The projected area of the concentric circle of the raw material gas distribution device 9 on the outer wall of the reactor shell side 2 is about 0.4D A catalyst is placed in the reaction tube 6, and the air feed rate can be kept at 500-1000 Nm3 / h. Methanol, ammonia and air enter the reactor when the preheating temperature is above 200°C.

[0055] The diversion device adopts the following settings. The upper diversion device 5-1 is provid...

Embodiment 4

[0058] The reactor shell 2 has a diameter of 0.5 meters, and contains 82 reaction tubes 6 with an outer diameter of 38 mm, a wall thickness of 3 mm, and a tube spacing of 48 mm. The length of each reaction tube 6 is 1.3 meters, and two casing-type temperature For the temperature measurement points of the detection device 8, 4 thermocouples are arranged in each group of detection devices. A raw material gas distribution device 9 with an opening of 100° is set at a distance from the upper head of the reactor, and four small holes of 3mm are opened on the top. The projected area of the concentric circle of the raw material gas distribution device 9 on the outer wall of the reactor shell side 2 is about 0.3D Catalysts are placed in the reaction tube 6, and the intake of raw materials can be kept at 180-200Nm 3 / h.

[0059] A mixture containing potassium nitrate and sodium nitrite is used as the heat transfer medium in the flow guiding device. On this basis, the central positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com