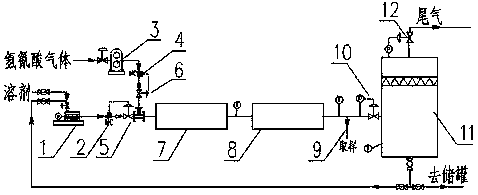

High-quality cyanide solution continuous production process and production system of high-quality cyanide solution

A production process and production system technology, which is applied in the continuous production process of high-quality cyanide solution and its production system field, can solve the problem that it is difficult to meet the requirements of high-end users that the product quality is continuous and stable, and the mass transfer of hydrogen cyanide gas is insufficient. , incomplete reaction of hydrocyanic acid, etc., to achieve the effect of improving product quality, reducing labor intensity of workers and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Hydrocyanic acid gas and 32% sodium hydroxide produced by the cracking method of light oil without purification are input into the static mixer at the same time according to the molar ratio of 1:1.01, and then enter the pipeline reactor for a reaction residence time of 20s. The temperature is 40~45℃ and the reaction pressure is 0.01~0.05MPa. Sampling and detection of sodium cyanide content at the end of the reaction is 32.11%, and free OH- content is 0.104%, reaching the end of the reaction;

[0039] The feed liquid after the above reaction is completed is introduced into the gas-liquid separator for separation, and the operating pressure of the gas-liquid separator is controlled to be -0.05~-0.06MPa. The reaction tail gas is drawn from the top of the gas-liquid separator and absorbed and treated with 20% sodium hydroxide. The colorless and transparent finished sodium cyanide solution obtained at the bottom of the gas-liquid separator is pumped into the finished product ...

Embodiment 2

[0041] The hydrocyanic acid gas and 42% potassium hydroxide produced by the unpurified light oil cracking method are input into the static mixer at the same time according to the molar ratio of 1:1.005, and then enter the pipeline reactor for a reaction residence time of 30s. The temperature is 30~35°C and the reaction pressure is 0.05~0.08MPa. The potassium cyanide content at the end of the reaction is 40.41% and the free OH- content is 0.072% by sampling, reaching the end of the reaction;

[0042] The feed liquid after the above reaction is completed is introduced into the gas-liquid separator for separation, and the operating pressure of the gas-liquid separator is controlled to be -0.075~-0.085MPa. The reaction tail gas is drawn from the top of the gas-liquid separator and absorbed and treated with 30% potassium hydroxide. The colorless and transparent finished potassium cyanide solution obtained at the bottom of the gas-liquid separator is pumped into the finished product ...

Embodiment 3

[0044] Hydrocyanic acid gas and 32% sodium hydroxide produced by cracking light oil without purification and 32% sodium hydroxide are input into the static mixer at the same time according to the molar ratio of 1:1.02, and then enter the pipeline reactor for a reaction residence time of 10s. The temperature is 50~55℃ and the reaction pressure is 0.1~0.15MPa. Sampling and detection of sodium cyanide content at the end of the reaction is 32.06%, and free OH- content is 0.147%, reaching the end of the reaction;

[0045] The feed liquid after the above reaction is completed is introduced into the gas-liquid separator for separation, and the operating pressure of the gas-liquid separator is controlled to be -0.02~-0.04MPa. The reaction tail gas is drawn from the top of the gas-liquid separator and absorbed and treated with 20% sodium hydroxide. The colorless and transparent finished sodium cyanide solution obtained at the bottom of the gas-liquid separator is pumped into the finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com