Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about "Alkali metal cyanides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly clean production method for high purity sodium cyanide

InactiveCN103073027ARealize recyclingAchieving a circular economy modelAlkali metal cyanidesPhosphoric acidSodium cyanide

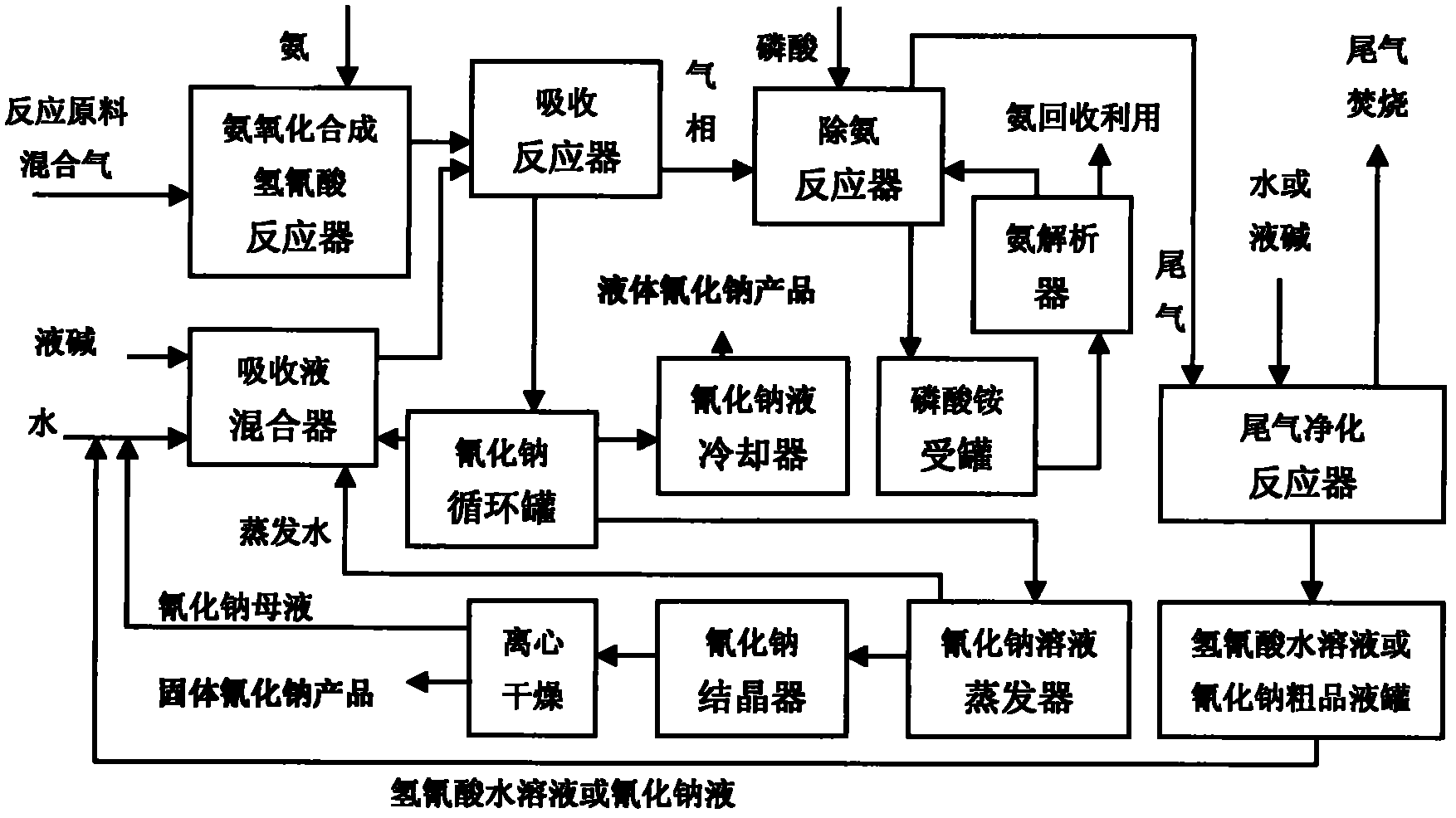

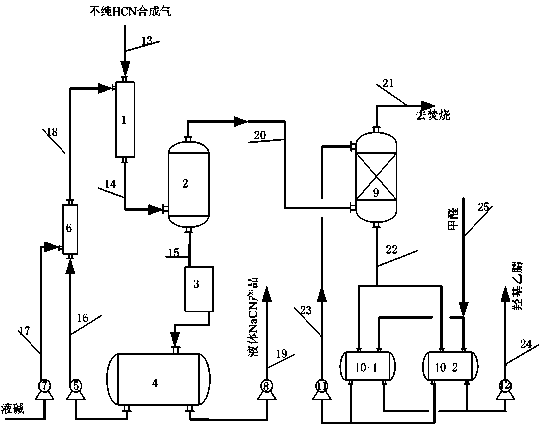

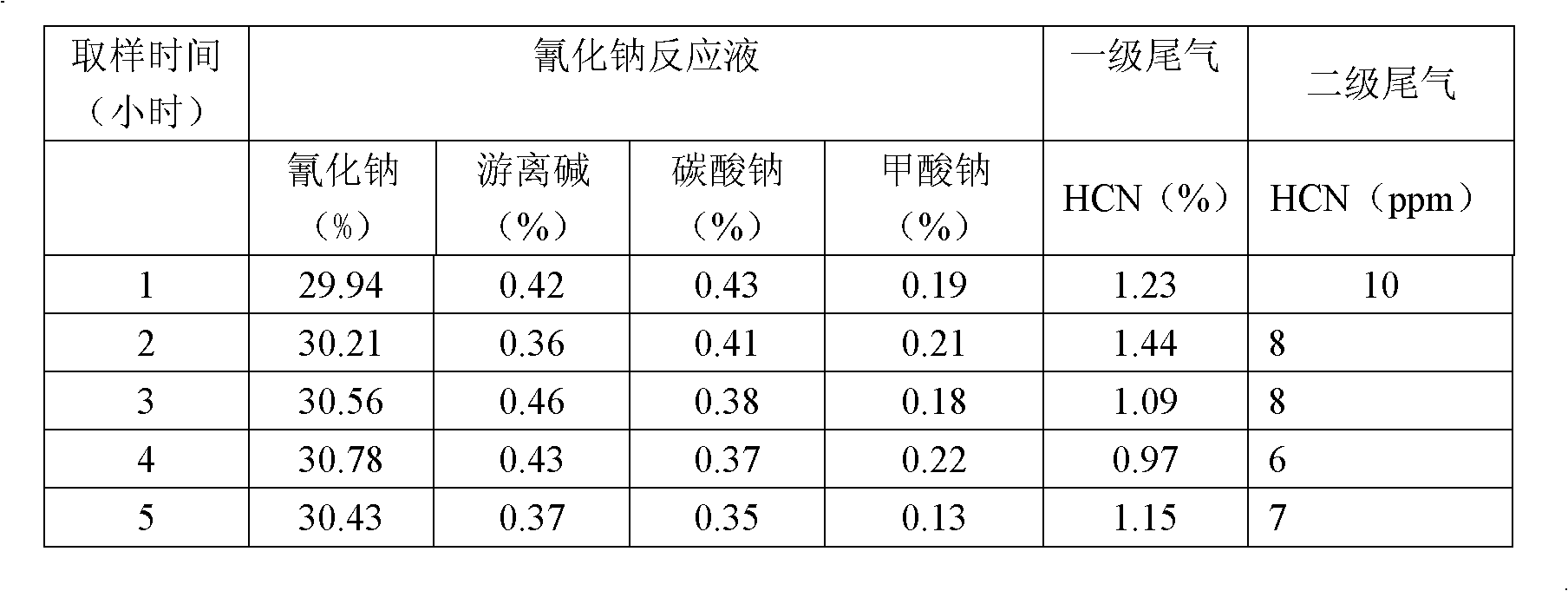

The invention provides an environment-friendly clean production method for high purity sodium cyanide. The production method comprises the following steps that: without removal of ammonia, hydrocyanic acid synthetic gas synthesized through ammoxidation is directly absorbed by and reacts with an aqueous sodium hydroxide solution to obtain a high purity aqueous sodium cyanide solution, and free ammonia remains in tail gas; the aqueous sodium cyanide solution is cooled and blended to obtain a high purity liquid sodium cyanide product, the high purity liquid sodium cyanide product undergoes condensation, crystallization and centrifugation to obtain a high purity solid sodium cyanide product, and mother liquor is indiscriminately used in liquid alkali absorption liquor; phosphoric acid or ammonium biphosphate is employed as a carrier for repeated cyclic indiscriminate application of ammonia so as to recover ammonia in the tail gas; and after recovery of ammonia, the tail gas is purified and absorbed with water or the aqueous sodium hydroxide solution, a small amount of the aqueous hydrocyanic acid solution or a crude aqueous sodium cyanide solution product is obtained while the tail gas is purified, the purified tail gas is burned with a tail gas boiler, and the aqueous hydrocyanic acid solution or the crude aqueous sodium cyanide solution product is indiscriminately used in the liquid alkali absorption liquor.

Owner:龙智

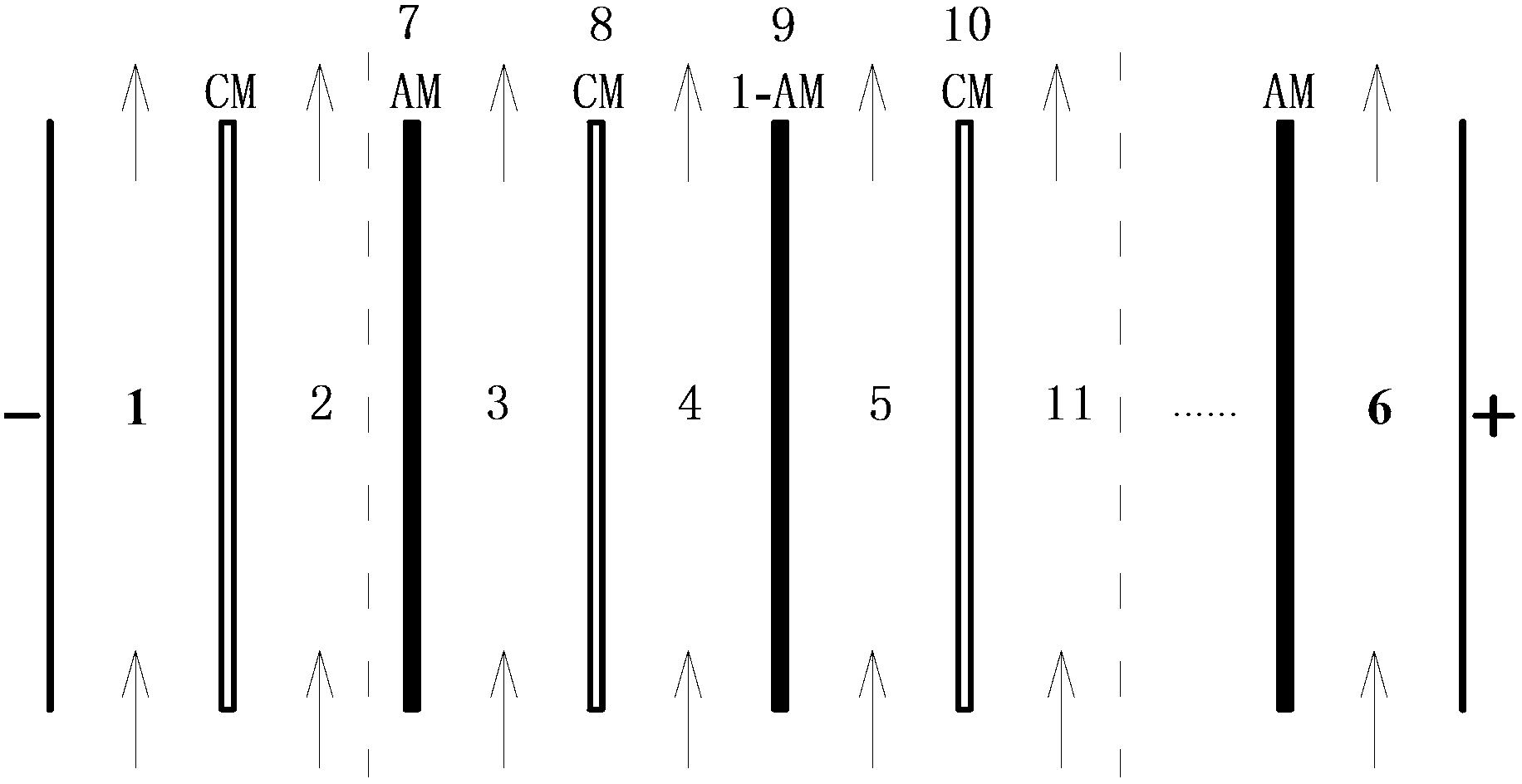

Method for recovering cyanide and ammonia nitrogen in acrylic nitrile waste water using membrane absorption method

InactiveCN101381127AIncrease concentrationLow costAlkali metal cyanidesWater/sewage treatment bu osmosis/dialysisSuspended particlesWater use

The invention relates to a method for recovering high-concentration cyanide and ammonia nitrogen in acrylonitrile waste water by utilization of the membrane absorption method. The method adopts the double-circulation process to adjust the pH value of the waste water to between 11 and 12 at first; the waste water enters into a tube pass of a hydrophobic hollow-fiber membrane after undergoing sand filtration and micro-filtration (MF) in turn to remove suspended particles; volatile NH3 gas in the waste water generates neutralization reaction with a H2SO4 solution on a boundary surface of the hollow-fiber membrane and an absorption liquid, and nonvolatile (NH4)2SO4 is generated and recovered; due to the hydrophobicity of the membrane, water and other nonvolatile substances are still kept in the waste water; and after the high-concentration ammonia nitrogen is recovered by the membrane absorption method, the pH value of the waste water is adjusted to between 5 and 6, an NaOH solution is used as the absorption liquid of HCN, and then the membrane absorption process is repeated. The membrane absorption method is simple and convenient to operate, has low energy consumption, can recover useful substances, and changes the high-cost treatment condition of the acrylonitrile waste water in the prior art to a certain degree.

Owner:TSINGHUA UNIV

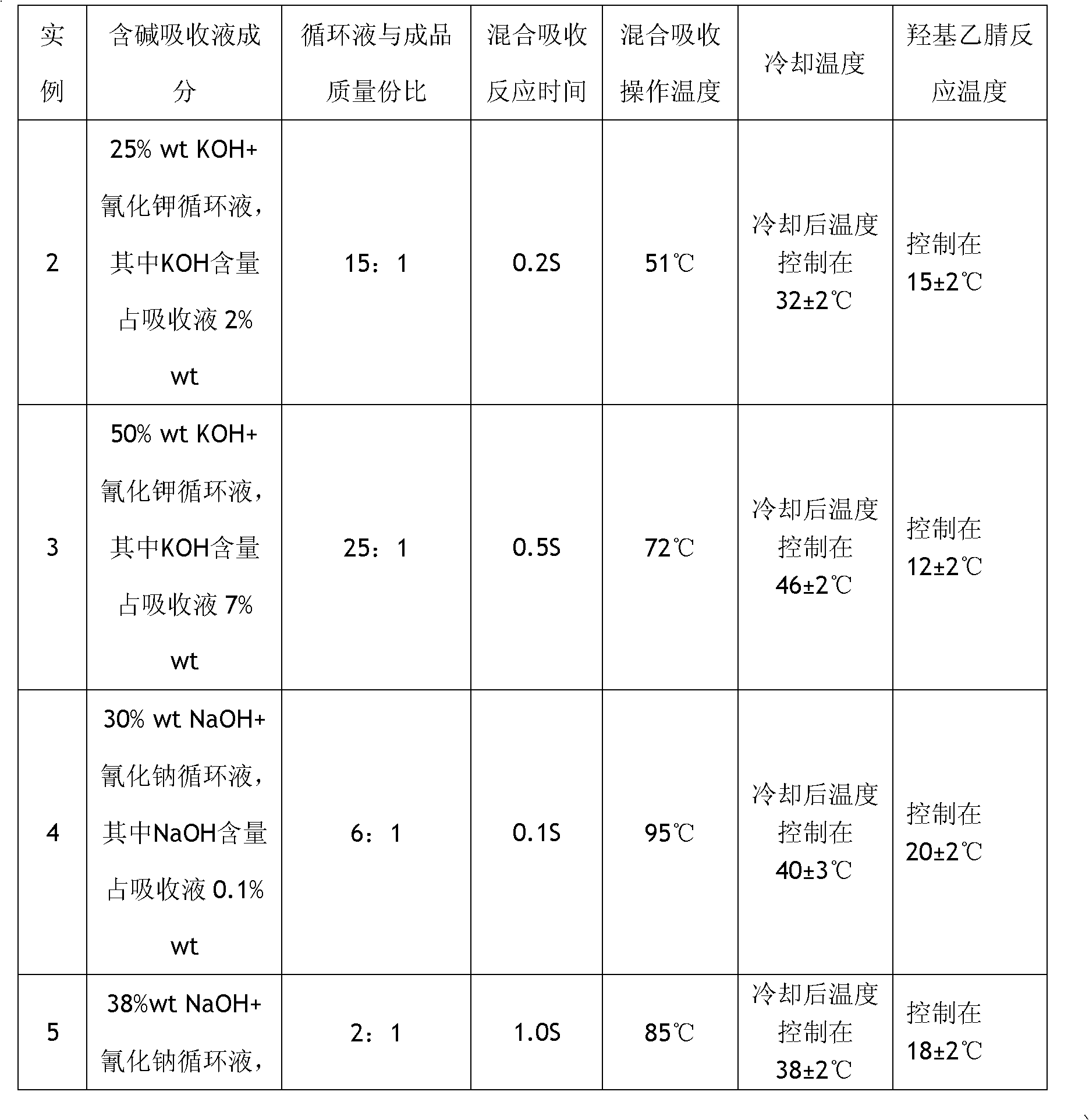

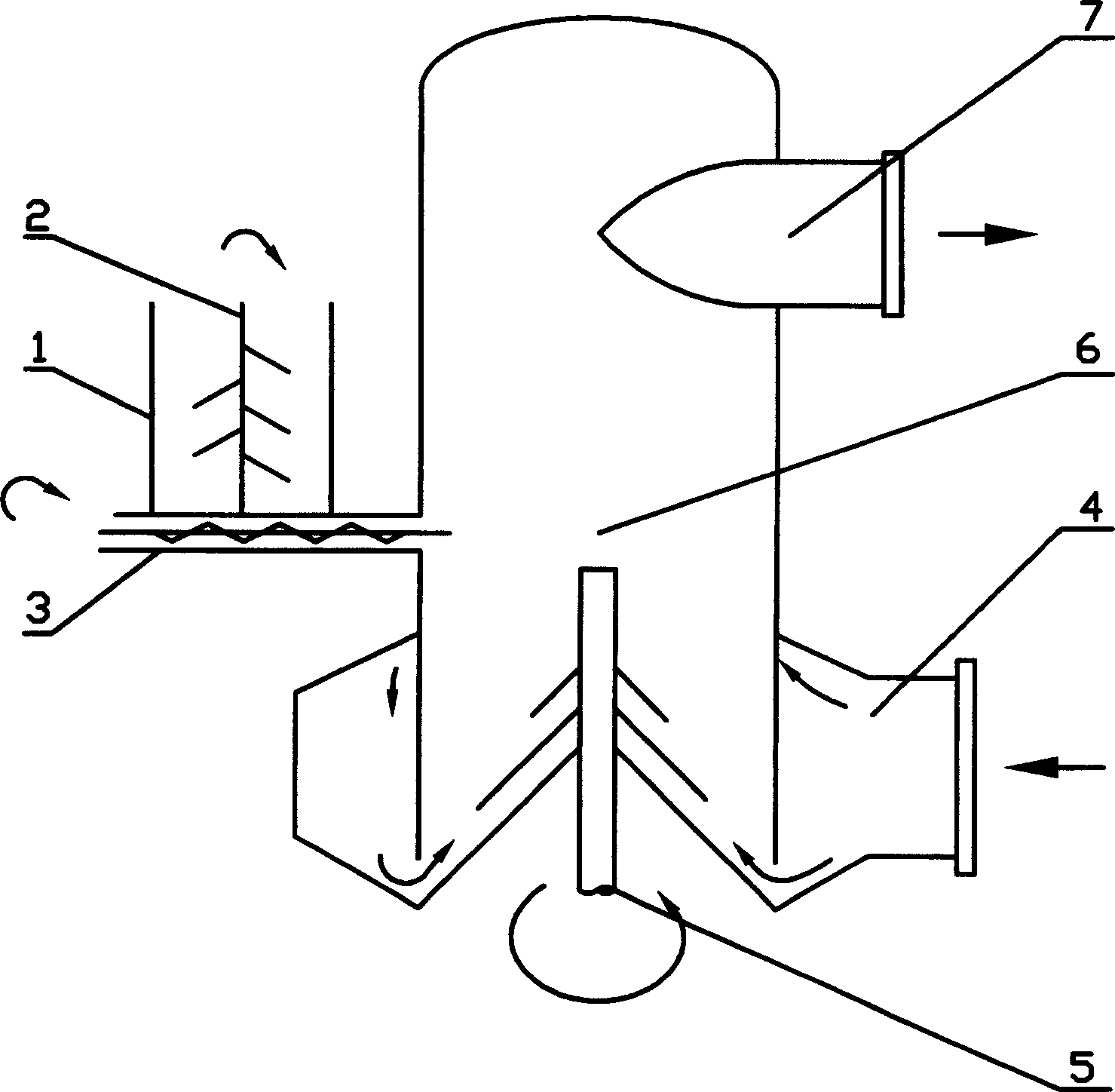

Preparation method for preparing alkali metal or alkali earth metal cyanide with high purity and high yield

ActiveCN102502708AHigh purityGood colorAlkali metal cyanidesChemical industryCyanideAlkaline earth metal

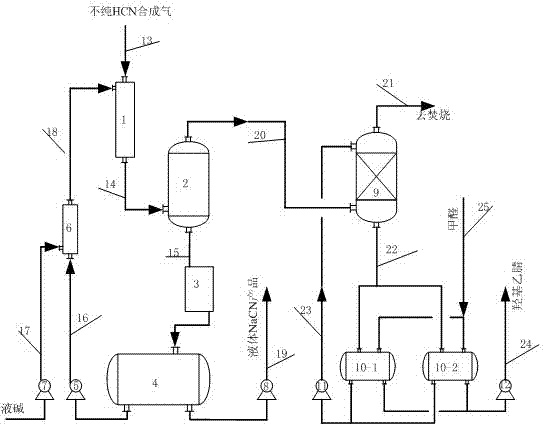

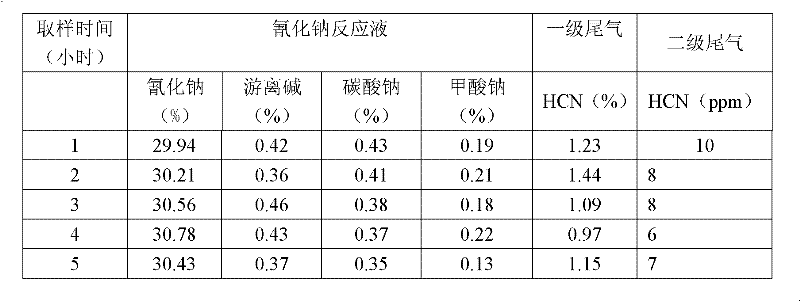

The invention relates to a preparation method for preparing alkali metal or alkali earth metal cyanide with high purity and high yield, which comprises the following steps of: mixing, absorbing and reacting HCN (hydrogen cyanide) synthetic gas synthesized by an Andrussow method with absorption liquid containing alkali and then carrying out gas-liquid separation and cooling to prepare the alkali metal or the alkali earth metal cyanide. The absorption and reaction contact time of the HCN synthetic gas with the absorption liquid containing the alkali can be controlled within 0.1-2.0 seconds; the concentration of free alkali in the absorption liquid containing the alkali can be controlled within 0.1-20 percent by weight; and the mass ratio of circulation fluid of the cyanide to product liquid is 2-40:1. The invention has the beneficial effects that the alkali metal or the alkali earth metal cyanide prepared by the preparation method is high in purity; the total content of carbonate can be controlled within below 0.45 percent by weight, the content of formate can be controlled within below 0.15 percent by weight, and the content of ocyhydrate (free alkali) can be controlled within 0.1-2.0 percent by weight; and the alkali metal or the alkali earth metal cyanide is good in color and is colorless transparent liquid.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

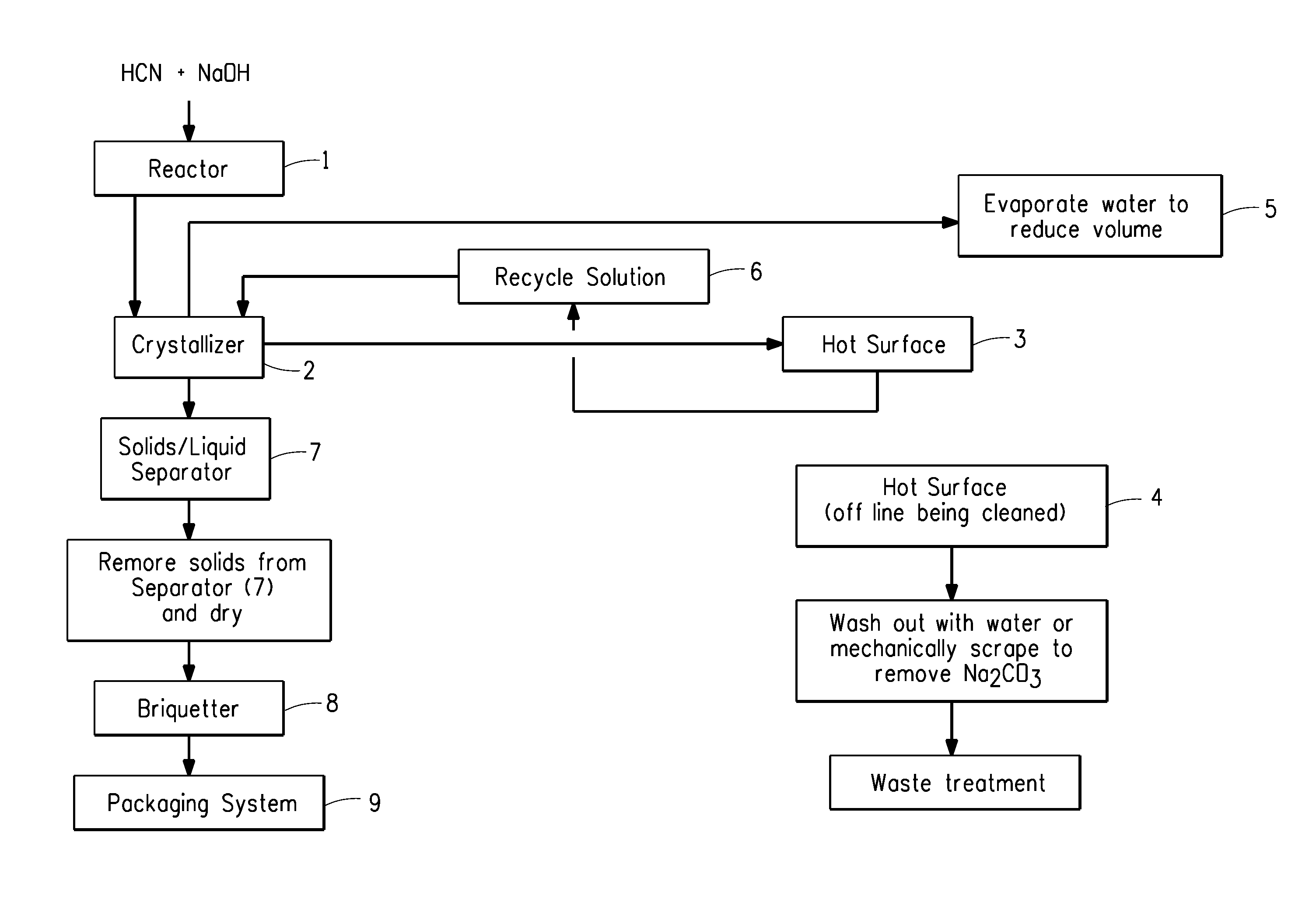

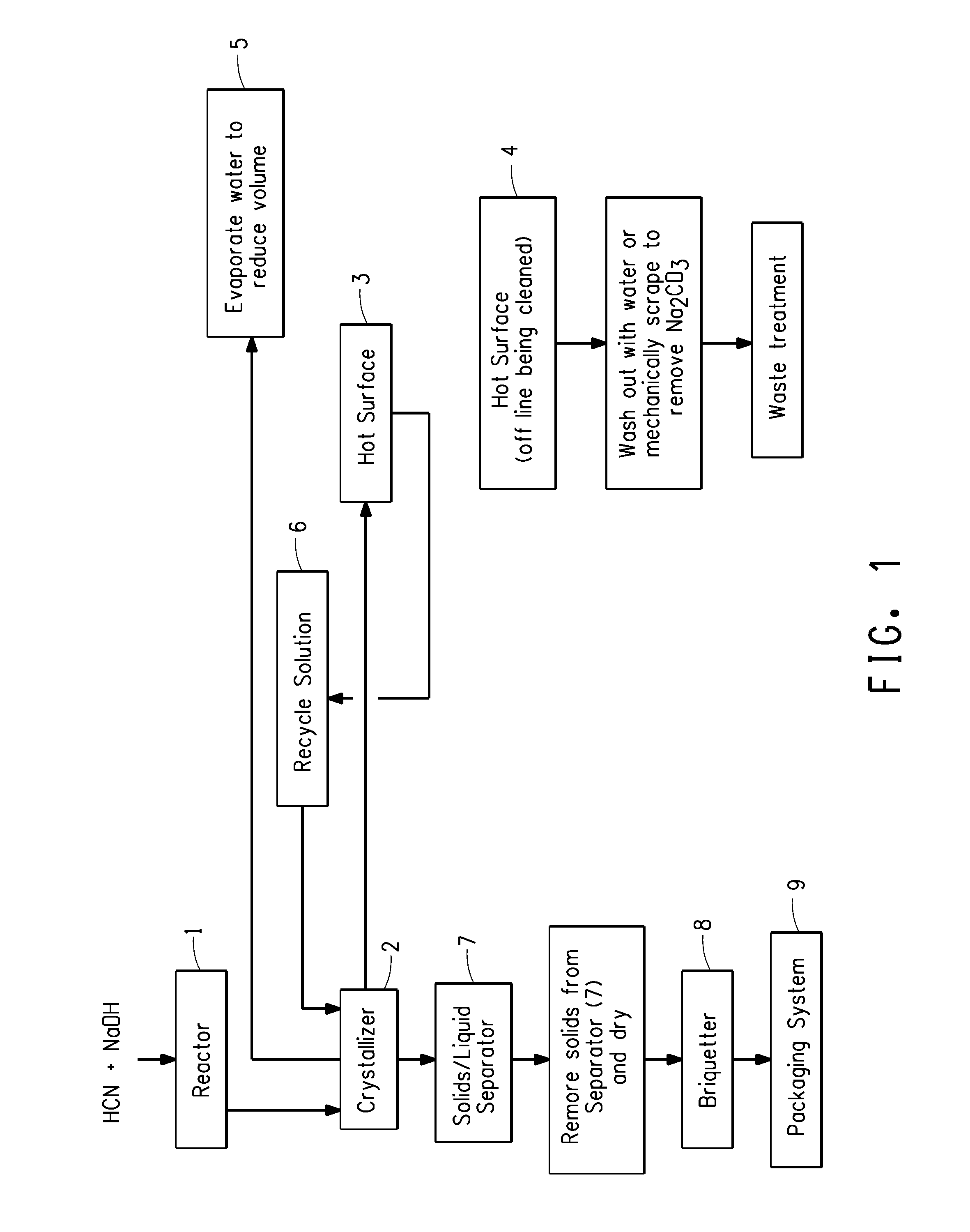

Sodium cyanide process

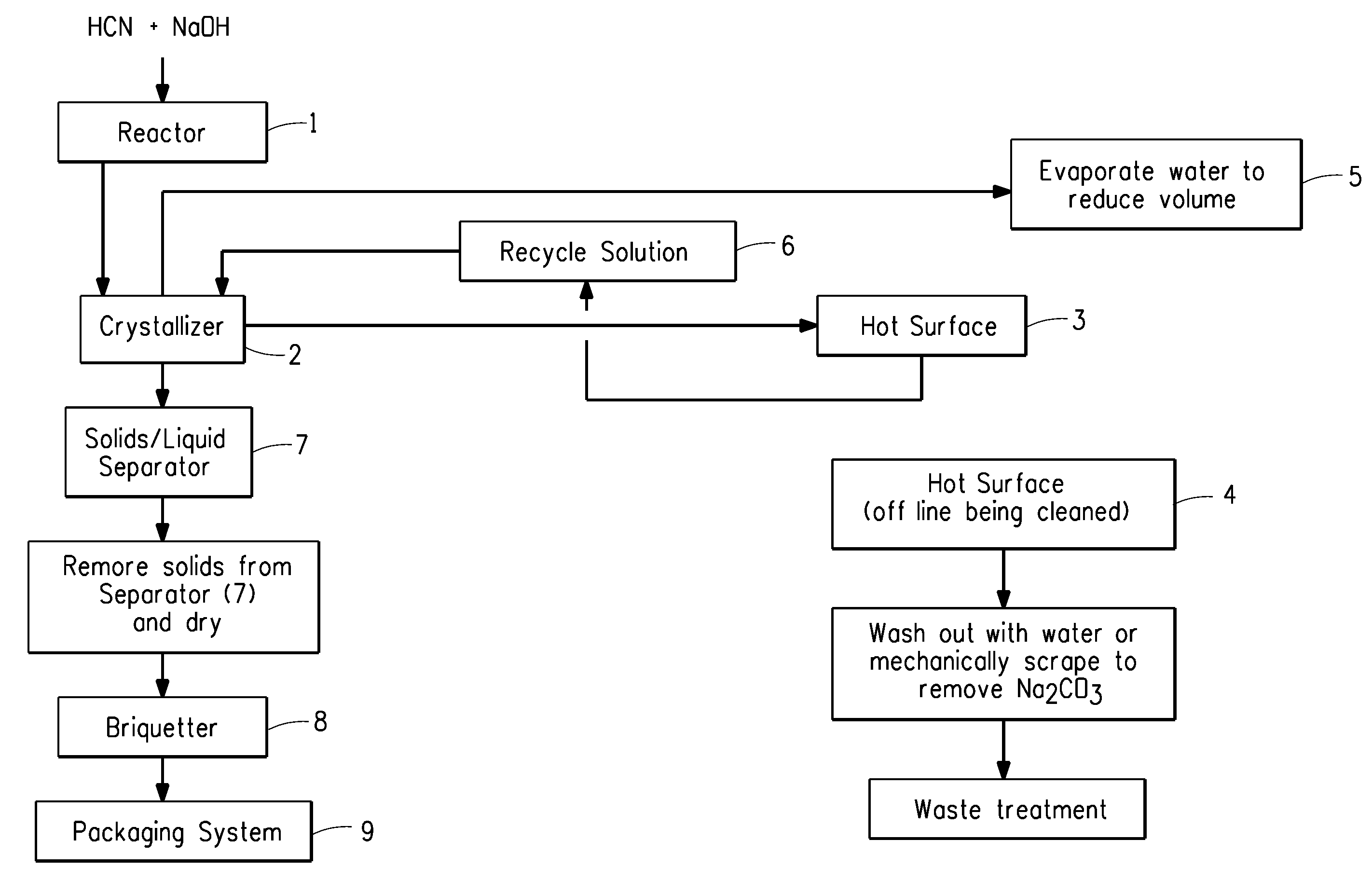

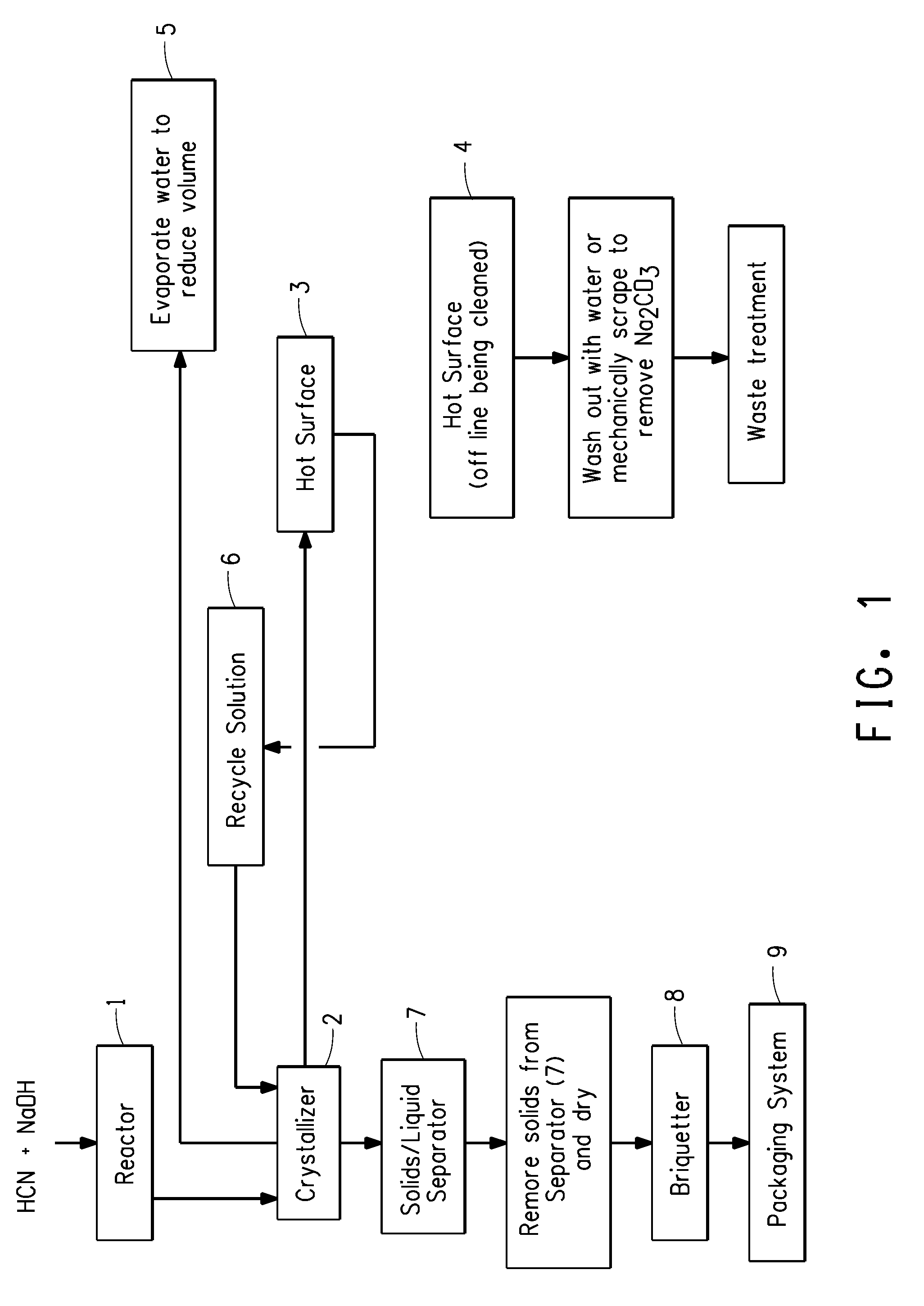

A process for the production of sodium cyanide crystals comprising;(a) contacting impure hydrogen cyanide and sodium hydroxide in a reactor with mixing for a maximum contact time of about 5 seconds;(b) feeding the resulting mixture to a continuous evaporative crystallizer to produce a slurry of sodium cyanide crystals;(c) passing the slurry of sodium cyanide crystals from the crystallizer over a hot surface to precipitate onto the surface and remove sodium carbonate, and passing said slurry back to the crystallizer; and(d) separating the sodium cyanide crystals from the slurry.

Owner:THE CHEMOURS CO FC LLC

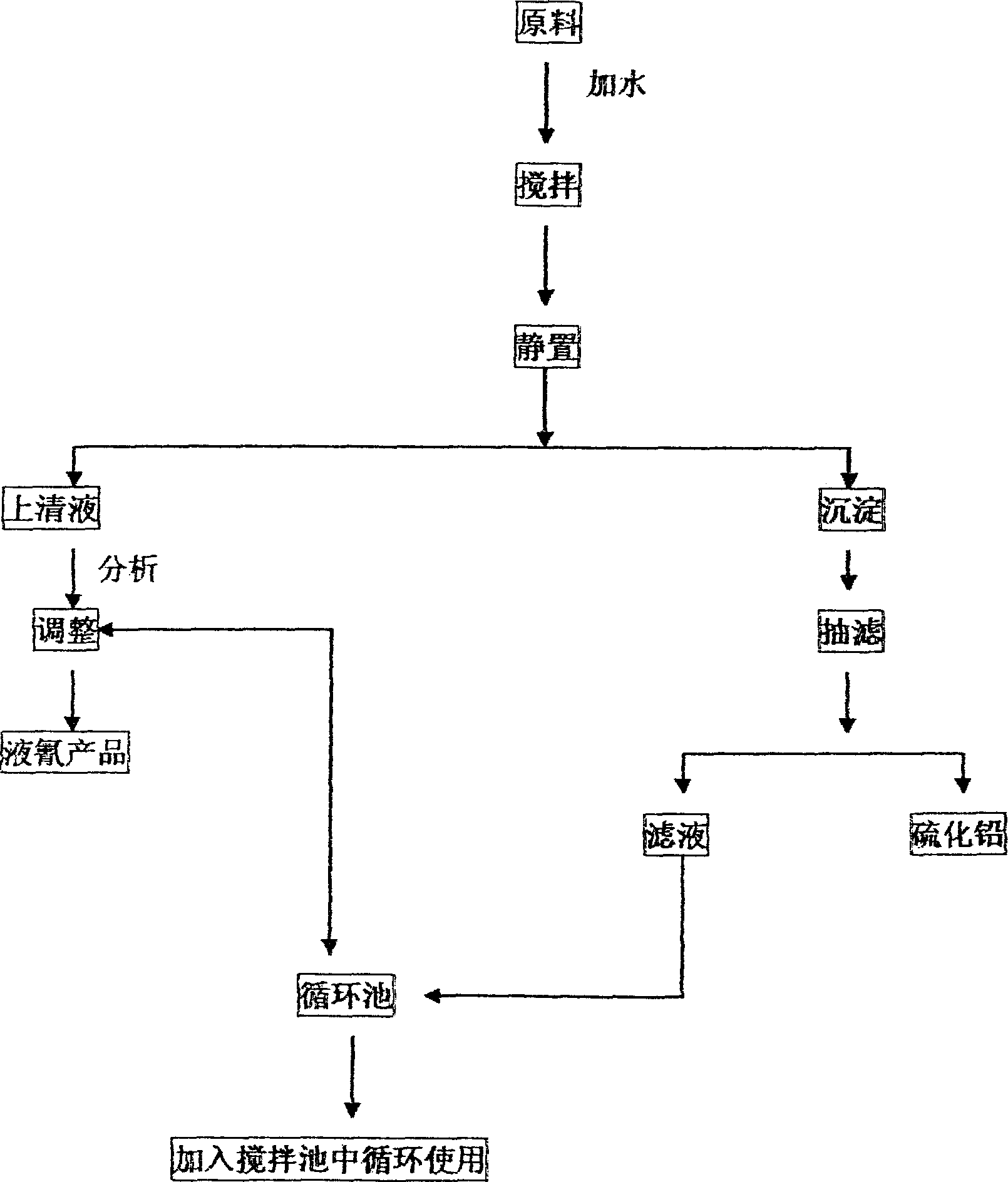

Process of preparing sodium cyanide and lead sulfide for gold ore sorting from waste sodium cyaide desulfurizing dreg

InactiveCN1673082AComplete resourceThe production process is simple and effectiveAlkali metal cyanidesLead sulfidesSodium cyanideLead sulfide

The waste sodium cyanide desulfurizing dreg containing various components with different physical and chemical properties, especially different dissolubility in water, is separated and extracted with water as medium to obtain liquid cyanide product with dissolved sodium cyanide and waste dreg, which is dried as the lead ore product. The said production process is simple and effective, and has no waste produced, no pollution, low cost, high yield and complete utilization of resource.

Owner:安庆盖娅环保科技有限公司

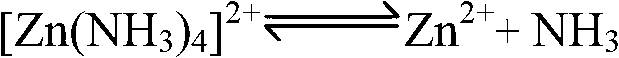

Recovery processing method of cyanide barren solution

InactiveCN102701339AHigh purityAvoid enteringAlkali metal cyanidesDispersed particle separationCyanide ionSodium cyanide

The invention relates to a recovery processing method of cyanide barren solution, which comprises the following steps: at first, ammonia water is added in the cyanide barren solution, the mass ratio of the ammonia water and the cyanide barren solution is 0.5% to 2%; then the cyanide barren solution in which the ammonia water is added is pumped into an electrodialysis device, CN<-> in the cyanide barren solution passes through an anion-exchange membrane and enters a sodium cyanide recovery chamber under the action of a direct-current electric filed, metal cations such as Cu<2+> and Zn<2+> pass through a cation-exchange membrane and enter a metal ion recovery chamber, CN<-> is continuously released from a cyano complex in the cyanide barren solution along with the continuous decrease of CN<-> and heavy metal cations such as Cu<2+> and Zn<2+>, metal ions such as Cu<2+> and Zn<2+> and NH3 are continuously released from a copper-zinc metal ammino complex, so that cyanide ion CN<-> in the cyano complex is promoted to be released, and sodium cyanide and metal ions are recovered. The method can reduce the treatment cost of the cyanide barren solution, remarkably improves the recovery rate and the purity of cyanide ions in the cyanide barren solution, and removes the copper, zinc and other heavy metal ions in the cyanide barren solution.

Owner:OCEAN UNIV OF CHINA

Method for producing liquid sodium cyanide by tailed-oil thermal-pyrolysis

ActiveCN101074102ALow priceRaise the outlet temperatureAlkali metal cyanidesEnergy inputWaste oilOxygen

A method for producing liquefied sodium cyanide by waste oil thermal cracking is carried out by vaporizing while mixing waste oil with liquid ammonia in proportion of 1:2-1:5, putting them into cracking reactor, taking petrol coke as heat carrier, thermal cracking at 1300-1500 degree to obtain pyrolysis gas containing oxygen-hydrogen acid, recovering pyrolysis gas waste heat by waste hot boiler, removing coke, cooling, absorbing continuously by liquid sodium hydrate to obtain liquid sodium cyanide product, firing by waste gas combustion system, recovering waste heat and absorbing tail gas from liquid sodium cyanide. It's safe, convenient, cheap and controllable and has no environmental pollution.

Owner:兰州寰球工程有限公司

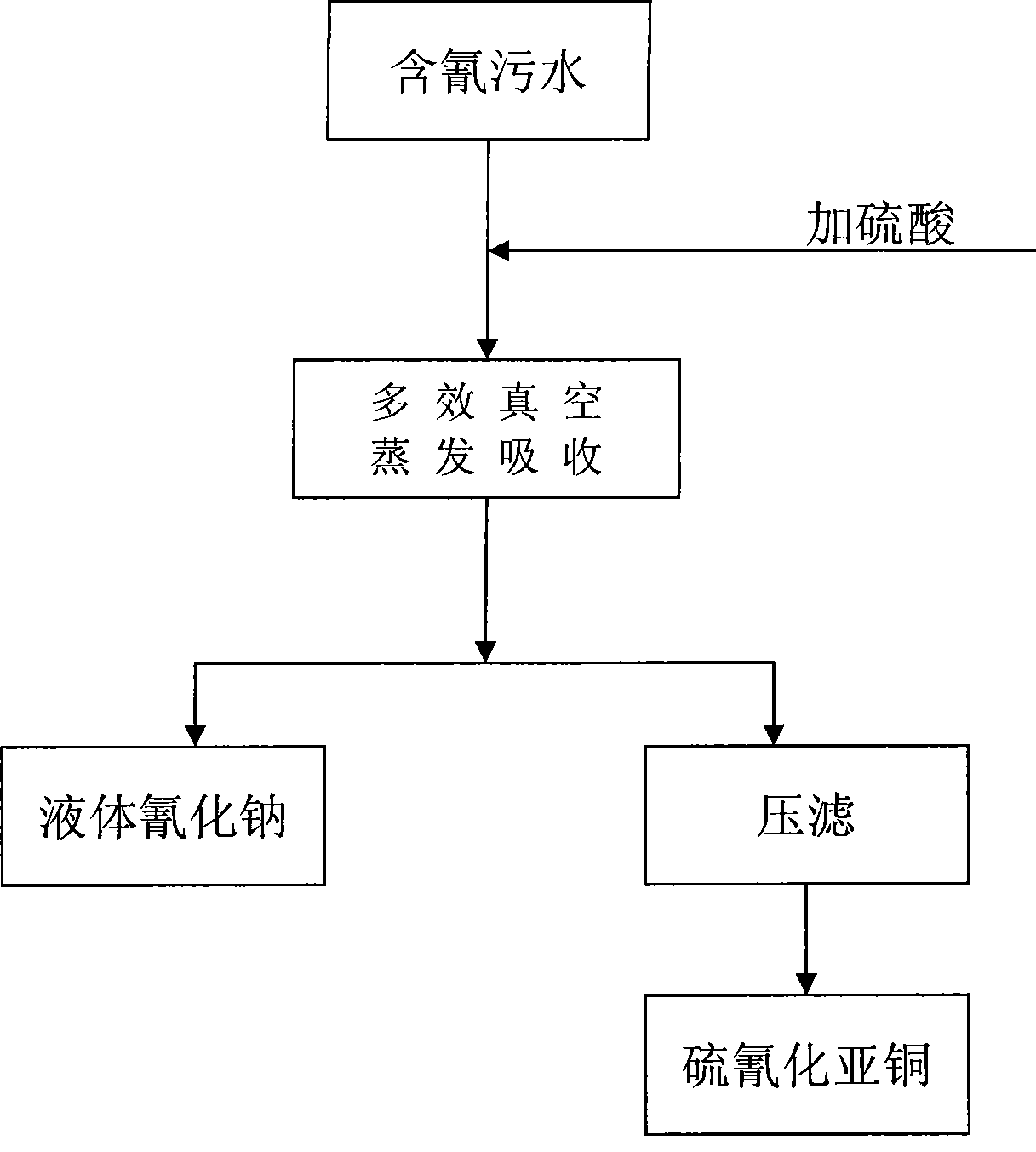

Cyanogens-containing sewage water multiple-effect vacuum evaporation recovery method and recovery device

InactiveCN101450826ASimple processAvoid the problem of high processing cost and easy to cause secondary pollutionAlkali metal cyanidesWater contaminantsRecovery methodChemical reaction

The invention relates to a cyanide-containing sewage multi-effect vacuum evaporation recovery method and a cyanide-containing sewage multi-effect vacuum evaporation recovery device. The cyanide-containing sewage multi-effect vacuum evaporation recovery method comprises the following steps: firstly, cyanide-containing sewage and sulfuric acid are sucked and escaped into a cyanide reaction tower under the action of vacuum negative pressure; secondly, when the cyanide-containing sewage is sprayed and declined from the upper part, hydrocyanic acid is evaporated and escaped from the sewage and separated out under the action of vacuum suction, sucked into a vacuum system, fully mixed with lye and absorbed, and subjected to chemical reaction to generate liquid sodium cyanide; and thirdly, the generated sodium cyanide is returned back to the process of cyanidation and gold extraction and reutilized. The method has simple technological process, performs one-off multi-effect vacuum evaporation recovery, has the recovery rate of 99 percent, solves the problems of high processing cost and easy generation of secondary pollution in the prior cyanide-containing sewage treatment process, achieves the aim of changing waste into valuable, directly recovers and reutilizes the cyanide-containing sewage, greatly saves the cost, and is energy-saving and environment-friendly.

Owner:王安理 +2

Sodium cyanide evaporation and concentration device and method

The invention discloses a sodium cyanide evaporation and concentration device and method. On the basis of the prior art, a vapor compressor, a reboiler and other main equipment are added, secondary steam generated in the material evaporation process and a working medium circulating in the reboiler are subject to heat exchange, and the working medium steam is compressed to heat the sodium cyanide liquid material so as to achieve the purposes of evaporation and concentration. The method can remarkably lower the steam consumption, has an obvious energy-saving effect, achieves evaporation and concentration under the condition of relatively low temperature, can effectively improve the product quality and is an efficient and economical method.

Owner:CHONGQING UNISPLENDOUR CHEM

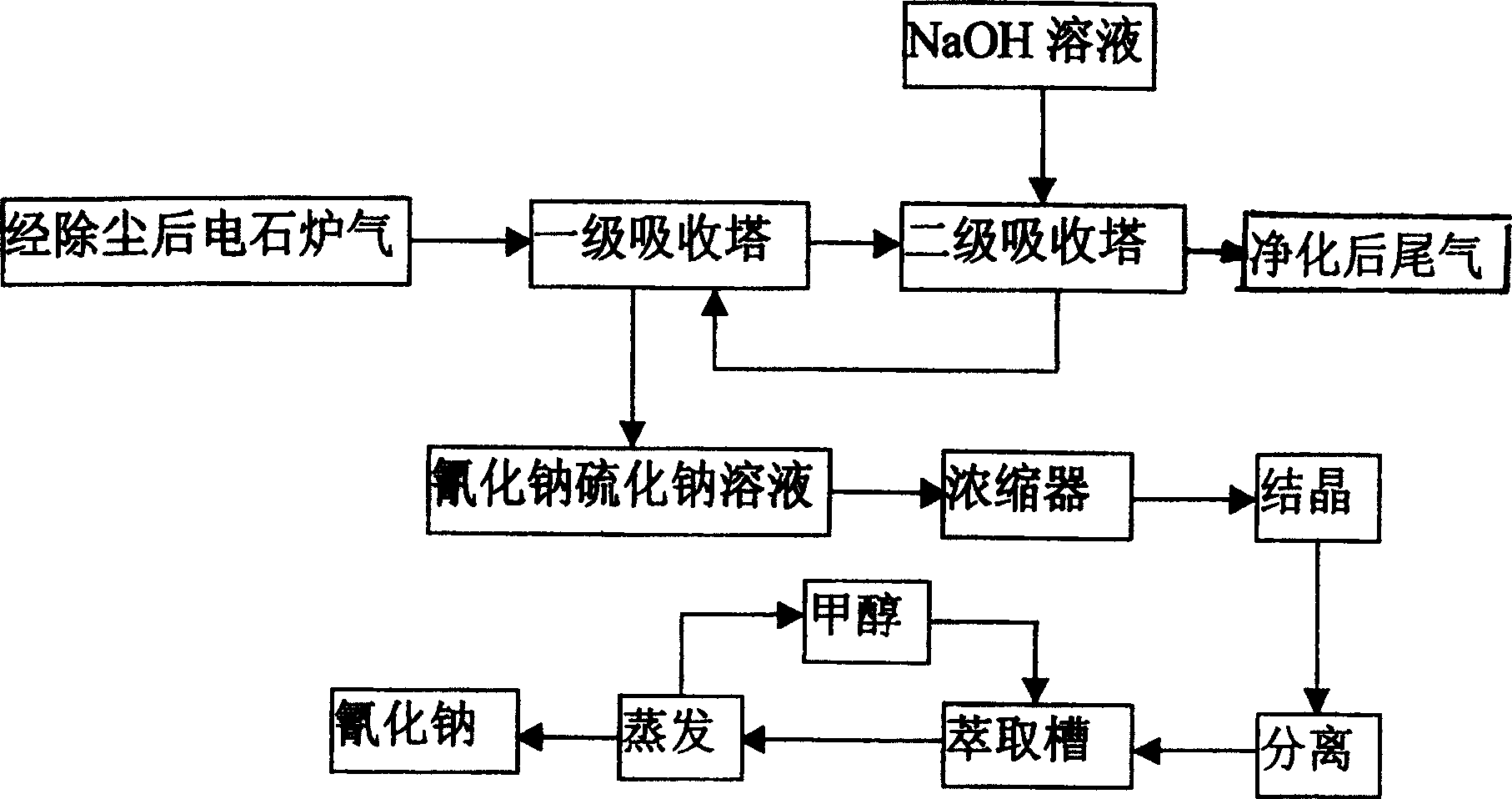

Method for removing hydrogen sulfide and hydrogen cyanide from calcium carbide furnace gas

InactiveCN1994530AReduce manufacturing costPollution controlAlkali metal cyanidesDispersed particle separationSodium cyanideImpurity

The invention relates to a method for purifying the acetylene and side product, wherein it comprises that: feeding acetylene into stuff tower, using 15-20wt% NaOH solution to reversely spray and wash to remove the hydrogen sulfide and hydrocyanic acid, to obtain purified tail gas and the mixture with sodium sulfide and sodium cyanide; evaporating, crystallizing, separating to obtain their mixture crystal; extracting the crystal with carbinol, separating the sodium sulfide and sodium cyanide; then evaporating the sodium cyanide carbinol solution, to recycle the carbinol, to obtain the sodium sulfide and sodium cyanide crystals. The invention can recycle sodium sulfide and sodium cyanide and reduce the pollution, while the sulfur and phosphor contents in tail gas are both lower than 50mg / Nm3.

Owner:KUNMING UNIV OF SCI & TECH

Sodium cyanide process

A process for the production of sodium cyanide crystals comprising;(a) contacting impure hydrogen cyanide and sodium hydroxide in a reactor with mixing for a maximum contact time of about 5 seconds;(b) feeding the resulting mixture to a continuous evaporative crystallizer to produce a slurry of sodium cyanide crystals;(c) passing the slurry of sodium cyanide crystals from the crystallizer over a hot surface to precipitate onto the surface and remove sodium carbonate, and passing said slurry back to the crystallizer; and(d) separating the sodium cyanide crystals from the slurry.

Owner:THE CHEMOURS CO FC LLC

Process method for co-preparing liquid hydrocyanic acid and sodium cyanide

ActiveCN104724724AReduce purification energy consumptionIncrease profitAlkali metal cyanidesHydrogen cyanide preparation/purification/separationAqueous sodium hydroxideSodium cyanide

The invention discloses a process method for co-preparing liquid hydrocyanic acid and sodium cyanide. The process method is characterized by comprising the following step: performing an ammonia removal procedure and a deep cooling procedure on light oil cracking hydrocyanic acid mixed gas which is taken as a raw material, so as to obtain the liquid hydrocyanic acid, wherein the ammonia removal procedure comprises the specific steps of absorbing the hydrocyanic acid mixed gas by sulphuric acid aqueous solution; the deep cooling procedure is cooling the hydrocyanic acid mixed gas to minus 10 to minus 20 DEG C, after the hydrocyanic acid mixed gas is cooled, a part of the hydrocyanic acid gas becomes a liquid to obtain the liquid hydrocyanic acid, and the other part of the hydrocyanic acid gas is a tail gas containing hydrocyanic acid; the deeply-cooled tail gas containing hydrocyanic acid is absorbed by sodium hydroxide aqueous solution to prepare a sodium cyanide aqueous solution. According to the process method disclosed by the invention, by using a method of combining direct deep cooling under a micro-negative pressure with tail gas absorption, a purification efficiency for hydrocyanic acid and a utilization efficiency for hydrocyanic acid can be remarkably increased, meanwhile, energy consumption during a purification process for hydrocyanic acid is greatly reduced and can be reduced by 90% to the greatest extent; moreover, the utilization rate of hydrocyanic acid is greater than 99.9%.

Owner:枣阳市金鹿化工有限公司

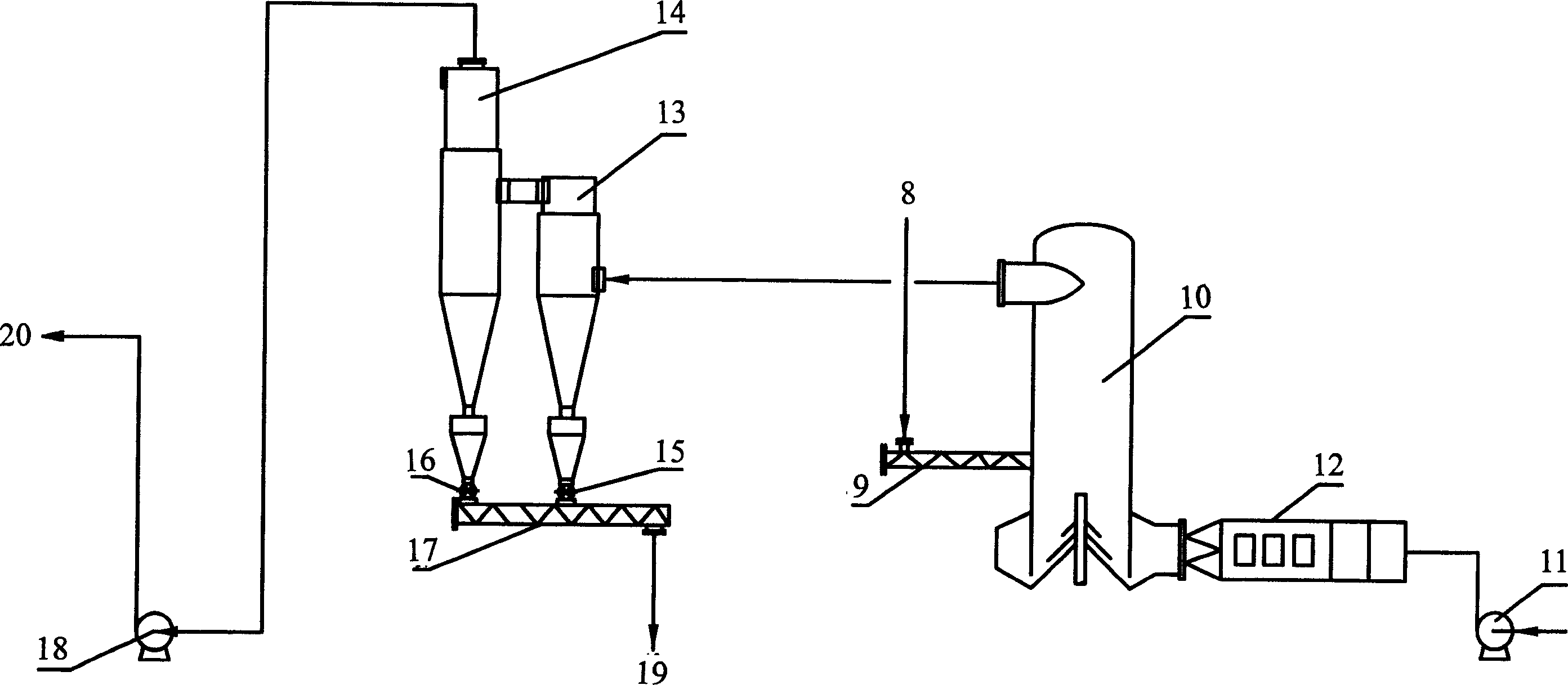

Sodium cyanide powder production system and sodium cyanide powder production method

ActiveCN107399745ACompact structurePrevent self-aggregationAlkali metal cyanidesProcess engineeringSodium cyanide

The invention discloses a sodium cyanide powder production system and a sodium cyanide powder production method. The production system comprises reactors, a reactor discharge pump, a reactor cooler, an evaporative crystallization system, a centrifugal separator, a flash drier, a cyclone separator and a molding packaging system; the production system is characterized in that the evaporative crystallization system comprises an evaporator, an evaporator condenser, an evaporator circulating pump, a crystallizer and an underflow pump; the reactors are arranged at a hydrocyanic acid inlet and a sodium hydroxide inlet; the reactors are communicated with the reactor cooler, an absorption segment at the upper part of the reactor and the evaporator through the reactor discharge pump separately; the reactor cooler is communicated with a mother liquor circulating inlet in the upper end of the reactor; the evaporator is communicated with the crystallizer; the crystallizer is communicated with the centrifugal separator through the underflow pump; the centrifugal separator is communicated with the flash drier; the flash drier is communicated with the cyclone separator; and the cyclone separator is communicated with the molding packaging system. The production system has the advantages that the structure is simple and reasonable, and safe, continuous and efficient industrial production of the sodium cyanide powder is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +2

Method of making inorganic gold compound

ActiveUS20180208476A1Simple and safe processHigh yieldAlkali metal cyanidesGold compoundsHalogenPotassium octatitanate

A method of making the inorganic gold compound, such as tetrachloroauric acid, sodium tetrachloroaurate, potassium tetrachloroaurate, sodium tetracyanoaurate, and potassium tetracyanoaurate, includes the step of: treating gold with a halogen-containing oxidizing agent in a hydrochloric acid to obtain the inorganic gold compound, wherein the halogen-containing oxidizing agent excludes chlorine gas. The method of making the inorganic gold compound is simple, safe, time-effective, cost-effective, and environment-friendly, and has the advantage of high yield.

Owner:TRIPOD TECHNOLOGY CORPORATION

Treatment and reuse method for cupric-cyanide-containing waste water

ActiveCN104003563AReduce processing costsDestroyer is goodAlkali metal cyanidesWater contaminantsFiltrationCupric cyanide

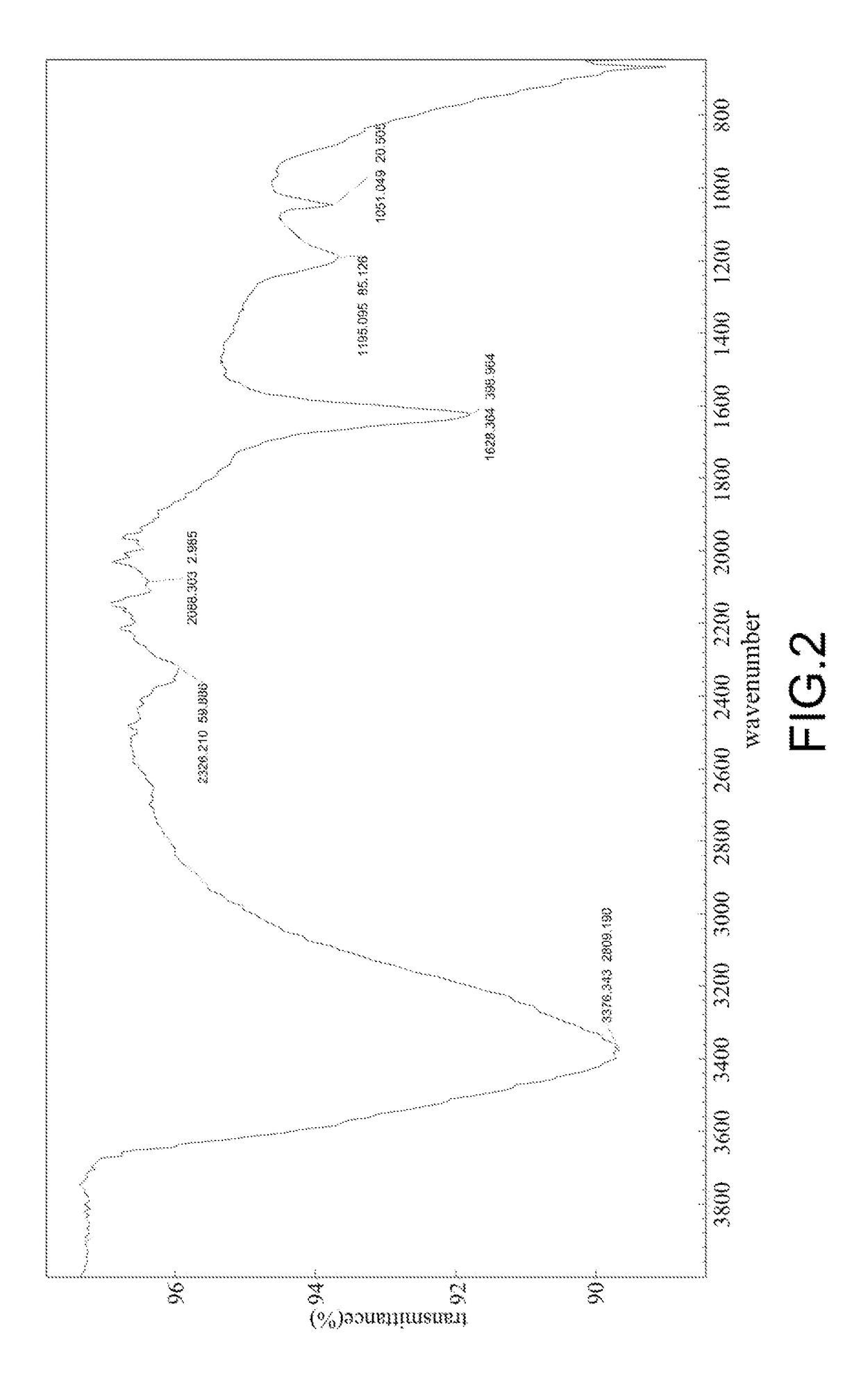

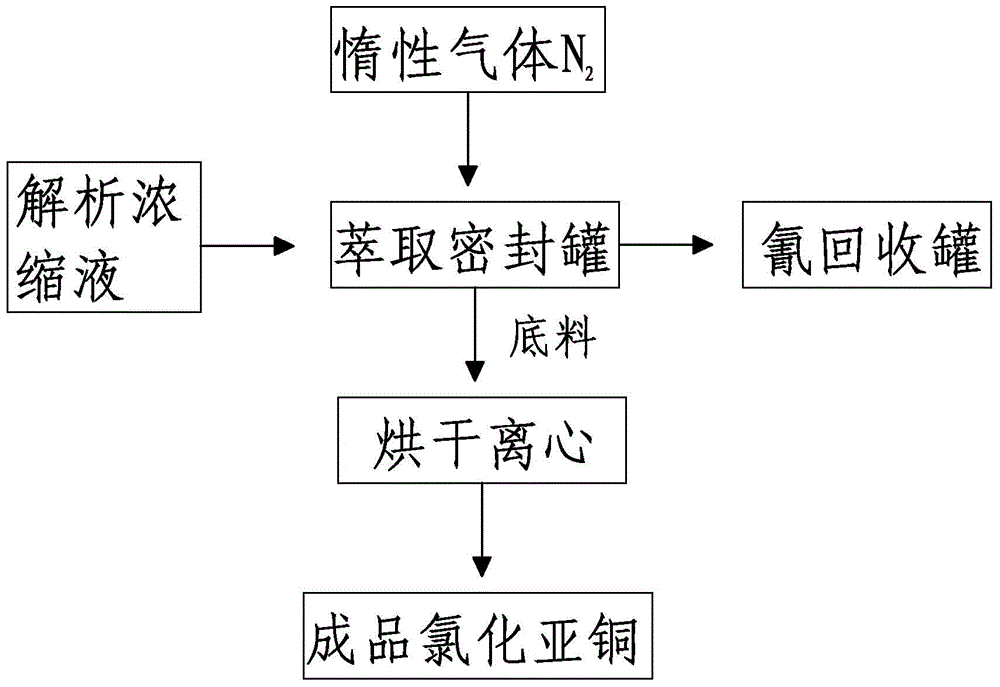

The invention provides a treatment and reuse method for cupric-cyanide-containing waste water. The treatment and reuse method comprises a low-concentration cyanophoric material ion recovery process and a cuprous extraction process, wherein the low-concentration cyanophoric material ion recovery process mainly comprises the steps that: (1) the cupric-cyanide-containing waste water is subjected to cartridge filtration for removing impurities in the cupric-cyanide-containing waste water; and (2) the cupric-cyanide-containing waste water subjected to impurity removal is introduced into a cyanide ion recovering machine, cyanide complexes and free cyanogen in the cupric-cyanide-containing waste water are collected, and an analysis concentrated solution and cyanogen-removed waste water are obtained. The cuprous extraction process mainly comprises the steps that: (1) the analysis concentrated solution is pumped into an extraction sealing tank; (2) inert gas is injected into the extraction sealing tank so that the analysis concentrated solution boils, extraction agents formed by proportionally mixing H2SO4 and NaCl are added, and obtained HCN enters a cyanogen recovery tank; and (3) remaining backing materials in the extraction sealing tank are CuCl, and CuCl finished products are obtained after vacuum drying and centrifugation. Therefore cyanogen and copper in the cupric-cyanide-containing waste water are respectively recovered and reused.

Owner:厦门市韩江环保科技有限公司

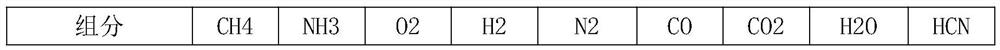

Environmentally-friendly clean technology for producing hydrocyanic acid derivatives from coal-bed methane

ActiveCN102897797AGood yieldAbundant raw materialsAlkali metal cyanidesPreparation by hydrogen cyanide additionSodium cyanideMethane gas

The invention provides an environmentally-friendly clean technology for producing hydrocyanic acid derivatives from coal-bed methane. The environmentally-friendly clean technology realizes production of hydrocyanic acid derivatives from low-concentration coal-bed methane. The environmentally-friendly clean technology is characterized in that hydrocyanic acid and its derivatives are prepared from concentrated methane having low content requirements; coal-bed methane is subjected to separation processes of pressure swing adsorption and the like to form relatively concentrated methane for production of hydrocyanic acid derivatives, wherein the relatively concentrated methane has relatively low concentration requirements and can retain residual nitrogen and oxygen having a large component ratio; and the relatively concentrated methane undergoes an ammoxidation synthesis reaction to produce hydrocyanic acid mixed gas, and the hydrocyanic acid mixed gas and a sodium hydroxide aqueous solution undergo a reaction to produce sodium cyanide for synthesis of downstream hydrocyanic acid derivatives, or the hydrocyanic acid mixed gas, formaldehyde and other aldehydes are synthesized into glycolonitrile and other derivatives for synthesis of downstream hydrocyanic acid derivatives, or the hydrocyanic acid mixed gas is absorbed by water or other solvents and then is purified to form high-purity liquid hydrocyanic acid for synthesis of downstream hydrocyanic acid derivatives.

Owner:李宽义

Preparation method for preparing alkali metal or alkali earth metal cyanide with high purity and high yield

ActiveCN102502708BHigh purityGood colorAlkali metal cyanidesChemical industryCyanideAlkaline earth metal

The invention relates to a preparation method for preparing alkali metal or alkali earth metal cyanide with high purity and high yield, which comprises the following steps of: mixing, absorbing and reacting HCN (hydrogen cyanide) synthetic gas synthesized by an Andrussow method with absorption liquid containing alkali and then carrying out gas-liquid separation and cooling to prepare the alkali metal or the alkali earth metal cyanide. The absorption and reaction contact time of the HCN synthetic gas with the absorption liquid containing the alkali can be controlled within 0.1-2.0 seconds; the concentration of free alkali in the absorption liquid containing the alkali can be controlled within 0.1-20 percent by weight; and the mass ratio of circulation fluid of the cyanide to product liquid is 2-40:1. The invention has the beneficial effects that the alkali metal or the alkali earth metal cyanide prepared by the preparation method is high in purity; the total content of carbonate can be controlled within below 0.45 percent by weight, the content of formate can be controlled within below 0.15 percent by weight, and the content of ocyhydrate (free alkali) can be controlled within 0.1-2.0 percent by weight; and the alkali metal or the alkali earth metal cyanide is good in color and is colorless transparent liquid.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Drying technology for preparing high content industrial solid sodium cyanide product

InactiveCN1559901AReduce granulation processLarge heat and mass transfer surface areaAlkali metal cyanidesHigh energyEngineering

The invention discloses a drying technique for preparing high-content industrial solid NaCl products, i.e. by controlling the feed quantity, it feeds sodium prussiate through a spiral transporter into the drying room with a rotary flash-vaporization drier, and at the same time, feeds normal-temperature air after filtered to an electric air heater for heating and then bellows the heated air through the bottom of the drying chamber into the drying chamber; makes the dried material powder leave the drying chamber together with the air flow, separates by a cyclone separator to discharge the material through a rotary valve to enter in the next working procedure. It shortens the technical flow, reduces energy consumption, and improves productivity and quality and simultaneously reduces the discharge of waste gas and waste water, and solves the problems of existing techniques, like high energy consumption, low output, high labor strength of workers, inconsistent product quality, etc.

Owner:ANHUI ANQING SHUGUANG CHEM GRP

Hydrothermal preparation method of editpotassium cyanide solution

The invention provides a hydrothermal preparation method of an editpotassium cyanide solution. According to the hydrothermal preparation method, potassium ferricyanide is used as a raw material. The hydrothermal preparation method comprises the steps of dissolution, hydrothermal reaction and separation of all units. The hydrothermal preparation method is characterized in that a K3Fe(CN)6 aqueous solution is put in a polytetrafluoroethylene lining of a hydrothermal kettle, after the hydrothermal kettle is sealed, the hydrothermal kettle is subjected to heat preservation for 24-72 hours at the temperature of 140-250 DEG C, after hydrothermal reaction, KOH solids, the amount of substance of which is three times as much as that of the K3Fe(CN)6, are added to the solution, after the KOH solids are dissolved by stirring, Fe2O3 precipitates are filtered out, and finally the KCN solution with corresponding concentration is obtained. By adopting the hydrothermal preparation method, equipment and technological processes can be simplified, and the cost is greatly reduced.

Owner:贾冲

Sodium cyanide process

A process that can be used to produce NaCN is provided. The process comprises contacting hydrogen cyanide with sodium hydroxide solution to produce a NaCN solution and crystallizing the NaCN solution wherein the process is carried out in the presence of an acid or a metal salt of the acid in which the acid has a pKa≦4.4. The NaCN crystals can be separated from the slurry and dried.

Owner:THE CHEMOURS CO FC LLC

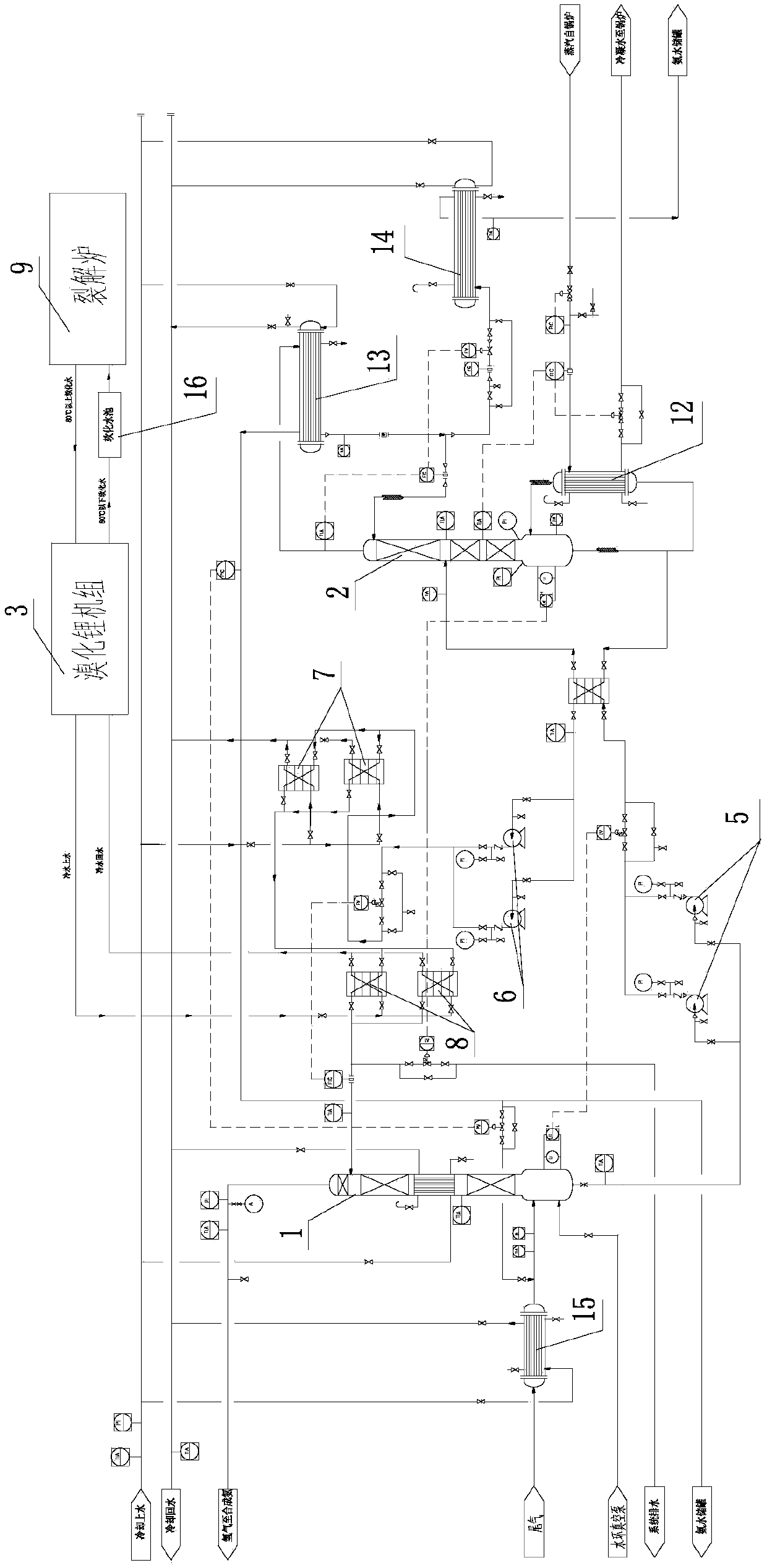

Energy-saving tail gas deamination process and equipment for production of sodium cyanide

PendingCN110563000ALow costReduce the temperatureAlkali metal cyanidesChemical industryLithium bromideChemistry

Belonging to the technical field of energy conservation and environmental protection, the invention particularly relates to an energy-saving tail gas deamination process and equipment for production of sodium cyanide. Specifically, high-temperature softened water coming out of a cracking furnace serves as a heat source of a lithium bromide unit and returns to a softened water pool after being cooled so as to get ready for entering the cracking furnace again; tail gas enters the lower part of an ammonia absorption tower, spray water enters the upper part of the ammonia absorption tower for spray deamination on the tail gas, the generated dilute ammonia water is sent into a kettle liquid heat exchanger through a dilute ammonia water pump, and then enters a distillation tower, part of the kettle liquid subjected to distillation deamination by the distillation tower undergoes heat exchange by the kettle liquid heat exchanger, and is sent as spray water by a spray water pump to two circulating water plate heat exchangers for primary cooling by cooling water, after coming out of the circulating water plate heat exchangers, the spray water enters two cold water plate heat exchangers for secondary cooling through cold water generated by the lithium bromide unit, and then the spray water returns to the ammonia absorption tower again to spray the tail gas. Through the recycling, the ammonia content of the tail gas can reach the production requirement of 0.8% or below.

Owner:营创三征(营口)精细化工有限公司

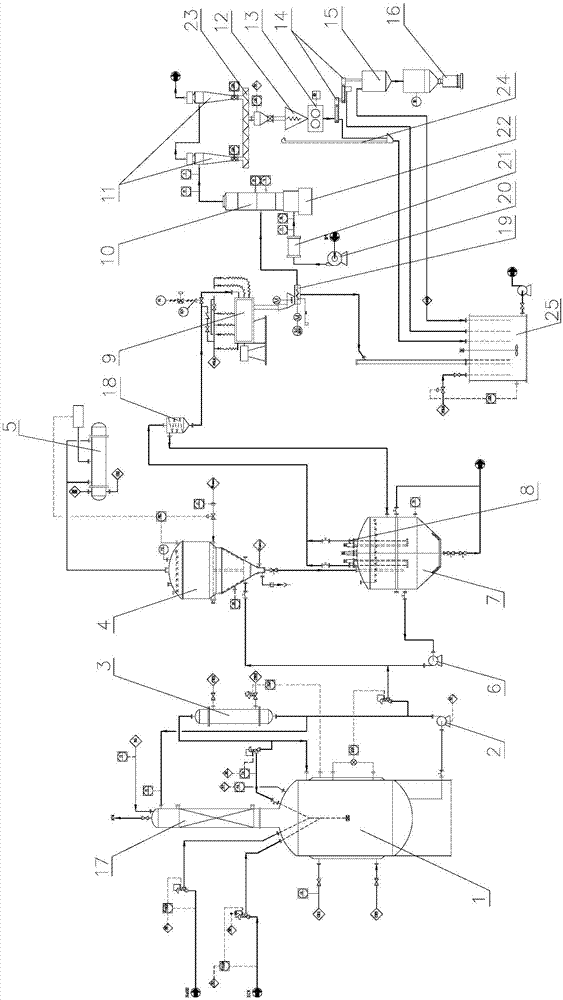

Production process and device for preparing high-purity sodium cyanide or potassium cyanide with high yield

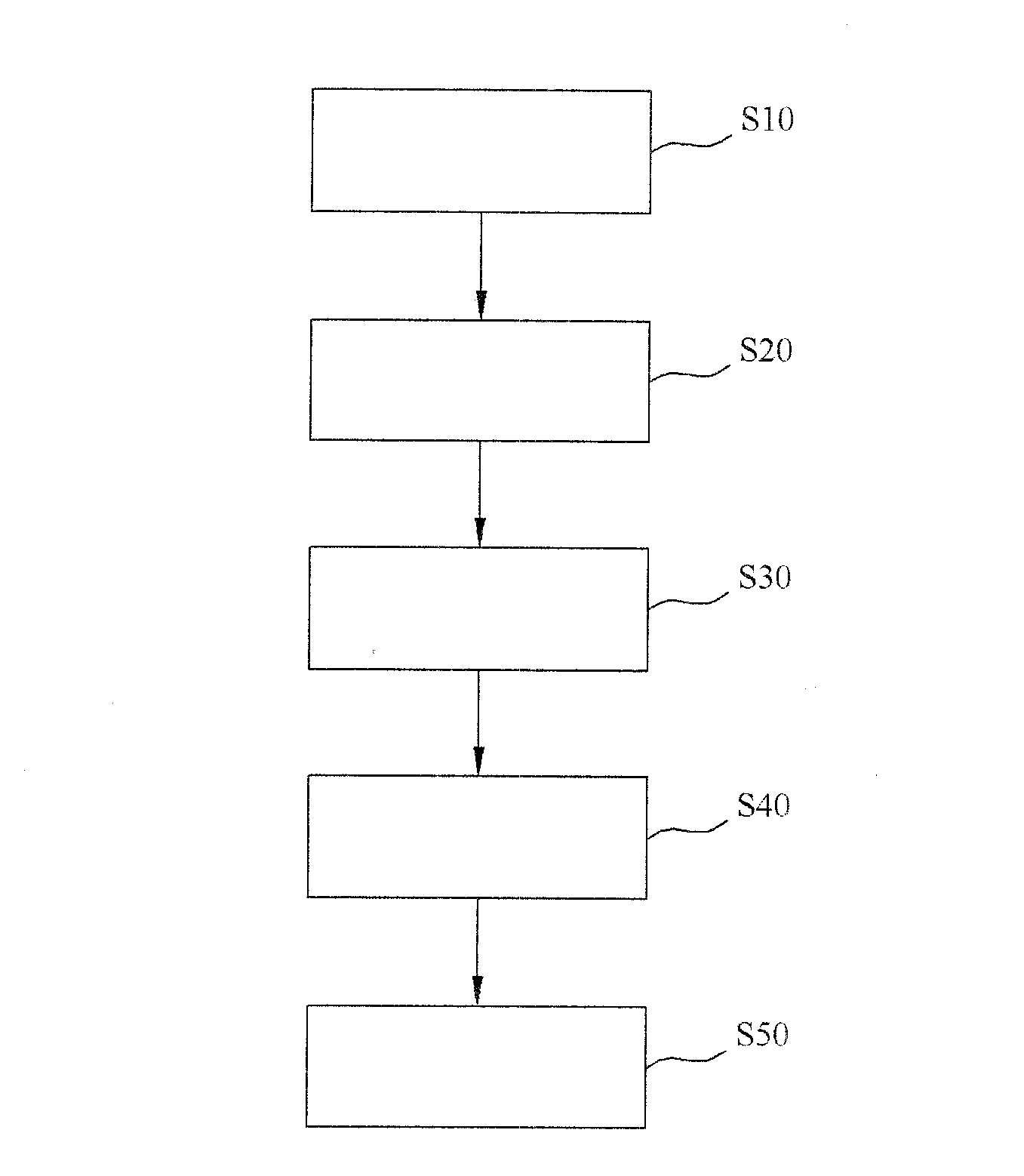

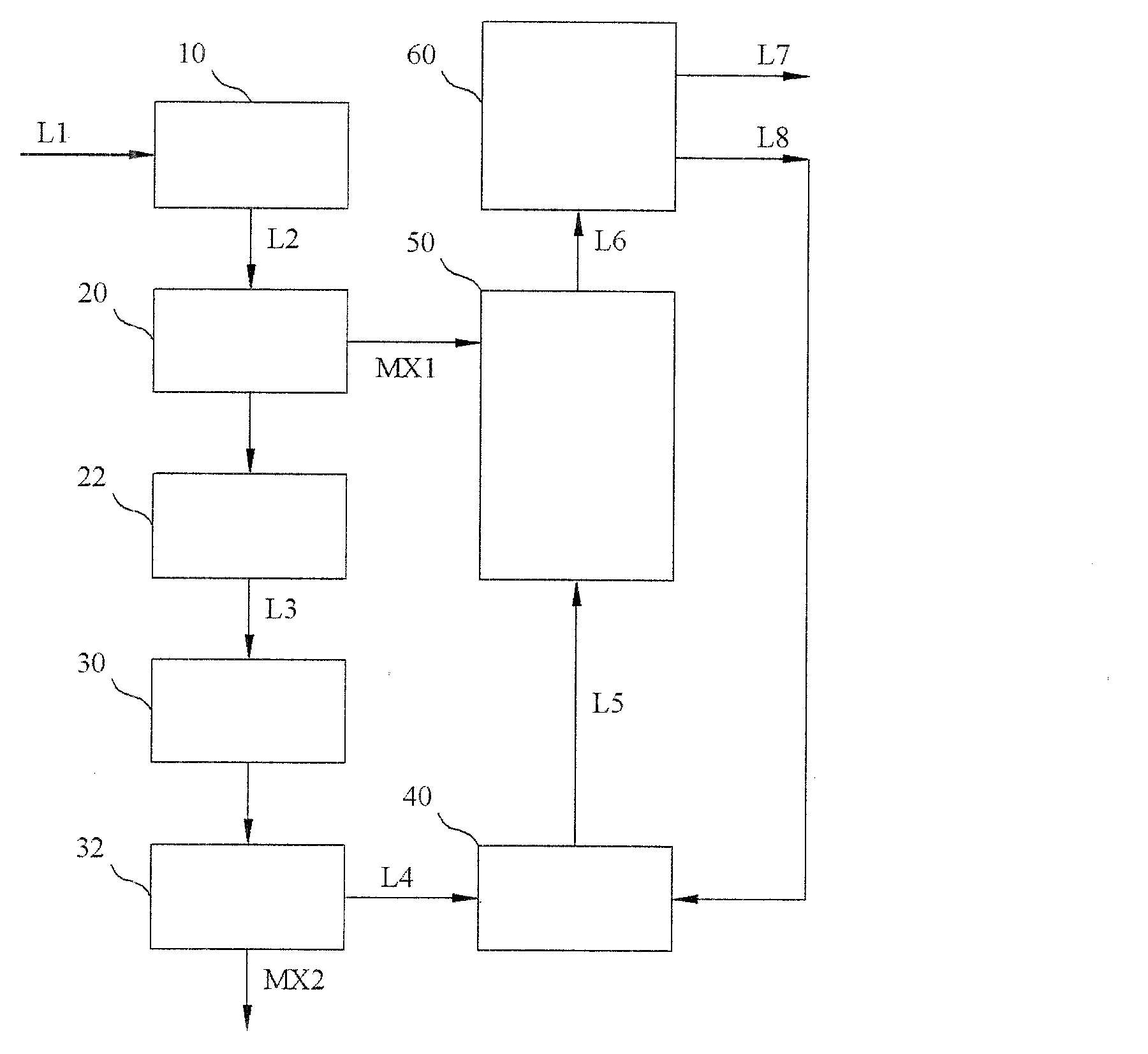

The invention discloses a production process and device for preparing high-purity sodium cyanide or potassium cyanide with high yield. The process comprises the following steps: 1) removing ammonia, and cooling to obtain ammonia gas removing HCN; 2) shunting the ammonia gas removing HCN; 3) carrying out an absorption reaction to obtain a crude cyanide solution; (4) carrying out decarburization reaction to obtain a decarburized solution; 5) adjusting the content of free alkali, and carrying out an absorption reaction on the decarburized solution obtained in the step 4) and the ammonia gas removing HCN entering an absorber II in the step 2) in the absorber II to obtain high-purity liquid sodium cyanide or potassium cyanide; and 6) carrying out tail gas treatment. The invention discloses a production device for preparing high-purity sodium cyanide or potassium cyanide with high yield. According to the invention, one part of HCN synthesis gas is utilized to generate a decarburized solution, the other part of HCN synthesis gas and the decarburized solution are subjected to continuous absorption reaction, and the content of free alkali in the decarburized solution is adjusted, so that the high-purity liquid sodium cyanide or potassium cyanide can be obtained, the cost is low, the yield is high, and the side reaction that the cyanide is decomposed at high temperature to generate formate is effectively inhibited.

Owner:重庆柒兴克米科技有限公司

Method for strengthening natural degradation of cyanide residue

PendingCN111760878AReduce manufacturing costReduce residual cyanideAlkali metal cyanidesWaste processingCyanideEngineering

The invention belongs to the technical field of environmental protection field pollutant treatment methods, and particularly relates to a method for strengthening natural degradation of cyanide residue. A greenhouse cleaning system, a turning and throwing machine, a medicament spraying system and a monitoring system are additionally arranged on an existing closed solar greenhouse, and when the cyanogen residue is treated, the temperature in the solar greenhouse is maintained at 50 DEG C or above, and the humidity is in a non-saturated state, and the cyanogen residue carries out material distribution and material mixing by the turning and throwing machine, the medicament spraying system is used for uniformly spraying medicament to the cyanide residue, the cyanide residue medicament treatment is combined with the low-temperature drying treatment, and the sprayed medicament plays the role in removing cyanide or stabilizing heavy metal in the cyanide residue, so that the efficient, economical and clean deep purification treatment of the cyanide residue is realized; and a sodium hydroxide absorption tower is additionally arranged at the tail end of a ventilation system to absorb hydrogen cyanide in vapor, so that the safety and environmental protection of a rectification treatment system are guaranteed, and meanwhile the hydrogen cyanide evaporated in the cyanide residue can be recovered.

Owner:CHANGCHUN GOLD RES INST

Sodium cyanide process

The present invention provides a method for producing NaCN. The process comprises contacting hydrogen cyanide and sodium hydroxide to produce a NaCN solution, and crystallizing the NaCN solution, wherein the process is carried out in the presence of an acid or a metal salt of the acid, wherein the acid has a pKa≤4.8, from the slurry The NaCN crystals were isolated from and dried.

Owner:THE CHEMOURS CO FC LLC

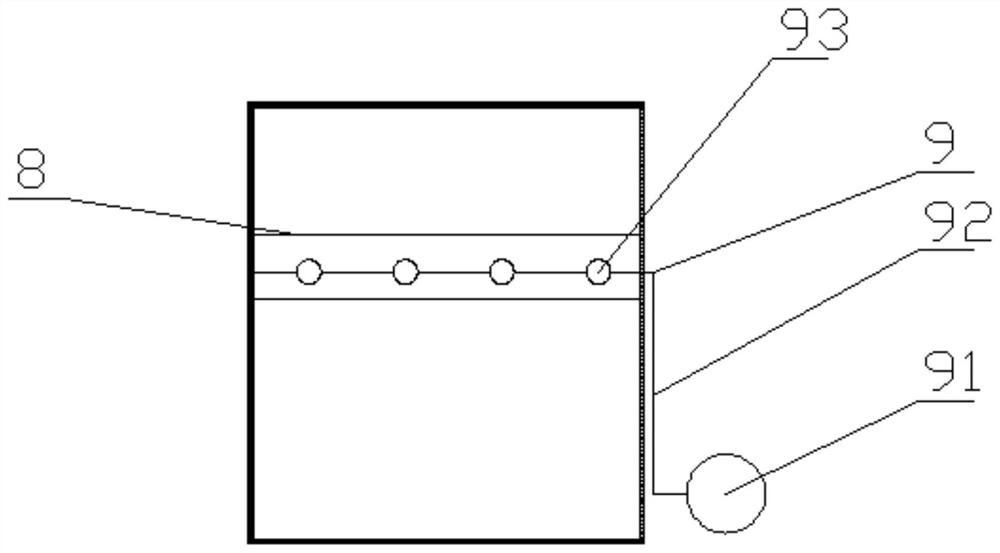

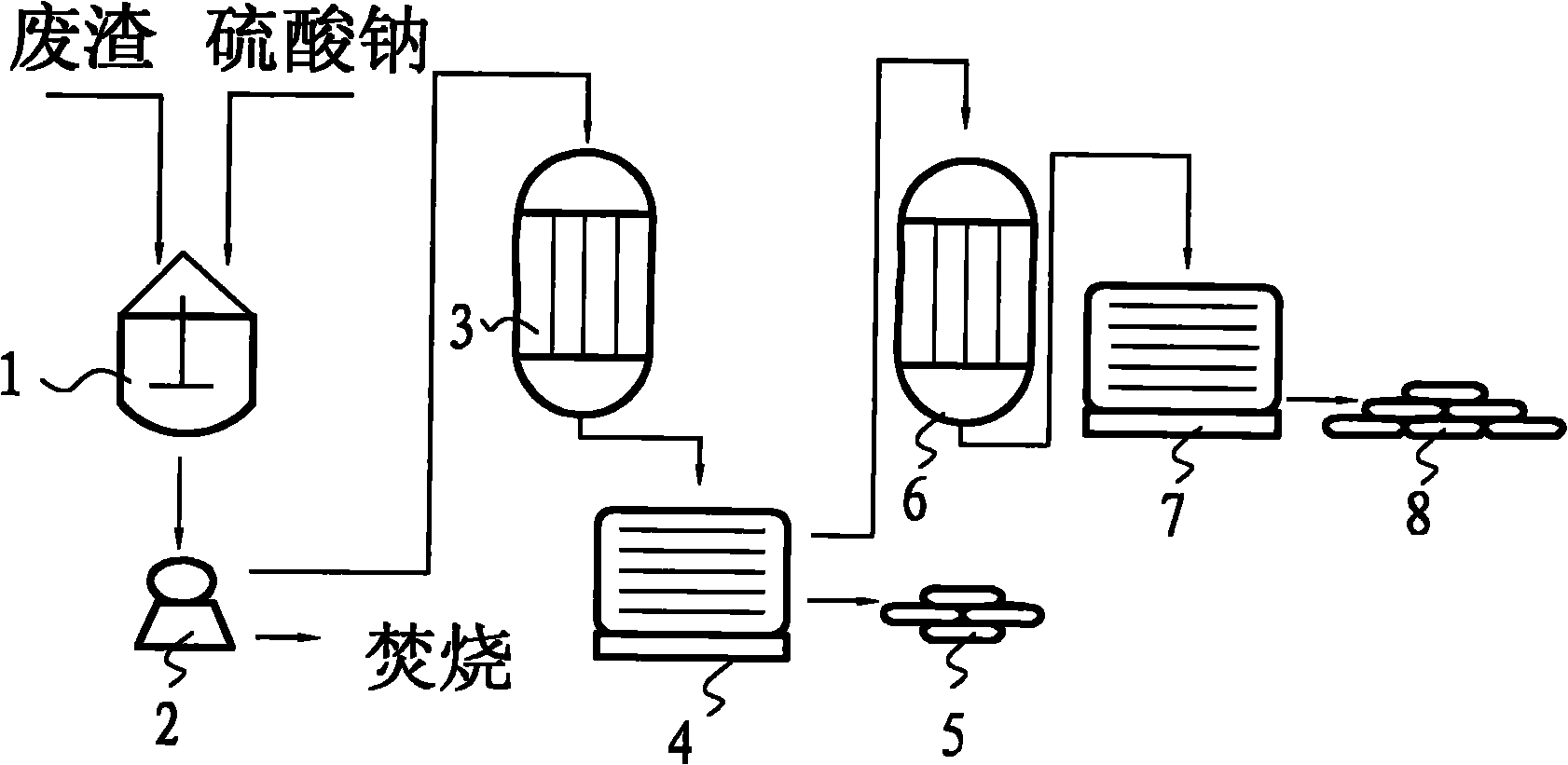

Method for preparing sodium cyanide co-production mixed sulfate from waste residues generated by cracking light oil

InactiveCN101955198AIncrease expansionEliminate pollutionAlkali metal cyanidesChemistrySodium cyanide

The invention relates to the technical fields of comprehensive treatment and utilization of waste residues generated by cracking light oil, in particular to a method for preparing sodium cyanide co-production mixed sulfate from the waste residues generated by cracking the light oil. The main technical scheme of the invention comprises the following steps of: washing the waste residues generated by cracking the light oil, with 5-10 percent of a sodium sulfate solution below 30 DEG C; subjecting the washed waste residues to suck filtration; then placing the washed waste residues into a vacuum distillatory for vacuum distillation at the low temperature of 40-60DEG C; cooling to obtain a sodium cyanide crystal; and re-distilling the residual liquid to obtain the mixed sulfate. According to the invention, the preparation process and equipment are simple and feasible and the cost is low; and the invention eliminates the influence on the environment and simultaneously creates products with certain economic value.

Owner:汪晋强

Method for producing liquid sodium cyanide by tailed-oil thermal-pyrolysis

ActiveCN101074102BLow priceRaise the outlet temperatureAlkali metal cyanidesEnergy inputWaste oilOxygen

A method for producing liquefied sodium cyanide by waste oil thermal cracking is carried out by vaporizing while mixing waste oil with liquid ammonia in proportion of 1:2-1:5, putting them into cracking reactor, taking petrol coke as heat carrier, thermal cracking at 1300-1500 degree to obtain pyrolysis gas containing oxygen-hydrogen acid, recovering pyrolysis gas waste heat by waste hot boiler, removing coke, cooling, absorbing continuously by liquid sodium hydrate to obtain liquid sodium cyanide product, firing by waste gas combustion system, recovering waste heat and absorbing tail gas from liquid sodium cyanide. It's safe, convenient, cheap and controllable and has no environmental pollution.

Owner:兰州寰球工程有限公司

Environment-friendly clean process method for producing hydrocyanic acid derivatives by purge gas

InactiveCN103086400ARealize comprehensive utilizationRealize environmental protection and clean productionAlkali metal cyanidesNoble gas compoundsDehydrogenationDissolution

The invention provides an environment-friendly clean process method for producing hydrocyanic acid derivatives by purge gas. The method is characterized in that: methane-containing purge gas is separated by a pressure swing adsorption device and other separation devices to obtain ammonia (or methanol), hydrogen, nitrogen, methane gas and tail gas; the ammonia (or methanol), hydrogen, and nitrogen are returned to an ammonia synthesis (or methanol synthesis) system for full utilization; the methane gas is used for synthesizing hydrocyanic acid derivatives; and the tail gas is used for argon recycle; the hydrocyanic acid synthesized by the methane gas is used for synthesizing various hydrocyanic acid derivatives: the methane gas is directly used for ammoxidation or ammonification dehydrogenation to synthesize hydrocyanic acid synthetic gas; an absorption reaction takes place between the synthetic gas and a sodium hydroxide aqueous solution to obtain sodium cyanide used for synthesizing downstream hydrocyanic acid derivatives; the synthetic gas reacts with formaldehyde and other organic aldehydes to synthesize hydroxy acetonitrile and other hydrocyanic acid derivatives used for synthesizing downstream hydrocyanic acid derivatives; the synthetic gas is subjected to absorption and dissolution purification by water or other solvents to obtain liquid hydrocyanic acid used for synthesizing downstream hydrocyanic acid derivatives.

Owner:四川创元丽安科技有限公司

Method for removing hydrogen sulfide and hydrogen cyanide from calcium carbide furnace gas

InactiveCN100486674CMeeting Syngas RequirementsReduce manufacturing costAlkali metal cyanidesDispersed particle separationSodium cyanideImpurity

The invention relates to a method for purifying the acetylene and side product, wherein it comprises that: feeding acetylene into stuff tower, using 15-20wt% NaOH solution to reversely spray and wash to remove the hydrogen sulfide and hydrocyanic acid, to obtain purified tail gas and the mixture with sodium sulfide and sodium cyanide; evaporating, crystallizing, separating to obtain their mixture crystal; extracting the crystal with carbinol, separating the sodium sulfide and sodium cyanide; then evaporating the sodium cyanide carbinol solution, to recycle the carbinol, to obtain the sodium sulfide and sodium cyanide crystals. The invention can recycle sodium sulfide and sodium cyanide and reduce the pollution, while the sulfur and phosphor contents in tail gas are both lower than 50mg / Nm3.

Owner:KUNMING UNIV OF SCI & TECH

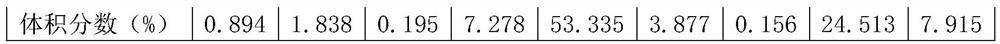

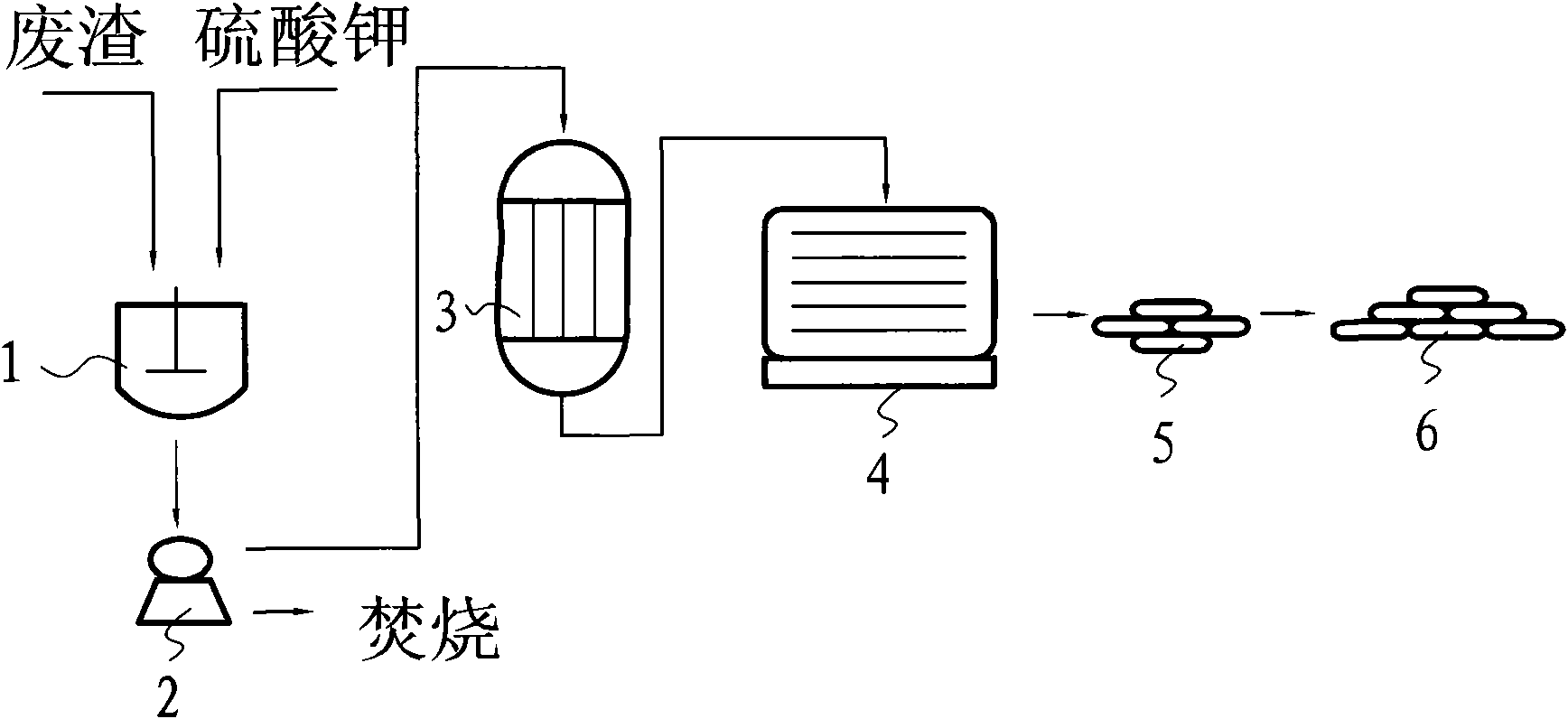

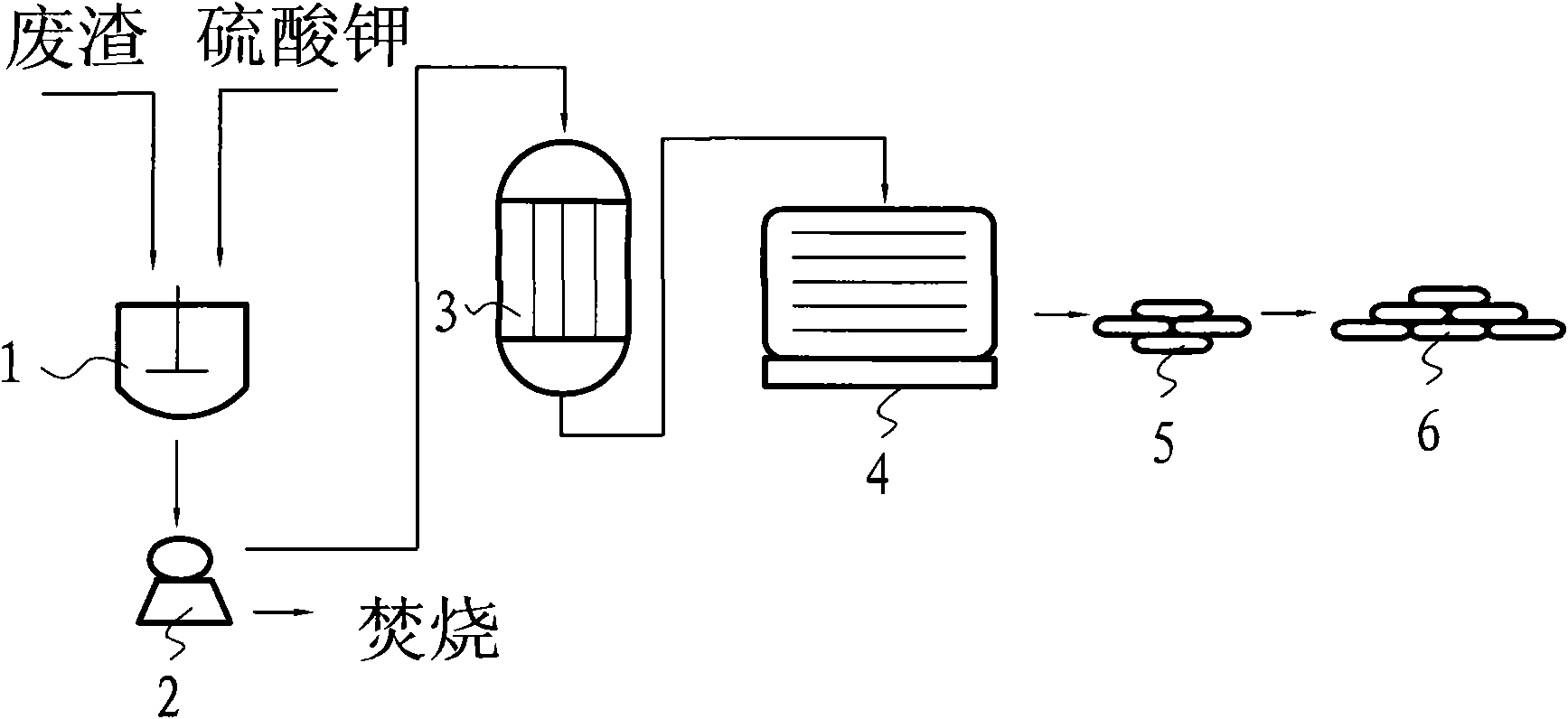

Method for preparing potassium cyanide co-production mixed sulfate by using ammonia sodium residues

InactiveCN101955200AEliminate pollutionAvoid stackingAlkali metal cyanidesDistillationPotassium cyanide

The invention relates to the technical field of comprehensively treating and utilizing ammonia sodium residues, in particular to a method for preparing potassium cyanide co-production mixed sulfate by using the ammonia sodium residues. The method comprises the main technical schemes of: firstly putting the ammonia sodium residues and sodium sulfate in a low-temperature closed reaction kettle according to the pure substance mass radio of 1:(1.29-1.69) to react, filtering after the reaction and sending filter cakes and impurities to be incinerated; firstly sending the filtrate to a reduced pressure distiller to carry out low-temperature distillation, then crystallizing the filtrate in a low-temperature crystallizer and at last obtaining potassium cyanide crystals and mixed sulfate. The invention not only has the advantages of simple and practicable preparation process and equipment and low cost, but also can completely eradicate CN- in the residues, eliminate the impact on the environment and simultaneously create products with certain economic value.

Owner:汪晋强

Method for recycling gold and cyanides in surface treatment wet-process cleaning solution

ActiveCN102795732ARealize the purpose of recovering goldAlkali metal cyanidesPhotography auxillary processesHigh concentrationFiber

The invention relates to a method for recycling gold and cyanides in a surface treatment wet-process cleaning solution, which comprises the following steps: filtering a plating solution or cleaning solution with a carbon fiber filter; carrying out electrodeposition treatment to precipitate gold and heavy metals to form a metal mixture, and carrying out separation treatment with a separating unit to adsorb residual gold; reacting white lime with boric acid to form a calcium borate precipitate, separating the calcium borate precipitate and citric acid with a nano filter membrane to form a regenerative solution, and storing the regenerative solution in a regenerative solution storage tank; dissolving gold in the metal mixture by using the regenerative solution, thereby forming a gold-containing solution; and separating the gold-containing solution with a reverse osmosis module to obtain an osmotic solution which osmoses through the reverse osmosis membrane and an unosmotic concentrated solution, wherein the osmotic solution is sent back to the regenerative solution storage tank. Therefore, the method provided by the invention can implement the goal of recycling gold by using the concentrated solution containing high-concentration gold potassium cyanide.

Owner:昊鼎环保科技(湖北)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com