Method for strengthening natural degradation of cyanide residue

A technology of cyanide slag and building body, which is applied in the field of strengthening natural degradation of cyanide slag, can solve the problems of secondary pollution, lower moisture content, large area restrictions, etc., and achieve the effect of cleaning and deep purification treatment and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Cyanide-containing tailings slurry from a gold mine, the mass concentration of the slurry is 40%, and the pollutant components in the liquid phase and tailings are shown in Table 1. After being filtered by a filter press, the moisture content of the filter residue is 20.5%, and the toxicity leaching test results are shown in Table 1. 2. The treated cyanide slag is required to meet the tailings pond disposal requirements in the "Technical Specifications for Cyanide Slag Pollution Control in the Gold Industry" (HJ 943-2018), see Table 3.

[0067] Table 1 Analysis of pollutants in cyanide-containing tailings pulp

[0068]

[0069] Table 2 Results of pressure filter residue toxicity leaching test

[0070]

[0071] Note: The index unit in the table is mg / L.

[0072] Table 3 Cyanide slag tailings disposal standard limits

[0073]

[0074] Note: The index unit in the table is mg / L.

[0075] The press filter residue is transported to the above-mentioned solar green...

Embodiment 2

[0081] The moisture content of the tailings slag after the harmless treatment of cyanide-containing tailings slurry in a gold mine is 21%. The results of the toxicity leaching test are shown in Table 5. 2018), see Table 6.

[0082] Table 5 cyanide slag toxicity leaching test results

[0083]

[0084] Note: The index unit in the table is mg / L.

[0085] Table 6 Cyanide slag backfill utilization standard limit

[0086]

[0087] Note: The index unit in the table is mg / L.

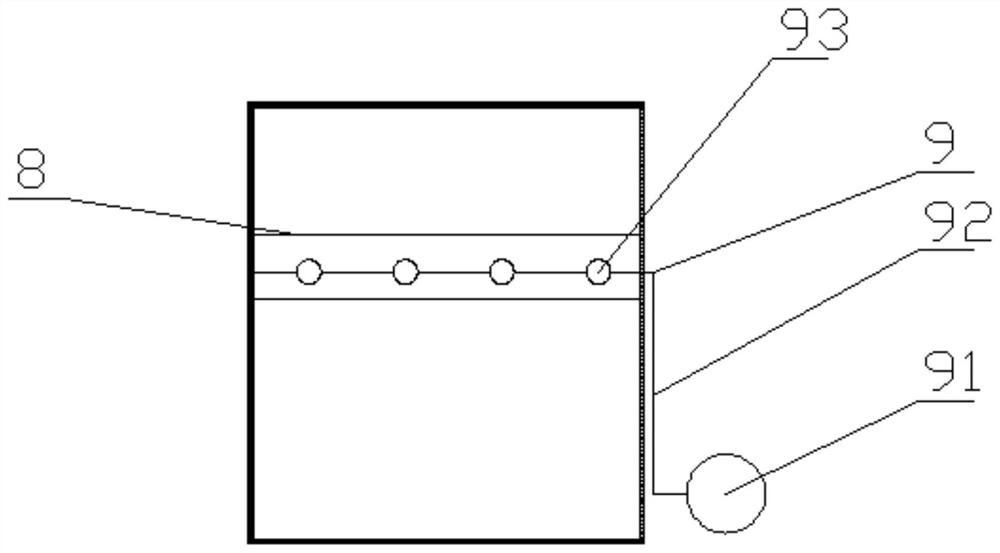

[0088] The press filter residue is transported to the above-mentioned solar greenhouse with a belt conveyor, that is, on the floor in the airtight room 1, and the heating system 3, the floor heating system 4, the ventilation system 5, the dehumidification system 6, the monitoring system 10 and the control system 11 are turned on. Utilize the throwing machine 8 to distribute the cyanide slag 2, so that the cyanide slag 2 is spread on the floor of the airtight room body 1, and the temperature in the airti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com