Drying technology for preparing high content industrial solid sodium cyanide product

A drying process, sodium cyanide technology, applied in the direction of metal cyanide, simple alkali metal cyanide, etc., can solve the problems of reducing the surface area of gas-solid two-phase mass transfer and heat transfer, the quality is difficult to further improve, and the heat energy utilization rate is not high. Reduce the frequency of failure shutdown and blockage, low power, and reduce the effect of granulation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

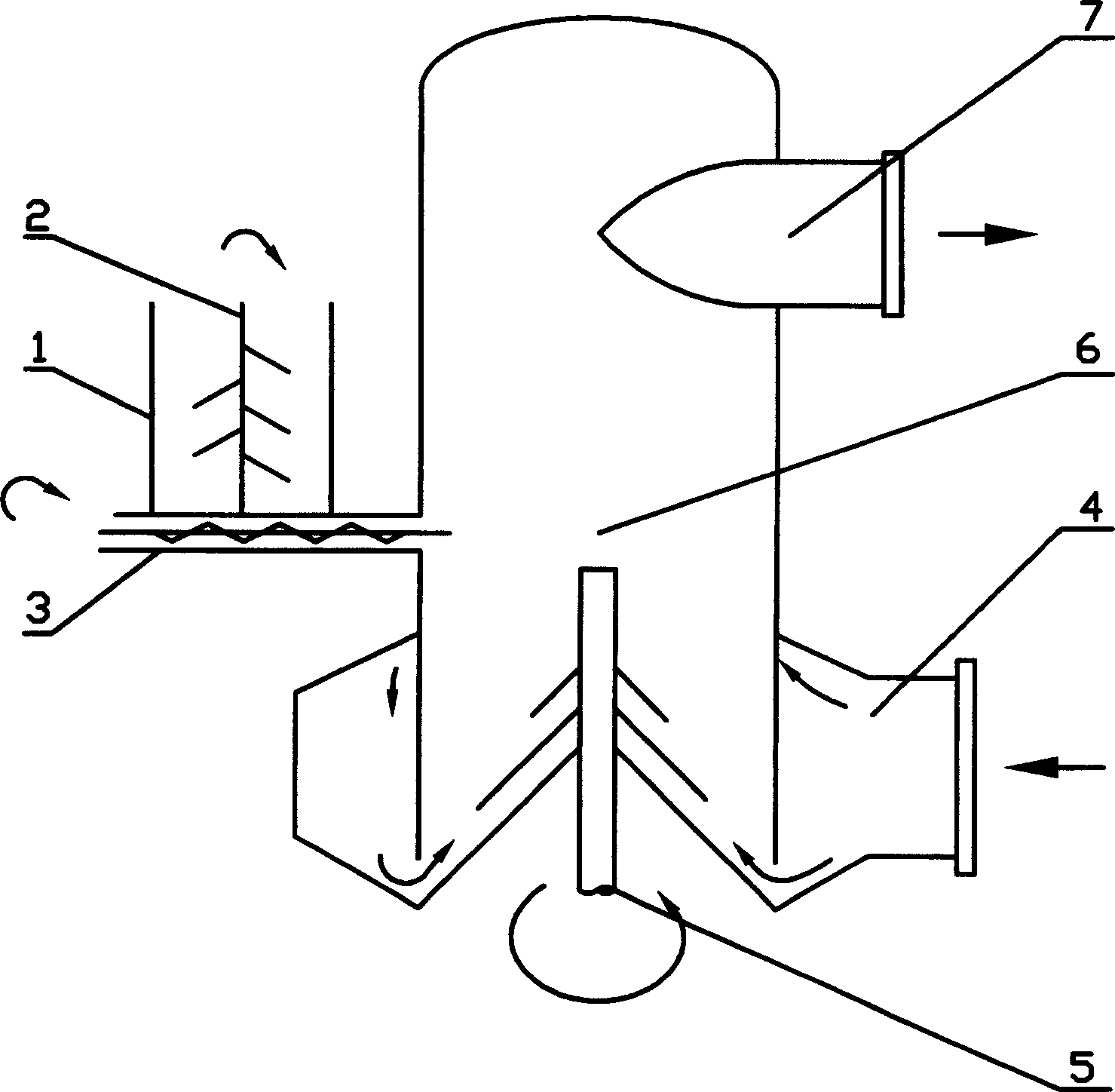

[0034] see figure 1 , The spin flash dryer is a combination of fluidized bed drying and airflow drying, and it is realized in one drying device. The spin flash dryer is suitable for drying powdery and filter cake materials. However, except for our company, there is no application performance of spin flash dryers in solid sodium cyanide manufacturers.

[0035] Its working principle is: the filter cake (or wet powder) is transported to the hopper 1 by the previous process, and is carried to the screw conveyor 3 by the agitator 2, which pushes the filter cake (or wet powder) to the In drying chamber 6. A lower agitator 5 is installed in the lower part of the drying chamber to promote the fluidization of the filter cake (or wet powder).

[0036] The preheated fresh air enters the drying chamber through the gas distributor 4. The hot air rotates and flows upwards, and under the joint action of the lower agitator, the filter cake (or wet powder) is dispersed, fluidized or dried,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com