Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

381results about How to "Reduce cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

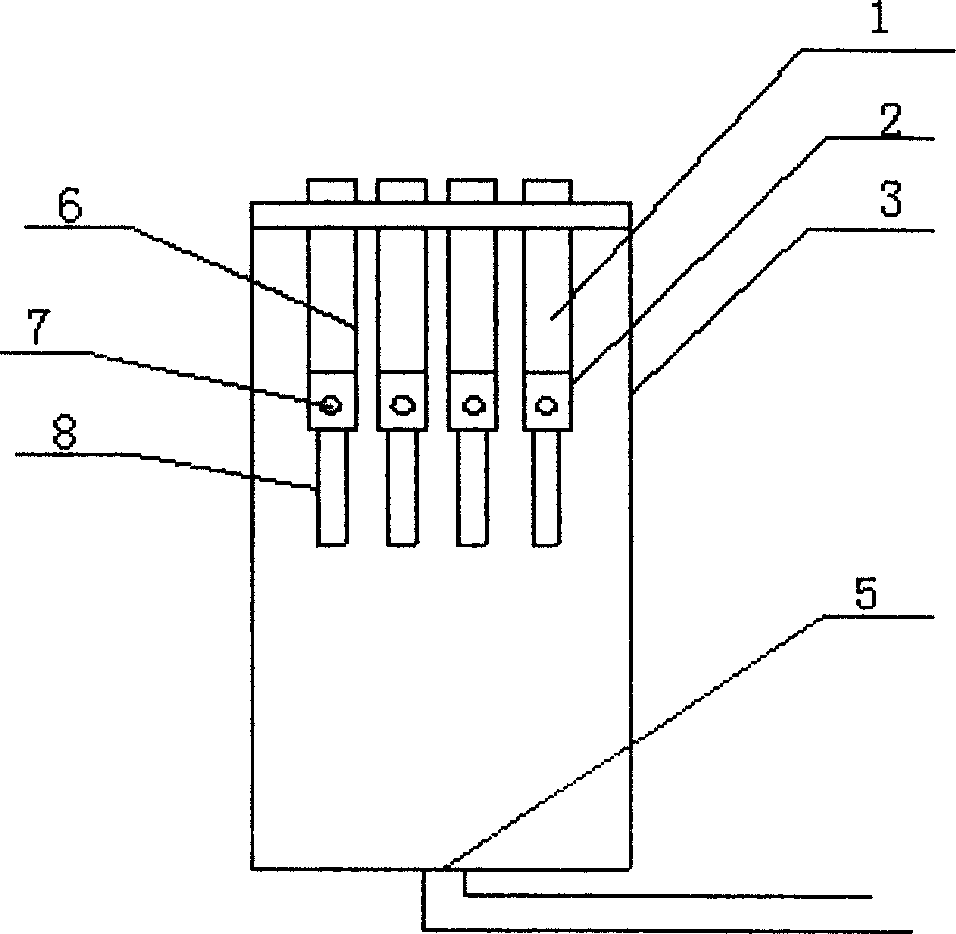

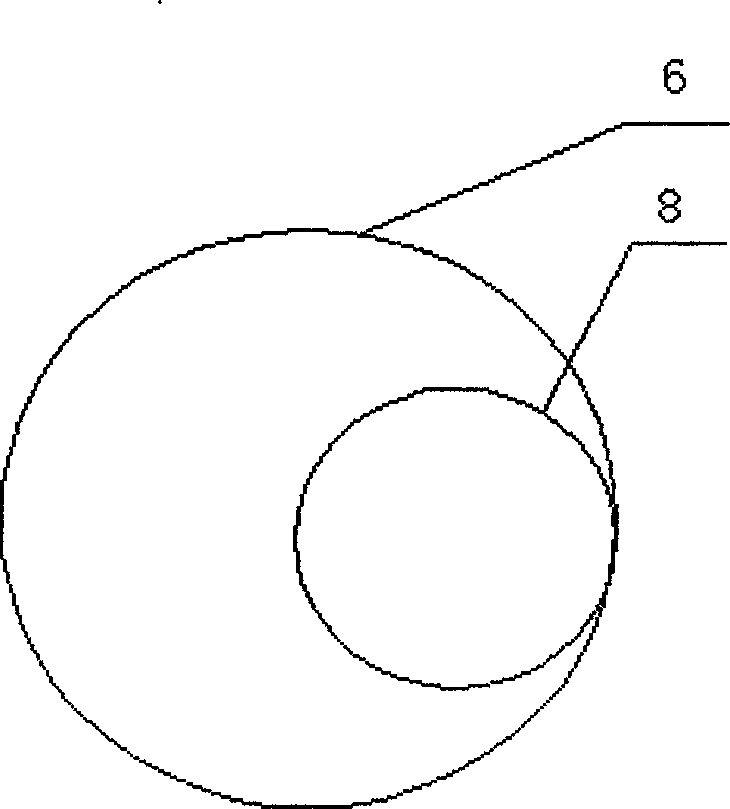

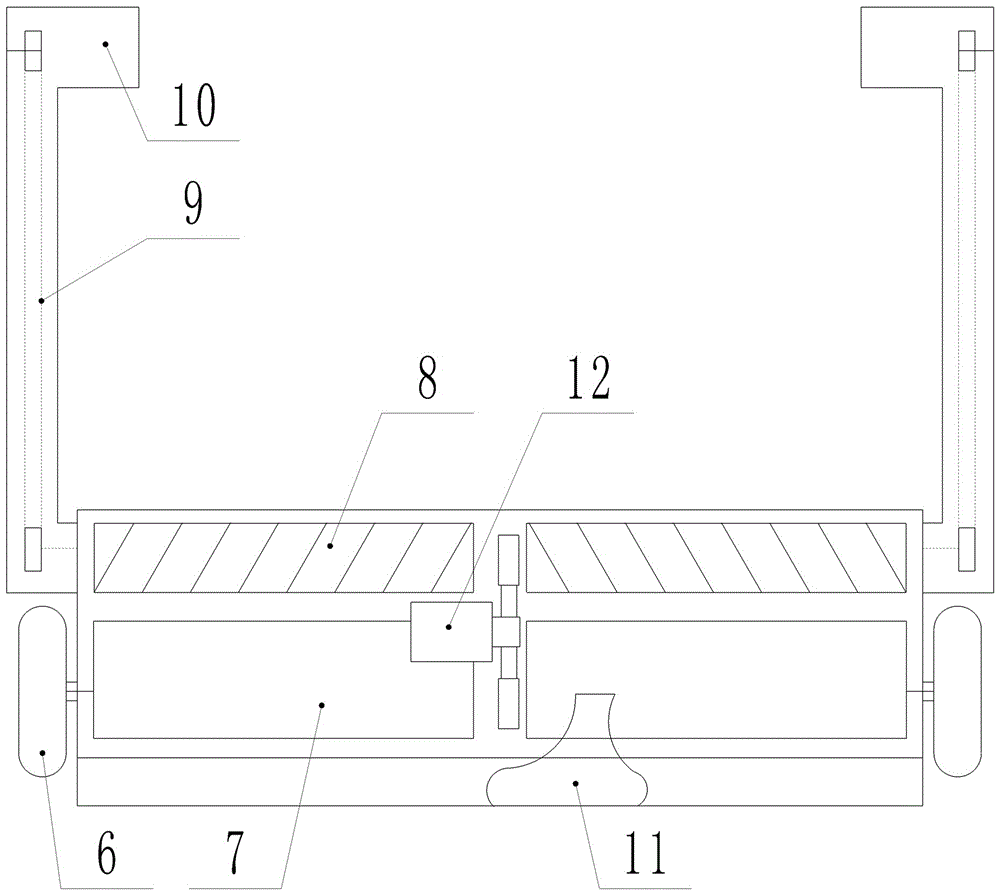

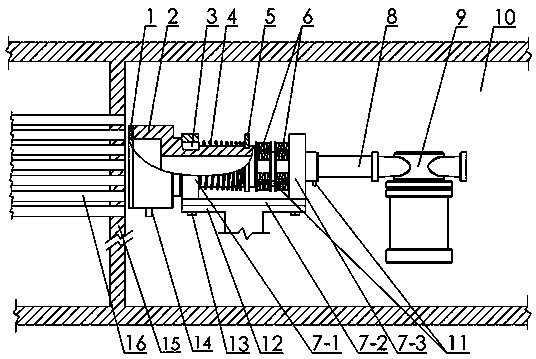

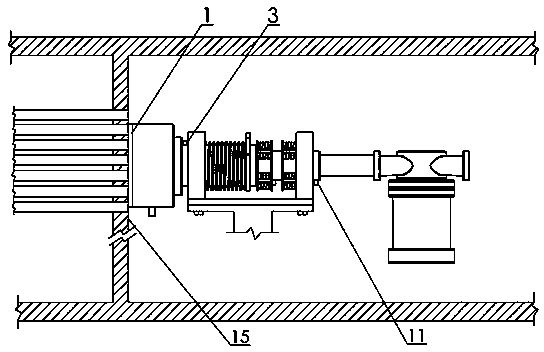

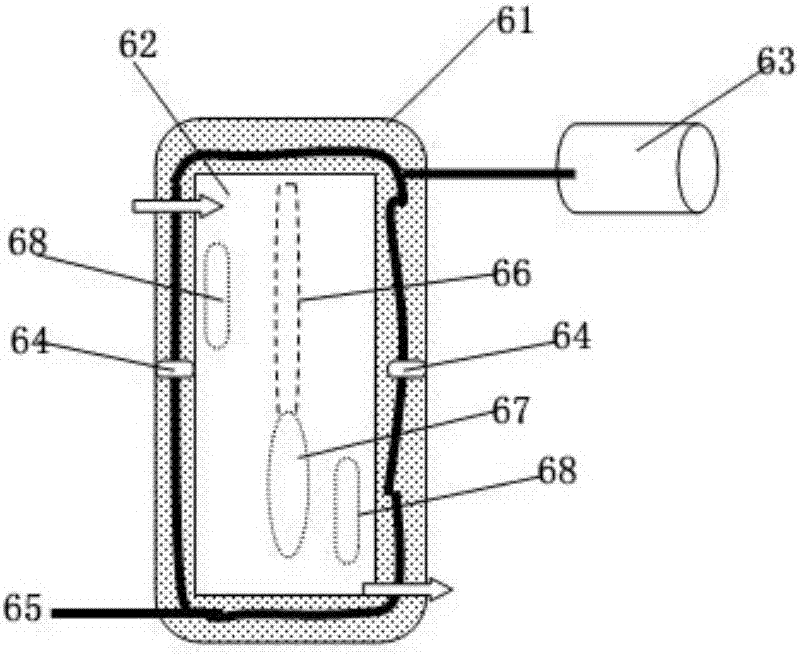

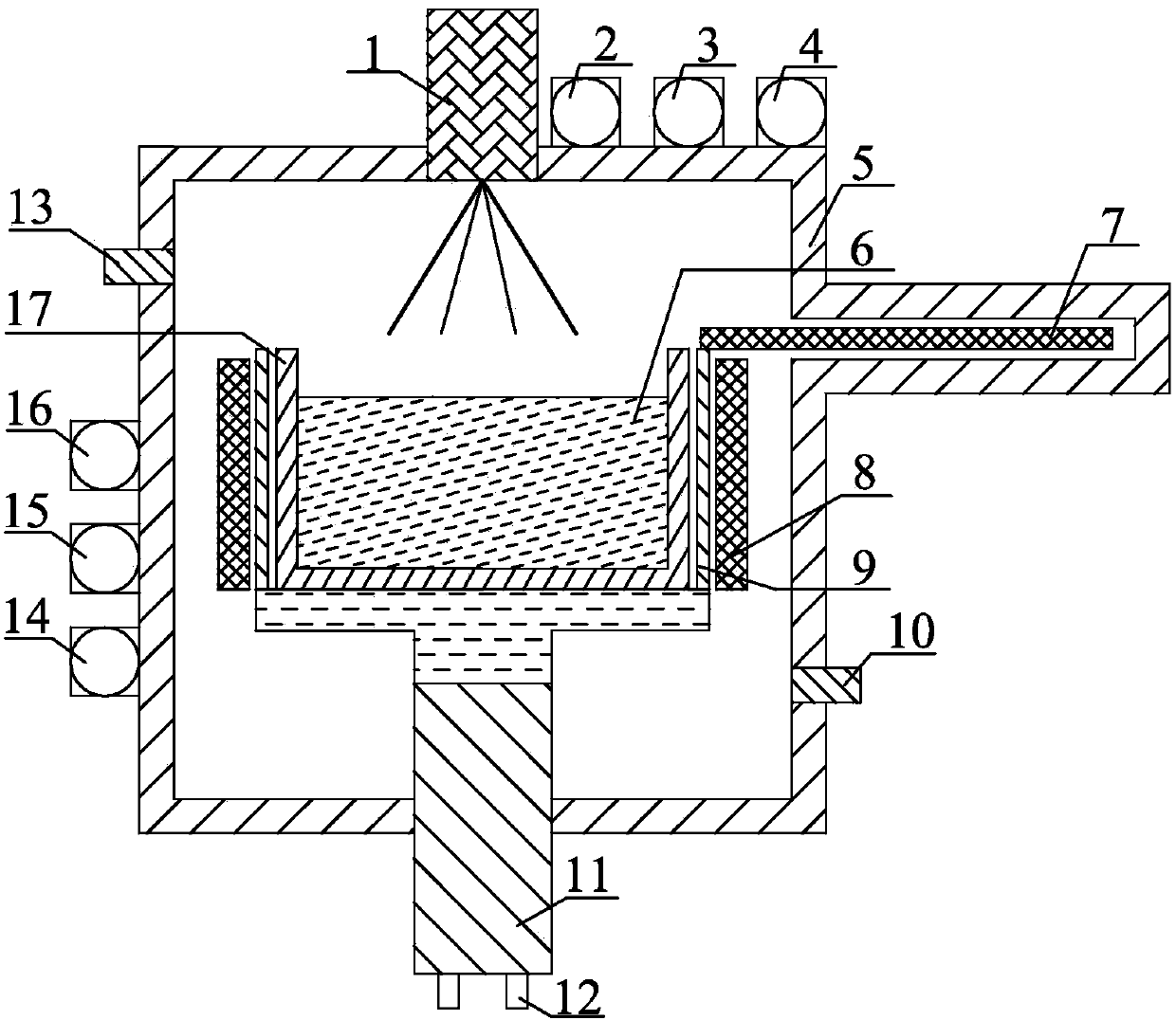

Filter element replacing device and method and fresh air fan

ActiveCN103983002AAvoid secondary pollutionReduce manual replacementLighting and heating apparatusSpace heating and ventilation detailsAir filtrationAir filter

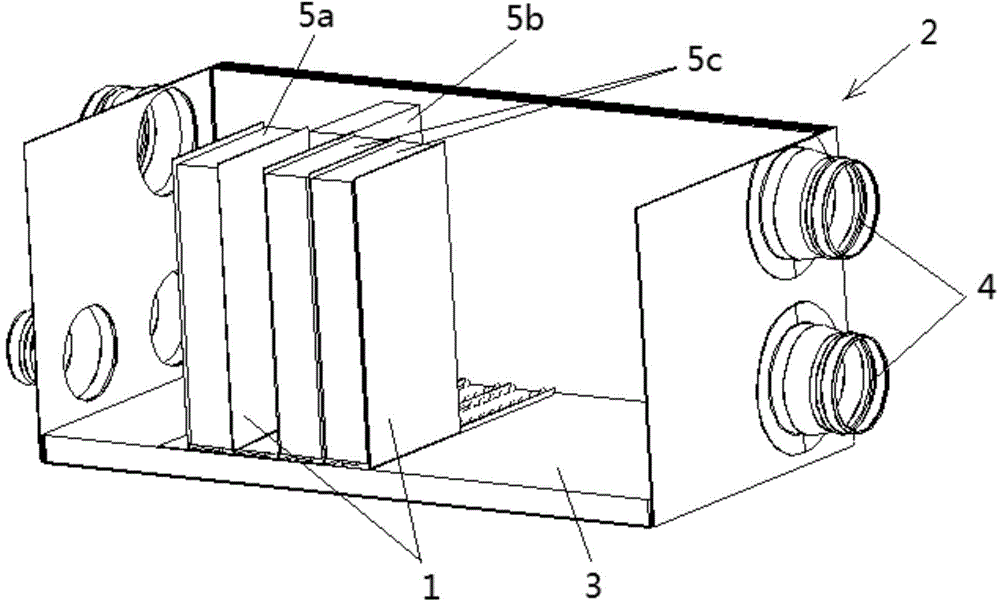

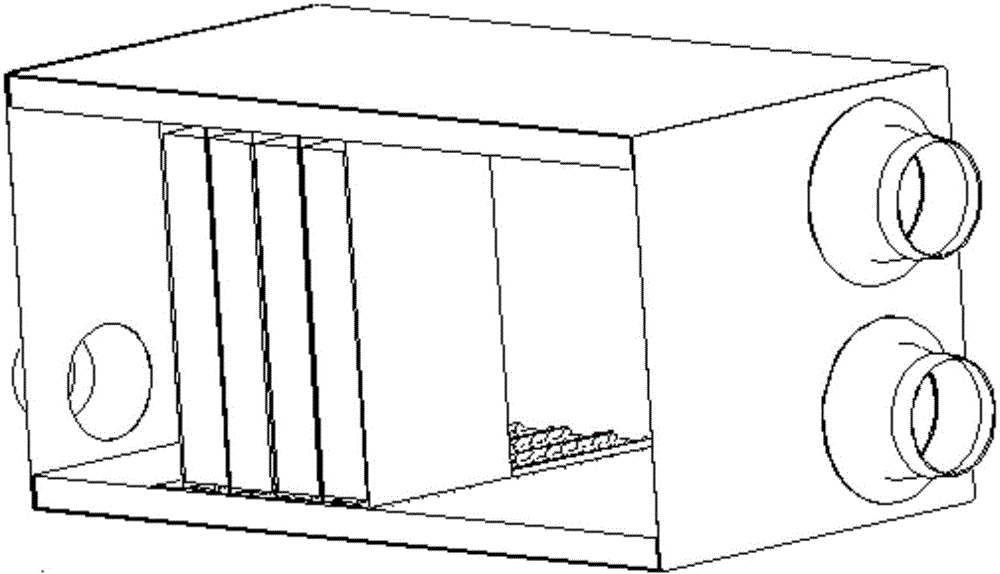

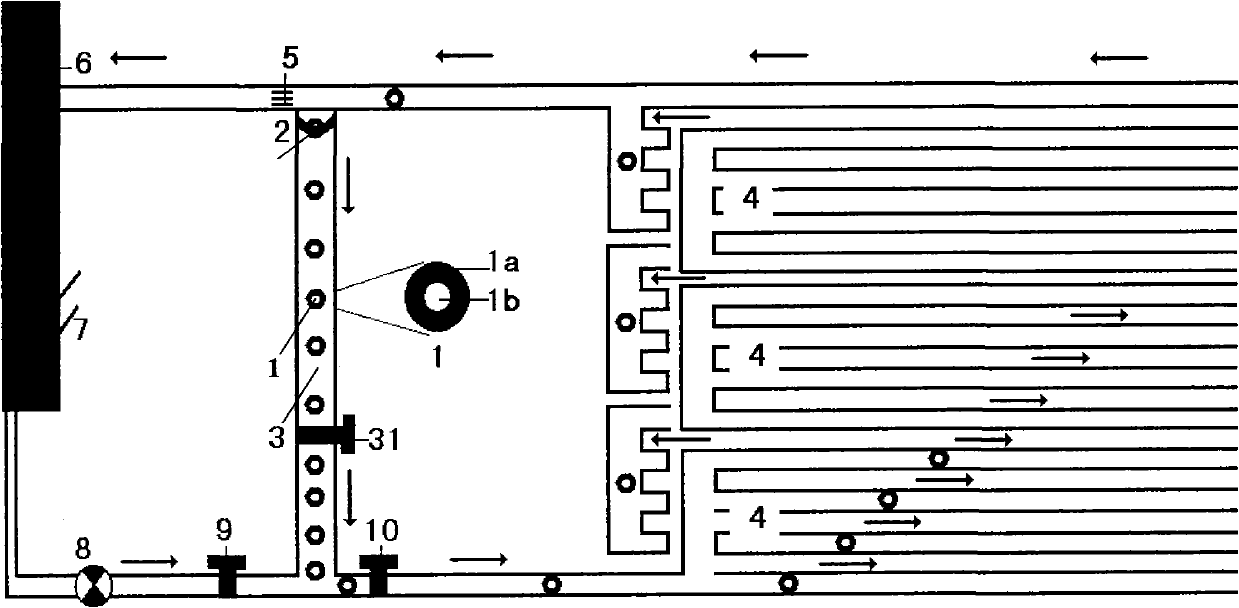

The invention relates to a filter element replacing device and method and a fresh air fan. The device comprises a filter element storage mechanism capable of accommodating at least two filter elements, and a power supply mechanism for driving a new filter element from the filter element storage mechanism to a working position and driving a filter element to be replaced to retract from the working position to the filter element storage mechanism. The filter element storage mechanism comprises a plurality of partition boards which are not smaller than the filter elements in size, and the partition boards enclose accommodating areas for accommodating the filter elements and separate the neighboring filter elements from one another. According to the filter element replacing device, the partition boards enclose the accommodating areas for accommodating the new filter elements and the old filter elements and separate the neighboring filter elements from one another, so that secondary pollution of pollutant particles on the old filter elements to the new filter elements due to the fact that the new filter elements and the old filter elements move close to each other; the power supply mechanism can convey the unused new filter element to the working position for performing air filtering operation and meanwhile convey the old filter element to be replaced back to the filter element storage mechanism for storage, so that the number of times for manual replacement and filter element cleaning can be reduced, and users can be worry-free and relieved.

Owner:GREE ELECTRIC APPLIANCES INC

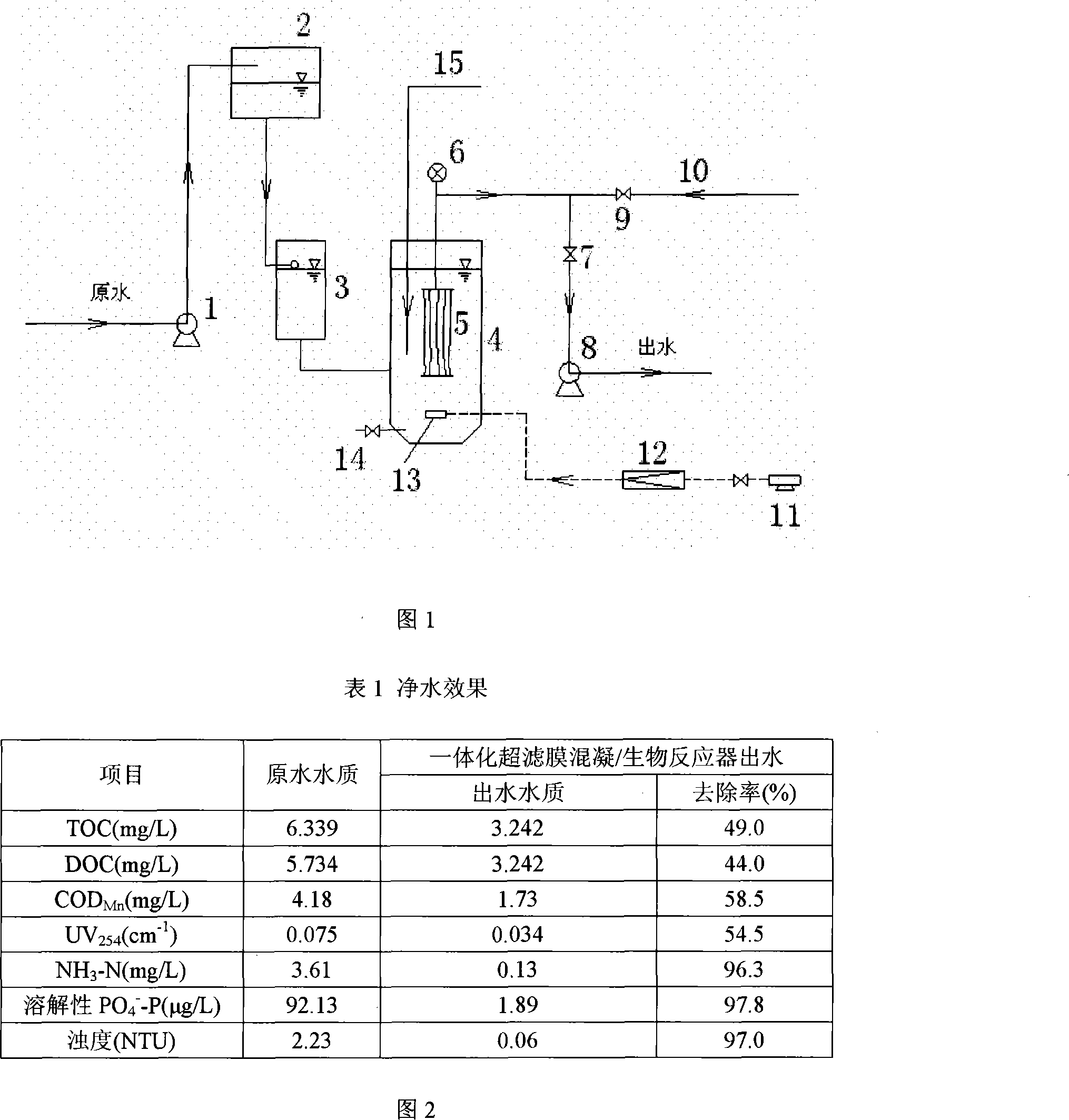

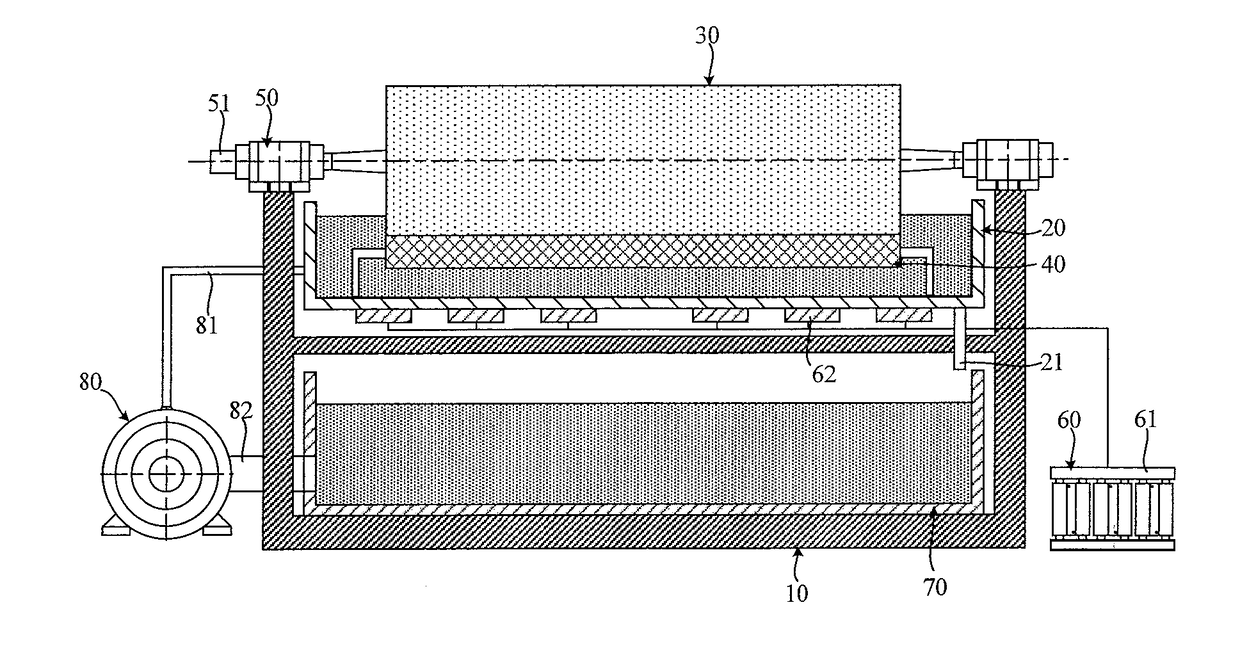

Integrated water purification processing method and device of ultrafiltration membrane coagulation/bioreactor

InactiveCN101219847AImprove water qualityReduce engineering cost and operating costUltrafiltrationMultistage water/sewage treatmentUltrafiltrationChemistry

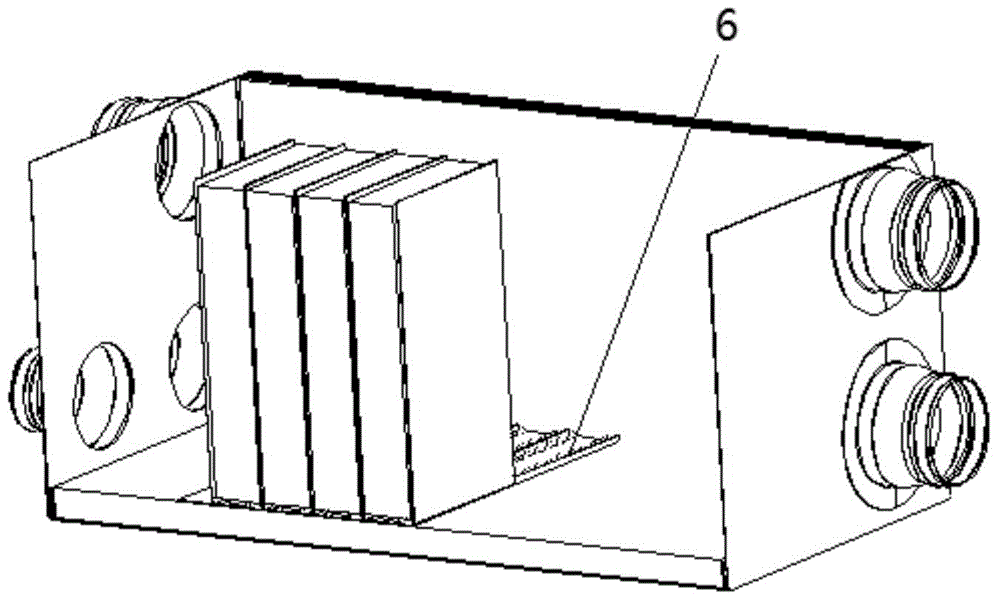

The invention discloses an integrated water treatment method of ultrafiltration membrane coagulation / biological reactor and a device thereof. The invention, the coagulation, and the biological reaction is combined and completed in a same reaction cell. Raw water enters the ultrafiltration membrane coagulation / biological reactor; activated sludge microorganism in the reactor biologically degrades ammonia nitrogen and organic matters with low molecular weight in the water; a coagulant adding system adds coagulant and adsorbent in the reactor to remove the organic matters with high molecular weight and phosphorus; at last, the immersion ultrafiltration membrane components arranged in the reactor carries out the solid-liquid separation to prepare drinking water with excellent quality. A perforated aeration pipe is arranged on the lower part of the reactor to be connected with a sludge discharge pip to discharge the residual sludge in the reactor regularly. In order to ensure the membrane flux, a membrane reverse washing system carries out the reverse washing for the ultrafiltration membrane components regularly. The invention combines the coagulation effect and the biological effect with the ultrafiltration physical interception effect so that the manufacturing cost and the operation cost are remarkably reduced, while the invention is a novel advanced purification process of the drinking water with the advantages of high efficiency, energy saving, convenient maintenance and management.

Owner:HARBIN INST OF TECH

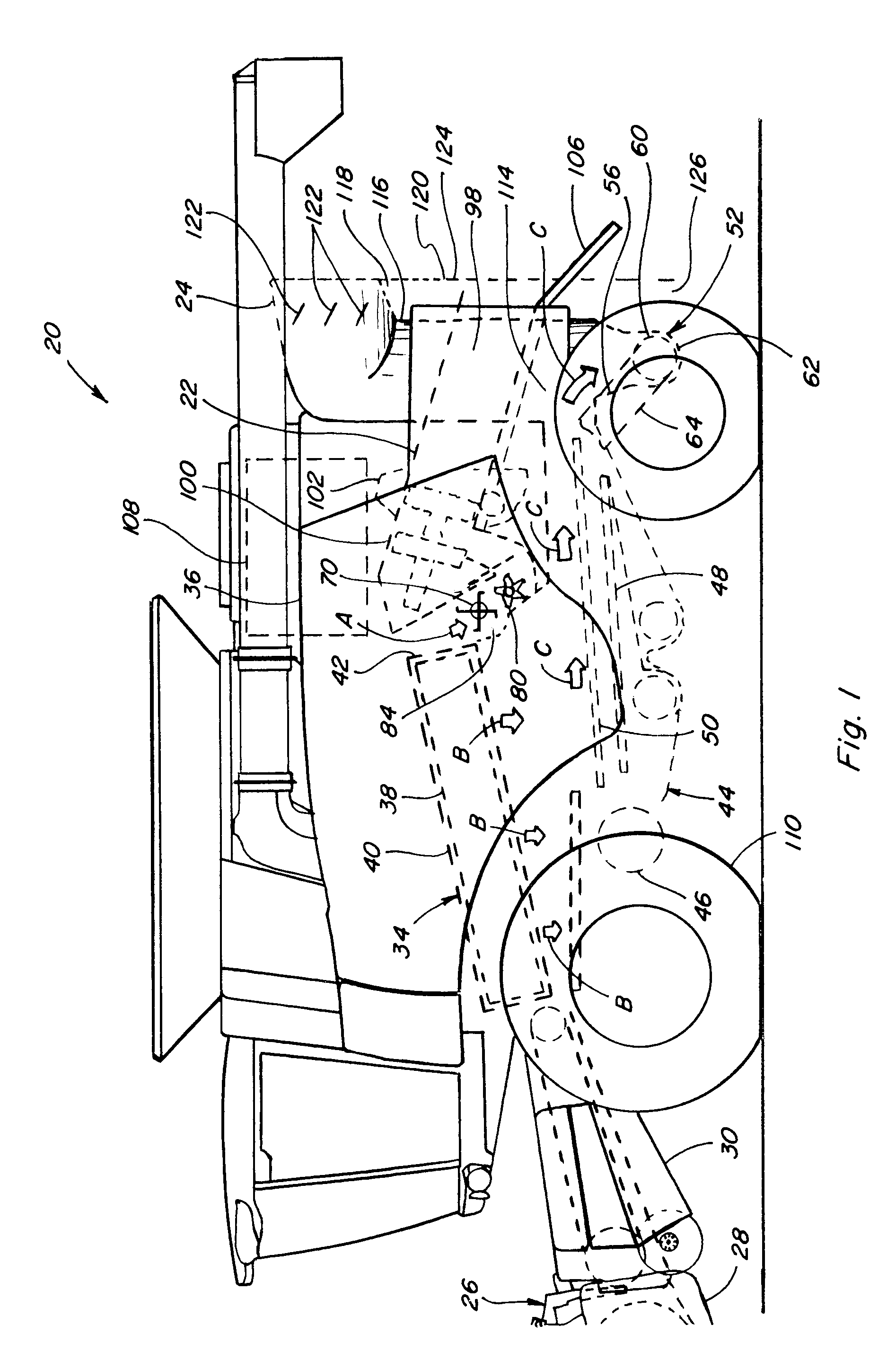

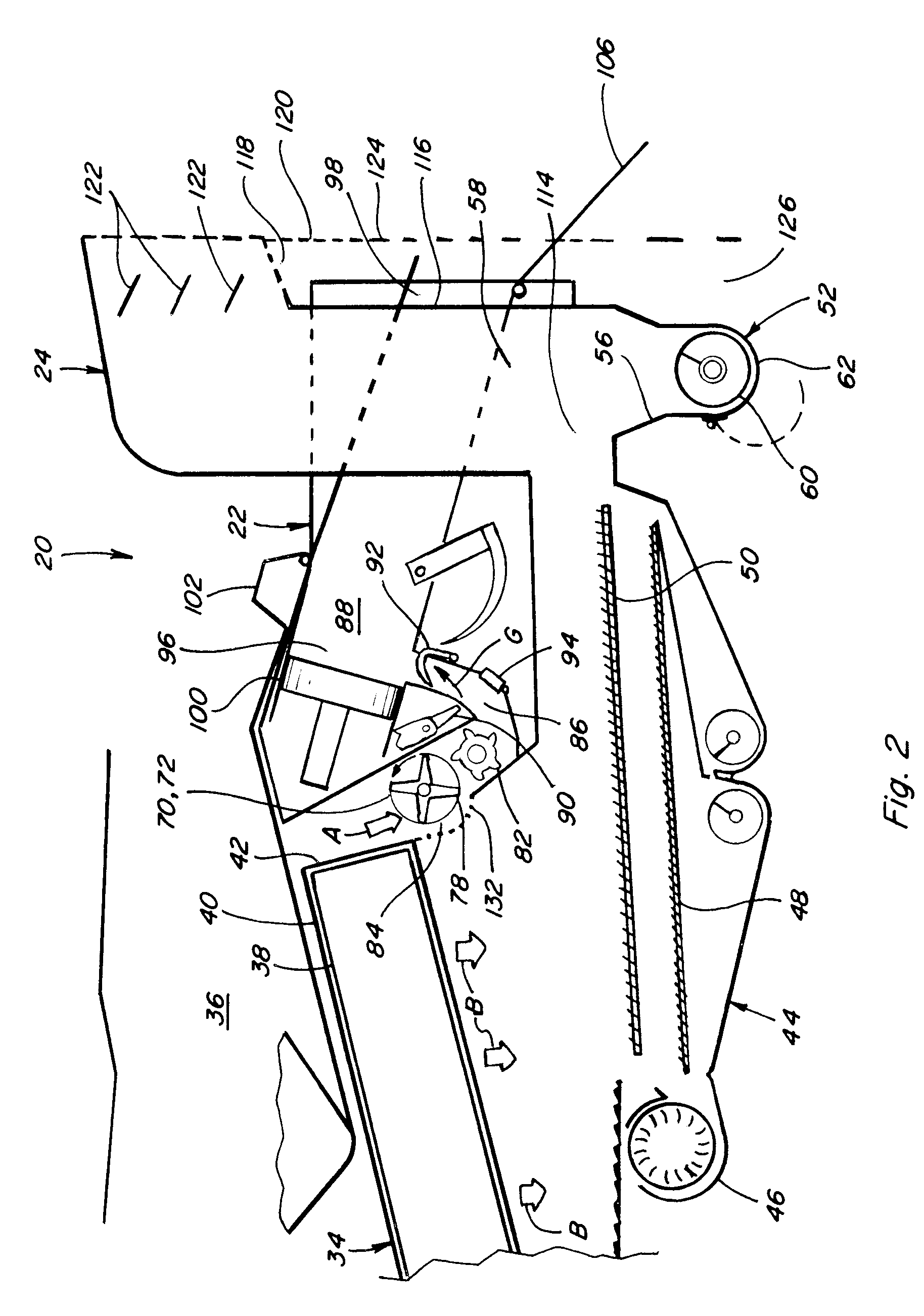

Agricultural combine with on-board baler and dust suppression capability

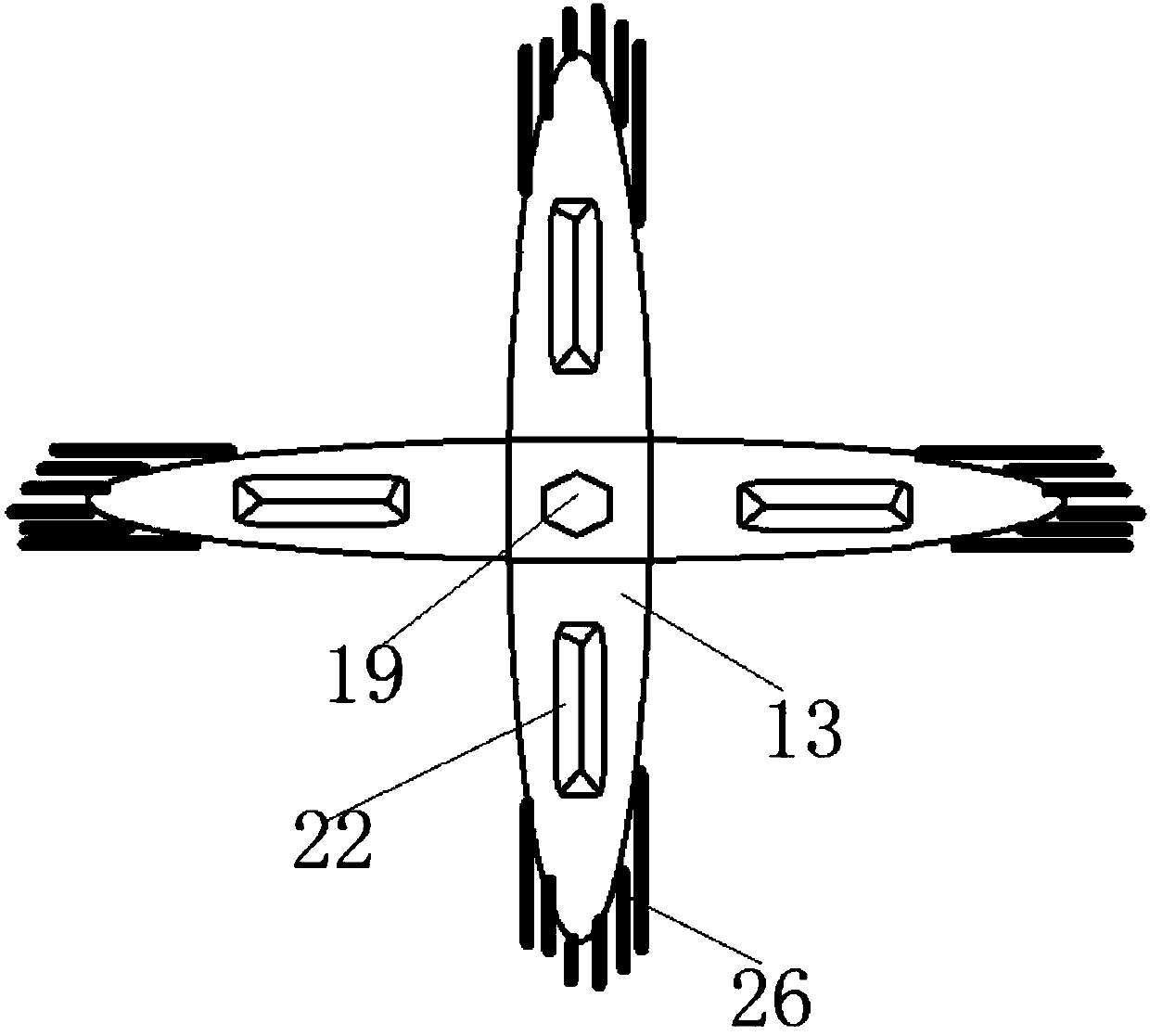

A self-propelled agricultural combine having a capability for baling crop residue produced by operation of the combine, including chaff from the cleaning system. The combine can also incorporate a dust suppression capability. The crop residue produced by threshing is in a compressed state, and is routed directly to a baler of the combine is essentially a continuous, compressed stream, while still in that state, and the chaff is mixed in before compaction into the bales. The dust suppression apparatus uses air flow of a cleaning system of the combine, to carry the dust and separates the air such that the dust will fall from the combine.

Owner:BLUE LEAF I P INC

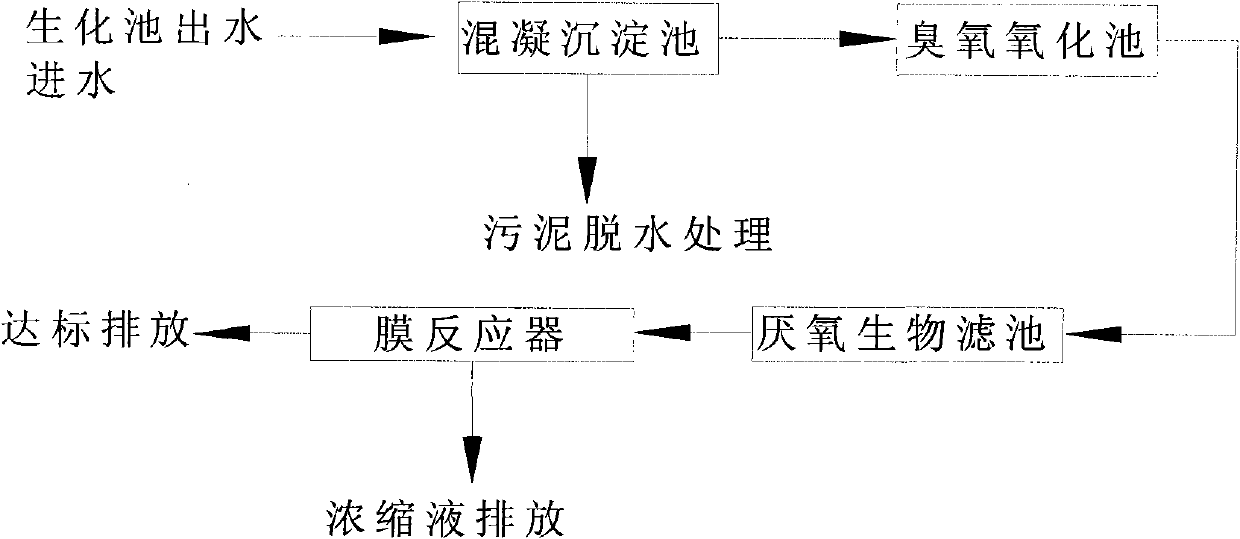

Deep treatment process of landfill leachate

ActiveCN102086075ALow priceLow costWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesSeparation technologyBiological filter

The invention relates to a deep treatment process of landfill leachate. The effluent of landfill leachate subjected to biochemical treatment is used as influent. The process adopts a coagulative precipitation tank, an oxidation tank, an anaerobic biological filter and a membrane treatment device and comprises the following steps of: (1) removing partial organic matter through coagulative precipitation to reduce chroma; (2) further removing refractory and non-biochemical organic matter with an oxidizer formed by ozone, and the like and improving the biodegradability of the effluent; (3) removing SS (Suspended Solid), organic matter and nitrate in the leachate through an anaerobic filter; and (4) ensuring that the effluent stability of the whole system through a membrane separation technology reaches the emission standard and canbe recyclable. The process has the advantages of lower operation cost, stable effluent, less quantity of generated concentrated liquid, less salt content in theconcentrated liquid, and the like, and the process of biochemistry and materialization of the pretreatment, which is used before using the membrane method, can prolong the service life of the membrane.

Owner:BMEI

Acid functional phosphorus-containing polyester powder compositions and powder coatings made therefrom

ActiveUS20070260003A1Improve adhesionIncrease resistanceSynthetic resin layered productsPowdery paintsPhosphoric acidPre treatment

The present invention provides storage stable powder compositions comprising one or more acid functional, phosphorus-containing polyester chosen from aromatic polyesters having an acid number of 15 or higher mg KOH / g polyester, aliphatic polyesters having an acid number of 20 or higher mg KOH / g polyester. The acid functional, phosphorus-containing polyester comprises the reaction product of one or more polyacid, one or more phosphorus-containing acid or salt thereof and one or more polyol. Preferably, the one or more polyol reactant contains no β-hydrogen such as, for example, neopentyl glycol (NPG). The acid functional, phosphorus-containing polyester may comprise all or part of a binder powder composition, such as a coating powder, or it may comprise an additive thereto that imparts improved pigment wetting and corrosion resistance to a binder composition Further, the composition may comprise one or more curing agent, such as hydroxyalkylamide (HAA) or epoxy resin. In addition, the invention provides coated substrates made from the powder composition, such as coated steel, aluminum, pretreated steel, and pretreated aluminum.

Owner:COVESTRO NETHERLANDS BV

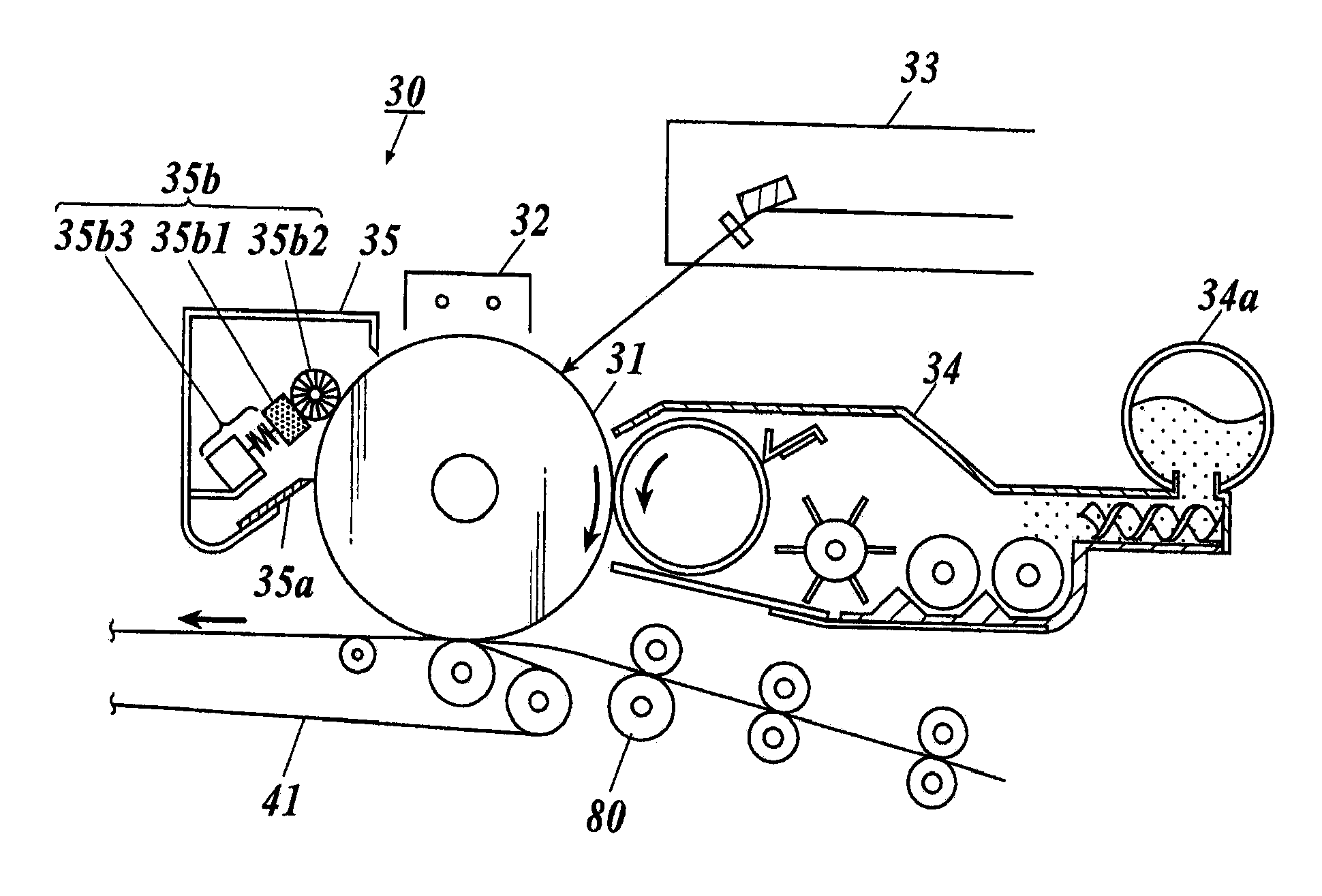

Method for manufacturing interdental cleaning device

Provided is a method for manufacturing an interdental cleaning device (1) including a base portion (10) having a handle portion (11) and a core portion (12); and a soft portion (20) having a cleaning soft portion (21), a non-slip portion (22), and connecting portions (23) extending from two sites of the non-slip portion (22) and being connected to the cleaning soft portion (21). The method includes causing a second gate (49) of second molds (40) and (41) for molding the soft portion (20) to open at a position substantially equally distant from positions of two communicating openings (48a) of a non-slip molding space (47) for molding the non-slip portion (22), the two communicating openings (48a) communicating with connecting portion molding spaces (48) for molding the connecting portions (23); and charging the elastomeric material from the second gate (49) into a second molding space (42) for molding the soft portion (20) to fill the molding space (42).

Owner:SUNSTAR SUISSE SA

Drinking water deeply purifying method and device

ActiveCN101219848AWater quality impactCraft greenUltrafiltrationMultistage water/sewage treatmentUltrafiltrationChemistry

The invention discloses an advanced purification method for drinking water and a device thereof. The advanced purification process for drinking water is explored aiming at generally existing micro-polluted source water and the process combines a biological activated carbon filter and an ultrafiltration membrane biological reactor to purify the drinking water in an advanced way. After the raw water being treated enters the biological activated filter first, the particulate matters in the water being partly intercepted; pollutants like organic matters and ammonia nitrogen and so on are partly degraded and the water quality is purified to some degree; load of the ultrafiltration membrane biological reactor is reduced; the water in the filter is discharged into the ultrafiltration membrane biological reactor; the activated sludge in the reactor biologically treats the water from the filter and the pollutants ammonia nitrogen and the organic matters in the water are degraded again; at last, the water after two-level biodegradation is drawn form ultrafiltration membrane component by a draw-suck pump and the remarkable effect of removal of particulate matters as well as interception of two insects, daphnia, red worms, alga, bacteria and even virus of the ultrafiltration membrane can be brought into play.Therefore, the safe and clean drinking water with excellent quality can be prepared.

Owner:东营工大水环境技术有限公司

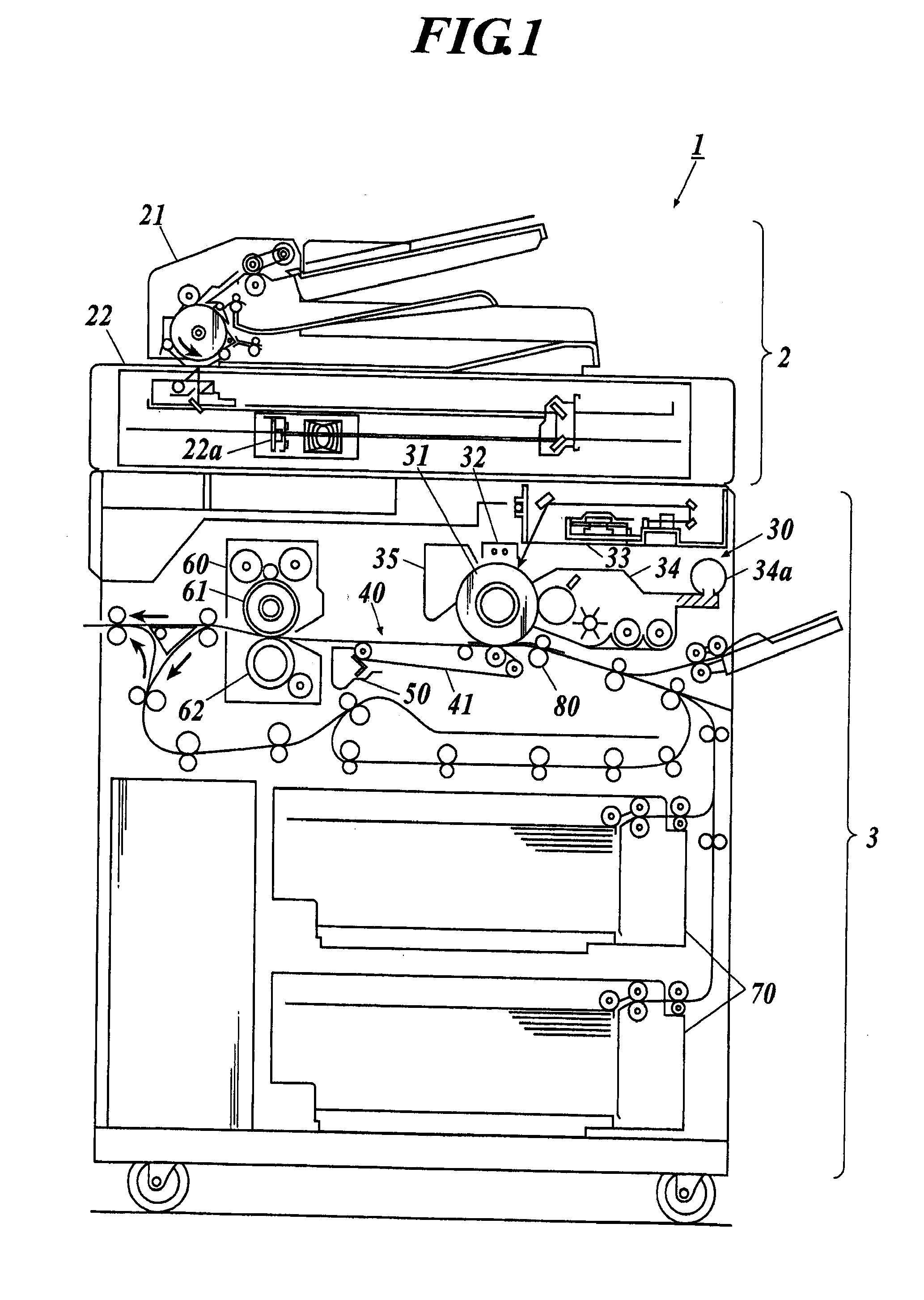

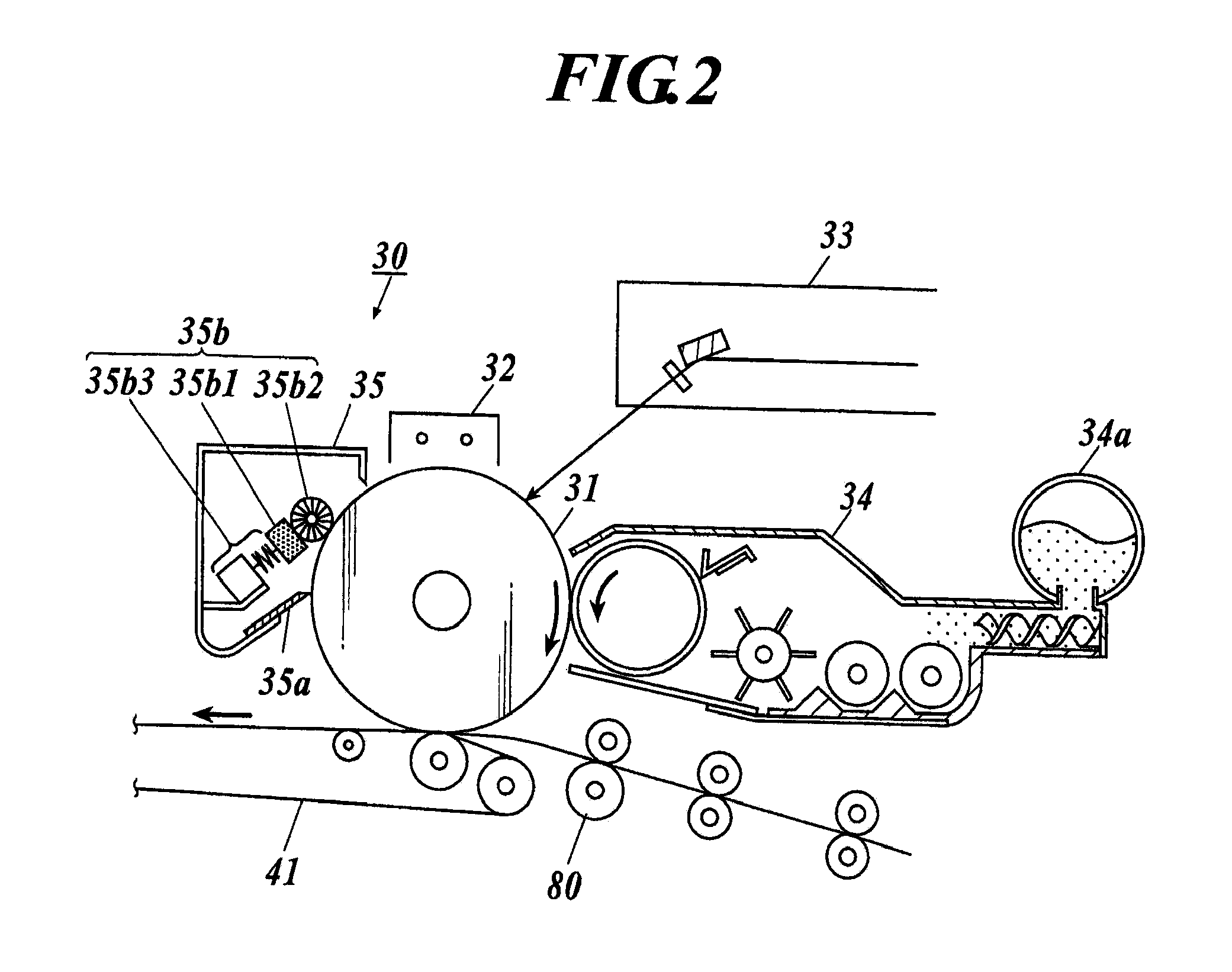

Image forming apparatus and cleaning method

InactiveUS20110268466A1Reduce cleaning effectElectrographic process apparatusImage formationEngineering

An image forming apparatus includes: an image holder on which a toner image is formed; a lubricant applying section which applies a lubricant to the image holder; a torque calculation section which calculates torque of a drive motor which drives the image holder; a cleaning section which cleans the image holder; and a control section which calculates a print rate of the toner image formed on the image holder, makes determination of an adhering lubricant amount of the lubricant adhering to the image holder based on the print rate and the torque, and forms a toner image of a toner forcibly-discharging-pattern or increases an applied lubricant amount of the lubricant applied to the image holder by the lubricant applying section according to the determination.

Owner:KONICA MINOLTA BUSINESS TECH INC

Uniform phase distribution device in liquid contained multiphase fluidized system

A uniform phase-distributing apparatus in the liquid-contained multi-phase fluidizing system where the density of solid phase is higher than that of liquid phase features that the material feeding inlet is arranged on the bottom of case, the sleeve pipe structure consisting of at least two nested pipes is arranged on the top of case, and the predistributor and master distributor are used. Its advantage is stable fluidizing state.

Owner:TIANJIN UNIV

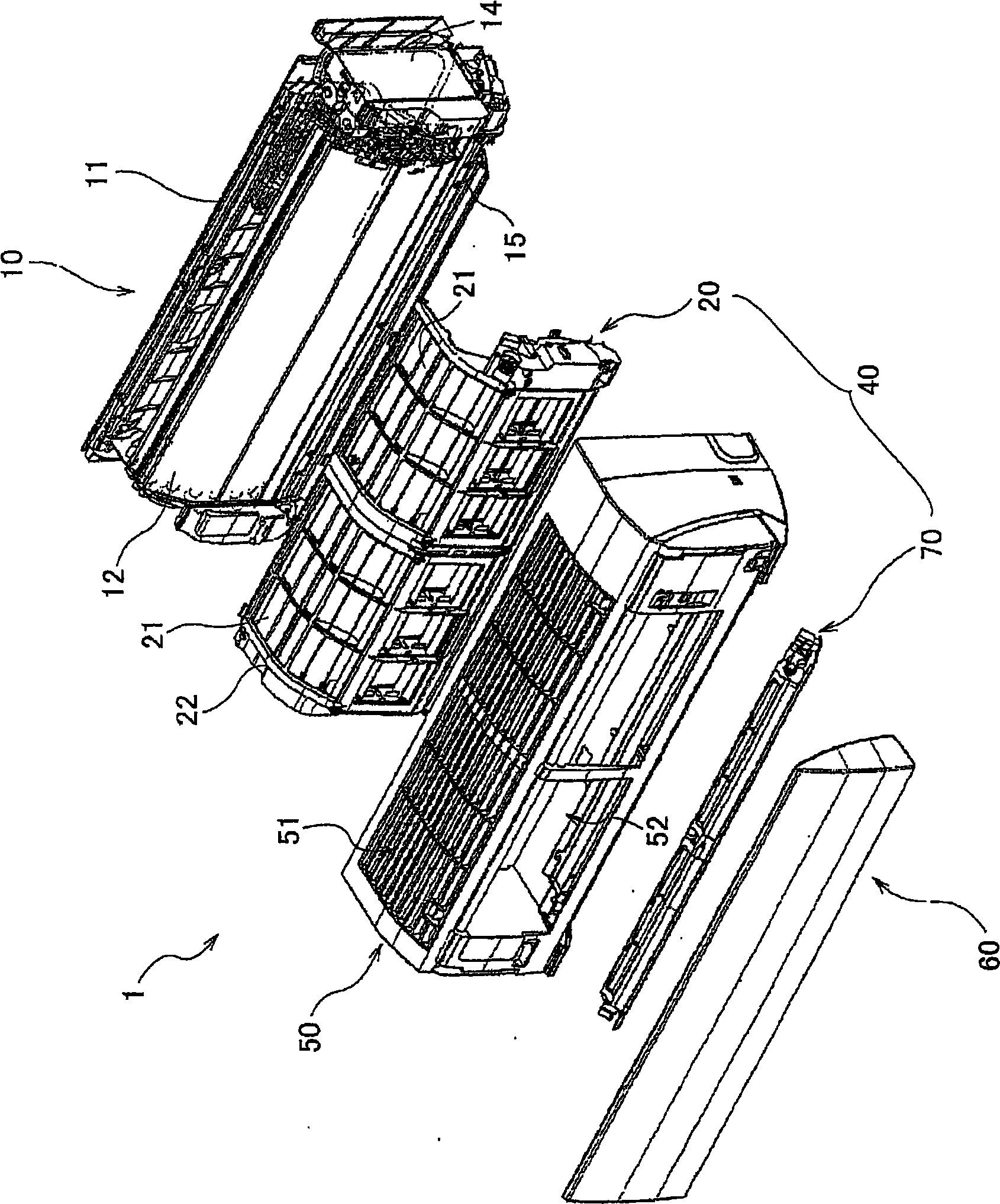

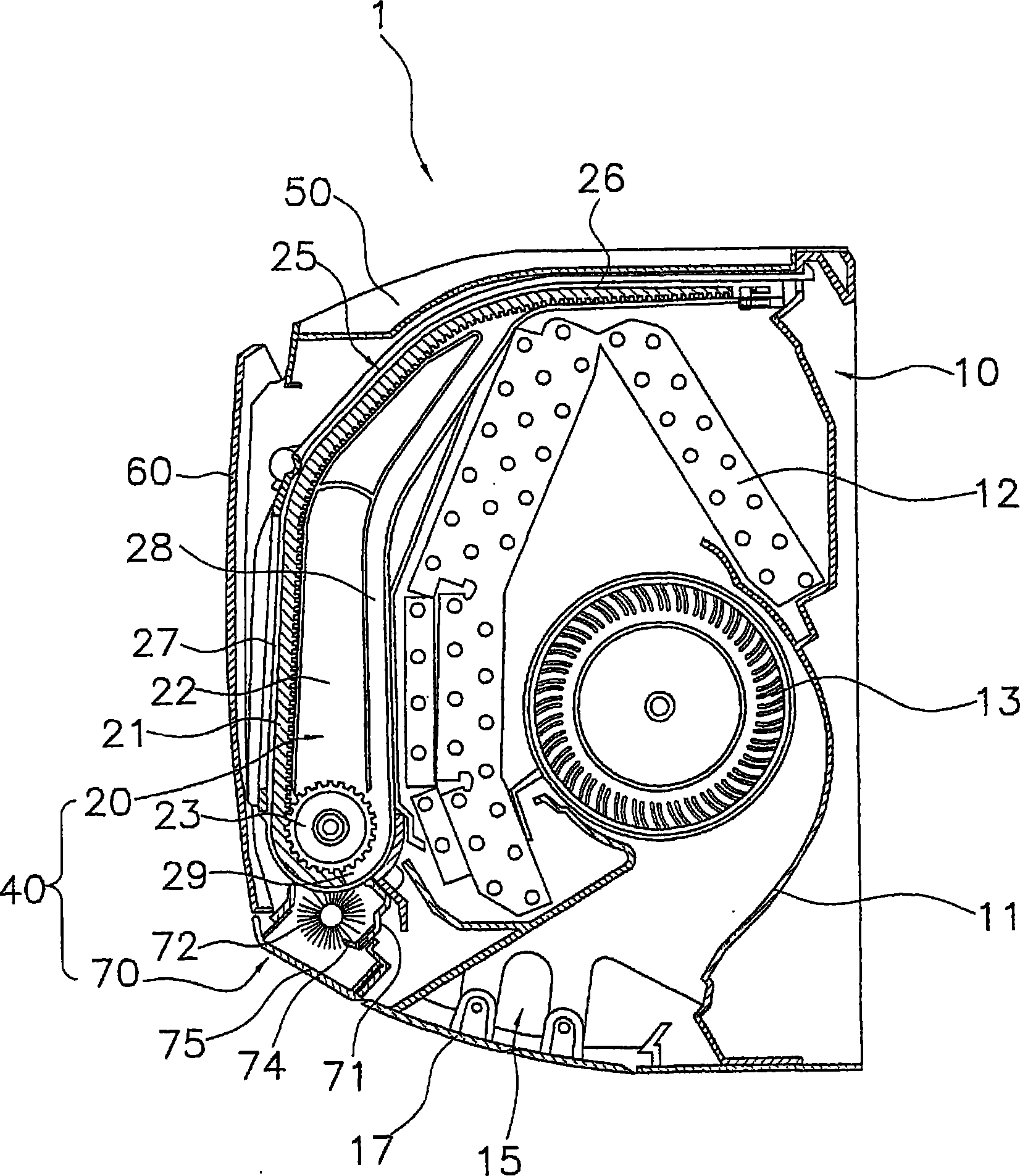

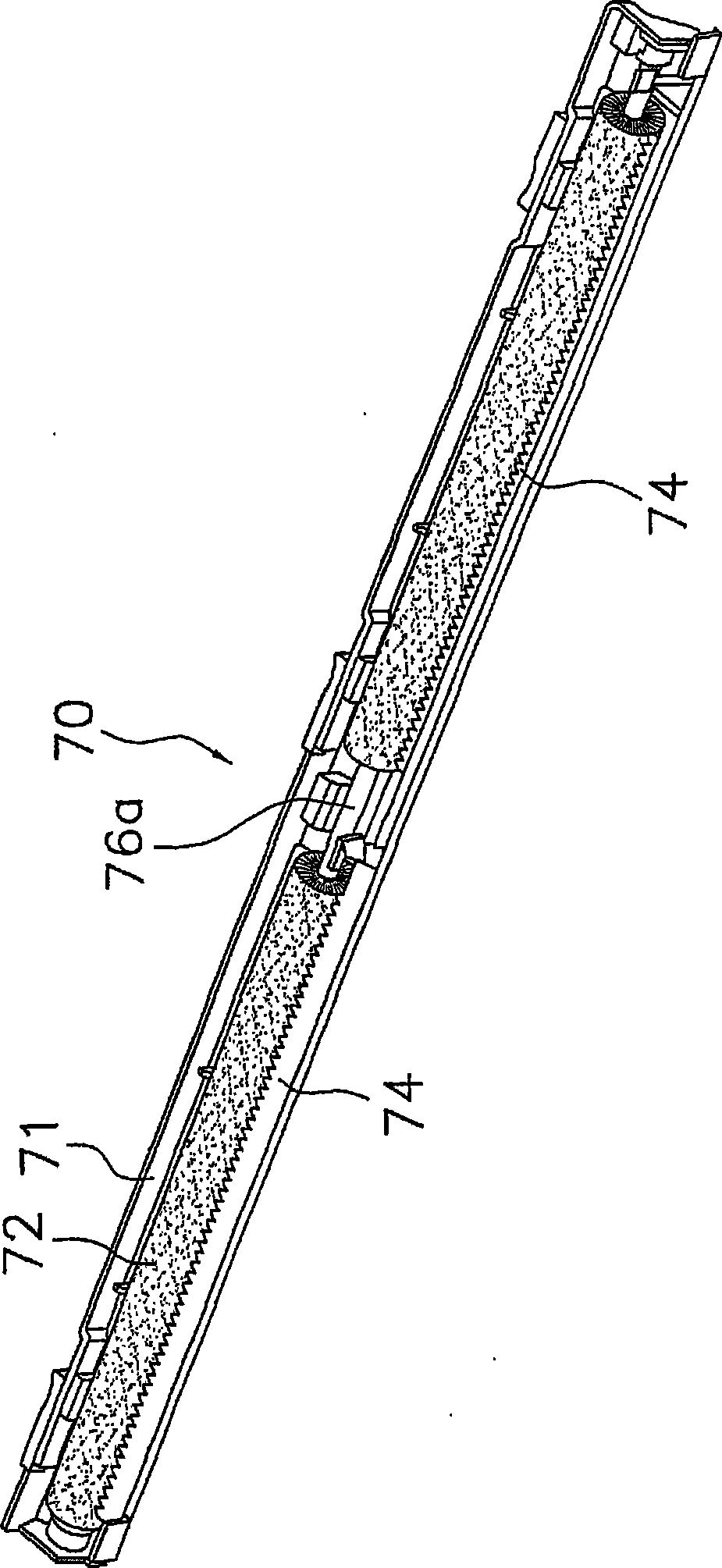

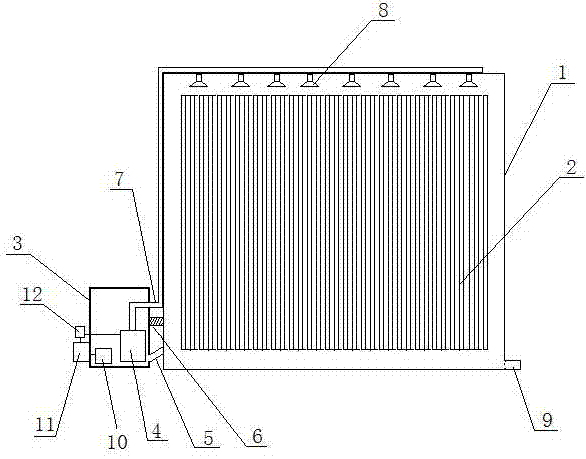

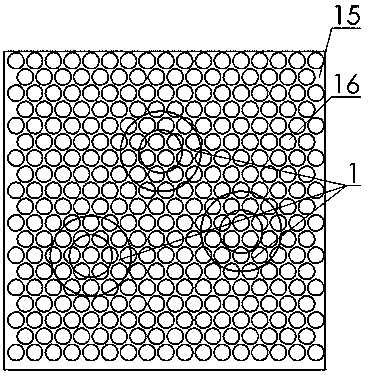

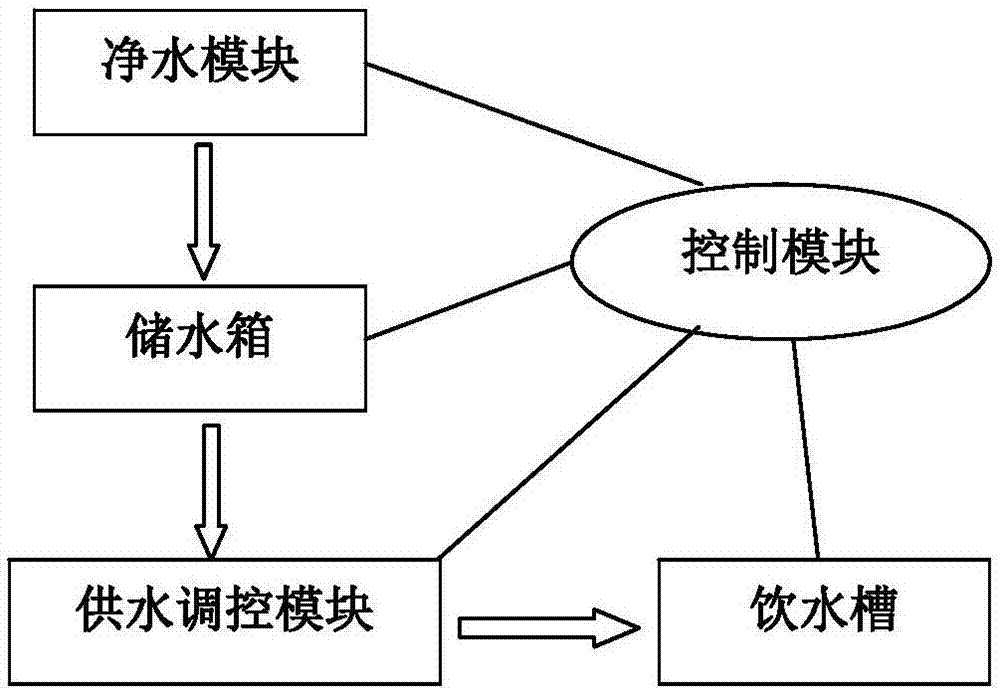

Filter cleaning mechanism for air conditioning apparatus

ActiveCN101548138AHigh densityEasy to handleMechanical apparatusLighting and heating apparatusEngineeringWire rod

Provided are a filter cleaning mechanism by which deterioration of filter cleaning performance can be suppressed, and an air conditioning apparatus. A filter cleaning mechanism (40) for an air conditioning apparatus is provided with a filter (21) for removing dusts from air passing through, a brush section (72), a brush driving section (73), and a brush cleaning section (74). The brush section (72) is provided with a core material (76), and a plurality of wire rods (77) arranged on the circumference of the core material (76), and dusts are removed from the filter (21) by bringing the wire rods (77) into contact with the filter (21). The brush driving section (73) rotates the brush section (72). The brush cleaning section (74) is arranged along the rotating shaft direction of the brush section (72) and has a comb-like shape that makes contact with the brush section (72). The brush cleaning section scrapes out dusts from the brush section (72) by rotating the brush section (72).

Owner:DAIKIN IND LTD

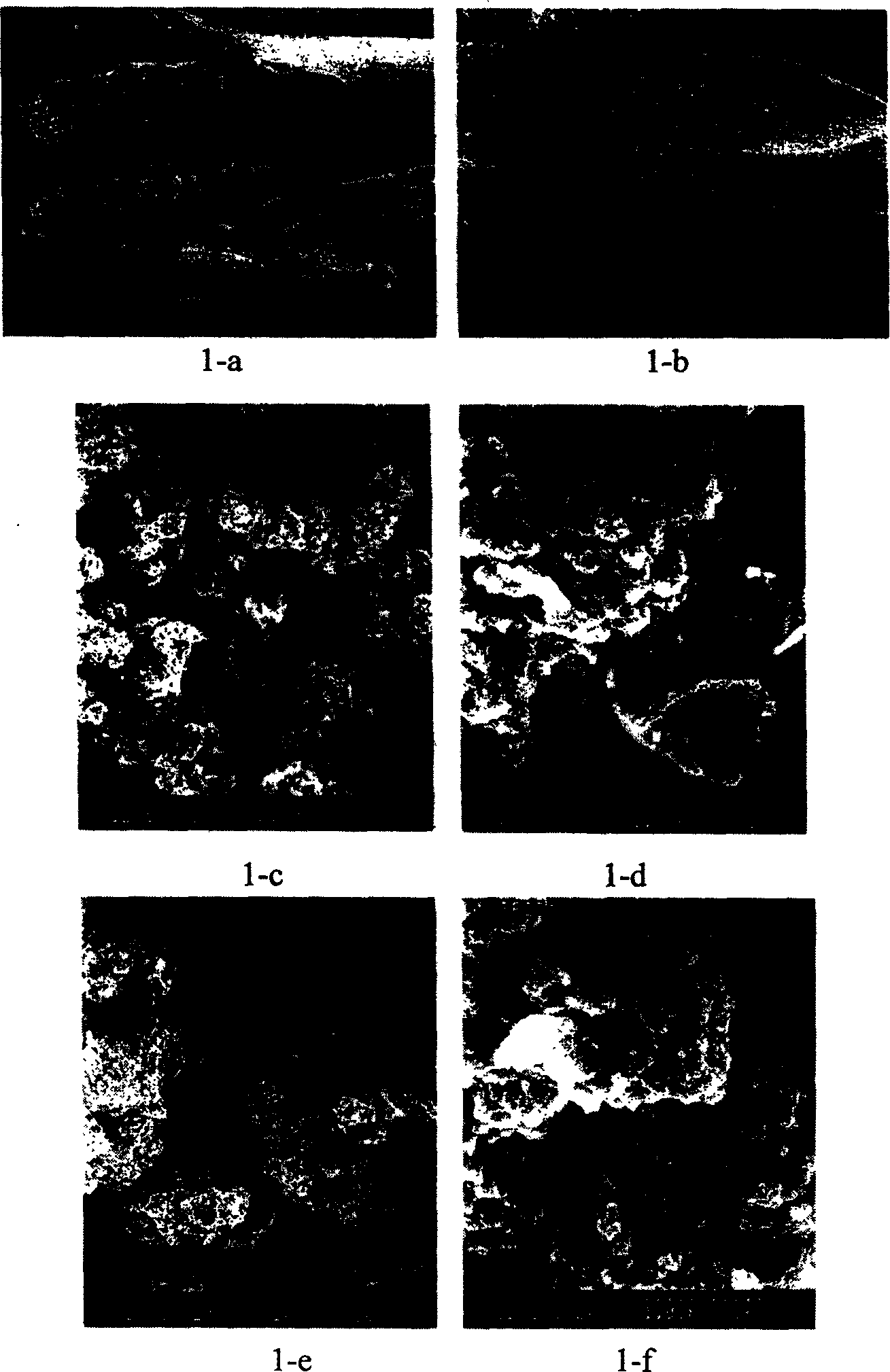

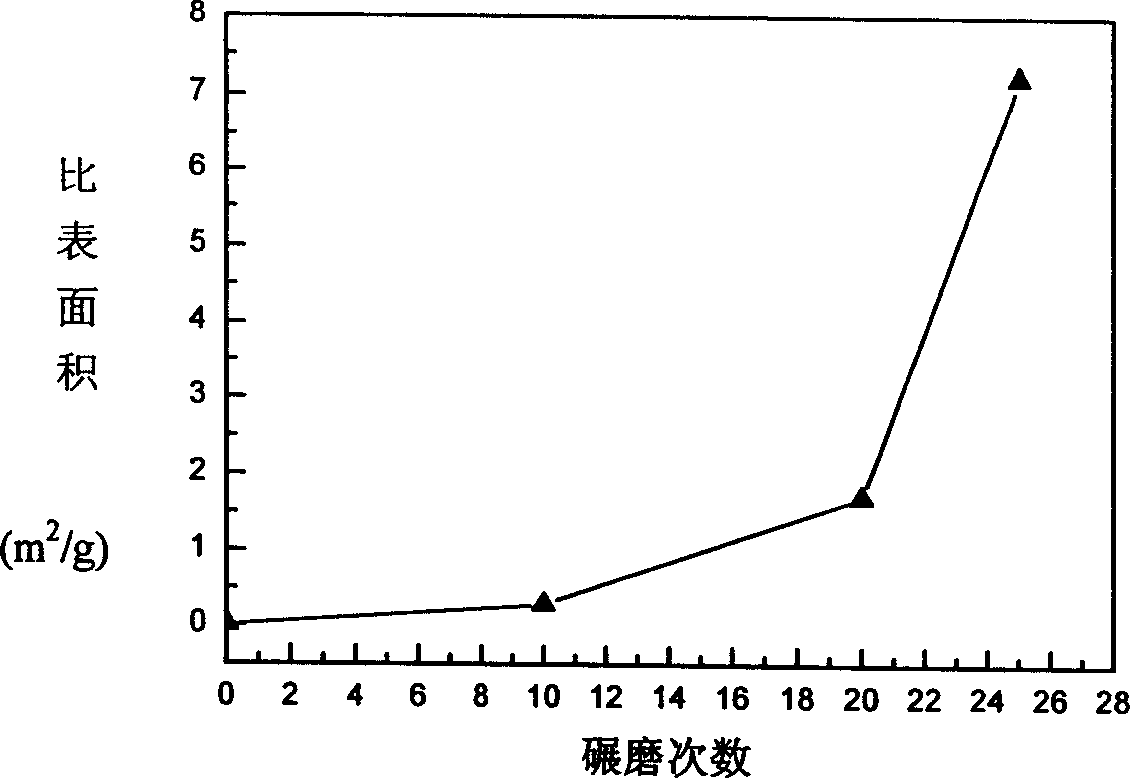

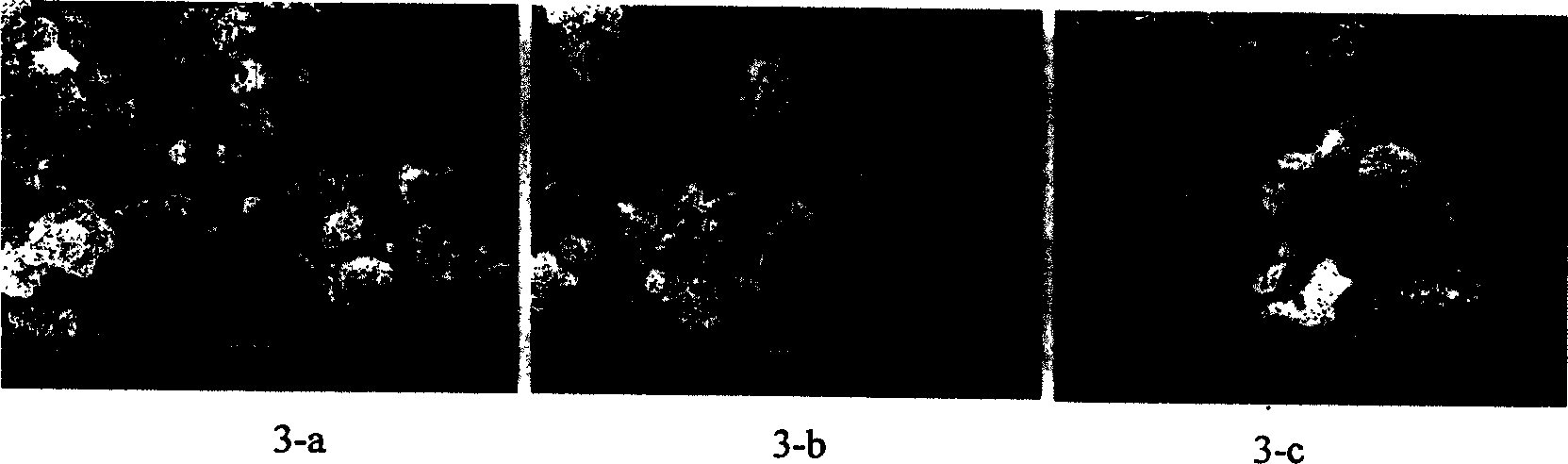

Method of preparation high surface activity rubber powder by waste tyre

ActiveCN1597121AImprove efficiencyReduced cleaning and separation proceduresCocoaGrain treatmentsAsphaltHigh surface

A process for preparing the rubber powder with high surface activity from the used tyre includes such steps as preparing the shreds or particles from used tyre, grinding by the 'millstone-shaped mechanico-chemical reactor' whose application number of Chinese patent is ZL95111258.9, and dispersing. It has high compatibility to polymer / rubber powder composite, asphalt and water-proof coiled material.

Owner:SICHUAN UNIV

Amalgamated dwelling flue purifying and discharging system

The invention provides an amalgamated dwelling flue purifying and discharging system which comprises a vertically arranged centralized flue. The centralized flue is communicated with each smoke exhaust ventilator arranged at each storey. The amalgamated dwelling flue purifying and discharging system is characterized in that the amalgamated dwelling flue purification discharging system further comprises a cleaning device, an oil stain recovery device, a pumping and drainage type static oil fume purifying and discharging device and a control device; the cleaning device is used for cleaning the centralized flue; the oil stain recovery device is arranged below the centralized flue and used for recovering oil stains and / or liquid waste generated after the centralized flue is cleaned; the pumping and drainage type static oil fume purifying and discharging device is used for forming negative pressure in the centralized flue so as to purify and discharge oil fume in the centralized flue; the control device is used for controlling the pumping and drainage type static oil fume purifying and discharging device according to preset time or oil fume concentration in the centralized flue to form negative pressure in the centralized flue. The amalgamated dwelling flue purifying and discharging system can prevent oil fume in the smoke exhaust ventilators from flowing backwards and avoid unsmooth fume discharging, and discharged oil fume is clean; particularly, the amalgamated dwelling flue purifying and discharging system can lower potential fire hazards and keep the centralized flue clean.

Owner:华信恒基(北京)科技发展有限公司 +1

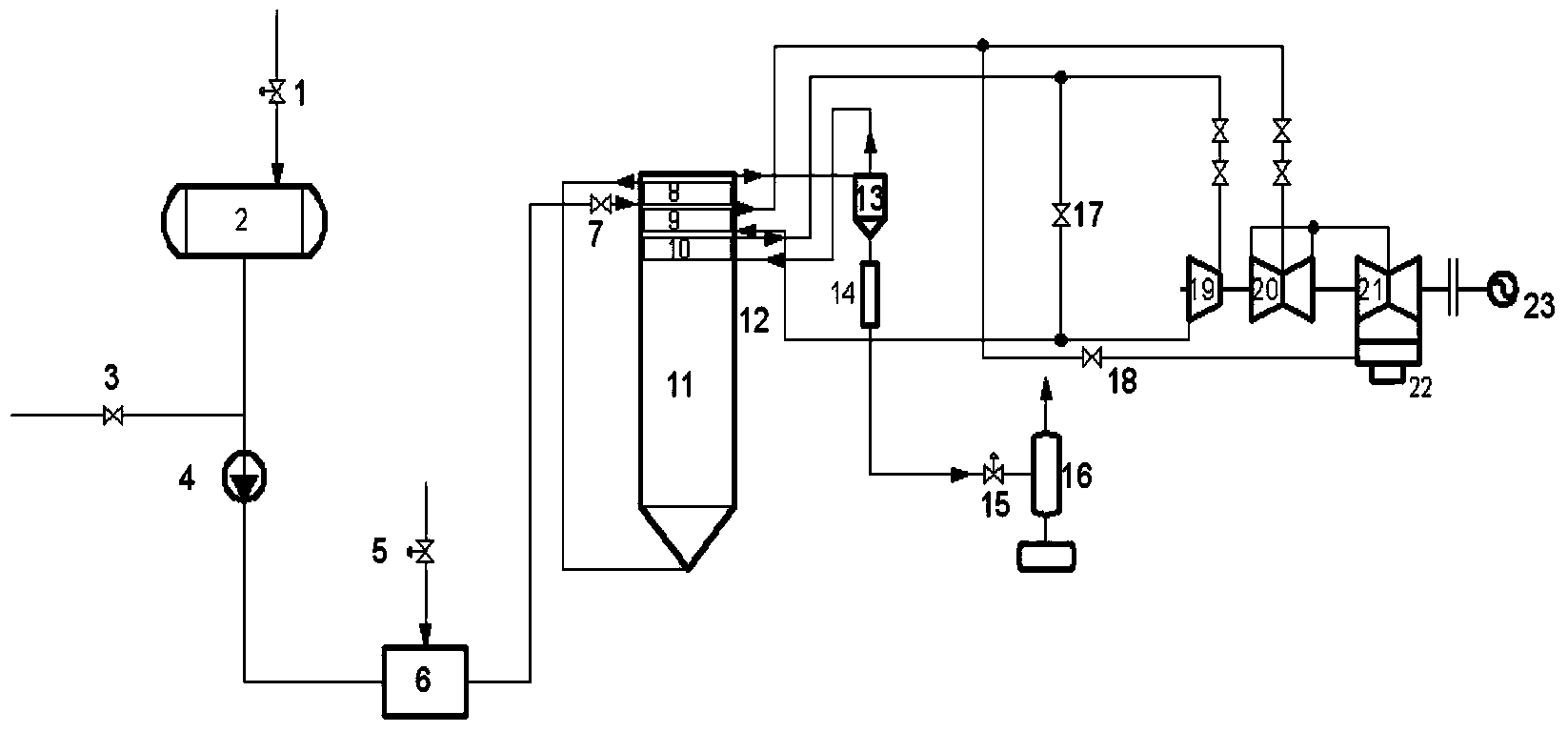

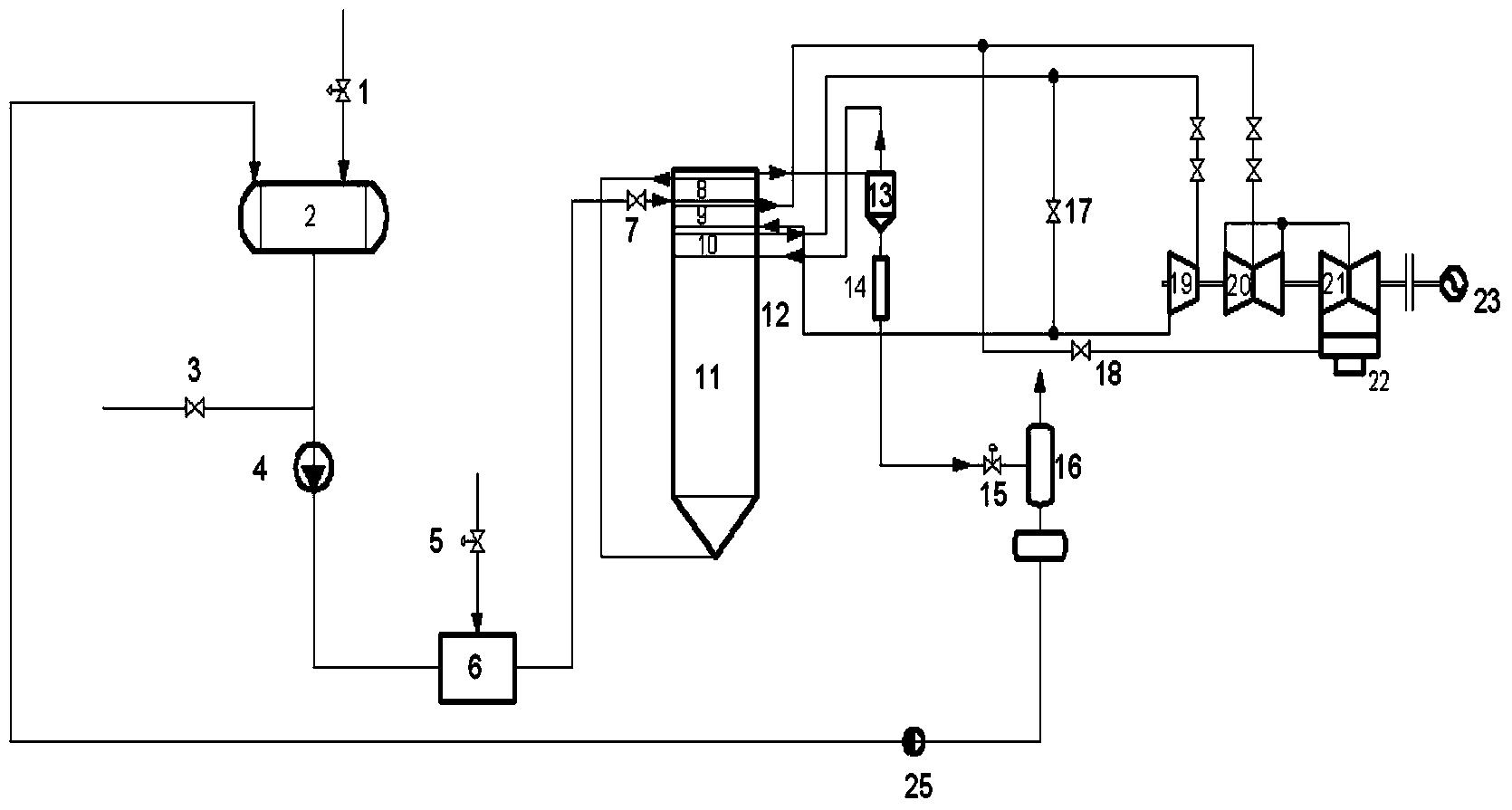

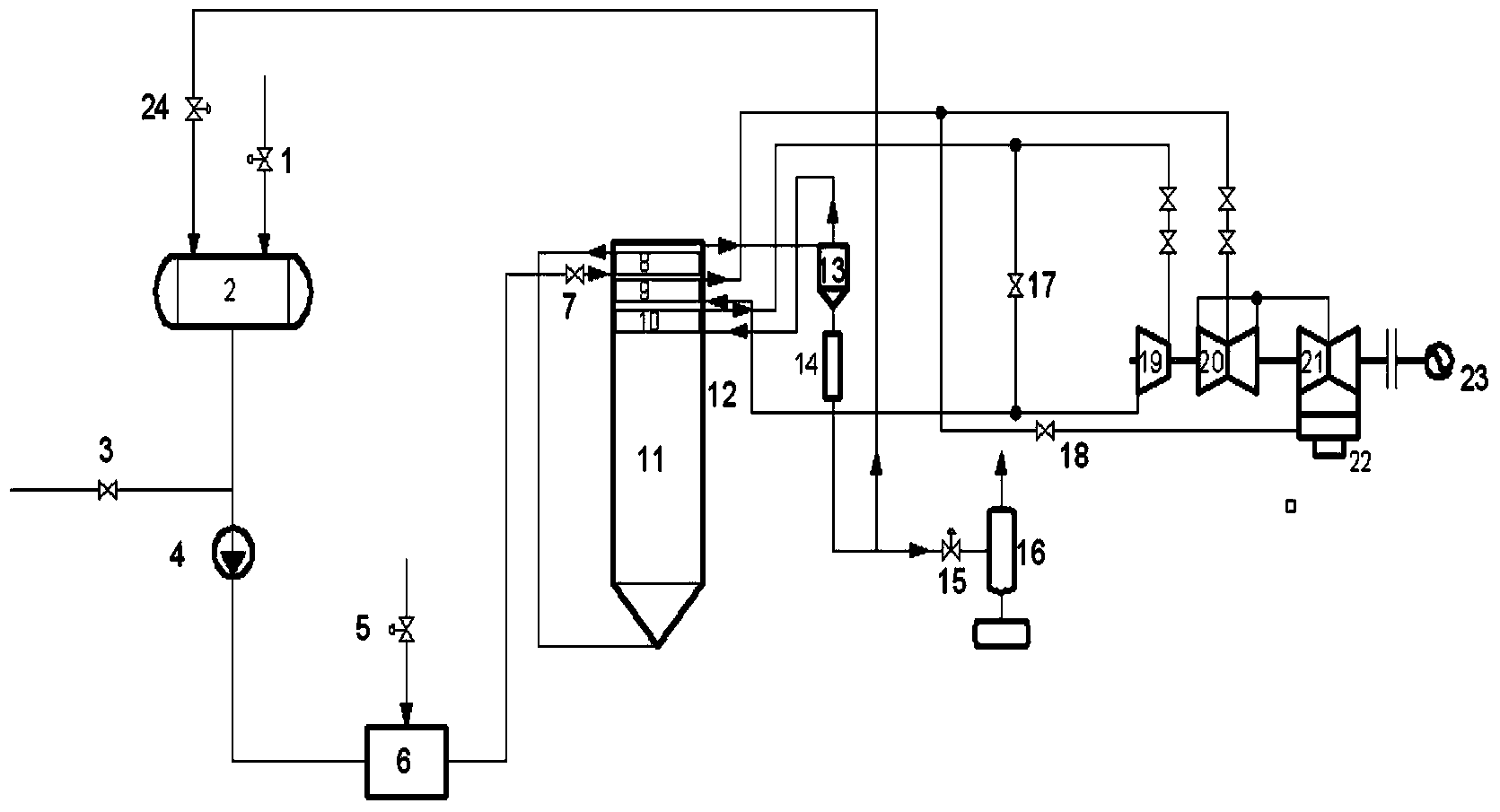

Energy-saving type quick start method for supercritical unit or ultra-supercritical unit

ActiveCN103712197AReduce startup timeIncrease temperature rise rateLiquid degasificationBoiler controlPressure riseThermal state

The invention discloses an energy-saving type quick start method for a supercritical unit or an ultra-supercritical unit. According to the method, steam from another resource is used for heating supplied water so that a boiler can be indirectly heated, and the thermal stress of a heated surface is reduced when the boiler is started so that the heating rate of the boiler can be improved; meanwhile, the heated high-temperature supplied water is converted into steam-liquid two-phase flow through throttling and pressure reduction, the flowing scouring action of the steam-liquid two-phase flow is far superior to the effect of thermal-state washing, and in other words, the boiler can complete thermal-state washing under the non-ignition condition, and can preheat the whole heated surface before ignition till certain pressure is reached. After ignition of the boiler, due to the fact that enthalpy of subcooling on an inlet of a water wall is eliminated, the problem of water power can be readily solved and the input speed of fuel can be increased. Meanwhile, by adjusting the open degree of a turbine bypass valve, the flow, the temperature rising speed and the pressure rising speed of main stream and reheat steam are controlled, and the temperature rising speed of the heated surface of the boiler is increased; when the temperature of the main steam and the temperature of the reheat steam are larger than the temperature of a turbine heating valve, valve heating is started, and a main machine can early satisfy the impulse starting condition.

Owner:冯伟忠

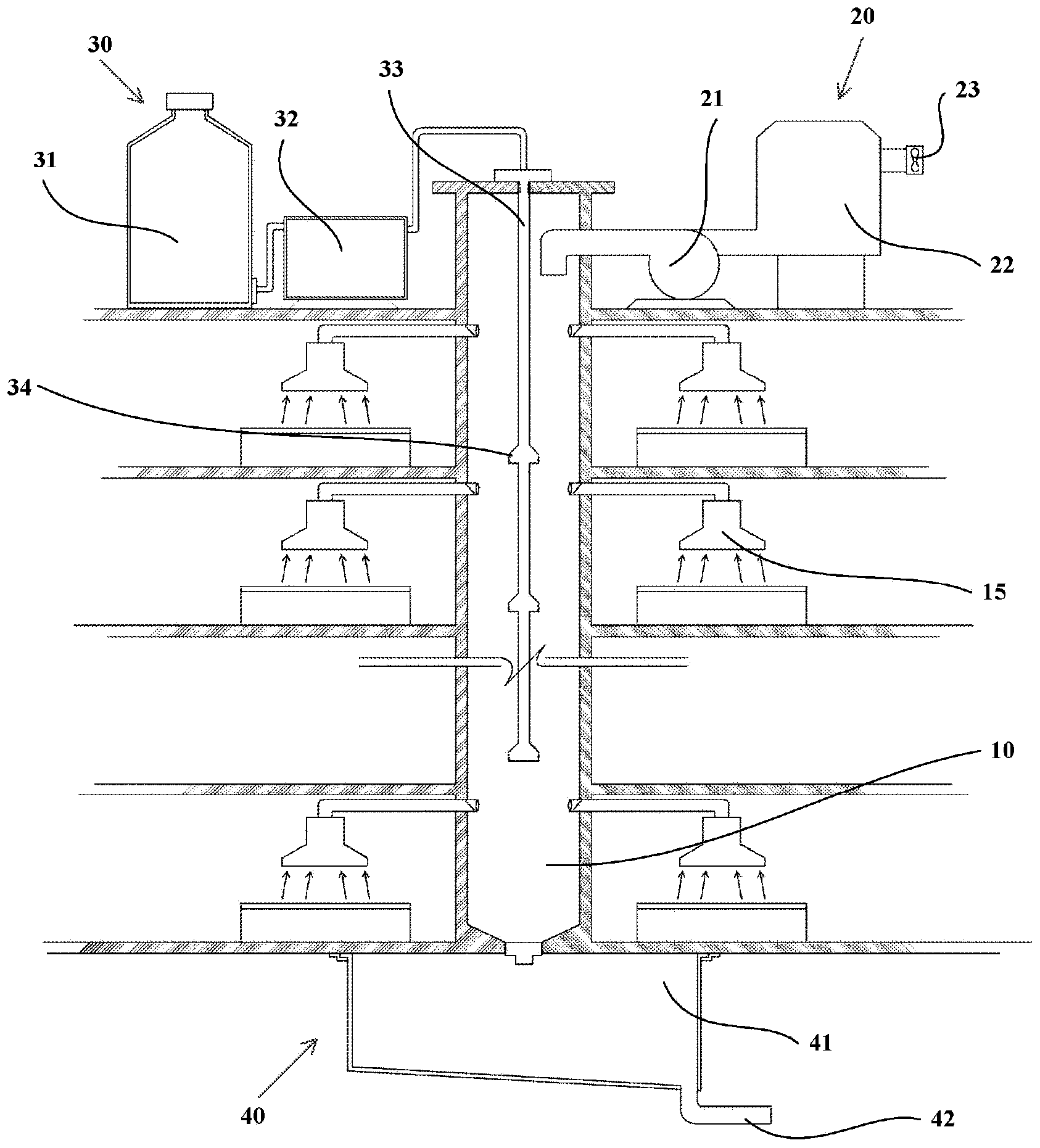

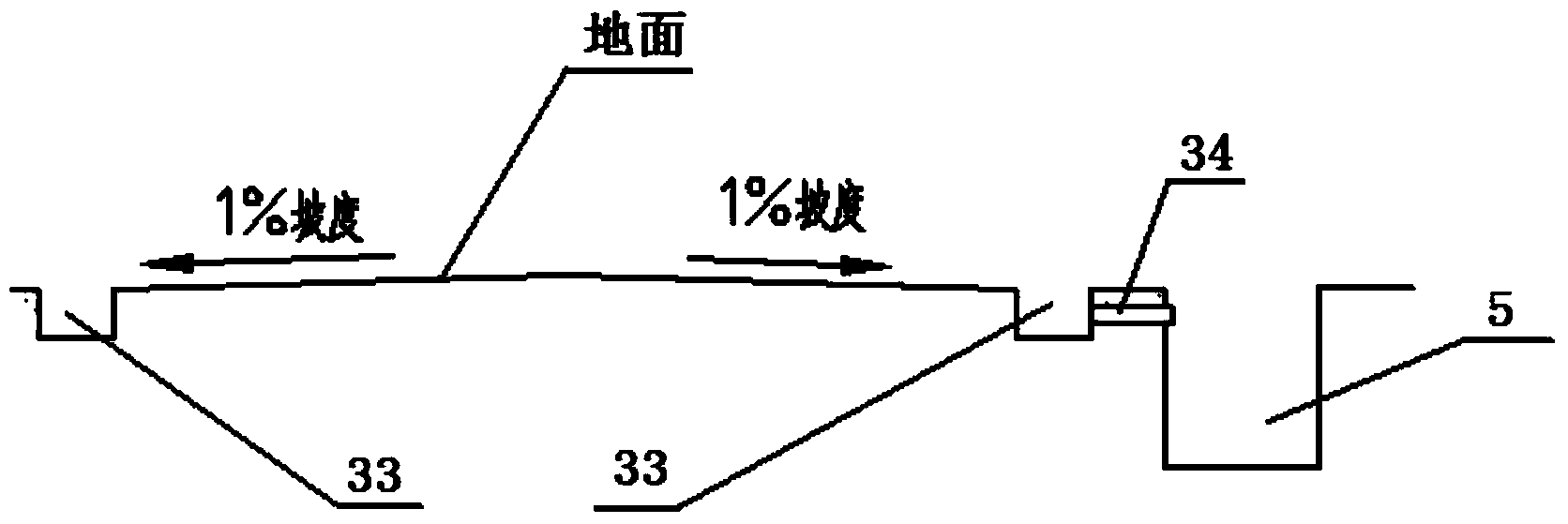

Air conditioner capable of utilizing drained condensate water for automatically cleaning outdoor unit

InactiveCN104713172AReduce cleaning effectReduce maintenanceMechanical apparatusSpace heating and ventilation safety systemsHeat sinkWater pipe

The invention belongs to the technical field of electronic products, and particularly provides an air conditioner capable of utilizing drained condensate water for automatically cleaning an outdoor unit. The air conditioner comprises the air conditioner outdoor unit and an internal power circuit of the air conditioner outdoor unit; a water storage tank which is connected with a condensate water draining pipe is mounted on the air conditioner outdoor unit through a support, and a water pump and a pressure sensor for measuring water pressure are arranged in the water storage tank; a control unit is arranged on the outer surface of the water storage tank and is electrically connected with the water pump through a switch; the control unit is further electrically connected with the pressure sensor and the internal power circuit, and a spraying head with the spraying direction pointing to cooling fins on the back of the spraying head is arranged on the air conditioner outdoor unit; and the water pump is connected with the spraying head through a water pipe, and a sewage draining pipe is arranged on the air conditioner outdoor unit. According to the air conditioner, a large amount of condensate water flowing out of the outdoor unit in the refrigeration process of the air conditioner can be fully utilized for carrying out spraying cleaning on related positions of the air conditioner outdoor unit, and the refrigerating effect of the air conditioner is improved; and cleaning and maintenance of the air conditioner outdoor unit are reduced, and living cost is saved.

Owner:XIAN KUNPENG INFORMATION TECH

Method for cleaning inner wall of pipeline type photobioreactor pipe

ActiveCN102000679AGood light permeabilityImprove cultivation efficiencyHollow article cleaningControl systemCulture fluid

The invention belongs to the biologic field of micro algae, relating to a method for cleaning inner wall of pipeline type photobioreactor pipe in micro algae culture. Magnetic sphere is placed into a pipeline type photobioreactor, culture solution flows when being pushed by power, the magnetic sphere randomly enters into the pipeline of photobioreactor along with the culture solution and does directional movement or slides under manual regulation of a control system outside the pipeline, and the magnetic sphere continuously slightly collides and rubs pipe wall in circulated moving process in the photobioreactor pipeline, so that algae cell material adhered onto transparent pipeline inner wall is rubbed into liquid phase used for culturing micro algae, the pipeline photobioreactor pipeline is effectively cleaned and light transmission thereof is maintained. The invention can effectively clean cells into algae liquid phase at initial stage of adherence, or substance such as cell adhered to the inner wall of the pipeline type photobioreactor pipe is removed, restriction of micro algae cell adherence to micro algae cell culture is overcome, and good light transmission and culture effect of photobioreactor are maintained.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Safe environmental-protection ore cleaning device

InactiveCN107671061AGuaranteed cleaning effectFalling smoothlyCleaning using toolsCleaning using liquidsWater storageImpeller

The invention discloses a safe environmental-protection ore cleaning device. The safe environmental-protection ore cleaning device comprises a feeding pipe, a box, a water inlet pipe, a pressing device, a water storage tank, a water pumping pipe, an extension rod, a filter plate, an impeller, cleaning shafts, turntables, a discharge pipe, brushes, a timer and a rotating shaft; the feeding pipe isarranged at the top end of the box; the box is provided with a liquid level meter; the water storage box communicates with the box through the water inlet pipe; the pressing device is mounted on the water inlet pipe; the rotating shaft is arranged in the box; the impeller is mounted on the rotating shaft; multiple cleaning shafts are arranged on the inner wall of the box; the turntables are arranged on the cleaning shafts; the brushes are arranged on the surfaces of the turntables; the filter plate is arranged in the box; the bottom surface of the filter plate is connected with the bottom endof the box through the extension rod; one end of the water pumping pipe is connected with the water storage tank, and a water filter screen is arranged at the other end of the water pumping pipe; thedischarge pipe is arranged on the side wall of the box; and a ultraviolet ray lamp is arranged in the box. The safe environmental-protection ore cleaning device accelerates the cleaning speed, improves the working efficiency, saves resources, realizes disinfection and sterilization, prevents wastes, is simple in structure and convenient to use, and facilitates popularization.

Owner:徐继传

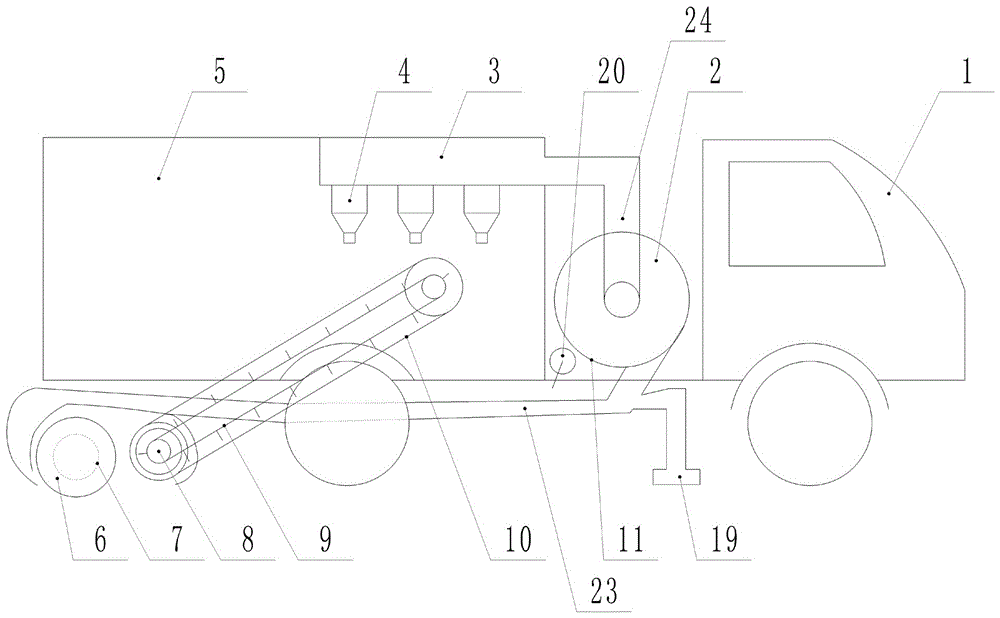

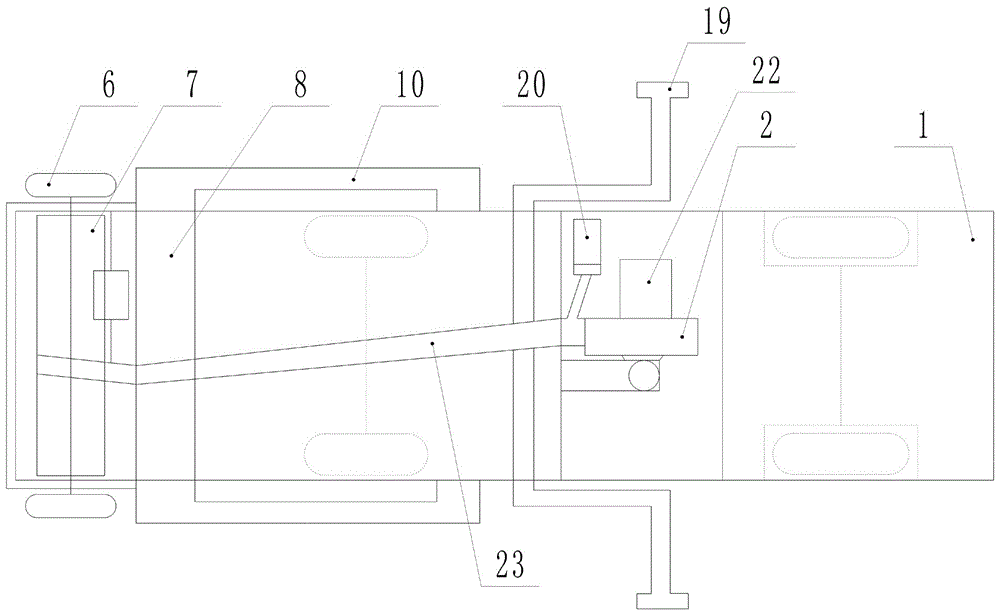

Efficient cyclone high-speed air circulation road sweeper

The invention discloses an efficient cyclone high-speed air circulation road sweeper which comprises a sweeper body and a cyclone dust sweeping collector, and further comprises a side sweeping cyclone blowing opening, wherein the side sweeping cyclone blowing opening is formed in the side face of the sweeper body and is communicated with an air outlet pipe of a cyclone generator in the cyclone dust sweeping collector through a ventilating pipeline. When the efficient cyclone high-speed air circulation road sweeper works, the side sweeping cyclone blowing opening blows air to the sweeper body; a sweeping hair rolling shaft of the cyclone dust sweeping collector is connected with a motor; the cyclone dust sweeping collector is arranged below the rear part of the sweeper body; the sweeping hair rolling shaft is arranged in front of an air blowing opening of the air outlet pipe of the cyclone generator; a waste collection trough is arranged in front of the sweeping hair rolling shaft; a spiral collection rolling shaft is arranged in the waste collection trough; and two ends of the spiral collection rolling shaft are communicated with a waste collection and separation tank through an air flow and mechanical hybrid waste conveying pipe. The sweeper has the advantages of larger sweeping width, less flying dust, lower energy consumption, better sweeping effect and more successful waste conveying.

Owner:重庆司科朗环卫服务有限公司

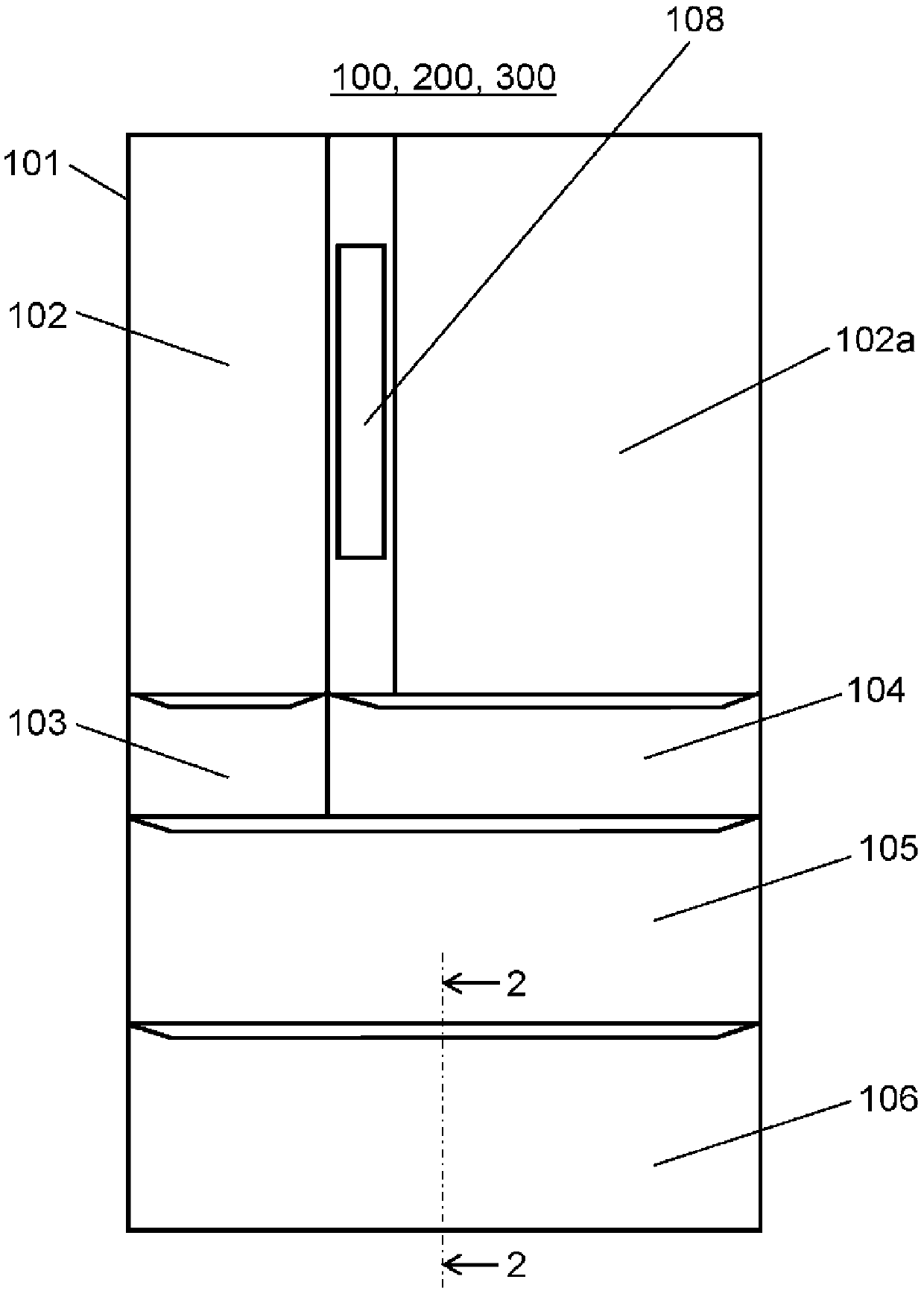

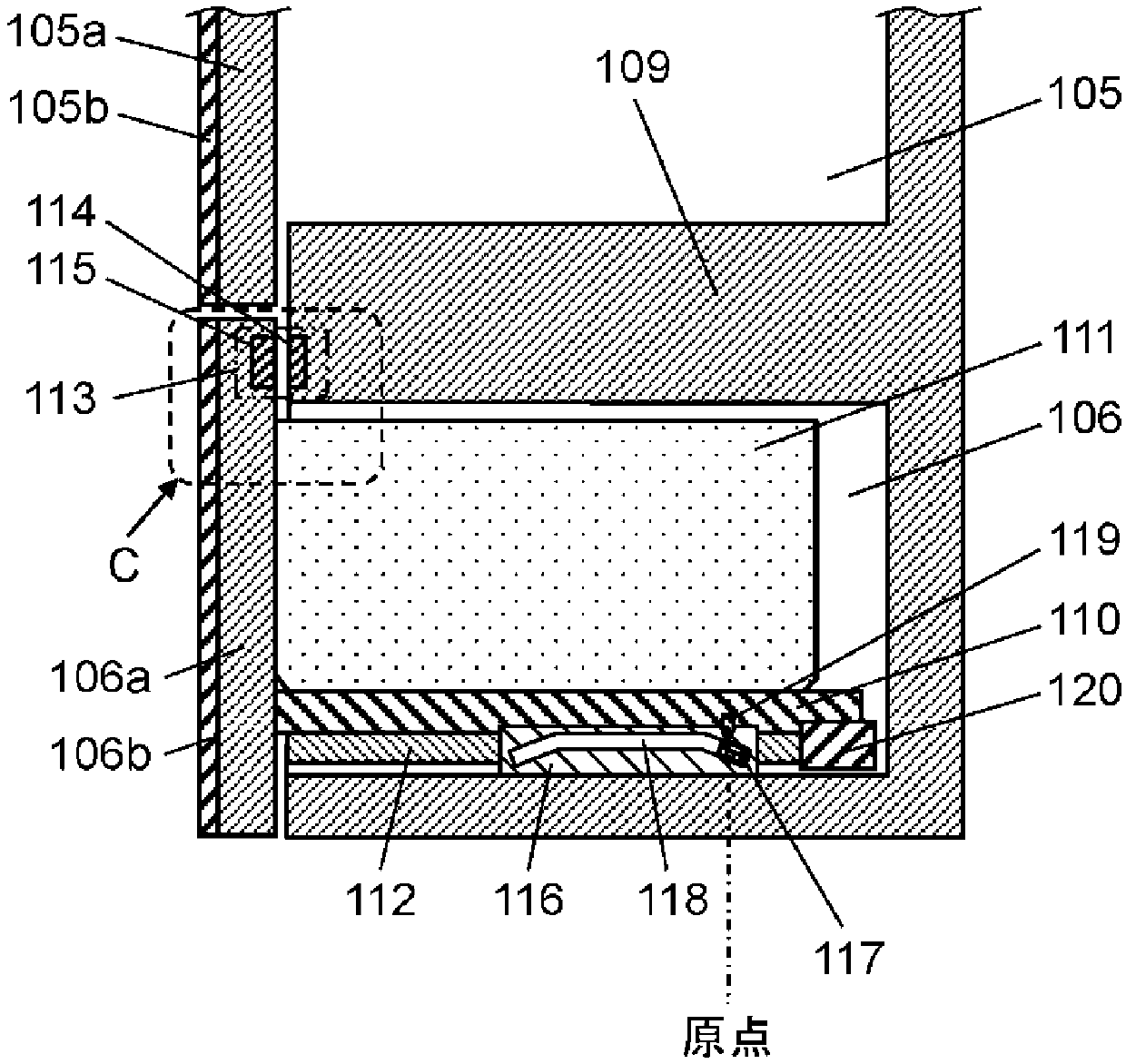

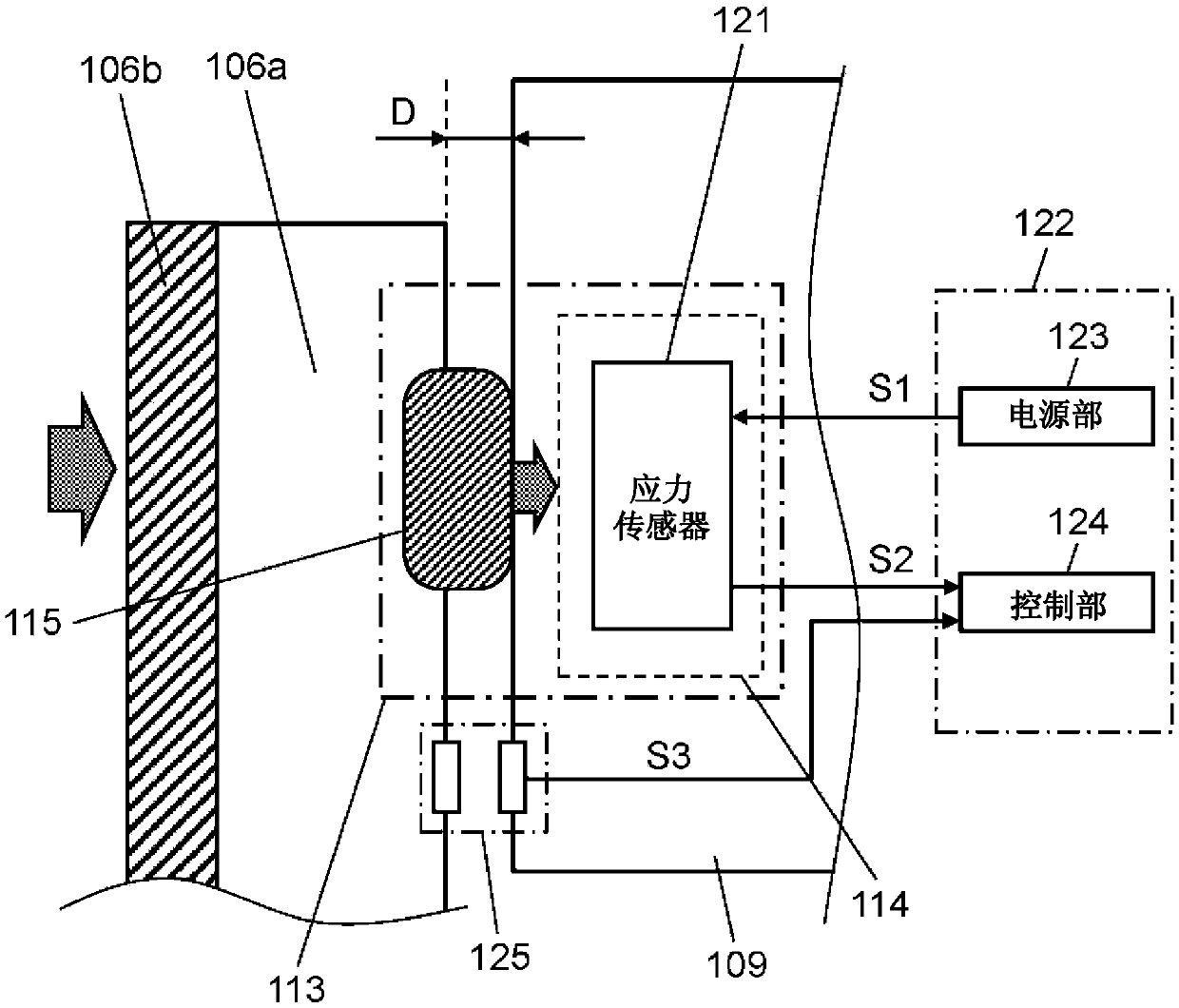

Refrigerator

ActiveCN109690213AEasy to useKeep a sense of luxuryLighting and heating apparatusCooling fluid circulationEngineeringStress sensor

Provided is a refrigerator, wherein an operation transmitting unit (115) is disposed on the inner wall on the side of a case of a pull-out type vegetable chamber door (106a) and a detecting unit (114)is disposed on a portion of an insulated partition plate (109) that faces the operation transmitting unit. Pushing the vegetable chamber door (106a) further in from the normal closed state is determined to be a door opening operation by a stress sensor (121).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Copper surface cleaning agent and use method thereof

The invention provides a copper surface cleaning agent and a using method thereof. The copper surface cleaning agent is composed of acid, hydrogen peroxide, a hydrogen peroxide stabilizer, a cationic surface active agent, a nonionic surface active agent and water. The concentration of the acid is 20 g / L-160 g / L, the concentration of the hydrogen peroxide is 1 g / L-75 g / L, the concentration of the hydrogen peroxide stabilizer is 0.02 g / L-10 g / L, the concentration of the cationic surface active agent is 0.01 g / L to 10 g / L, and the concentration of the nonionic surface active agent is 0.01 g / L to 20 g / L. The cleaning agent has a good cleaning effect on oxides, dust, grease, fingerprints and other impurities on the copper surface under the condition of the low micro-etching amount, the problem that coarsening is reduced or uneven after coarsening and micro-etching of the copper surface can be solved, and the yield of finished products can be better increased.

Owner:珠海市板明科技有限公司

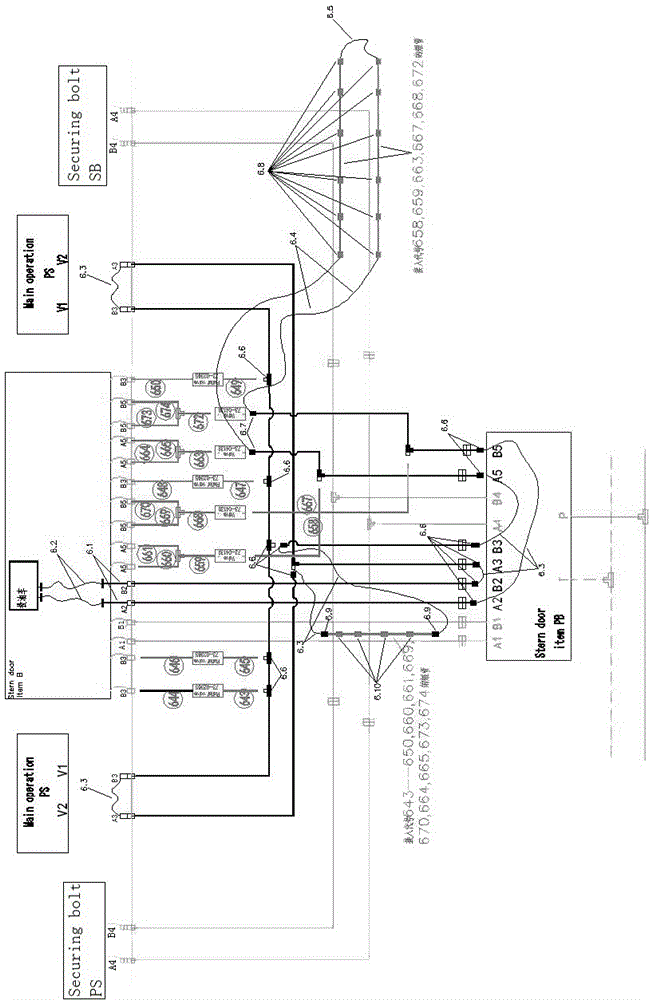

Process method for in-dock oil putting washing of hydraulic pipeline of roll-on/roll-off facility of container roll-on/roll-off ship

The invention relates to a process method for in-dock oil putting washing of a hydraulic pipeline of a roll-on / roll-off facility of a container roll-on / roll-off ship. The method includes the following steps that S1, a pipe to be subject to oil putting is pre-treated; S2, oil putting equipment is checked and washed; S3, the hydraulic pipeline is installed; S4, oil putting of the hydraulic pipeline is carried out; and S5, pipeline resetting after oil putting is carried out. According to the method, on the basis of existing equipment layout of the ship, the system pipeline moving direction is used, oil putting equipment such as an oil putting hydraulic unit, a temporary hose, a connector and an oscillator are distributed, it is guaranteed that the oil putting results meet the requirement, layout of the equipment on the ship and a pipe system is sufficiently used, the pipe disassembling, assembling and oil putting time is shortened, the oil putting washing period of the hydraulic pipeline is shortened, an in-dock production joints are well used, the in-dock hydraulic pipeline oil putting washing task is completed, and sufficient time is guaranteed for follow-up equipment debugging.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

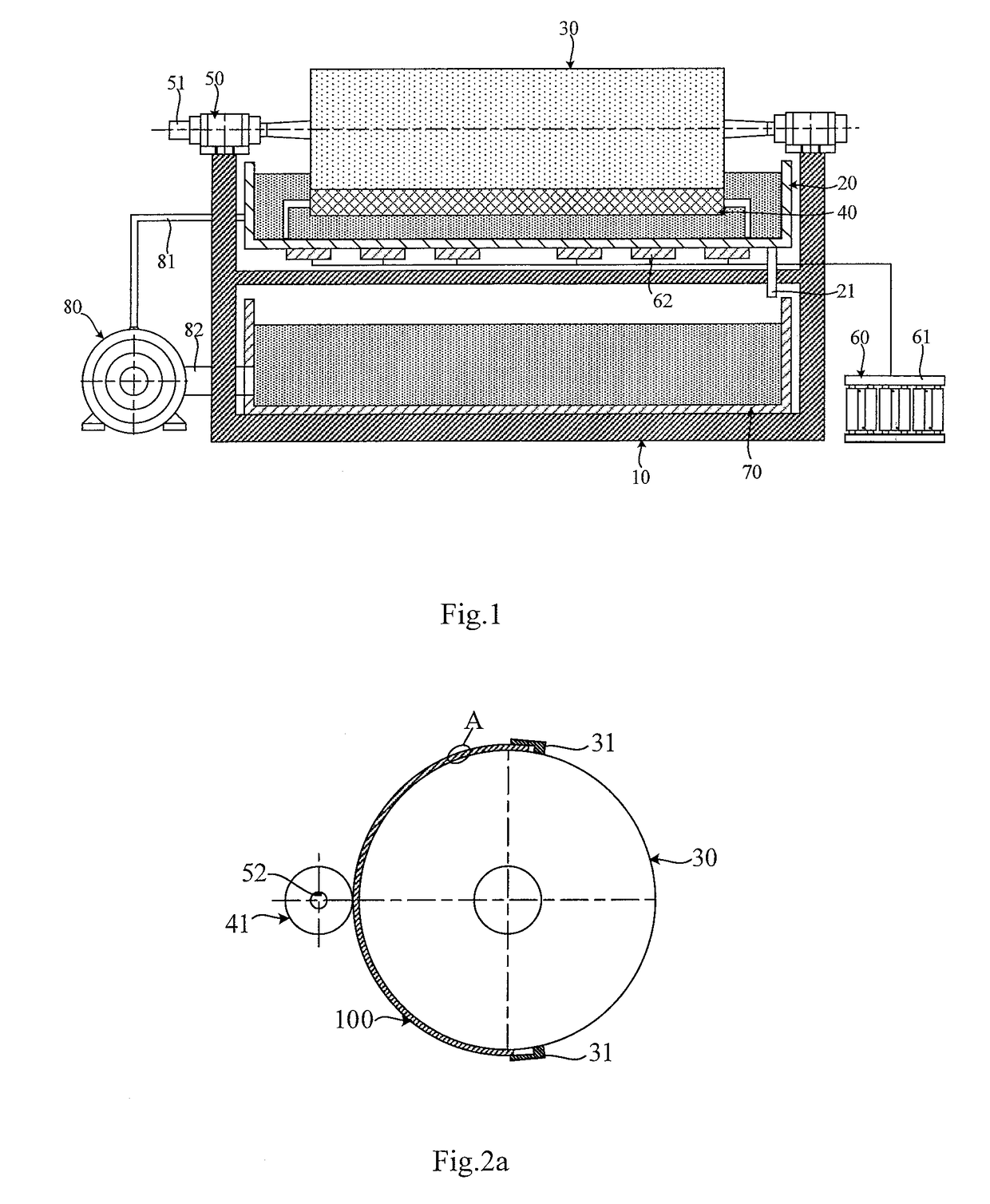

Sandwich composite pipe and rapid forming method thereof

ActiveCN102494238AShorten molding timeShorten the production cycleElongated constructional elementsSynthetic resin layered productsBiomedical engineeringRapid prototyping

The invention discloses a sandwich composite pipe and a rapid forming method thereof, which are mainly applied to electric power bearing pipe engineering. The sandwich composite pipe consists of an inner skin and an outer skin, wherein a sandwich layer is clamped between the inner skin and the outer skin. The sandwich composite pipe is characterized in that the sandwich layer is composed of an outline board which is formed by horizontally arranging and fixing a plurality of stripped materials into a whole. The forming method comprises the following steps of: forming the inner skin and the outer skin and paving the sandwich layer between the inner skin and the outer skin, wherein the sandwich layer is composed of the outline board which is formed by horizontally arranging and fixing a plurality of stripped materials into a whole. The forming steps of the outline board are as follows: (1) processing any one selected from a bamboo board, a cork wood, a foam material or an extruding and drawing rod into the stripped materials; and (2) juxtaposedly arranging several stripped materials on a plane and fixing into a row; compounding the inner skin, the outline board and the outer skin on a tubular die to form a pipe, and solidifying and forming. The sandwich composite pipe is light in weight, small in deformation amount, low in cost, rapid in forming and easy to popularize and apply.

Owner:北玻电力复合材料有限公司

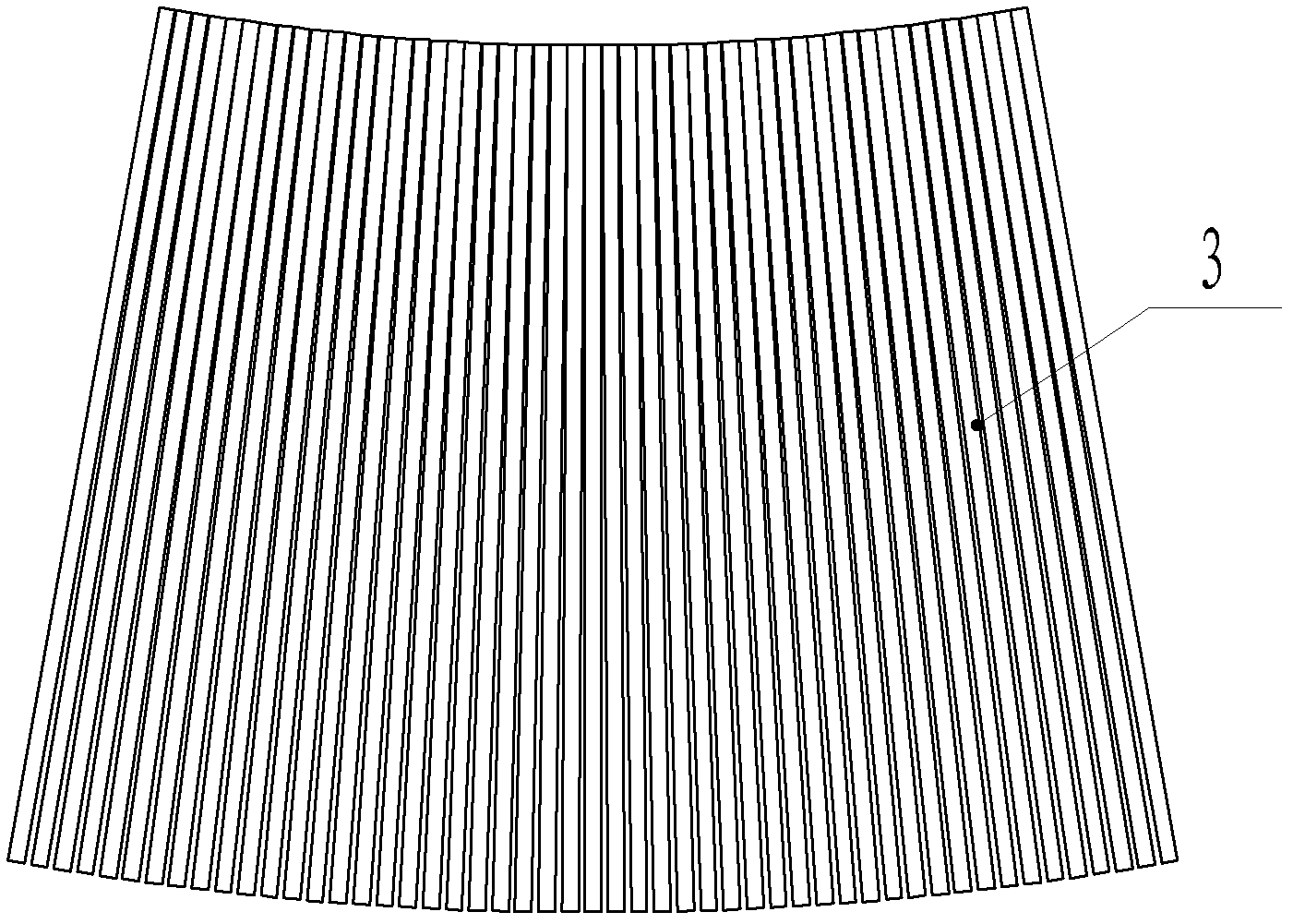

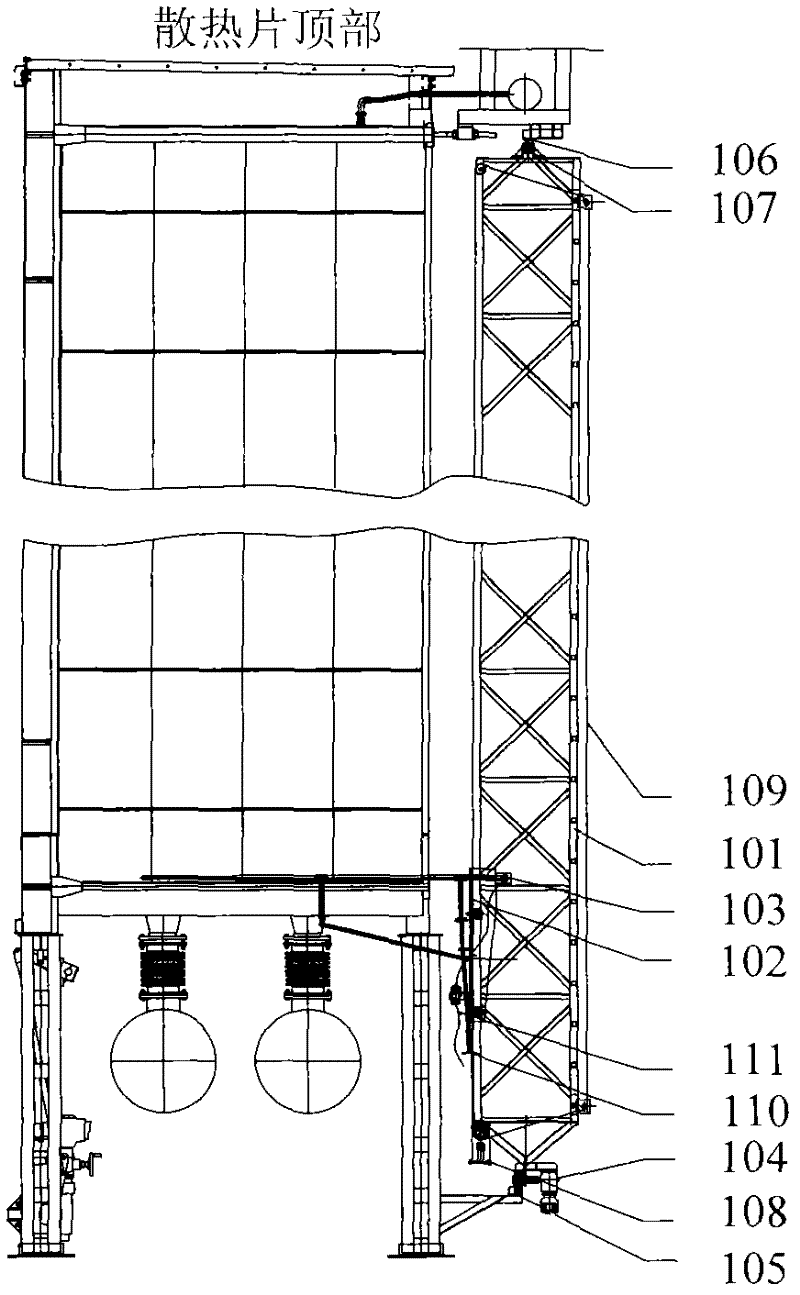

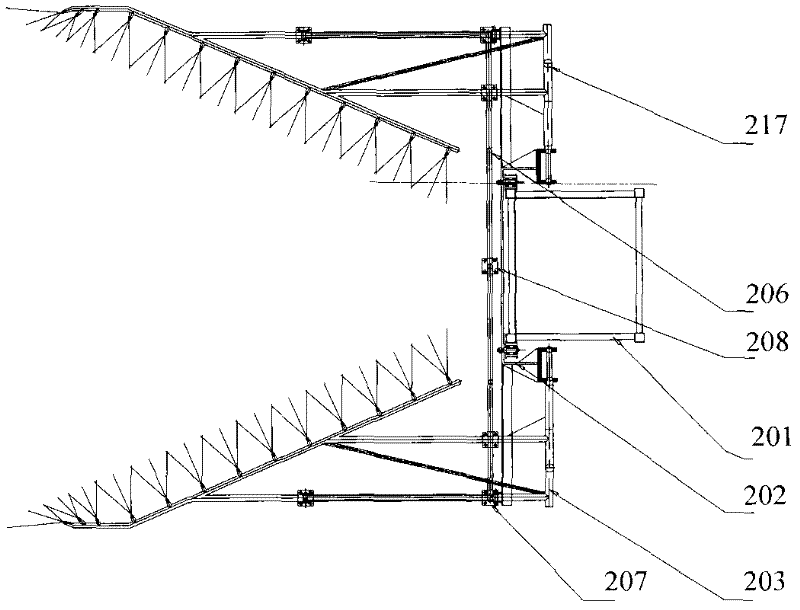

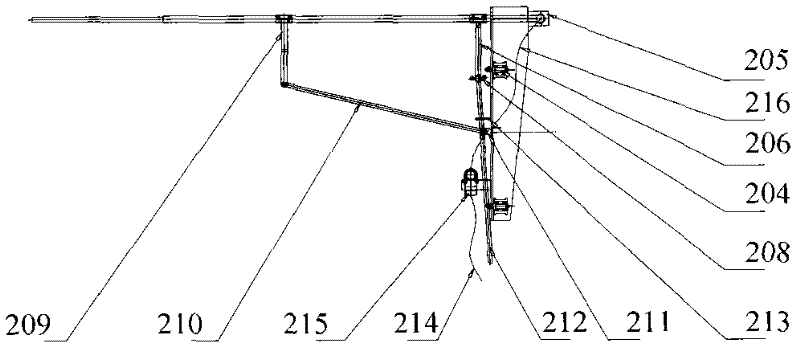

Cleaning device in indirect air cooling tower

ActiveCN102288068AImprove cleaning qualityImprove cleaning efficiencyFlush cleaningCooling towerWorking environment

The invention relates to a cleaning device in an indirect air cooling tower. The device comprises a cleaning crawling ladder, a horizontal walking mechanism, a nozzle plate support, a longitudinal walking mechanism and a cleaning pipeline. For the cleaning device in the indirect air cooling tower provided by the technical scheme of the invention, aiming at the typical working environment of the indirect cold cleaning (such as the frontage of a triangle tube bundle is provided with obstructs of a louver window, a lacing bar and the like), the up and down walking cleaning of a surrounding nozzle plate in the tower replaces the original three-rack-pipe louver window external cleaning mode out of the tower, thus the cleaning quality and efficiency are improved, the heat radiation efficiency of the tube bundle is improved, the power generation efficiency is improved, and at the same time, the operation and maintenance cost of the device is lowered.

Owner:江苏科能电力机械有限公司

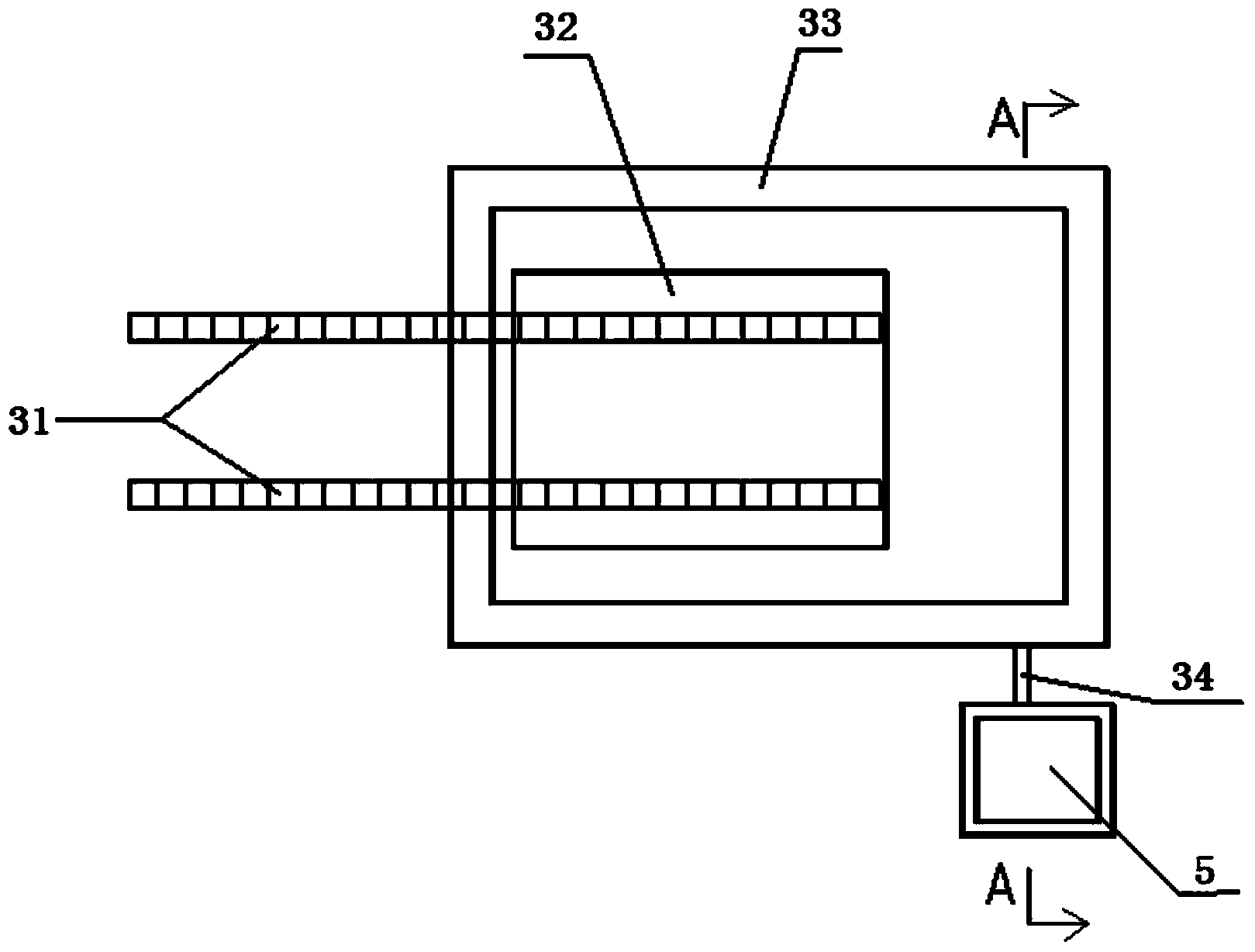

Cleaning head device and on-line cleaning robot of condenser

The invention discloses a cleaning head device and an on-line cleaning robot of a condenser. The cleaning head device comprises a cleaning nozzle, a mechanical arm connecting device, an elastic reset device, a front electrifying solenoid and a rear electrifying solenoid, wherein the cleaning nozzle is hollow and is tubular, the mechanical arm connecting device comprises a front structural part, a rear structural part and a connecting plate, the cleaning nozzle is sleeved with both the front structural part and the rear structural part, the front structural part and the rear structural part are connected through the connecting plate, the cleaning nozzle is sleeved with both the front electrifying solenoid and the rear electrifying solenoid, the front electrifying solenoid and the rear electrifying solenoid are located between the front structural part and the rear structural part, the rear electrifying solenoid is fixedly connected with the rear structural part, the front electrifying solenoid is fixedly connected with the cleaning nozzle, the elastic reset device is arranged between the front electrifying solenoid and the front structural part, and a sealing gasket is arranged on the front end face of the cleaning nozzle. The cleaning robot is arranged in a water chamber of the condenser and comprises the cleaning head device, a mechanical arm, a connecting pipe and a booster pump. The on-line cleaning robot of the condenser is simple in structure, convenient to install and use, and low in maintenance cost.

Owner:NANJING SCIYON AUTOMATION GRP

Apparatus for cleaning transfer plate and method for cleaning the same

ActiveUS20180169715A1Quality improvementReduce productionCleaning using toolsCleaning using liquidsEngineeringCleaning methods

Owner:BOE TECH GRP CO LTD +1

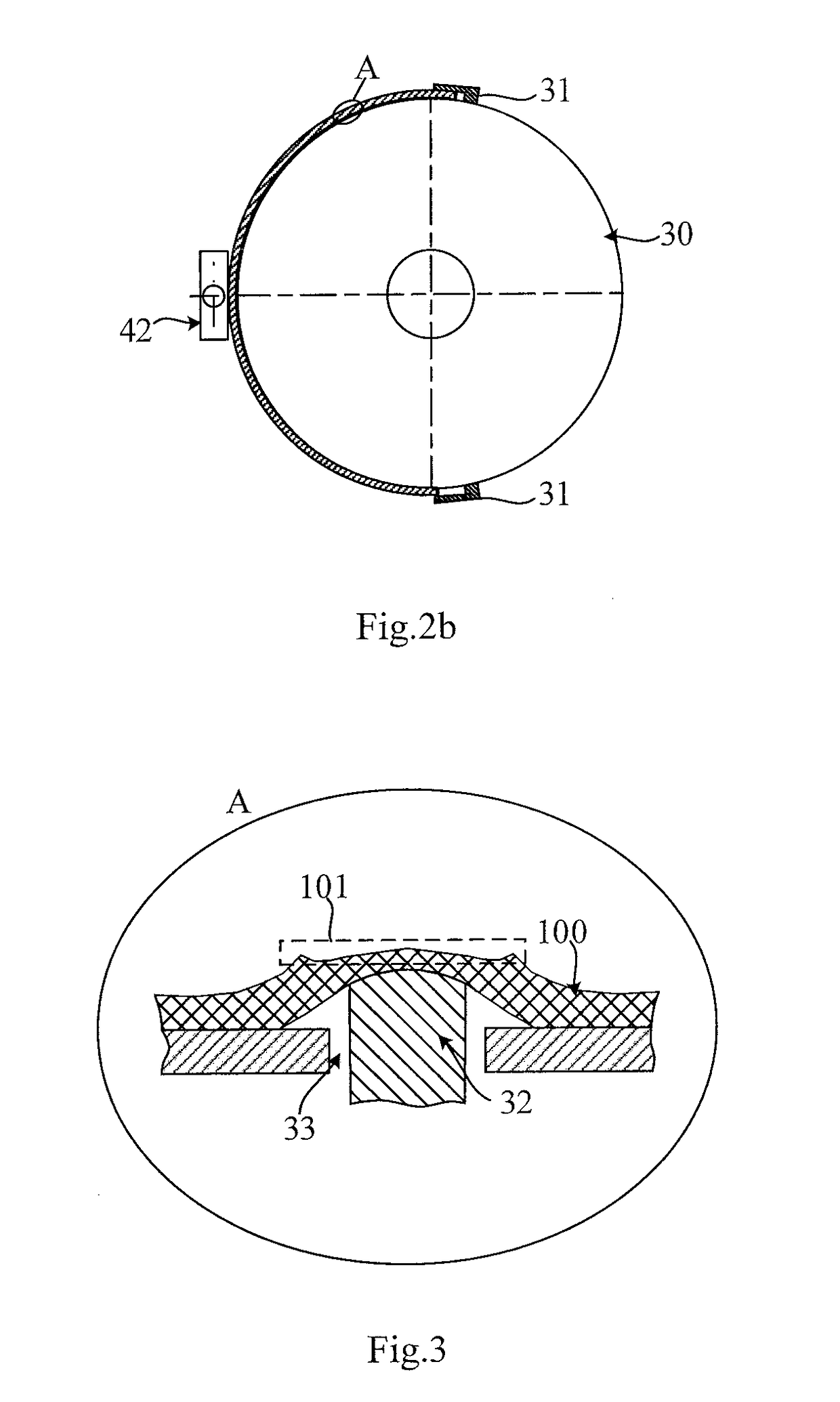

Automatic intelligent breeding industry water supply apparatus

InactiveCN106900584AHas the function of purifying waterGuarantee healthy and rapid developmentAnimal watering devicesElectricityWater storage

The invention specifically discloses an automatic intelligent breeding industry water supply apparatus. The automatic intelligent breeding industry water supply apparatus comprises a water storage box and a water drinking tank, and also comprises a water purifying module, a water supply regulation and control module and a control module, wherein the water storage box, the water drinking tank, the water purifying module and the water supply regulation and control module are respectively electrically connected with the control module, and a water pipe passage is successively the water purifying module, the water storage tank, the water supply regulation and control module and the water drinking tank. The automatic intelligent breeding industry water supply apparatus not only has an automatic water supply effect, but also has a water purifying function, improves the safety of drinking water for animals in the breeding industry, and ensures the healthy and rapid development of the breeding industry; and the automatic intelligent breeding industry water supply apparatus is also innovatively provided with a water quality detection module, the water drinking tank is also provided with an electric heating bar and an ultraviolet lamp, so that water of an appropriate temperature can be provided for the animals; and when the animals do not need to drink water, the water drinking tank can be physically sterilized by utilizing the ultraviolet lamp, so that the breeding of bacteria and viruses in the water drinking tank can be reduced. The automatic intelligent breeding industry water supply apparatus is convenient to use and easy to install and clean, and has wide market prospect.

Owner:广州智达机械技术有限公司

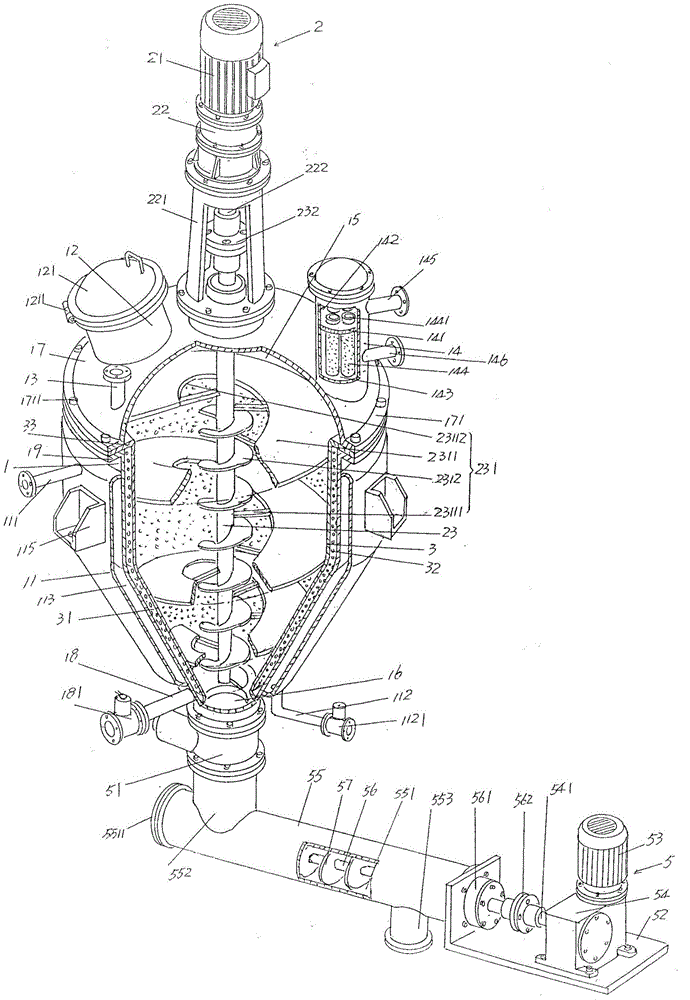

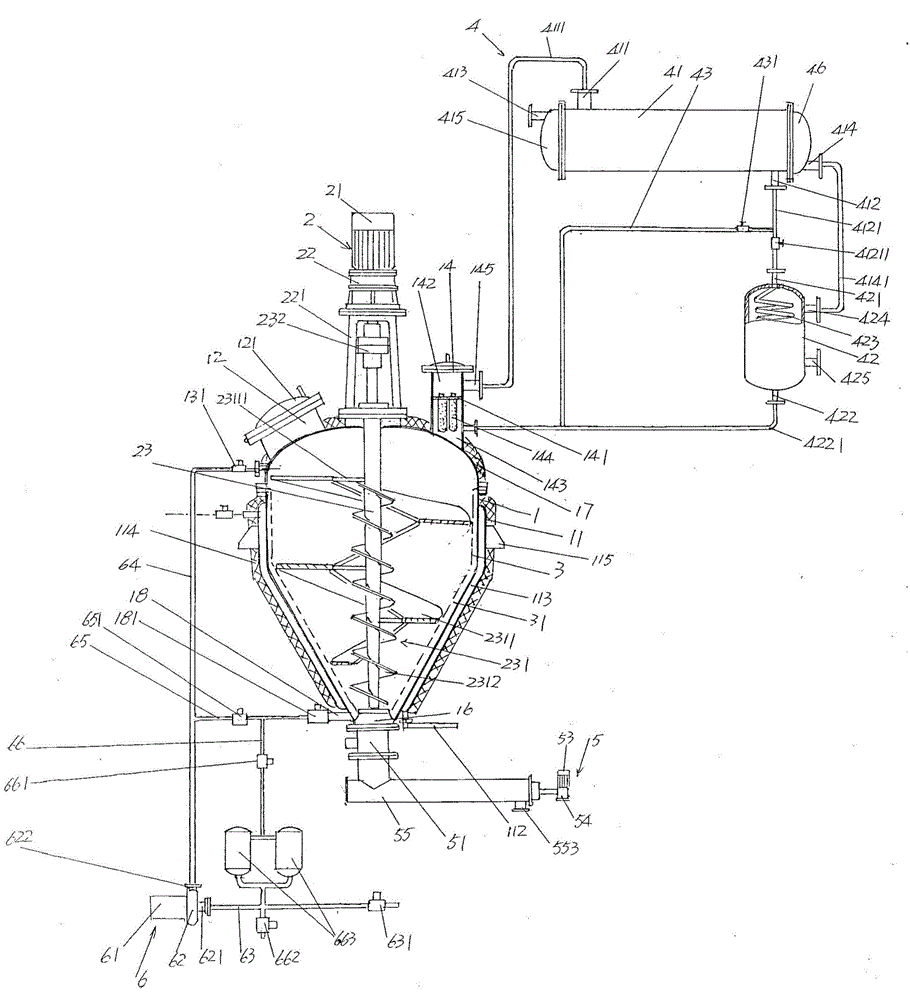

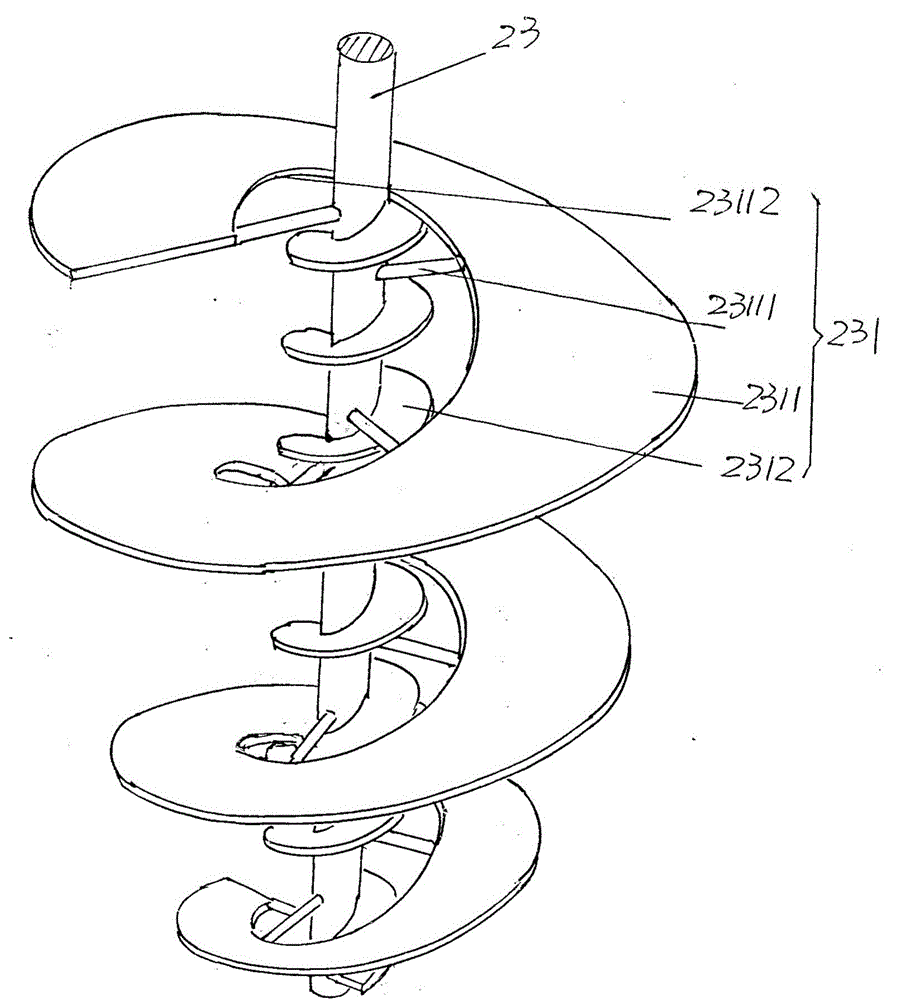

Cage-type dynamic forced extraction pot

The invention discloses a cage-type dynamic forced extraction pot and belongs to the technical field of traditional Chinese medicine preparation machinery. The cage-type dynamic forced extraction pot comprises an extraction pot body, the extraction pot body is provided with a heating spacer bush, the upper part of the extraction pot body is provided with a heating medium introduction interface, the lower part of the extraction pot body is provided with a heating medium discharge outlet, the cage-type dynamic forced extraction pot also comprises a stirring mechanism, the stirring mechanism is fixed to the top of the extraction pot body, and a stirring shaft is provided with a spiral stirring device. The cage-type dynamic forced extraction pot is characterized in that the pot comprises a stranding cage, the stranding cage is arranged in the pot cavity, a liquid outlet gap is formed between the outer wall and the wall of the pot cavity, the stirring shaft and the spiral stirring device are located in the stranding cage, the spiral stirring device comprises large and small spiral plates, the upper part of the extraction pot body is a cylinder, the lower part of the extraction pot body is an inverted circular truncated cone, a slag discharge outlet is connected to a slag discharge mechanism, and the slag discharge mechanism comprises a slag valve, a speed reducer support, a motor, a speed reducer, a slag discharge pipe, a slag discharge spiral piece shaft and a slag discharge spiral piece. The cage-type dynamic forced extraction pot guarantees cleaning effects, improves heating extraction efficiency, realizes extraction of material effective components, reduces slag water content, improves seal effects and an environment and realizes extrusion of effective ingredients of the slag.

Owner:JIANGSU SHAJIABANG CHEM EQUIP

Method for preparing resistant starch by treating B-type starch by using high static pressure

The invention discloses a method for preparing resistant starch by treating B-type starch by using high static pressure. The method comprises the following steps: mixing starch and water in a mass ratio of 1:(2-10) at normal temperature, and stirring uniformly to obtain a starch milk suspension; putting the starch milk into a nylon-polyethylene composite bag, and carrying out vacuum packaging, wherein the vacuum degree is controlled at 0.1 MPa; putting the starch milk subjected to vacuum packaging into a treatment kettle, and carrying out high static pressure treatment, wherein the high static pressure is 100-600 MPa, the treatment time is 10-60 minutes, and the treatment temperature is 20-50 DEG C; and filtering the treated starch milk, drying, pulverizing, and screening to obtain the finished product. The high static pressure technique is adopted to prepare the resistant starch under the condition of lower than gelatinization temperature, so the method has the advantages of short preparation time and high resistant starch yield. The method avoids adding abundant enzymes and other reagents in the preparation process, thereby reducing the subsequent cleaning and sewage treatment and belonging to green clean processing.

Owner:刘培玲

Device and process method for preparing polycrystalline silicon through coupling of electron beam smelting and crystal growing technology

InactiveCN103435043AEfficient removalStrengthen the surface volatilization effectSilicon compoundsFilling materialsCoupling

The invention belongs to the field of polycrystalline silicon ingot, and particularly relates to a device and a process method for preparing polycrystalline silicon through the coupling of electronic beam smelting and the crystal growing technology. The device for preparing the polycrystalline silicon through the coupling of the electron beam smelting and the crystal growing technology is characterized in that a graphite crucible is arranged inside a furnace body, the outer wall of the graphite crucible is sequentially provided with a graphite heating body and a graphite insulating sleeve from inside to outside, an upper graphite cover plate of the graphite insulating sleeve can be horizontally moved, and the position on one side of the furnace body, parallel to the upper graphite cover plate, is externally connected with a hollow plate groove; a water-cooling ingot pulling mechanism is installed on the center position of the bottom of the graphite crucible; a cooling circulating water pipe is arranged inside the water-cooling ingot pulling mechanism; the top of the furnace body is provided with an electron gun, the upper end of the side part of the furnace body is provided with an inflating valve, and the lower end is provided with a deflation valve. The process method for preparing the polycrystalline silicon through the coupling of the electron beam smelting and the crystal growing technology comprises the steps of filling materials, vacuumizing, charging argon to increase the pressure, heating to smelt the silicon material, smelting through an electron beam, growing the crystal, annealing the ingot, cooling and opening the furnace to take the ingot.

Owner:QINGDAO XINSHIJI SOLAR ENERGY TECH CO LTD

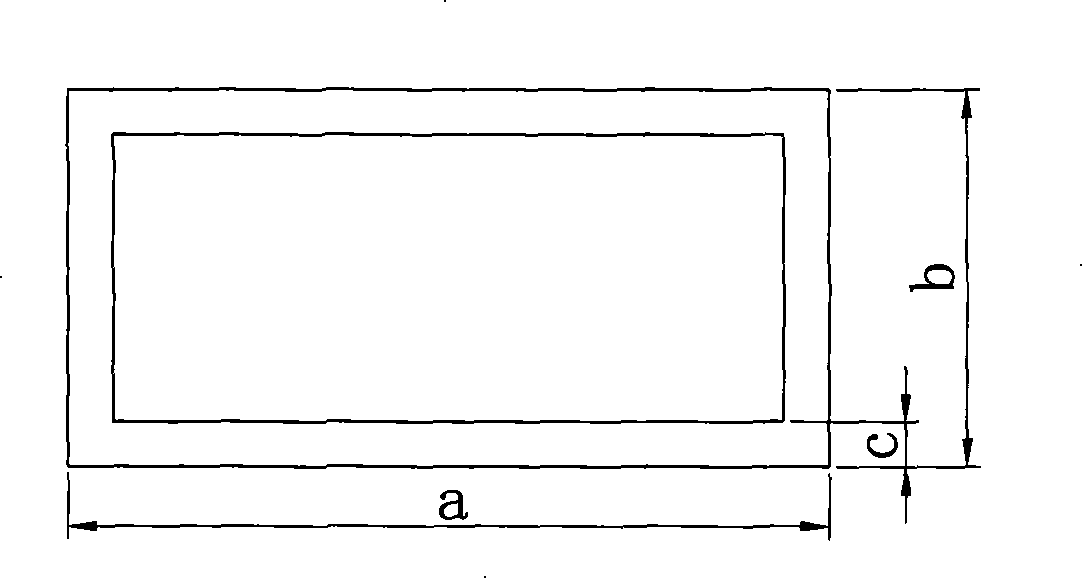

Method for processing austenite seamless stainless steel rectangular water pipe used for turbine generator

ActiveCN101245879AReduced intermediate annealingReduce cleaning effectRigid pipesRare-earth elementLanthanum

The invention relates to a processing method of an austenitic seamless stainless steel rectangle water pipe used for a turbo-generator, which sequentially has the processing steps of hot rolling round bar, continuous extruding round pipe, drawing an elliptic pipe with a non-core bar, drawing a rectangle pipe with a short core bar, and carrying out solution treatment and annealing to obtain the finished product. According to the mass percentage, the stainless steel which is adopted by the water pipe contains carbon less than or equal to 0.030%, silicon less than or equal to 1.0%, manganese less than or equal to 2.0%, sulphur less than or equal to 0.030 %, phosphorus less than or equal to 0.035%, chromium ranging from 18.00% to 20.00%, Ni ranging from 9.0% to 13.0%, rare earth element Re ranging from 0.002% to 0.008%, silver ranging from 0.001% to 0.005%, and iron and other impurities with the residual quantity; wherein, the rare earth element is a compound which consists of 40% to 45% of Ce, 40% to 45% of lanthanum and Yt with residual quantity according to the mass percentage. The processed water pipe has good toughness, strong corrosion resistance and low magnetic permeability, and is an ideal material used for the motor stator water pipes of 1000MW-class turbo-generators.

Owner:TAIXING SHENGDA COPPER IND CO LTD

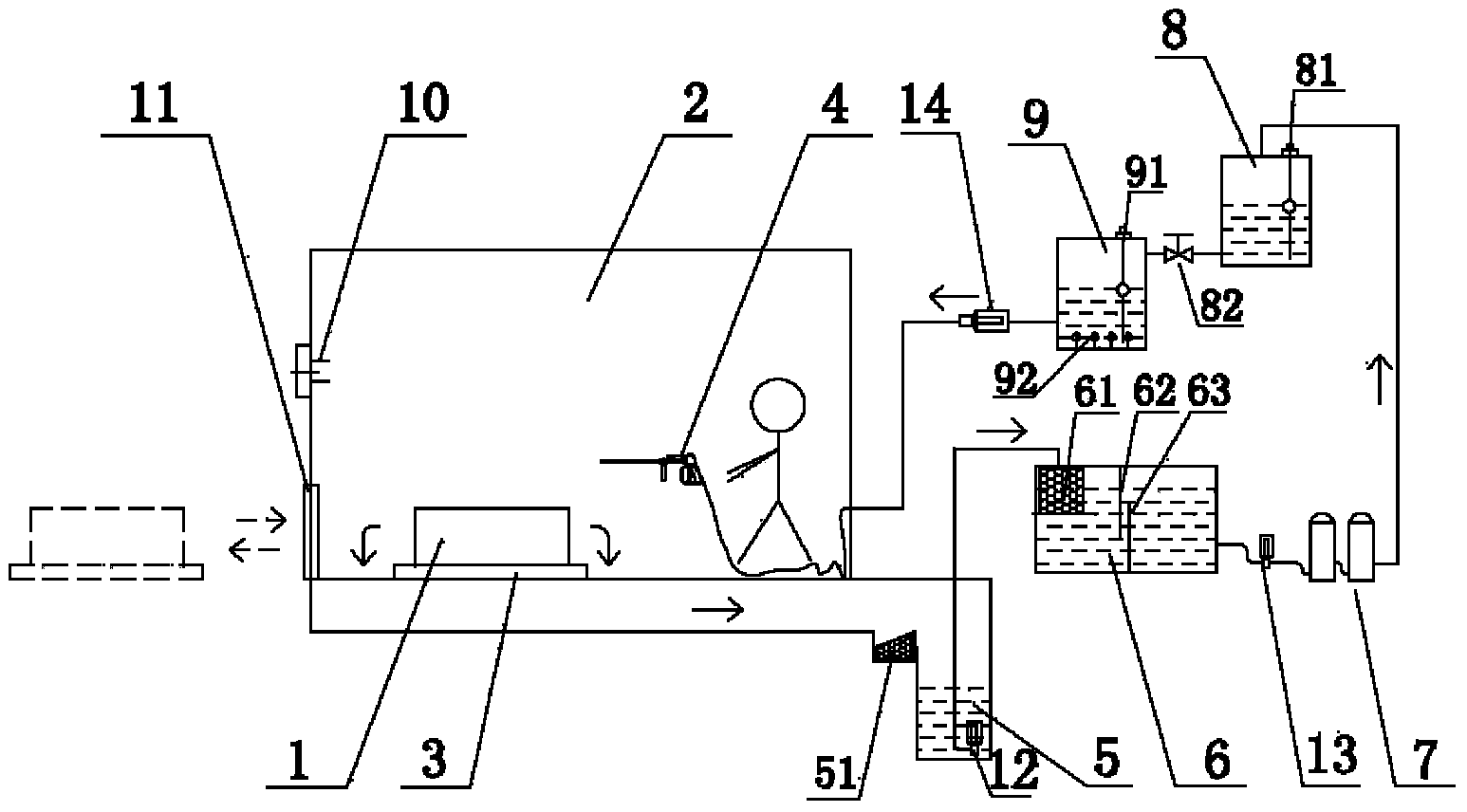

Cleaning system and cleaning method for automotive metal plate stamping die

ActiveCN103521471ALow costImprove decontamination abilityMagnetic separationCleaning using liquidsFiltrationEngineering

The invention provides a cleaning system for an automotive metal plate stamping die. The cleaning system comprises a cleaning chamber, a bearing mechanism, a collecting tank, a sedimentation basin and a secondary filtering device. A spraying device used for spraying cleanout fluid to a die to be cleaned is arranged in the cleaning chamber. The bearing mechanism is used for bearing the die to be cleaned to enter and go out of the cleaning chamber. The collecting tank is located below the ground of the cleaning chamber so as to collect the cleanout fluid sprayed out from the spraying device. The sedimentation basin is used for pumping the cleanout fluid from the collecting tank, and a magnetic filtering device and an oil-liquid separating device are arranged in the sedimentation basin so as to carry out large-particle sedimentation, metal particle filtration and oil-liquid separation on the cleanout fluid. The secondary filtering device is used for pumping the cleanout fluid from the sedimentation basin and carries out fine filtering on the cleanout fluid to enable the cleanout fluid to be sent back to the spraying device. The invention further provides a cleaning method for the automotive metal plate stamping die. The cleaning system and the cleaning method can be used for eliminating the influence of excess component impurities on the filtering device in the cleanout fluid cyclic utilization process, so the cleaning effect can be better, cost can be lower and environment protection can be achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com