Copper surface cleaning agent and use method thereof

A cleaning agent and copper surface technology, which is applied in the field of copper surface cleaning agent, can solve problems such as unevenness and coarsening decline, and achieve the effects of improving coarsening decline or unevenness, improving product yield, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

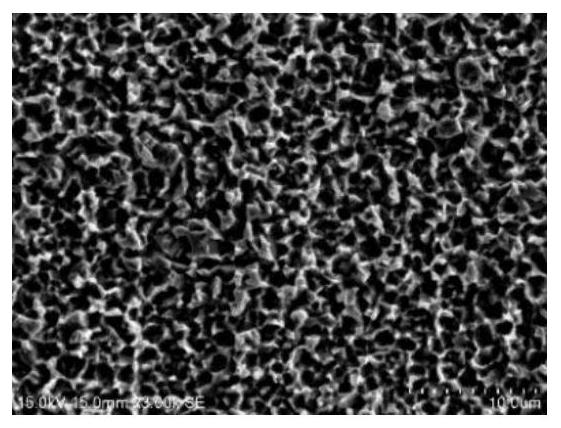

Image

Examples

Embodiment 1

[0038] A copper surface cleaning agent is made up of acid, hydrogen peroxide, hydrogen peroxide stabilizer, cationic surfactant, nonionic surfactant and water, the concentration of the acid is 90g / L, and the concentration of the hydrogen peroxide is 36g / L, The concentration of the hydrogen peroxide stabilizer is 5g / L, the concentration of the cationic surfactant is 5g / L, and the concentration of the nonionic surfactant is 10g / L.

[0039] The acid is sulfuric acid. The hydrogen peroxide stabilizer is sodium p-hydroxybenzenesulfonate. The cationic surfactant is polyethyleneimine polymer. The nonionic surfactant is isooctyl alcohol polyoxyethylene ether.

[0040] The method for using the copper surface cleaning agent in this embodiment is to use the above-mentioned copper surface cleaning agent to perform microetching cleaning on the copper surface at 30° C., the cleaning time is 60 s, and the microetching amount is 0.3 μm. The microetching cleaning method is soaking.

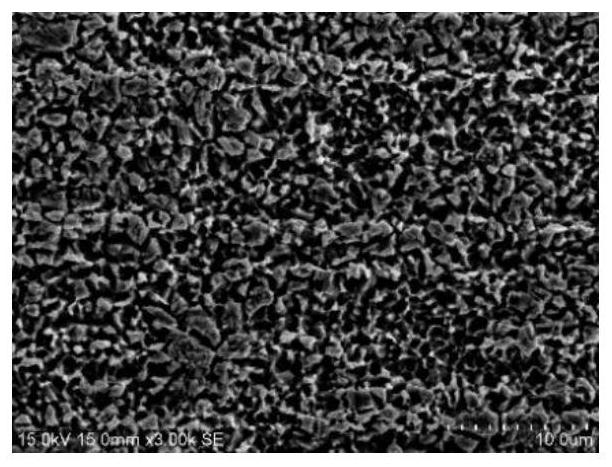

Embodiment 2

[0042] A copper surface cleaning agent is made up of acid, hydrogen peroxide, hydrogen peroxide stabilizer, cationic surfactant, nonionic surfactant and water, the concentration of the acid is 20g / L, and the concentration of the hydrogen peroxide is 75g / L, The concentration of the hydrogen peroxide stabilizer is 10g / L, the concentration of the cationic surfactant is 0.01g / L, and the concentration of the nonionic surfactant is 10g / L.

[0043] The acid is sulfuric acid. The hydrogen peroxide stabilizer is sodium p-hydroxybenzenesulfonate. The cationic surfactant is a polyallylamine cationic surfactant. The nonionic surfactant is isooctyl alcohol polyoxyethylene ether.

[0044] The method for using the copper surface cleaning agent in this embodiment is to use the above-mentioned copper surface cleaning agent to perform microetching cleaning on the copper surface at 30° C., the cleaning time is 60 s, and the microetching amount is 0.3 μm. The microetching cleaning method is so...

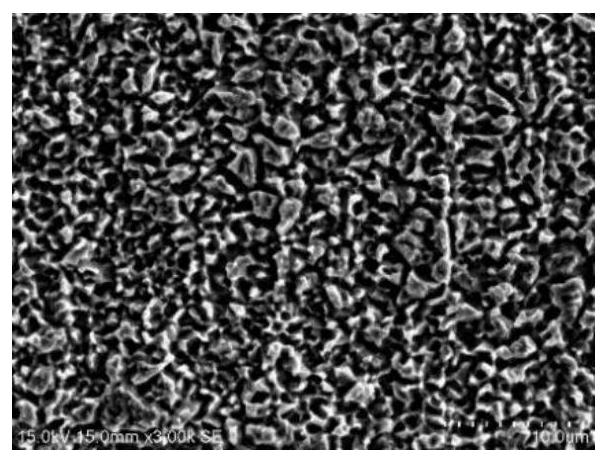

Embodiment 3

[0046] A copper surface cleaning agent is made up of acid, hydrogen peroxide, hydrogen peroxide stabilizer, cationic surfactant, nonionic surfactant and water, the concentration of the acid is 160g / L, and the concentration of the hydrogen peroxide is 1g / L, The concentration of the hydrogen peroxide stabilizer is 0.01g / L, the concentration of the cationic surfactant is 5g / L, and the concentration of the nonionic surfactant is 0.01g / L.

[0047] The acid consisted of 140 g / L sulfuric acid and 20 g / L citric acid. The hydrogen peroxide stabilizer is sodium p-hydroxybenzenesulfonate. The cationic surfactant is polyethyleneimine polymer. The nonionic surfactant is isooctyl alcohol polyoxyethylene ether.

[0048] The method for using the copper surface cleaning agent in this embodiment is to use the above-mentioned copper surface cleaning agent to perform microetching cleaning on the copper surface at 30° C., the cleaning time is 60 s, and the microetching amount is 0.3 μm. The mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com