Process method for in-dock oil putting washing of hydraulic pipeline of roll-on/roll-off facility of container roll-on/roll-off ship

A process method and technology for hydraulic pipes, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of insufficient power, long pipelines, and high requirements for system cleanliness, so as to reduce the risk of damage , Shorten the construction period and improve the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

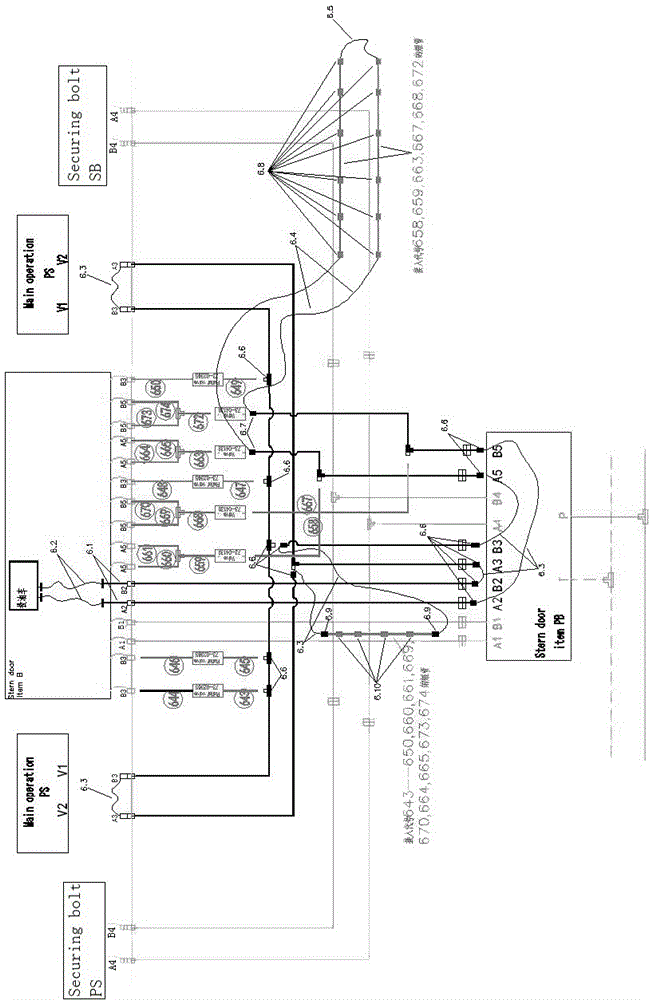

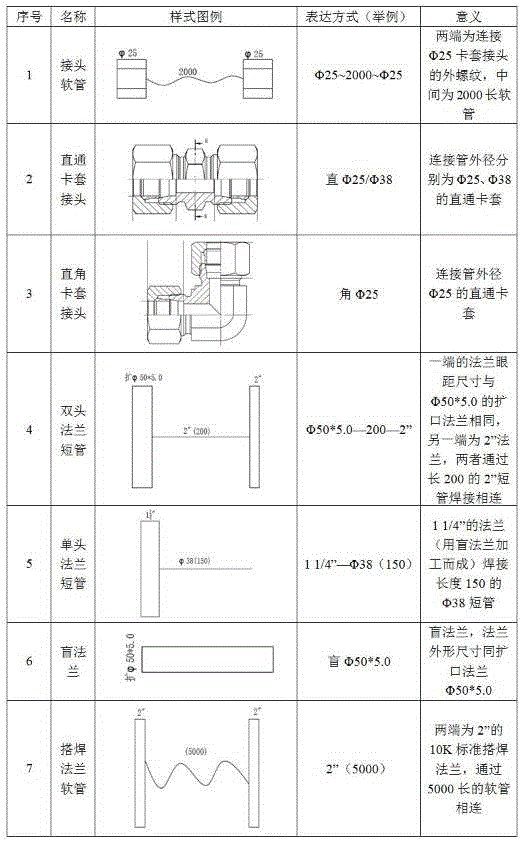

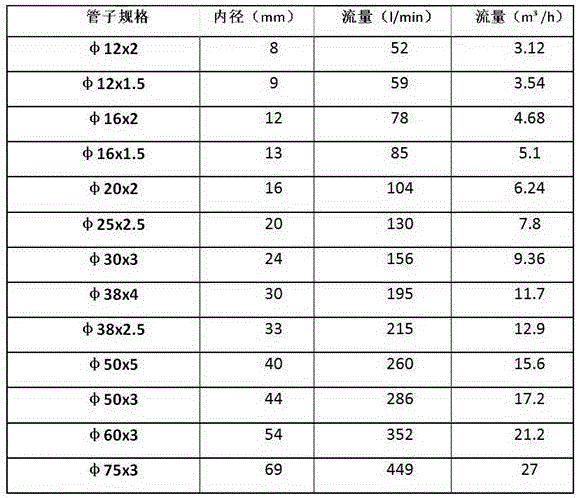

[0050] Below in conjunction with the accompanying drawings, a process method of the present invention for oil-throwing and cleaning in the hydraulic pipeline dock of the ro-ro ship ro-ro equipment will be further described in detail, in order to understand the application process of the method of the present invention more clearly, but The protection scope of the present invention cannot be limited by this.

[0051] This embodiment is used for the technical method of throwing oil in the hydraulic pipeline dock of the ro-ro ship ro-ro equipment for cleaning, and the method includes the following steps:

[0052] S1, pretreatment of the pipeline to be injected:

[0053] S1.1 Check whether the interior of the oil pipe and pipe accessories to be injected is clean, check whether there are iron filings and rust attached to the interior of the oil pipe to be injected and pipe accessories,

[0054] S1.2 Use a sponge ball or burlap to penetrate the pipeline to be injected, or use dry a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com