Method for toughening polyformaldehyde under synergistic effect of thermoplastic polyurethane and rigid particle calcium carbonate

A technology of thermoplastic polyurethane and rigid particles, which is applied in the field of polyoxymethylene toughening, can solve the problems of poor toughening effect of polyoxymethylene products, etc., and achieve the effect of reducing the granulation process, excellent comprehensive performance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

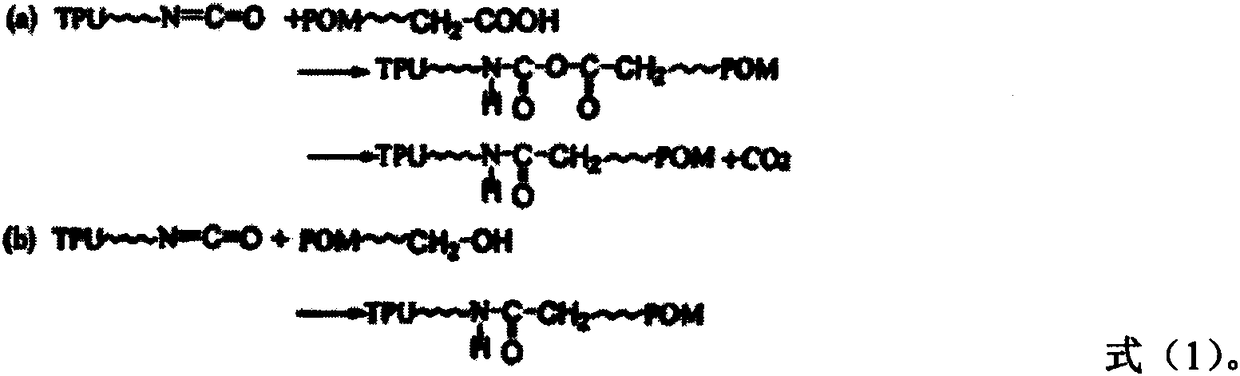

Method used

Image

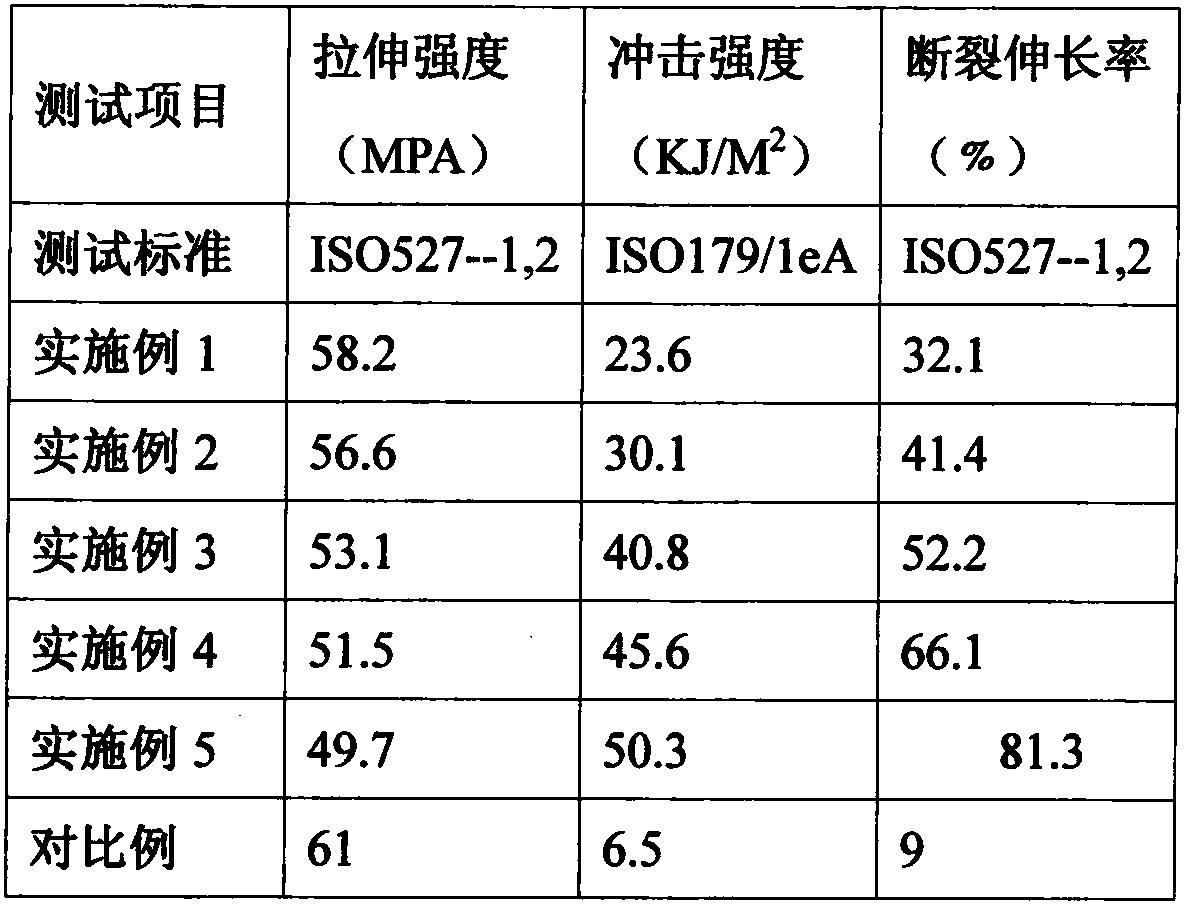

Examples

Embodiment 1

[0031] A method of thermoplastic polyurethane synergistic rigid particle calcium carbonate toughened polyoxymethylene:

[0032] Weigh 10 parts by weight of TPU, 4 parts by weight of calcium carbonate masterbatch, and 86 parts by weight of POM pellets containing compatibilizer MDI, and put the three into a plastic mixer at the same time to stir and mix evenly; dry the mixture in a drying oven Dry at 90°C for 2 to 4 hours; put the dried mixture into an injection molding machine, and perform melt injection molding at a temperature of 160 to 200°C in sections. The injection speed is medium, the injection cycle is 45s, and the mold temperature is 50°C. Get POM products.

Embodiment 2

[0034] A method of thermoplastic polyurethane synergistic rigid particle calcium carbonate toughened polyoxymethylene:

[0035] Weigh 15 parts by weight of TPU, 4 parts by weight of calcium carbonate masterbatch, and 81 parts by weight of POM pellets containing compatibilizer MDI, and put the three into a plastic mixer at the same time to stir and mix evenly; Dry at 90°C for 2 to 4 hours; put the dried mixture into an injection molding machine, and carry out melt injection molding at a temperature of 160 to 200°C in sections. The injection speed is medium, the injection cycle is 45s, and the mold temperature is 50°C. Injection molding to obtain POM products.

Embodiment 3

[0037] A method of thermoplastic polyurethane synergistic rigid particle calcium carbonate toughened polyoxymethylene:

[0038] Weigh 20 parts by weight of TPU, 4 parts by weight of calcium carbonate masterbatch, and 76 parts by weight of POM pellets containing compatibilizer MDI, and put the three into a plastic mixer at the same time to stir and mix evenly; dry the mixture in a drying oven Dry at 90°C for 2 to 4 hours; put the dried mixture into an injection molding machine, and perform melt injection molding at a temperature of 160 to 200°C in sections. The injection speed is medium, the injection cycle is 45s, and the mold temperature is 50°C. Get POM products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com