Method for preparing potassium cyanide co-production mixed sulfate by using ammonia sodium residues

A technology of potassium cyanide and sulfate, applied in the directions of metal cyanide, simple alkali metal cyanide, etc., can solve the problem of not completely eradicating waste residue and the like, and achieve the effects of low cost, simple preparation process and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

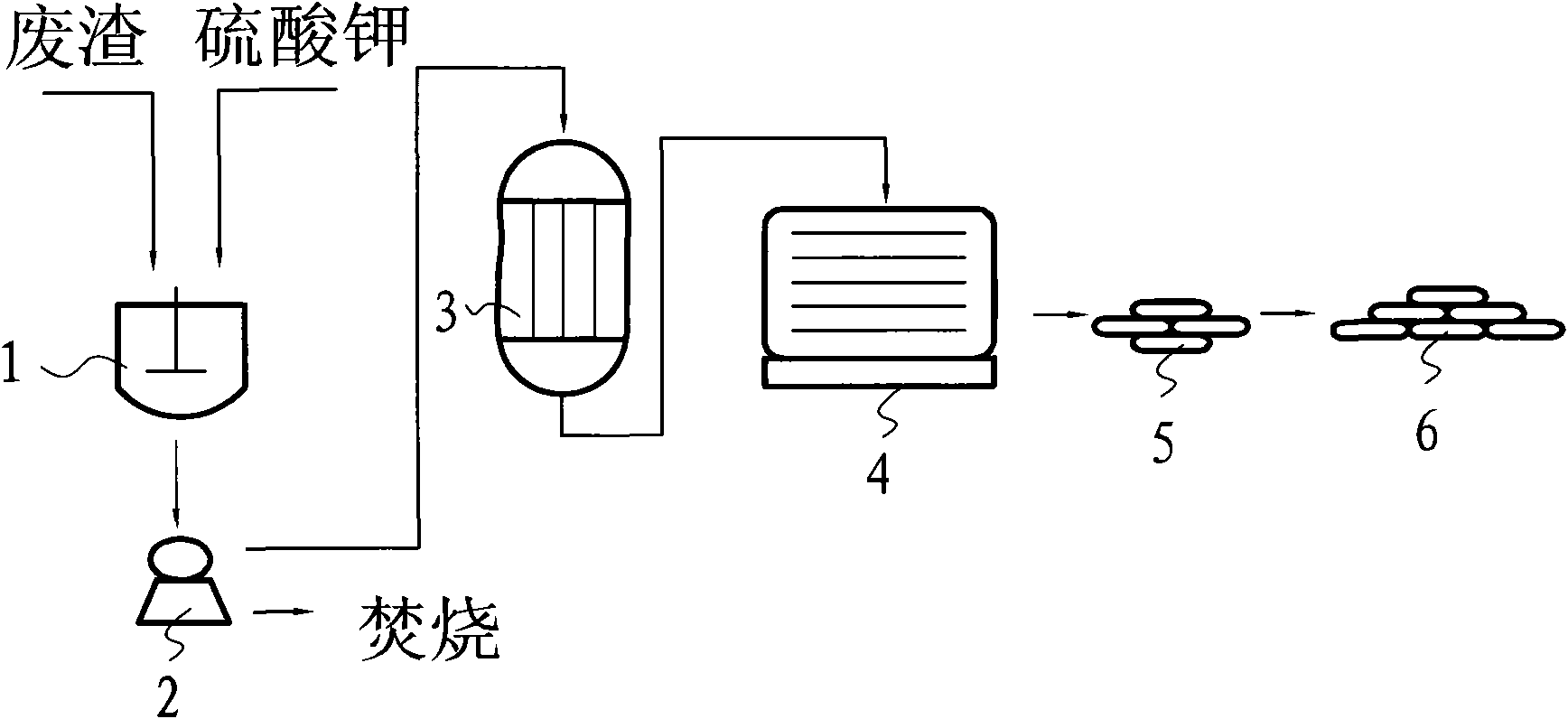

[0021] The method for preparing potassium cyanide co-production mixed sulfate from sodium ammonia method waste residue comprises the following preparation steps:

[0022] Step A, the waste residue obtained in the preparation of the product by the sodium ammonia method, zinc cyanide is calculated in 200kg, and sodium sulfate is dropped in the airtight reactor 1 according to the mass ratio of pure substance 1: 1.29, stir simultaneously, in the reactor The temperature is controlled at 60°C, and the stirring speed is 60 revolutions per minute;

[0023] Step B, filter the mixture after the complete reaction in step A with filter 2;

[0024] Step C, burning the filter cake obtained by filtering in step B;

[0025] Step D, the filtrate obtained by filtering in step B is sent to the vacuum distiller 3 for low-temperature distillation, and the distillation temperature is 40°C;

[0026] Step E, the liquid after distillation in step D is carried out crystallization through low-temperat...

Embodiment 2

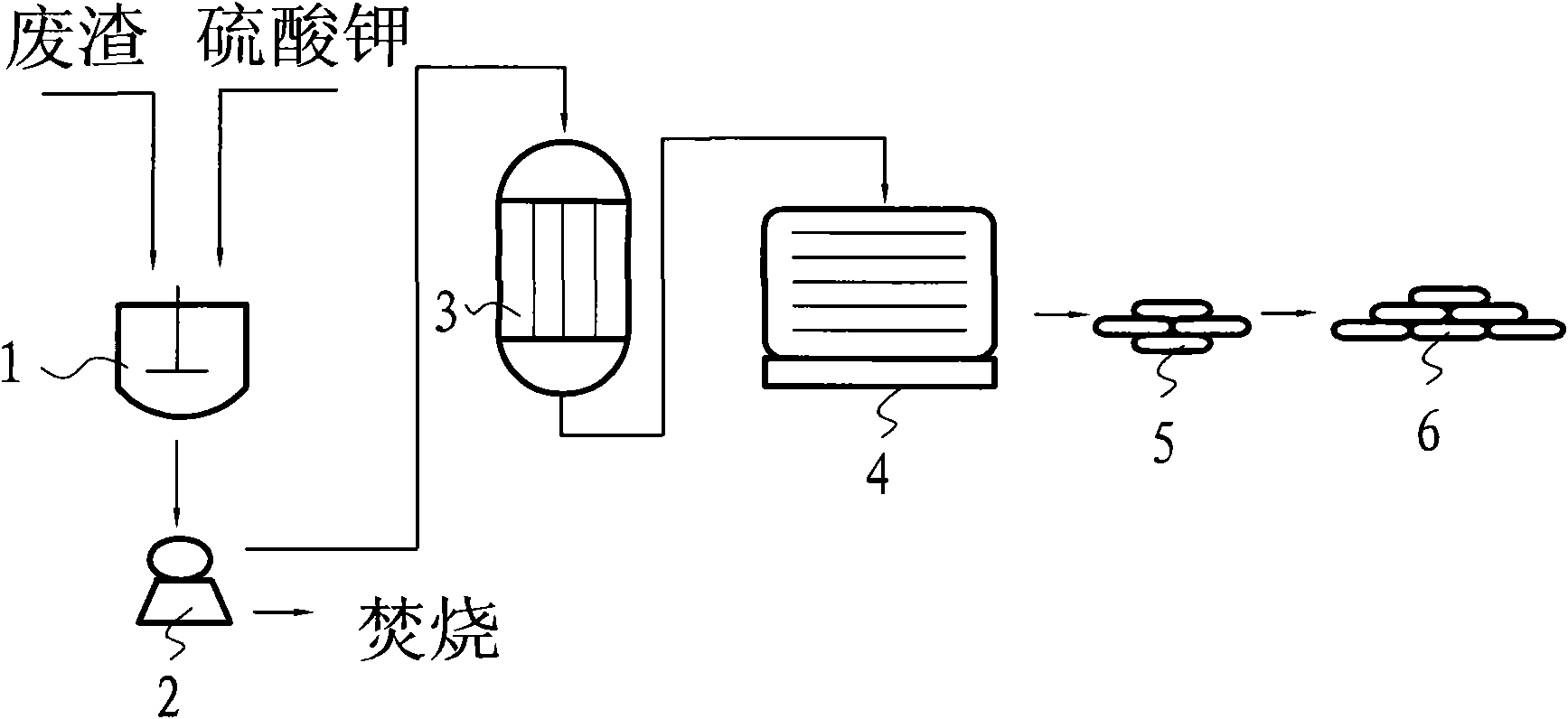

[0028] The method for preparing potassium cyanide co-production mixed sulfate from sodium ammonia method waste residue comprises the following preparation steps:

[0029] Step A, the waste residue obtained in the preparation process of the product by the sodium ammonia method, zinc cyanide in 200kg, and sodium sulfate are put into the airtight reactor 1 according to the mass ratio of pure substance 1: 1.49, stir simultaneously, in the reactor The temperature is controlled at 65°C, and the stirring speed is 60 revolutions per minute;

[0030] Step B, filter the mixture after the complete reaction in step A with filter 2;

[0031] Step C, burning the filter cake obtained by filtering in step B;

[0032] Step D, the filtrate obtained by filtering in step B is sent to the vacuum distiller 3 for low-temperature distillation, and the distillation temperature is 50°C;

[0033] Step E, the liquid after distillation in the step D is carried out crystallization through low-temperature...

Embodiment 3

[0035] The method for preparing potassium cyanide co-production mixed sulfate from sodium ammonia method waste residue comprises the following preparation steps:

[0036] Step A, the waste residue obtained in the preparation process of the product by the sodium ammonia method, zinc cyanide is calculated in 200kg, and sodium sulfate is put into the airtight reactor 1 according to the mass ratio of pure substance 1: 1.69, stir simultaneously, in the reactor The temperature is controlled at 70°C, and the stirring speed is 60 revolutions per minute;

[0037] Step B, filter the mixture after the complete reaction in step A with filter 2;

[0038] Step C, burning the filter cake obtained by filtering in step B;

[0039] Step D, the filtrate obtained by filtering in step B is sent to the vacuum distiller 3 for low-temperature distillation, and the distillation temperature is 70 ° C;

[0040] Step E, the liquid after distillation in the step D is crystallized through low-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com