Sodium cyanide powder production system and sodium cyanide powder production method

A production system, sodium cyanide technology, applied in the direction of metal cyanide, simple alkali metal cyanide, etc., can solve the problem of high loss of sodium cyanide products, complex equipment structure, synthesis of sodium cyanide products, evaporation crystallization, separation and drying molding Problems such as difficulties in the process, etc., to achieve the effect of compact structure, simple and compact structure, and prevention of self-aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

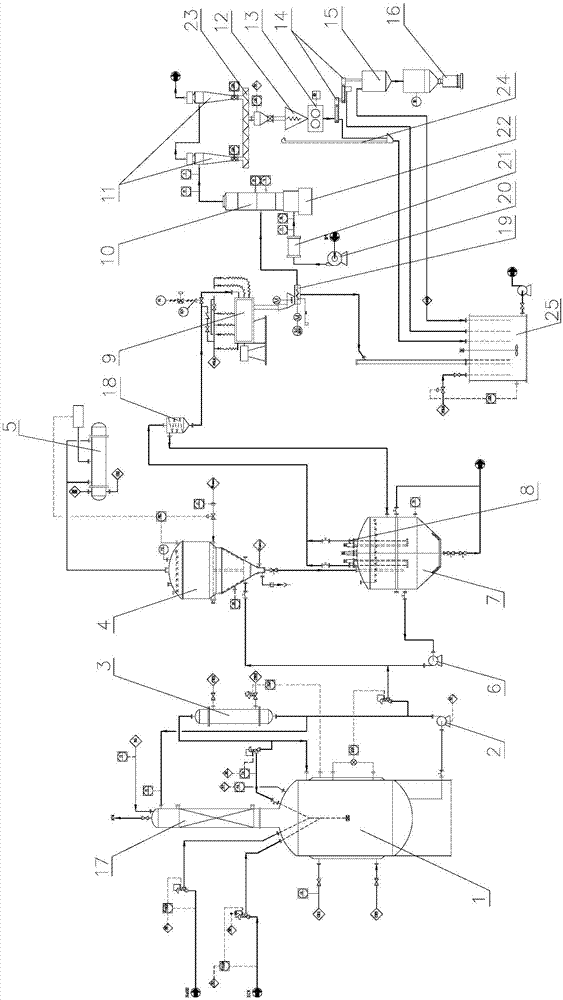

[0025] A kind of sodium cyanide powder production system and production method of the present invention will be described in further detail below in conjunction with accompanying drawing, but not as limiting the present invention.

[0026] Such as figure 1 As shown, a sodium cyanide powder production system mainly includes a reactor 1, a reactor discharge pump 2, a reactor cooler 3, an evaporator 4, an evaporator condenser 5, an evaporator circulation pump 6, and a crystallizer 7. Concentrated slurry pump 8, centrifugal separator 9, flash dryer 10, cyclone separator 11 and forming packaging system.

[0027]In the reaction process, the reactor 1 is provided with a hydrocyanic acid feed inlet and a sodium hydroxide feed inlet, and the material outlet of the reactor is respectively connected with the material inlet of the reactor cooler 3 and the reactor 1 through the reactor discharge pump 2. The reactor absorption section 17 at the top communicates with the material inlet at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com