Treatment and reuse method for cupric-cyanide-containing waste water

A copper cyanide and waste water technology, applied in metallurgical waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

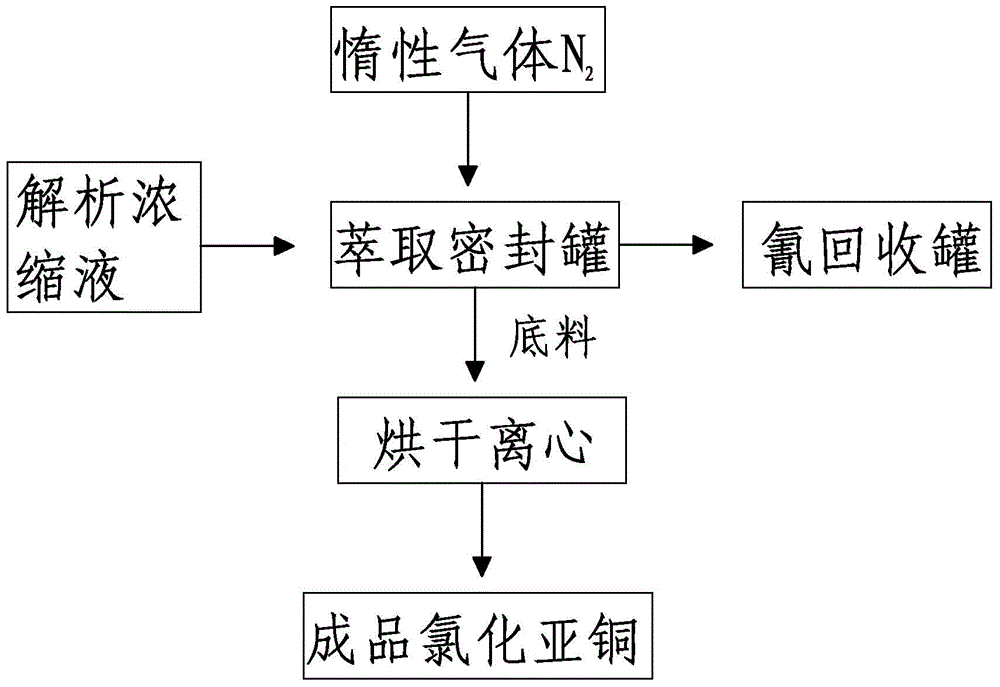

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The invention provides a method for treating and reusing waste water containing copper cyanide, which is divided into ion recovery of low-concentration cyanide and extraction of cuprous;

[0031] refer to figure 1 , the main steps of the ion recovery low-concentration cyanide are:

[0032] Add a guide pipe to the electroplating cleaning tank in the workshop to collect the cleaning water in a special cyanide-containing collection tank; the copper cyanide-containing wastewater in the cyanide-containing collection tank is pumped into the security filter by the motor to filter out the copper cyanide-containing wastewater The solid impurities in the copper cyanide wastewater; the copper cyanide wastewater containing impurities is passed into the cyanide recovery machine, and the cyanide complex and free cyanide in the copper cyanide wastewat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com