Method of making inorganic gold compound

a technology of inorganic gold and compound, which is applied in the field of making inorganic gold compound, can solve the problems of high investment cost, large amount of toxic nitrogen oxide generated, and polluted working environment, and achieves high yield, high yield, and safe time-saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

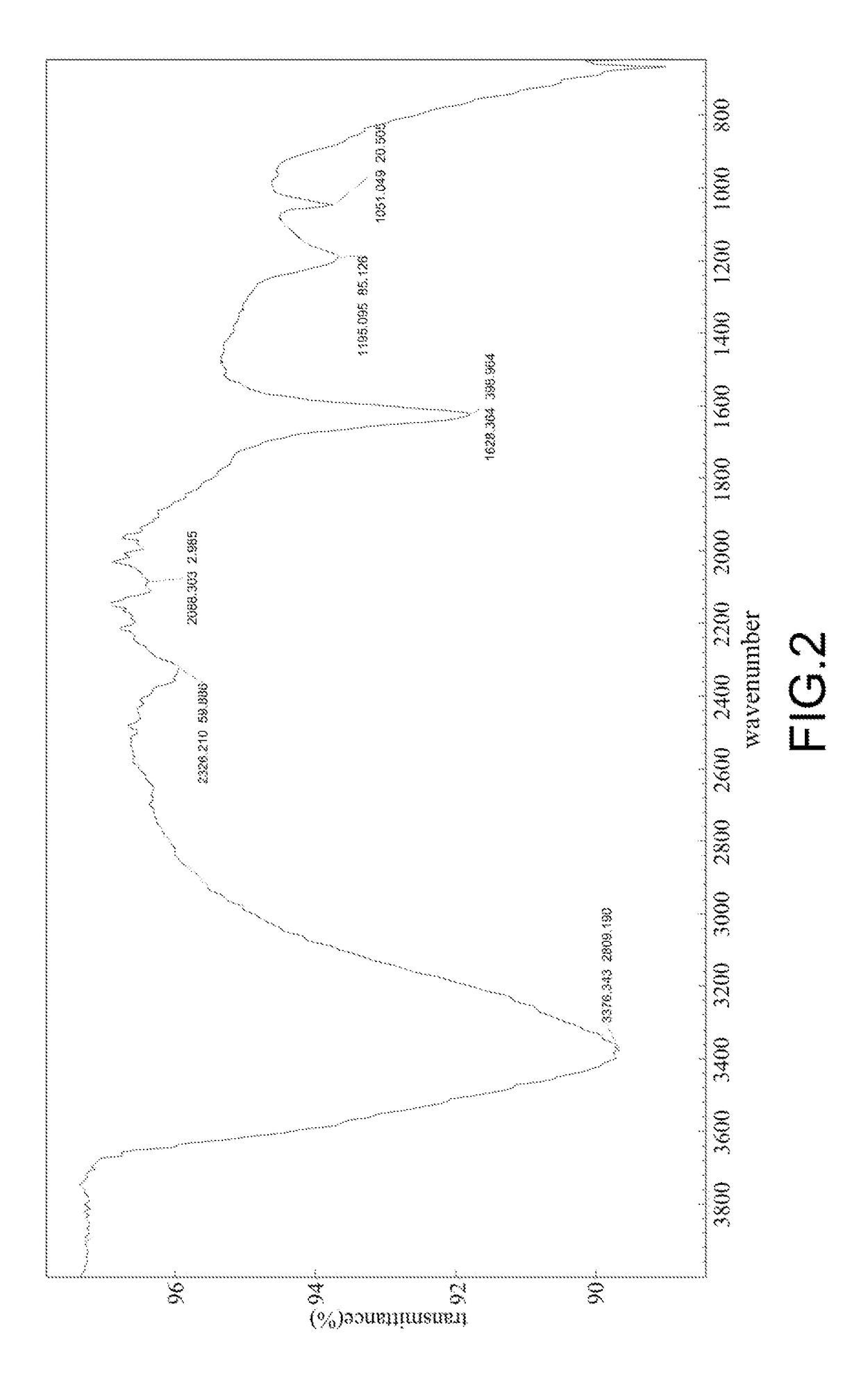

Image

Examples

example 1

Synthesis of Sodium Tetrachloroaurate Using Sodium Chlorite in Hydrochloric Acid

[0112]Gold powder (5 g) and concentrated HCl (125 mL of aqueous solution containing 36 wt % of hydrochloric acid) were placed in a 250 mL flat-bottomed flask. 5 mL of aqueous solution containing 5 wt % of sodium chlorite (NaClO2) was added into the flask and a mixture was obtained. The mixture was stirred for 10 min until the gold powder was consumed to obtain a product solution containing sodium tetrachloroaurate. The product solution was concentrated by rotary evaporation at 100° C. under a pressure of 0.5 mbar and stood at room temperature to give crystalline sodium tetrachloroaurate (>99% yield).

example 2

Synthesis of Sodium Tetrachloroaurate Using Sodium Chlorate in Hydrochloric Acid

[0113]Gold powder (0.5 g) and concentrated HCl (25 mL of aqueous solution containing 36 wt % of hydrochloric acid) were placed in a 100 mL flat-bottomed flask. 5 mL of aqueous solution containing 5 wt % of sodium chlorate (NaClO3) was added into the flask and a mixture was obtained. The mixture was stirred for 10 min until the gold powder was consumed to obtain a product solution containing sodium tetrachloroaurate. The product solution was concentrated by rotary evaporation at 100° C. under a pressure of 0.5 mbar and stood at room temperature to give crystalline sodium tetrachloroaurate (>99% yield).

example 3

Synthesis of Tetrachloroauric Acid Using Iodic Acid in Hydrochloric Acid

[0114]Gold powder (0.5 g) and concentrated HCl (25 mL of aqueous solution containing 36 wt % of hydrochloric acid) were placed in a 100 mL flat-bottomed flask. 5 mL of aqueous solution containing 5 wt % of iodic acid (HIO3) was added into the flask and a mixture was obtained. The mixture was stirred for 5 min until the gold powder was consumed to obtain a product solution containing hydrochloric acid. The product solution was concentrated by rotary evaporation at 100° C. under a pressure of 0.5 mbar and stood at room temperature to give crystalline hydrochloric acid (>99% yield).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com