Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Iodic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iodic acid, HIO₃. It is a white water-soluble solid. Its robustness contrasts with the instability of chloric acid and bromic acid. Iodic acid features iodine in the oxidation state +5 and is one of the most stable oxo-acids of the halogens. When heated, samples dehydrate to give iodine pentoxide. On further heating, the iodine pentoxide further decomposes, giving a mix of iodine, oxygen and lower oxides of iodine.

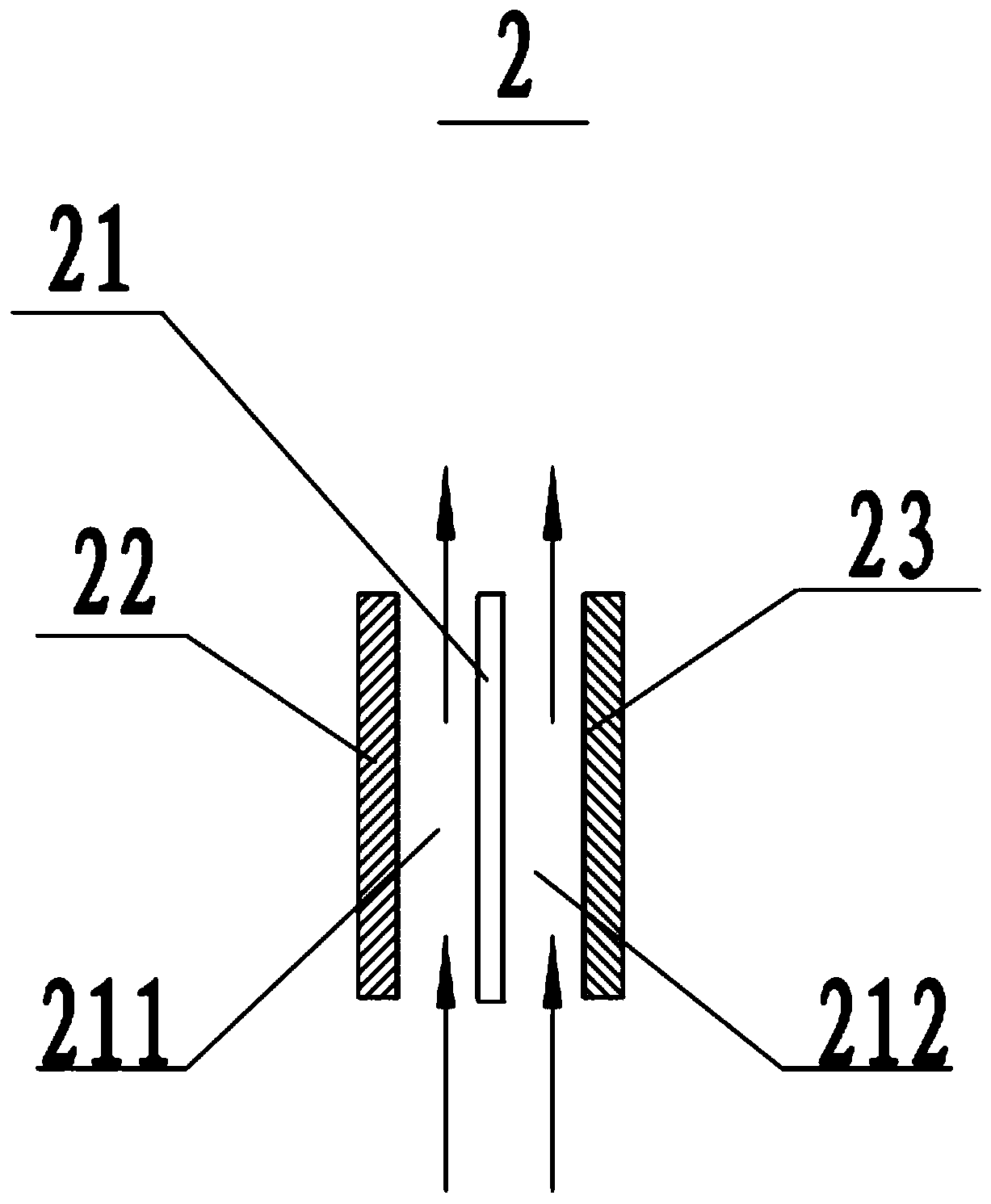

Automatic acid mixing apparatus and method thereof, and automatic pipeline iodic acid apparatus and method thereof

ActiveCN102351945AUniform precipitationRapid precipitationPeptide preparation methodsOther dairy technologyHigh concentrationAutomatic control

An objective of the invention is to provide an automatic acid mixing apparatus and a method thereof, and an automatic pipeline iodic acid apparatus and a method thereof. Therefore, problems of nonuniform mixing and over high local acidity are solved, wherein the problems exist in a current on-line souring system. The automatic pipeline iodic acid apparatus comprises a material pipeline, a material variable frequency pump, an acid pipeline, a diluted acid variable frequency pump, a Venturi tube and a mixer; an entrance section of the Venturi tube is connected with a premixer; an acid jetting pipeline is arranged in the premixer; and a tail portion of the mixer is connected with an iodic acid pH monitor, which is connected with an automatic control module. according to the invention, the automatic pipeline iodic acid apparatus is utilized to enable automatic iodic acid to be realized; a diluted acid that is configured by the automatic iodic acid apparatus enters the automatic acid mixing apparatus to carry out automatic acid mixing. Besides, materials can be mixed fully, rapidly and high efficiently; occurrences of unstable acid concentration and a local peracid phenomenon during the iodic acid processing can be effectively avoided; and denaturation of active materials with acid nonresistant performance on the condition of acid with high concentration can be reduced.

Owner:甘肃华羚乳品股份有限公司

Manufacturing method of epoxy modification acrylate latex automatic deposit paint

This invention relates to preparation method of a epoxy modified acrylic latex automotive sediment dope. It adopts ethoxyline resin to modify acrylate, take acrylics monomer as solvent to dissolve ethoxyline resin, emulsify it to gain micro milk particle, then adopt hud emulsion polymerization craft to gain latices. It takes glycollic acid , iodic acid, citric acid as accelerating component of self- sediment painting. Add this self- sediment dope into obtained copolymer emulsion, not at all use organic solvent, avoid harm to environment.

Owner:增城市裕新涂料有限公司

Chemical nickel phosphor plating method for magnesium alloy

InactiveCN1769521ASimple ingredientsEasy to prepareLiquid/solution decomposition chemical coatingChemical platingThiourea

This invention relates to a magnesium alloy chemical nickel and phosiphoric coating method, which belongs to the chemistry coating film technology filed. The charater of this invention has the following steps: 1) preparing the chemical plating solution; wherein, the composing and weight as follows: the main salt alkali carbonic nickel 10í½30g / Lú”The reducer hypo-phosphorous natrium 20í½40g / Lú”The complex emulsion 15í½25g / Lú¼the succinic acid 4í½8g / Lú¼the acetic natrium 10í½20g / Lú¼the citric acid 3í½15g / Lú¼then choosing one or more from the raleted complex emulsion; The stabilizer thiourea 0.5í½3.0mg / Lú¼the iodic acid natrium 5í½15mg / Lú¼then choosing one or two from the stabilizer; The antiseptic hydrogen fluoride ammonium 15í½30g / Lú”The rest is water. 2) Degreasing and pouring the magnesium and cleaning its surface. 3) Dipping zinc, withdrawing zinc and twice dipping zinc.4) Chemical plating nickel; the temperature is 80í½90íµ, H 6í½7ú¼the time is 45í½60min. 5) Washing, doing heat treatment with it for 6h under 200íµ; at last obtaining the nickel phosiphoric alloy coating with the thickness of 15í½20 micron.

Owner:SHANGHAI UNIV

Non-linear optical crystal of iodic acid zinc potassium

InactiveCN101831698ANonlinear Optical Performance ImprovementPolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalSpace group

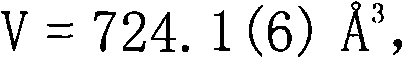

The invention relates to a non-linear optical crystal of iodic acid zinc potassium. The iodic acid zinc potassium has a chemical formula of K2Zn(IO3)4(H2O)2 and the molecular weight of 864.74 and belongs to a monoclinic system; and the iodic acid zinc potassium has a space group C2 and unit-cell parameters are as follows: a is equal to 13.936 (6), b is equal to 7.7609(18), alpha and gamma are both equal to 90 degrees, beta is 126.75(3) degrees and Z is 1. The iodic acid zinc potassium is prepared by using a hydrothermal method. The iodic acid zinc potassium (K2Zn(IO3)4(H2O)2) has excellent non-linear optical performance and the powder second harmonic generation (SHG) coefficient of the iodic acid zinc potassium is 2.3 times that of KDP (KH2PO4) and is equivalent to that of LBO (lithium triborate).

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Antibody diagnosing reagent kit for detecting HepatitisType C virus, its preparation and method for detection

InactiveCN1670532AHigh detection activitySolve the shortcomings of only detecting IgG antibodiesMaterial analysis by observing effect on chemical indicatorAntigenIodic acid

This invention relates to hepatitis C virus diagnose agent box and its process method, which comprises the following steps: joining HCV regroup antigen to the buffer liquid into the enzyme yoke plate; hatching overnight for buffer liquid washing enzyme yoke plate; then joining buffer liquid and after hatching to abandon hole liquid for total enzyme yoke plate to complete the process of yoke plate; combining the marked HCV regroup antigen and horse radish peroxides enzyme through improved iodic acid method to complete the enzyme marked HCV antigen. The agent box has color liquid A and B, terminal liquid, sample diluent, negative comparing normal serum, positive comparing human serum with HCV antibody.

Owner:北京科卫临床诊断试剂有限公司

Load type molecular iodine complementary agent, and its prepn. method and use

InactiveCN1861091AFix stability issuesEasy to implementMetabolism disorderInorganic non-active ingredientsFowlHydrotalcite

An iodine supplement used for the forage of animals and fowls and human health-care food or medicine is a hydrotalcite carried molecular iodine. It is prepared through providing hydrotalcite as micro reactor and reducing or oxidizing reaction to reduce iodic acid (or iodate) or oxidize iodide to obtain molecular iodine.

Owner:ZHEJIANG UNIV

Preparation method of iodine-containing disinfectant with stable component content

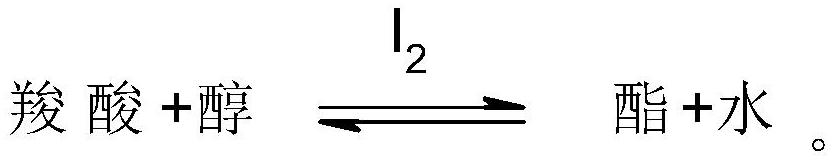

ActiveCN112806387AComponent stabilityStable disinfection and sterilization effectAntibacterial agentsBiocideTrans esterificationPtru catalyst

The invention discloses a preparation method of an iodine-containing disinfectant with a stable component content, which comprises the following steps: mixing raw materials together and conducting reacting at 50-150 DEG C for 5-20 hours, wherein the raw materials comprise elemental iodine and any one of the following seven raw materials: (1) carboxylic acid and alcohol, (2) carboxylic acid, alcohol and water, (3) carboxylic acid, alcohol, carboxylic ester and water, (4) alcohol, carboxylic ester and water, (5) carboxylic acid, carboxylic ester and water, (6) carboxylic ester and water, and (7) carboxylic acid and water. According to the iodine-containing disinfectant, carboxylic acid, alcohol, water, ester and the like in the iodine-containing disinfectant are balanced through reversible esterification and / or ester exchange reaction under the condition that iodine serves as a catalyst, and / or simple substance iodine is subjected to disproportionation reaction under the condition that acid and water are contained to obtain stable balance among simple substance iodine, iodide ions and iodic acid. The iodine-containing disinfectant is stable in component and convenient to prepare, the content of iodine, iodide and carboxylic acid is kept stable after long-term storage (at least two years), and the iodine-containing disinfectant has a stable disinfection and sterilization effect.

Owner:FOSHAN STANDARD BIO TECH

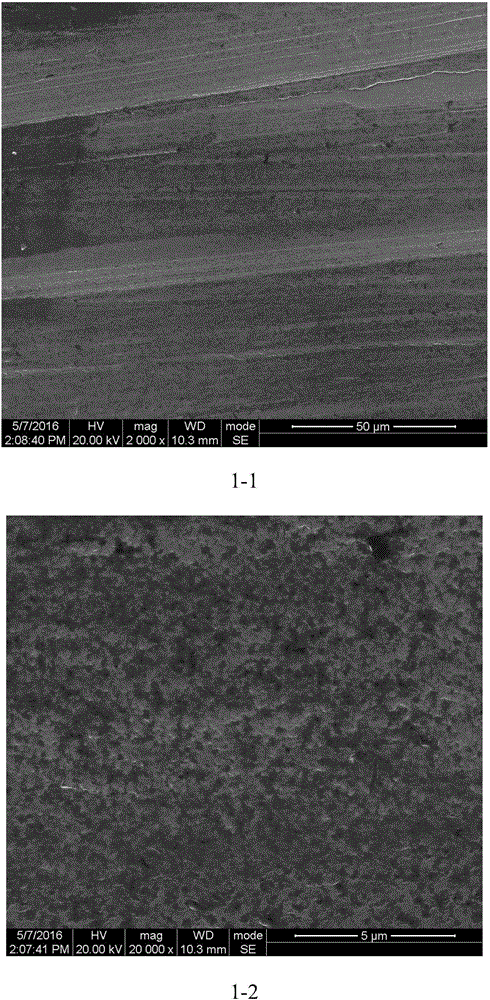

Surface-modified lithium metal negative electrode material and preparation method thereof

InactiveCN106099091ASolve the problem of low Coulombic efficiencyReduce polarizationCell electrodesSecondary cellsOrganic solventLithium metal

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Non-linear optical crystal iodic acid vanadium potassium

ActiveCN102534786ANonlinear Optical Performance ImprovementPolycrystalline material growthFrom normal temperature solutionsNonlinear optical crystalSpace group

A non-linear optical crystal iodic acid vanadium potassium is characterized in that a chemical formula is K (VO2)2 (IO3)3, molecular weight is 729.68, the non-linear optical crystal iodic acid vanadium potassium belongs to an orthorhombic system and a space group Ima2, and unit cell parameters include that a=14.136 (3), b=10.201 (2), c=8.064 (1), alpha=beta=gamma=90 degrees, V=1162.8 (3) and Z=4. A hydrothermal method is adopted for preparation. The iodic acid vanadium potassium K (VO2)2(IO3)3 has good non-linear optical performance, and a second harmonic generation (SHG) coefficient of powder of the iodic acid vanadium potassium is 3.6 times that of potassium titanyl phosphate (KTP).

Owner:徐翔

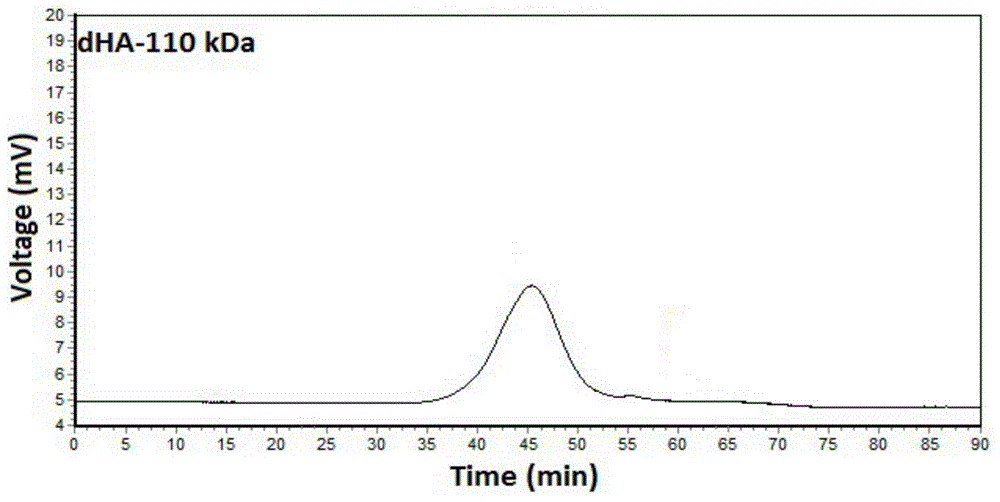

Preparation method and application of high-molecular-weight deacetylated hyaluronic acid

InactiveCN104910294AIncreased degree of deacetylationGood degree of deacetylationImmunological disordersFreeze-dryingIodic acid

The invention discloses a preparation method and application of high-molecular-weight deacetylated hyaluronic acid. The preparation method comprises the following steps: dissolving hyaluronic acid in anhydrous hydrazine containing 1% of hydrazine sulfate, reacting in a deoxidized nitrogen protective atmosphere at 60 DEG C for 72 hours, precipitating the reaction product with cold ethanol, dissolving the precipitate in 5% glacial acetic acid, adding 0.5M of iodic acid, standing at 4 DEG C for 2 hours, and adding excessive iodic acid into 57% hydriodic acid; and carrying out ether extraction to remove generated iodine, neutralizing, and carrying out freeze-drying to obtain the high-molecular-weight deacetylated hyaluronic acid. The zwitterion hyaluronic acid polysaccharide disclosed in the invention is used for immunological diseases, and has the advantages of obvious curative effect and no side effect.

Owner:NORTHWEST A & F UNIV

Iodine alginate aqua medical fertilizer and preparation method thereof

ActiveCN101423440AImprove securityRaise iodine thresholdFertilizer mixturesTO-18Monopotassium phosphate

The invention discloses an alga iodic acid aqueous medical fertilizer and a preparation method thereof. Each liter of the aqueous medical fertilizer comprises the following raw materials in mass percentage: 20 to 30 percent of alginic acid, 10 to 30 percent of mannite, 8 to 72 percent of potassium iodide, 1.6 to 15 percent of potassium iodate, 2 to 18 percent of iodine, 100 to 150 percent of monopotassium phosphate, 44 to 71 percent of anhydrous borax and the balance being water. The preparation method comprises the following steps: (1) the raw materials are taken out for standby according to mass ratio; (2) the anhydrous borax is dissolved in water to obtain a borax liquid; (3) the alginic acid is placed in the borax liquid, is evenly mixed, is added with the mannite and the monopotassium phosphate, and is stirred and dissolved to obtain a standby liquid A; (4) the potassium iodide, the potassium iodate and the iodine are placed in the water and are dissolved to obtain a standby liquid B; and (5) the standby liquid A and the standby liquid B are evenly mixed and stirred; after stirring and precipitation, a supernatant liquid is obtained and is the alga iodic acid aqueous medical fertilizer. The alga iodic acid aqueous medical fertilizer is suitable for various crops, is safe and reliable, has no pollution, no residue and no harm, is not influenced by geographical environment and climate, can promote growth of the crop, improve adverse resistance and the like.

Owner:山东三碘生化科技有限公司

Slow-released type iodine complement agent, and prepn. method and use-thereof

InactiveCN1911241AEasy to implementSuitable for industrial productionMetabolism disorderAnimal feeding stuffDiseaseSupplement use

A slow-release I-supplement used as the I-supplementing additive of forage or to prepare I-supplementing food or medicine for treating diseases is an anionic exchange resin containing the iodic acid radicals or I ions. It is prepared through the ionic exchange between iodic acid radicals or I ions and anionic exchange resin.

Owner:ZHEJIANG UNIV

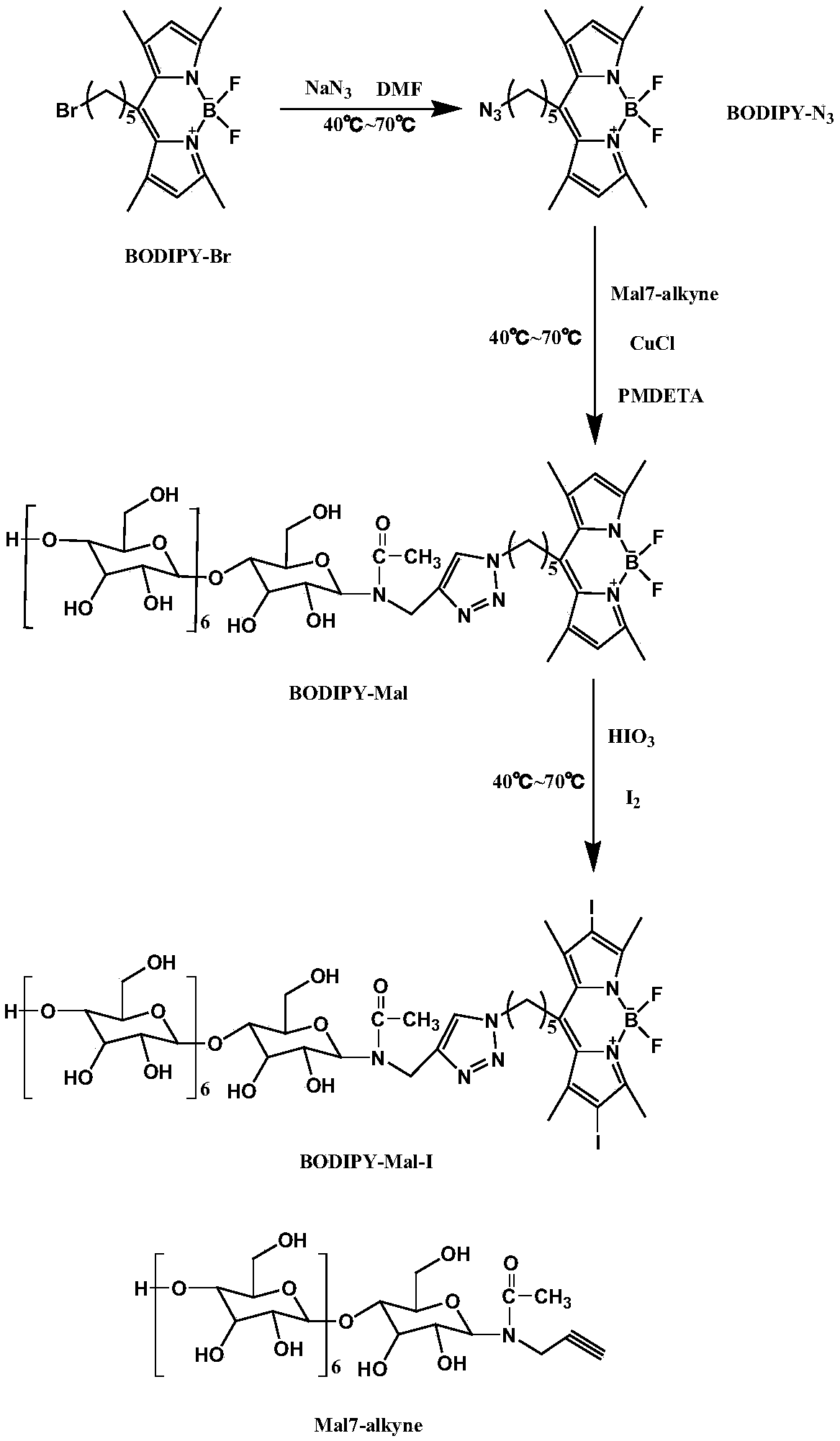

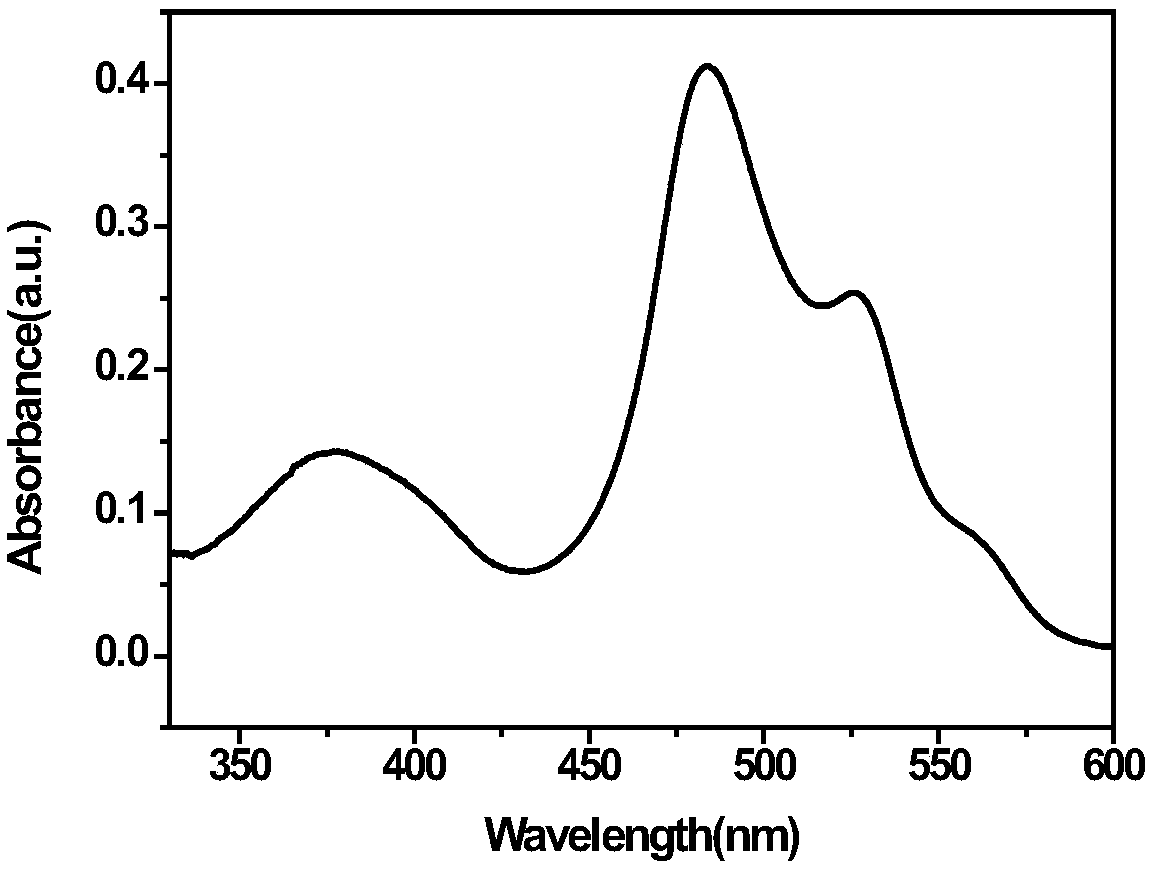

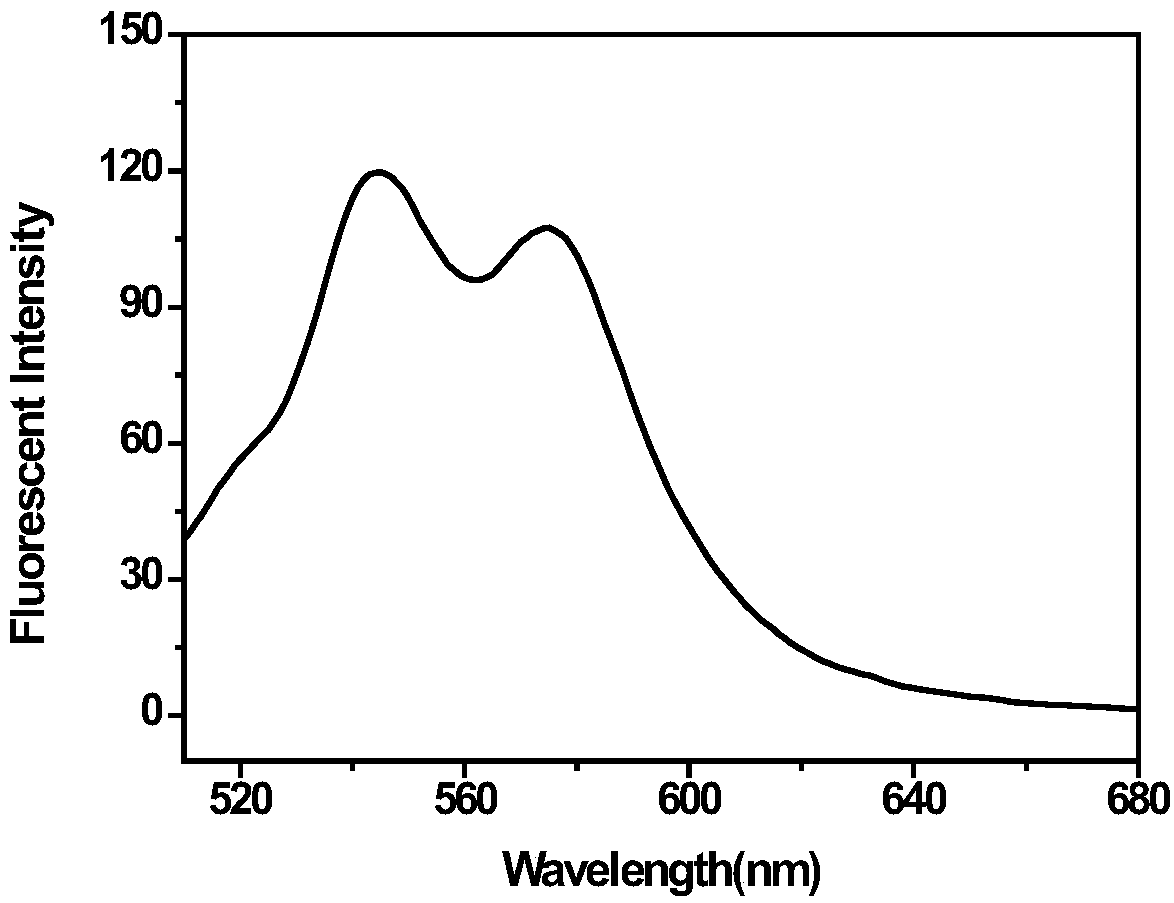

BODIPY-containing bactericidal material and preparation method and application thereof

ActiveCN108752401AComplete retention propertiesReserved natureAntibacterial agentsAntimycoticsSolubilityYeast

The invention discloses a BODIPY-containing bactericidal material and a preparation method and application thereof. The preparation method comprises that BODIPY-Br and sodium azide undergo a reactionto produce BODIPY-N3, BODIPY-N3 and acetylated maltoheptaose undergo a reaction under the catalytic action of a CuCl / PMDETA complex to produce BODIPY-Mal, and the BODIPY-Mal, iodic acid and iodine undergo an iodination reaction to produce the BODIPY-Mal-I bactericidal material. The BODIPY-Mal-I bactericidal material has good water solubility and completely retains the properties of BODIPY. The photodynamic power generated by BODIPY-Mal-I can effectively inactivate yeast cells and especially kill gram-positive bacteria. The preparation method has the advantages of simple processes, mild reaction conditions, low risk and low toxicity.

Owner:SOUTHWEST UNIVERSITY

Method for preparing ZnO/I-doped ZnO core/shell structure nanowire array

ActiveCN104851942AImprove adsorption capacityImprove performanceFinal product manufacturePhotovoltaic energy generationNano structuringIodic acid

The invention discloses a method for preparing a ZnO / I-doped ZnO core / shell structure nanowire array. First a hydrothermal method is adopted to prepare a ZnO nanowire array on the surface of transparent conductive glass; then the ZnO nanowire array is put in a mixed solution of methyl alcohol containing iodic acid, zinc acetate and hexamethylene tetramine and water to prepare the ZnO / I-doped ZnO core / shell structure nanowire array. The I-doped ZnO shell layer prepared by the method provided by the invention can reduce the forbidden band width of ZnO, causing a light absorption range of ZnO to expand towards a visible light area, and the prepared composite structure can effectively improve application of a ZnO nanostructure to fields of solar cells, photocatalysis, photoelectric conversion, thermoelectric conversion and the like.

Owner:SHANDONG ANWEIXIAN BIOLOGICAL TECH CO LTD

Pearl beverage raw material and preparation method thereof

InactiveCN1666673AImprove the crushing finenessIncrease iodic acidFermentationAnimal proteins working-upInorganic saltsAquatic animal

The invention discloses a pearl beverage raw material and preparation process which comprises, disintegrating pearl raw material, charging iodic acid and edible acid to steep 24-72 hours, adjusting pH to neutral, charging minced aquatic animal meat, mixing and placing in reaction still, adjusting pH to neutral, charging 0.1-0.25% papain and 0.1-0.25% trypsin, carrying out catalytic reaction for 1.5-4 hours at 40-65 deg. C, finally filtering and removing the filtering deposit to obtain filter liquor.

Owner:DAHU AQUACULTURE +1

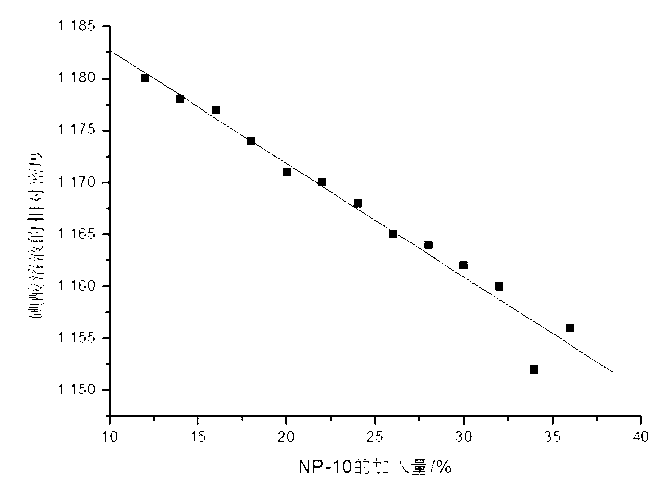

Iodic acid solution for aquaculture and preparation method thereof

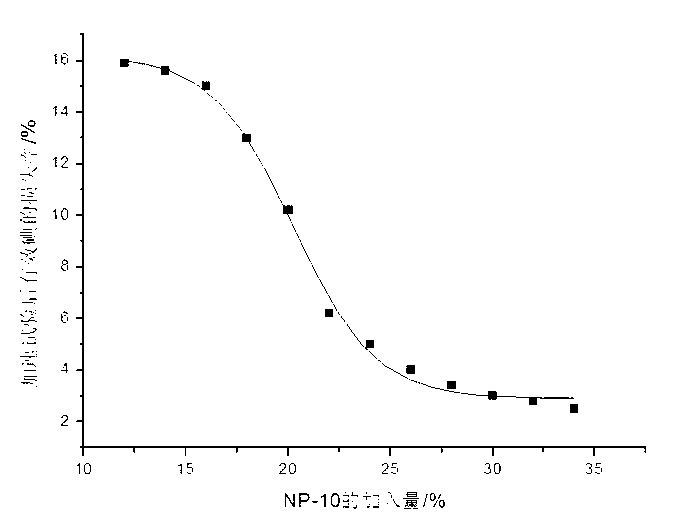

The invention relates to an iodic acid solution for aquaculture. The iodic acid solution comprises the following components by weight percent: 3% of iodine, 0.4-1% of iodide, 20-30% of nonionic surfactant, 9-16% of phosphoric acid with the concentration of 85%, 14-28% of sulfuric acid with the concentration of 98% and the balance of water, wherein the total weight percent of phosphoric acid and sulfuric acid is 30-37%. The invention further relates to a preparation method of the iodic acid solution for aquaculture. The iodic acid solution for aquaculture is smart in design, high in stability and good in sterilization effect, reduces the waste of production cost due to volatilization of a large amount of iodine, is prepared by a step feeding method, is simple and convenient to operate and reasonable, lowers the pressure-resistant and heat-resistant requirements on production equipment, reduces the production cost, and is suitable for large-scale popularization and application.

Owner:SHANGHAI YUKING NEW MATERIAL TECH

Cleaning liquid and cleaning method

InactiveUS20120065116A1Easy to cleanEfficient removalDetergent mixture composition preparationSemiconductor/solid-state device manufacturingPhosphoric acidCerium

Disclosed is a cleaning liquid which is capable of cleaning an object to be cleaned, to the surface of which cerium oxide adheres, by dissolving and removing cerium oxide in the form of cerium ions. A cleaning method using the cleaning liquid is also disclosed. The cleaning liquid for removing cerium oxide is characterized by containing hydrogen fluoride, at least one acid selected from the group consisting of hydrochloric acid, nitric acid, sulfuric acid, acetic acid, phosphoric acid, iodic acid and hydrobromic acid, and water. The cleaning liquid is also characterized by dissolving and removing cerium oxide in the form of cerium ions.

Owner:STELLA CHEMIFA CORP

Stable iodine-containing disinfectant and preparation method thereof

ActiveCN112841181ALong-term compositional stability resultsMeet the requirements of quality standardsBiocideDisinfectantsAlcoholIodide

The invention discloses a stable iodine-containing disinfectant and a preparation method thereof, and the iodine-containing disinfectant comprises the following components by weight: 0.1-10% of elemental iodine or 1-40% of an iodine complex, 0.1-10% of iodide, 0.01-1.0% of an iodic acid compound, 0.1-40% of carboxylic acid and / or an acidic salt of carboxylic acid, 5-80% of alcohol, 0.1-30% of carboxylic ester, and 5-88% of water. The iodide is composed of iodine negative ions and hydrogen ions or metal cations or ammonium ions or quaternary ammonium ions. The iodine-containing disinfectant is simple in preparation method and stable in component content after long-term storage.

Owner:FOSHAN STANDARD BIO TECH

Lanthanum-iodine co-doped photocatalyst composite material and preparation method thereof

InactiveCN107999097AImprove light responsivenessEnhanced recycling capabilitiesPhysical/chemical process catalystsWater/sewage treatment by irradiationMicrosphereIodic acid

The invention relates to a magnetic lanthanum-iodine co-doped photocatalyst composite material and a preparation method thereof. The composite material is prepared by the following method: using ferroferric oxide nanoparticles as a magnetic core and using ethyl orthosilicate as a silicon source, coating the surface of the ferroferric oxide nanoparticles with a porous active silicon layer to obtaina porous magnetic carrier by using a sol-gel method, then using titanate as a titanium source and iodic acid as a raw material, and baking to obtain a precursor; and then adopting a precipitation-impregnation method, using lanthanum nitrate as a raw material, and preparing lanthanum-iodine co-doped visible-light catalytic magnetic porous titanium dioxide composite microspheres, namely the magnetic lanthanum-iodine co-doped photocatalyst composite material. According to the lanthanum-iodine co-doped photocatalyst composite material prepared by the fractional step method, lanthanide iodine andanatase titanium dioxide can be simultaneously doped and are attached to the magnetic matrix, and not only can the light response ability of the material be improved, but also the recycling capacity of the catalyst can be enhanced.

Owner:WENZHOU UNIVERSITY

Method for synthesizing 3-iodine-phenylcarbazole

The invention discloses a method for synthesizing 3-iodine-phenylcarbazole, which comprises the following steps of: synthesizing 9-phenylcarbazole by performing Ullmann reaction on carbazole serving as an initial raw material and phenyl iodide under the action of cuprous oxide serving as a catalyst; and synthesizing a target compound 3-iodine-phenylcarbazole by performing iodo-reaction on the 9-phenylcarbazole and iodine under the catalysis of iodic acid and concentrated sulfuric acid. The synthesis method has the characteristics of high yield, low production cost and low pollution, and is simple.

Owner:山东盛华新材料科技股份有限公司

Iodate preparation method

InactiveCN105271126AImprove solubilityObvious superiorityIodine oxygen compoundsHalogenReaction temperature

The invention relates too an iodate preparation method, which comprises: A, iodic acid preparation, wherein hydrogen peroxide is used as an oxidant, small amounts of nitric acid and halogen acid such as chloric acid, bromic acid and iodic acid are adopted as catalysts of an oxidation reaction, refined iodine is oxidized into the iodic acid, the addition amount of the used nitric acid is 1-10% of the added refined iodine, the addition amount of the used halogen acid is 0.5-50% of the added refined iodine, the reaction temperature is 50-100 DEG C, and the reaction time is 4-8 h; and B, iodate preparation, wherein the pure iodic acid solution obtained through the step A is neutralized directly with a carbonate solution of a hydroxide or alkali metal, the neutralization reaction temperature is controlled at 20-50 DEG C, and the neutralization PH value is 7.

Owner:谈丽娜

Preparation method of etching fluid for liquid crystal displayers

The invention discloses a preparation method of etching fluid for liquid crystal displayers. The etching fluid includes, by weight percentage, 0.5%-2.3% of ceric ammonium nitrate, 0.2%-1.8% of o-fluorobenzoic acid, 1.2%-2.6% of n-pentanoic acid, 1.2%-2.6% of iodic acid, 1.5%-2.3% of hydrochloric acid, 2.5%-3.3% of non-ionic surface active agents, 1.5%-2.6% of antifoaming agents and the balance distilled water. Due to the fact that the ceric ammonium nitrate, o-fluorobenzoic acid, n-pentanoic acid, iodic acid and hydrochloric acid are added on the basis of the prior art, etching can be performed without permeation of an etch-resistant coating, the etching speed of a chromium metal film is remarkably increased, the etching speed is controllable, an etch-resistant protective layer is effectively restrained from degrading, a chromium metal film wire with a flat and smooth surface is obtained, and the preparation method has significant application value.

Owner:WUXI IMPRINT NANO TECH

Preparation method of iodate

InactiveCN105329856AObvious superiorityAdvancedBromine oxygen compoundsReaction temperatureIodic acid

A preparation method of iodate is characterized by comprising the following two steps: 1, iodic acid preparation: oxidizing refined iodine into iodic acid by using hydrogen peroxide as an oxidant, and using a small amount of nitric acid and hydracids such as chloric acid, bromic acid, and iodic acid as the catalyst for the oxidation reaction, wherein the amount of nitric acid is 1-10% of the fined iodine, the amount of hydracids is 0.5-50% of the refined iodine, the reaction temperature is 50 DEG C to 100 DEG C, and the reaction time is 4-8 h; and 2, iodate preparation: directly neutralizing the pure iodate solution obtained by step 1 by using hydrogen oxide or carbonate solution of alkali metal, wherein the reaction temperature of neutralization reaction is controlled in the range of 50-100 DEG C and the neutralization pH value is equal to 7.

Owner:马井芳

Synthesis method of rare earth/iodine co-doped photo-degradation catalyst

InactiveCN108404943AEnhance photodegradation activitySimple preparation processPhysical/chemical process catalystsWater bathsSynthesis methods

The invention discloses a synthesis method of a rare earth / iodine co-doped photo-degradation catalyst. The synthesis method comprises the following steps: stirring and quickly dissolving iodic acid, adding deionized water, dropwise adding tetra-n-butyl titanate (Ti(OBu)4) slowly, and producing foam precipitate; after the tetra-n-butyl titanate is completely dissolved in water, performing ultrasonic dispersing on the tetra-n-butyl titanate until the tetra-n-butyl titanate is dispersed uniformly, reacting at 70 to 90 DEG C to obtain milk white gel, slowly decreasing the temperature after the gelis dried, and preparing to obtain a powder I / TiO2 precursor; roasting the powder at 380 to 420 DEG C, and cooling; dropwise adding rare earth nitrate solution slowly with continuous stirring, stirring uniformly, performing ultrasonic dispersing, and then evaporating water in a water bath at 70 to 90 DEG C; drying in a drying box, and roasting at 340 to 360 DEG C in a muffle furnace to obtain a light yellow powdery rare earth / I / TiO2 photocatalyst. The synthesis method of the rare earth / iodine co-doped photo-degradation catalyst is simple in preparation process and lower in cost; rare earth isdoped in titanium dioxide, which is beneficial to improving the photodegradation activity of a catalyst.

Owner:姚刚 +1

Preparation method of iodic acid mixed solution and iodic acid mixed solution prepared thereby

ActiveCN106937646ASimple preparation processEasy to manufactureBiocideDisinfectantsIodic acidInorganic chemistry

The invention provides a preparation method of an iodic acid mixed solution and the iodic acid mixed solution prepared thereby. In the method, by adding a stabilizer in the preparation reaction process, the stability of the obtained iodic acid mixed solution can be effectively improved. Meanwhile, the iodic acid mixed solution has the advantages of high effective iodine content of the solution, good stability and the like.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

ITO film etching solution for liquid crystal panel manufacturing process and preparation method thereof

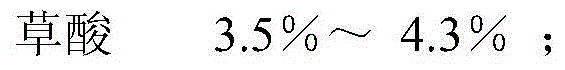

ActiveCN104962287AReduce surface tensionModerate speedSurface treatment compositionsIodic acidLiquid crystal

The invention discloses an ITO film etching solution for a liquid crystal panel manufacturing process. The ITO film etching solution comprises, by weight, 3.5-4.3% of oxalic acid, 0.2-0.8% of butyric acid, 1.2-2.6% of n-pentanoic acid, 1.2-2.6% of iodic acid, 15-20% of hydrochloric acid and the balance pure water. Through use of additives such as butyric acid, n-pentanoic acid, iodic acid and hydrochloric acid based on the original technology, ITO etching solution surface tension is effectively reduced, penetration and infiltration effects are produced, an indium tin oxide semiconductor transparent conductive film etching rate is moderate and a reaction is stable so that product etching effects are improved without influence on product quality, the product can be stored at a low environment temperature, incomplete etching produced by the original technology is avoided, and storage at a low temperature is realized. The ITO film etching solution is suitable for large scale production.

Owner:JIANGYIN JIANGHUA MICROELECTRONICS MATERIAL

Method for preparing iodate

The invention relates to an industrial method for preparing pure iodic acid and a salt thereof. According to the method, pure iodine is oxidized by hydrogen peroxide, a small amount of nitric acid or oxoacid or non-oxoacid of halogen is added to prepare pure iodic acid solution, the yield of the pure iodic acid solution can reach 98% on the basis of iodine, hydroxide or carbonate of alkali metal is adopted to neutralize an iodic acid solution, so that the pH of the iodic acid solution is equal to 7, crystal of the pure iodate can be prepared, and the crystal is washed and dried to obtain the finished product. The purity of the iodate reaches 99.0%, and the yield of the iodate is 85-95% on the basis of iodic acid.

Owner:颜笑天

Iodic acid and hydroiodic acid preparation all-in-one machine device

The invention relates to an iodic acid and hydroiodic acid preparation all-in-one machine device, and relates to the technical field of chemical engineering. The iodic acid and hydroiodic acid preparation all-in-one machine device is used for solving the technical problems that the processing efficiency is hot high in the prior art. The iodic acid and hydroiodic acid preparation all-in-one machinedevice comprises an electrooxidation reduction reactor, by adopting the same raw material and the same device, namely, elemental iodine is adopted to simultaneously obtain iodic acid and hydroiodic acid, an oxidation reaction occurs in an oxidizing chamber of the electrooxidation reduction reactor to generate the iodic acid, a reduction reaction occurs in a reduction chamber of the electrooxidation reduction reactor to generate the hydroiodic acid, a reaction endpoint is controlled by an electric potential in the whole process, the preparation purity is high, concentration is high, no dangerous and waste liquid generates, and more environmental protection is achieved.

Owner:ZIBO GERUI WATER TREATMENT ENG

Alcohol-free iodine-containing disinfectant with high component stability and preparation method of alcohol-free iodine-containing disinfectant

ActiveCN112755050AReduce acid contentExtended shelf lifeAntibacterial agentsInorganic non-active ingredientsFree iodineAlcohol

The invention discloses an alcohol-free iodine-containing disinfectant with high component stability and a preparation method of the alcohol-free iodine-containing disinfectant. The iodine-containing disinfectant comprises the following components by weight: 0.1-10% of elemental iodine, 0.1-10% of iodide, 0.01-2% of iodic acid and / or iodate, 0.1-20% of carboxylic acid, 60-90% of water, 0.01-1% of iron (Fe <3+>) salt, and 0.01-1% of ferrous (Fe<2+>) salt. The iodide is composed of iodine negative ions and hydrogen ions or metal cations or ammonium ions or quaternary ammonium ions. The iodine-containing disinfectant has the advantages of simple preparation method and stable component content after long-term storage.

Owner:FOSHAN STANDARD BIO TECH

ITO film plating rework treatment etching solution and preparation method thereof

InactiveCN106381147AGuaranteed to be fully etchedImprove wettabilitySurface treatment compositionsEtchingPhosphoric acid

Belonging to the field of TFT-LCD thinning film plating, the invention discloses an ITO (indium tin oxide) film plating rework treatment etching solution and a preparation method thereof. The ITO film plating rework treatment etching solution is formed by mixing the five raw materials hydrochloric acid, oxalic acid, organic polybasic phosphoric acid, iodic acid and pure water evenly. The preparation process of the ITO film plating rework treatment etching solution consists of: adding strong acid cation exchange resin into hydrochloric acid, conducting mixing, then filtering out the strong acid cation exchange resin, and controlling or removing impurity ions in hydrochloric acid; and successively adding oxalic acid crystals, part of pure water, hydrochloric acid, organic polybasic phosphoric acid, iodic acid and residual pure water, and finally performing filtering to obtain the ITO film plating rework treatment etching solution. The etching solution provided by the invention has good wettability to an ITO layer, and guarantees complete etching of ITO on TFT-LCD, thus reducing scrap rate of the product. After etching, the microcrystal residue is few, thereby ensuring that the etching solution does not block a filter during use.

Owner:赣州帝晶光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com