Surface-modified lithium metal negative electrode material and preparation method thereof

A technology of surface modification and negative electrode materials, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low Coulombic efficiency, achieve simple preparation methods, improve Coulombic efficiency and discharge capacity, and reduce polarization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

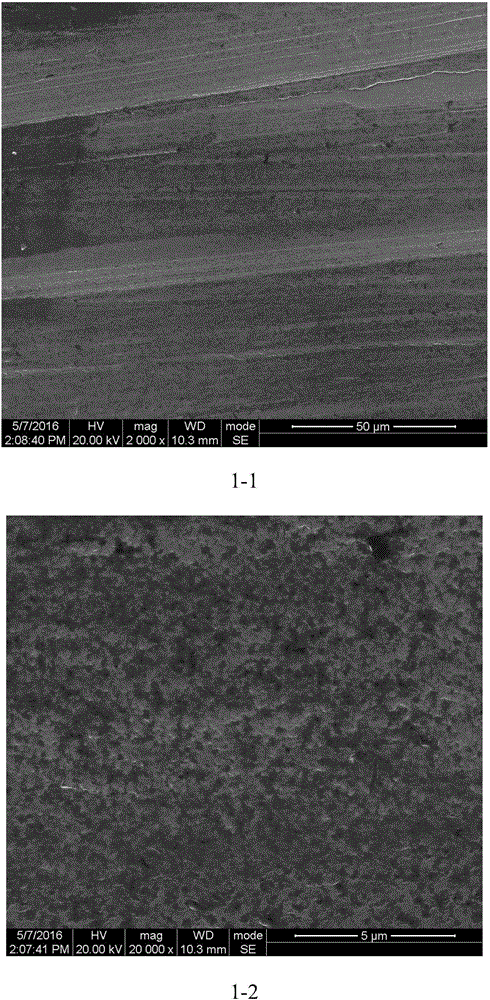

Image

Examples

Embodiment 1

[0029] A surface-modified metallic lithium negative electrode material, the preparation method of which comprises the following steps:

[0030] (1) iodic acid is dissolved in anhydrous dimethyl sulfoxide, so that the mass concentration of iodic acid is 0.1%;

[0031] (2) Lithium metal is placed in an anhydrous and oxygen-free glove box filled with argon, and then the surface of lithium metal is polished until the surface reveals a metallic luster;

[0032] (3) Soak the polished lithium metal in the solution obtained in step (1) for 5 min.

Embodiment 2

[0034] A surface-modified metallic lithium negative electrode material, the preparation method of which comprises the following steps:

[0035] (1) Ortho-periodic acid is dissolved in anhydrous tetrahydrofuran, so that the mass concentration of iodic acid is 0.2%;

[0036] (2) Lithium metal is placed in an anhydrous and oxygen-free glove box filled with argon, and then the surface of lithium metal is polished until the surface reveals a metallic luster;

[0037] (3) Soak the polished lithium metal in the solution obtained in step (1) for 30 min.

Embodiment 3

[0039] A surface-modified metallic lithium negative electrode material, the preparation method of which comprises the following steps:

[0040] (1) Metaperiodic acid is dissolved in anhydrous N-methylpyrrolidone, so that the mass concentration of iodic acid is 0.3%;

[0041] (2) Lithium metal is placed in an anhydrous and oxygen-free glove box filled with argon, and then the surface of lithium metal is polished until the surface reveals a metallic luster;

[0042] (3) Soak the polished lithium metal in the solution obtained in step (1) for 60 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com