Coupled carbon nano tube-graphene composite three-dimensional network structure-coated ternary material and preparation method thereof

A carbon nanotube, ternary material technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve the problem of reducing the electrochemical performance of materials, poor high-rate performance, large irreversible losses, etc. It can achieve great theoretical guiding significance and engineering application value, improve conductivity and lithium ion diffusion coefficient, and reduce the effect of interface resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

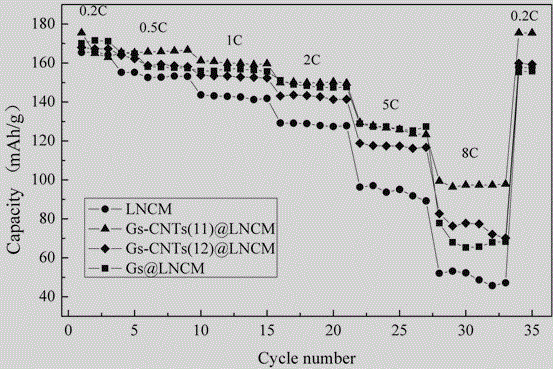

Embodiment 1

[0035] (1) Disperse 0.1g of graphene in an organic solvent, ultrasonically disperse for 40 minutes to obtain a graphene dispersion, then add carbon nanotubes with a weight ratio of 0.1g and a small amount of silane coupling agent to the solution, and stir for 30 minutes. Obtain a coupled graphene-carbon nanotube dispersion; at room temperature, dissolve 1.0g of polyvinylpyrrolidone in 50.0g of deionized water, after physical mixing and dispersion, add 50.0g of nickel-cobalt-manganese ternary material, and stir for 40min to obtain Ternary material dispersion;

[0036] (2) Pour the coupled graphene-carbon nanotube dispersion into the ternary material dispersion. After dispersing for 10 minutes, place it in a constant temperature stirrer and stir at 80°C to evaporate the solvent;

[0037] (3) After grinding the above product, sieve it with 400 mesh, put it in a nitrogen atmosphere and sinter it, raise the temperature to 300°C at 2°C / min, and keep it warm for 5 hours. After natur...

Embodiment 2

[0045] The difference between this embodiment and Example 1 is the ratio of the graphene-carbon nanotube composite material selected in step one. The specific preparation method is as follows:

[0046] The graphene of 0.067g is dispersed in the organic solvent, ultrasonic dispersion 40min obtains graphene dispersion liquid and then adds the carbon nanotube that weight ratio is 0.133g in the solution, and a small amount of silane coupling agent, stirs 30min, obtains the coupled Graphene-carbon nanotube dispersion liquid; at room temperature, dissolve 1.0g polyvinylpyrrolidone in 50.0g deionized water, after physical mixing and dispersion, add 50.0g nickel-cobalt-manganese ternary material, stir for 40min to obtain ternary material dispersion liquid;

[0047] Other steps were the same as in Example 1 to obtain the positive electrode material in the present invention, that is, Gs-CNTs(12) LNCM.

Embodiment 3

[0049] The difference between this embodiment and Example 1 is the ratio of the graphene-carbon nanotube composite material selected in step one. The specific preparation method is as follows:

[0050] The graphene of 0.05g is dispersed in the organic solvent, acoustic dispersion 40min obtains the graphene dispersion liquid and then adds the carbon nanotube that is 0.15g in weight ratio to the solution, and a small amount of silane coupling agent, stirs 30min, obtains the coupled Graphene-carbon nanotube dispersion liquid; at room temperature, dissolve 1.0g polyvinylpyrrolidone in 50.0g deionized water, after physical mixing and dispersion, add 50.0g nickel-cobalt-manganese ternary material, stir for 40min to obtain ternary material dispersion liquid;

[0051] Other steps were the same as in Example 1 to obtain the positive electrode material in the present invention, that is, Gs-CNTs(13) LNCM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com