Electrochemical hydrogen cyanide gas sensor

A gas sensor, hydrogen cyanide technology, applied in the field of sensors, can solve the problems of life safety threats of surrounding people, inaccurate measurement, inconvenient to carry, etc., and achieve the effect of reducing interference gas interference, fast response speed, and maintaining sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

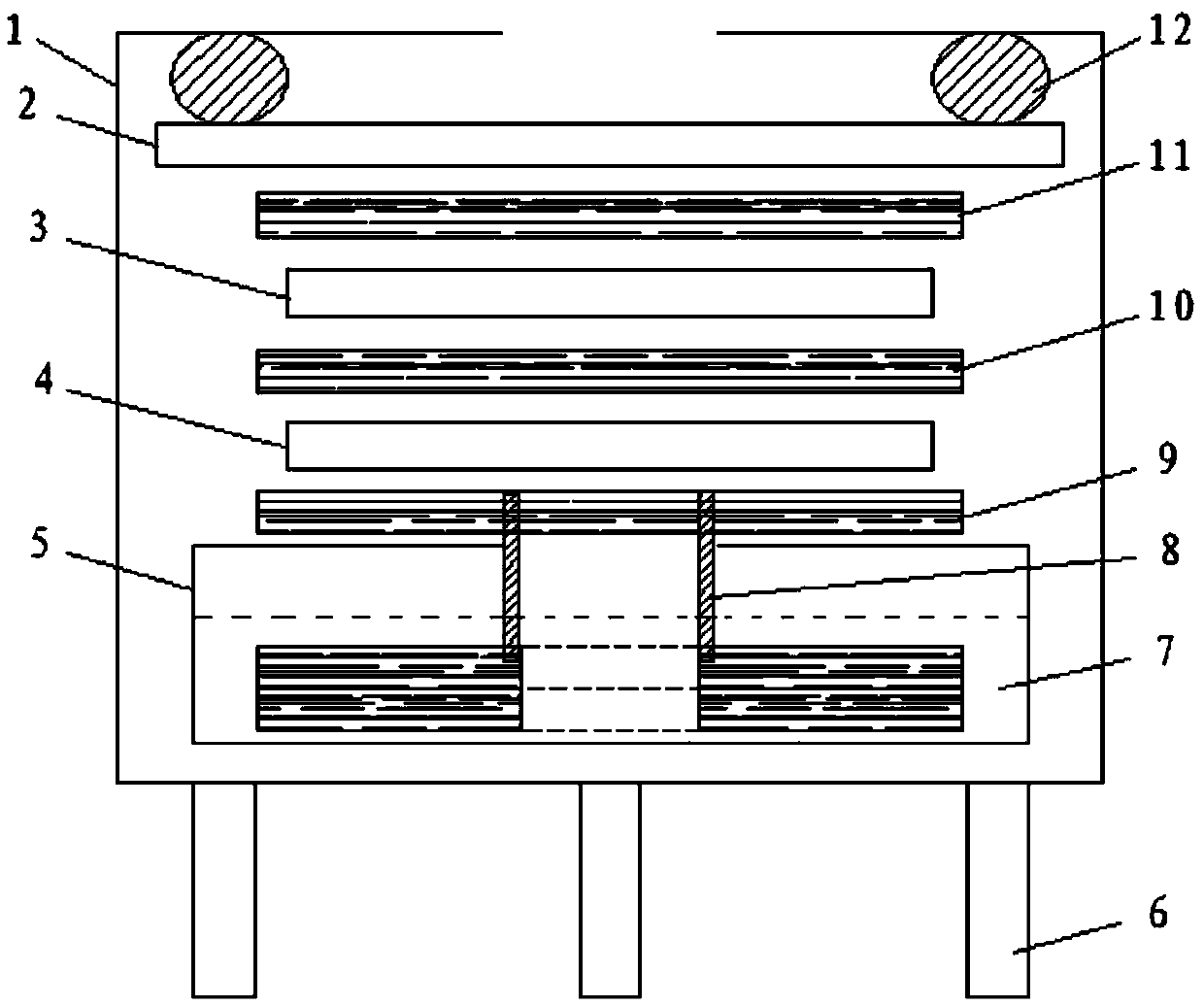

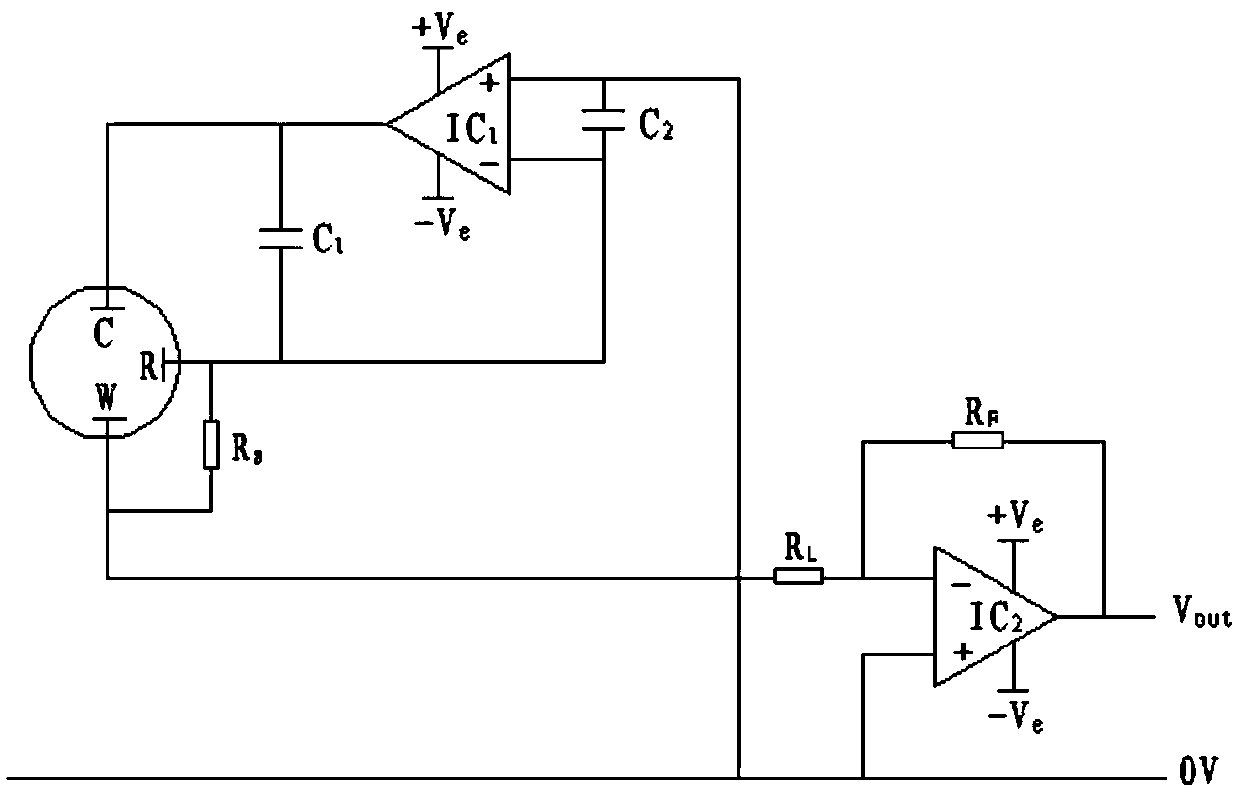

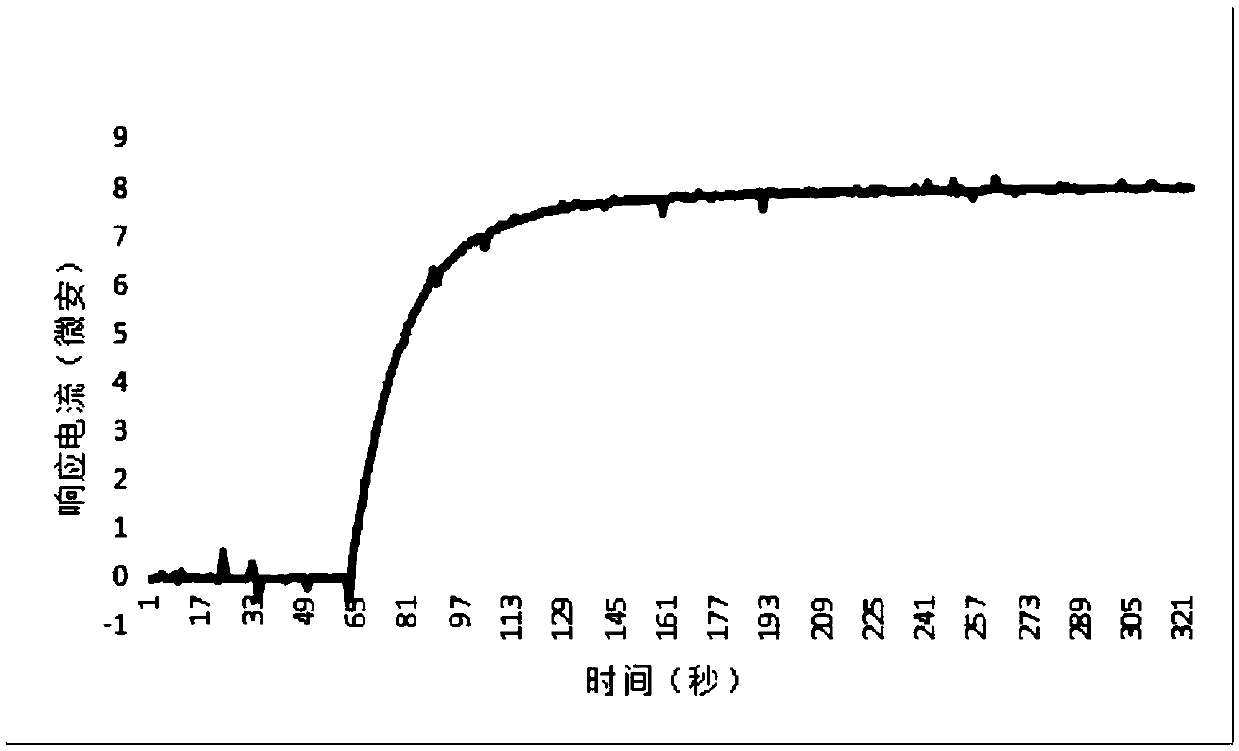

Method used

Image

Examples

Embodiment 1

[0039] Example 1, the preparation method of the working electrode: the first nanomaterial with a mass ratio of 1:1 is mixed with polytetrafluoroethylene particles to obtain a mixture, and the mixture is rolled, sprayed or printed on the electrode film to obtain a working electrode. For the electrode, the first nanometer material is silver nanometer material, and the electrode film can be a polytetrafluoroethylene film.

Embodiment 2

[0040] Example 2, the preparation method of the reference electrode: the second nanomaterial with a mass ratio of 5:1 is mixed with polytetrafluoroethylene particles to obtain a mixture, and the mixture is rolled, sprayed or printed on the electrode film to obtain a reference electrode. For the electrode, the second nanometer material is silver nanometer material, and the electrode film can be a polytetrafluoroethylene film.

Embodiment 3

[0041] Example 3, the preparation method of the counter electrode: the third nanomaterial with a mass ratio of 10:1 is mixed with polytetrafluoroethylene particles to obtain a mixture, and the mixture is rolled, sprayed or printed on the electrode film to obtain a counter electrode For the electrodes, the third nanomaterials include at least one of silver nanomaterials and rhodium nanomaterials, and the electrode film can be a polytetrafluoroethylene film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com